Impacting ball-pressure testing and evaluation method of engineering material

A technology of ball pressure test and engineering materials, applied in the direction of testing material hardness, measuring devices, instruments, etc., can solve problems such as structural failure, unprofessional testing process, and increase surface physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

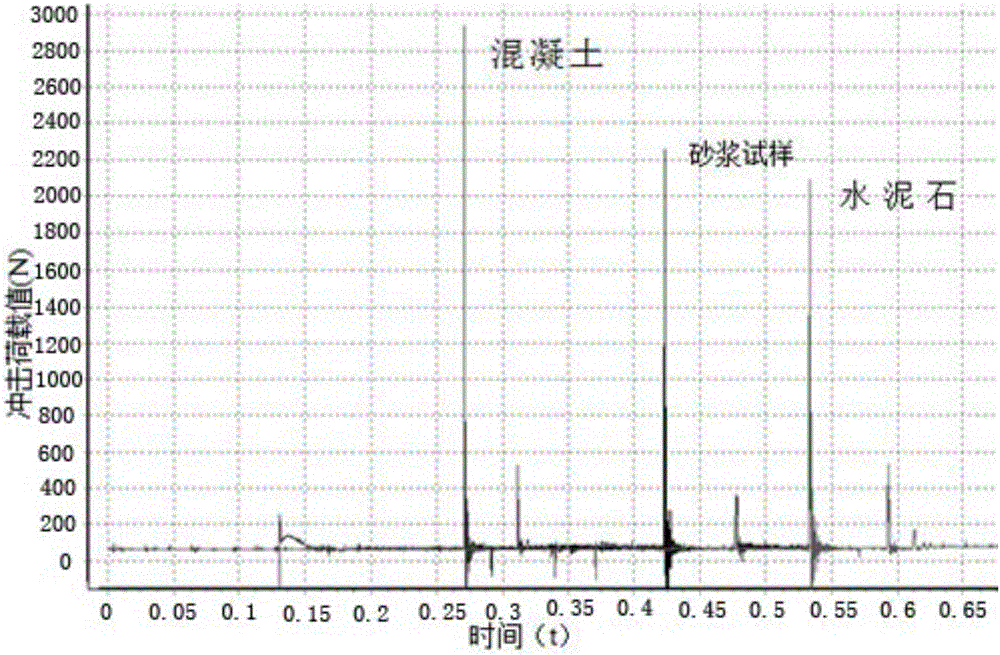

[0045] A rigid sphere of mass m, radius R, modulus of elasticity, Poisson's ratio is in contact with a specimen of modulus of elasticity E, Poisson's ratio. Under the action of impact load, the maximum value of the normal vertical load of the contact point on the surface of the material is shown in formula (1):

[0046] ;

[0047] is the relative velocity of the ball head before it touches the surface of the material, is the effective elastic modulus of the contact system:

[0048] ;

[0049] The maximum contact radius is:

[0050] ;

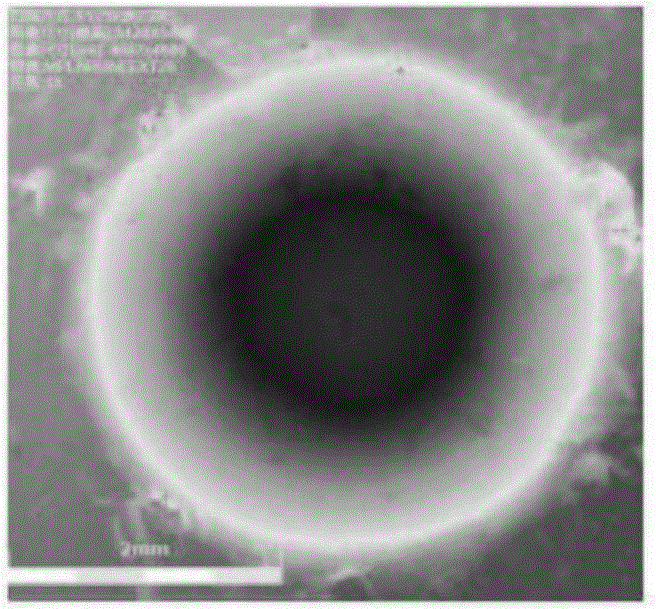

[0051] During the impact process of the cement mortar sample, the dynamic hardness value can reflect the ability of different materials to resist deformation, r is the radius of the measured indentation value, F is the collected impact load value, and the dynamic hardness value The calculation formula is:

[0052] ;

[0053] In the formula, .

[0054] All the energy of the ball head before the impact is kinetic energy, and ...

Embodiment 2

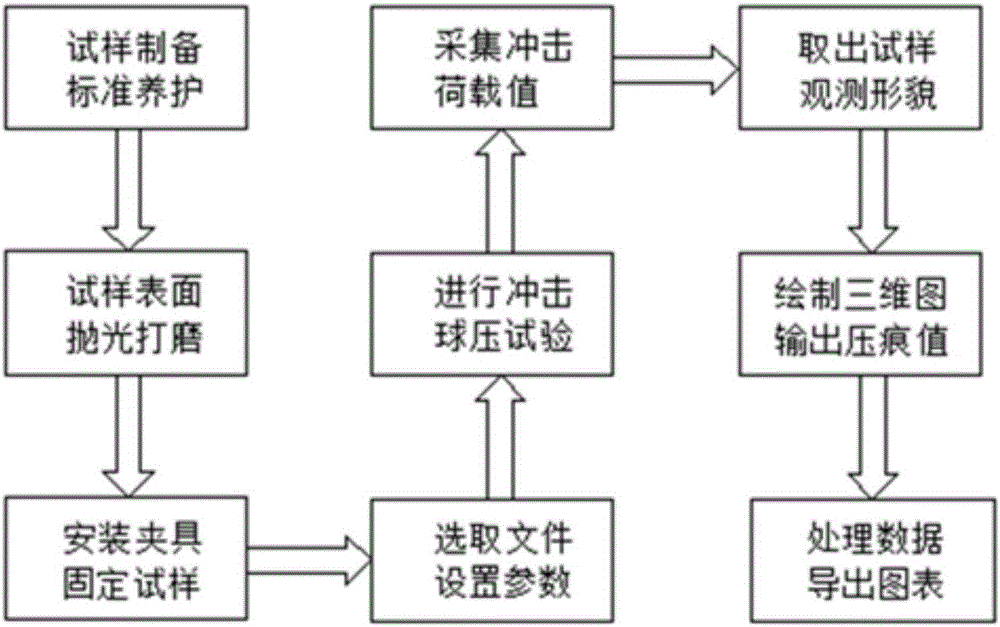

[0060] Such as figure 1 As shown, and selected concrete, mortar and cement stone samples cured for 56 days, the impact ball pressure test was carried out with these three samples as examples. First, prepare a 100mm×100mm×100mm cube test block according to the calculated mix ratio. After 24 hours of molding, the sample is removed from the mold and placed in a standard curing room for 56 days of curing. Then the sample is taken out. Since the three samples are all multi-phase composite materials, the surface is relatively rough, which will affect the reading of the impact load value of the ball head during the impact test, so the TLD-SM-2 grinding wheel is used before the impact ball pressure test The grinding machine performs strict grinding and polishing on the concrete sample. Since there is a layer of cement slurry on the surface of the sample, if the grinding thickness is too thin, the indentation value will be affected. If the grinding thickness is too large, the large sto...

Embodiment 3

[0062] The polished and polished three samples were immediately placed in a 45°C oven to dry for 24 hours, and then the impact ball pressure test was performed. The 6 faces of the concrete sample correspond to one impact height, and 6 impact points are set for each face, and the sample is fixed on the fixture of the automatic ball pressure impact instrument to prepare for the impact ball pressure test. Open the impact ball pressure test software on the programming software, select a new file, and select the number of sample blocks, the number of impact ball pressure sample surfaces and the number of impact points from each impact surface, and then start the impact ball pressure test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com