Chemical-free production of graphene-reinforced inorganic matrix composites

A technology of graphite material and inorganic matrix, applied in the field of graphene material production, can solve problems such as adverse effects, expensive plasma generation equipment, affecting electrical properties, thermal properties and mechanical properties, etc., and achieves high electrical conductivity and thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

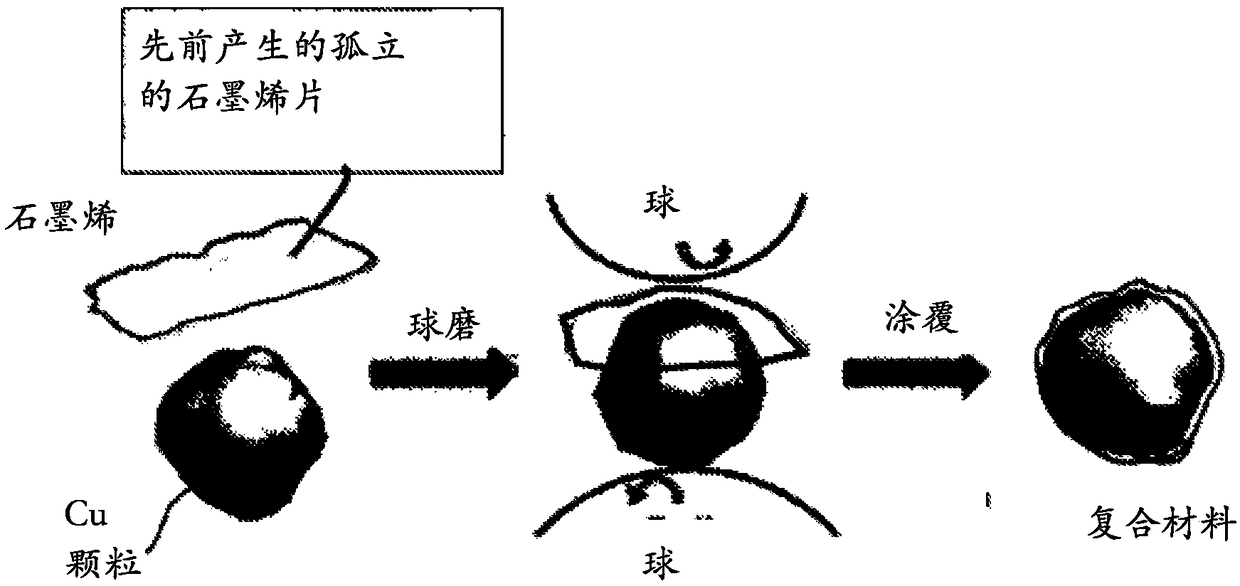

[0152] Example 1: Graphene reinforced copper matrix composite

[0153] In the experiment, 1kg copper powder, 100g flake graphite, 50 mesh (average particle size 0.18mm; Asbury Carbons, Asbury NJ) and 110g magnetic stainless steel The needle (Raytech Industries, Middletown CT, Connecticut) was placed in the vessel of a high energy ball mill. The ball mill was operated at 300 rpm for 4 hours. Remove the container lid and remove the stainless steel pin via magnetic separation. It was found that the particles of the inorganic carrier material were coated with a dark layer, which was confirmed to be graphene by Raman spectroscopy. The support material is placed on a 50-mesh sieve and a small amount of raw graphite flake is removed.

[0154] A 10 gram material sample was compacted into a disc by pressing, and then it was sintered in a furnace with flowing argon at an appropriate temperature. An additional 10 grams of sample was compressed and densified by hot isostatic pressing (HIP)...

example 2

[0156] Example 2: Functionalized graphene reinforced copper matrix inorganic composite material

[0157] Repeat the method of Example 1, which contains 50 grams of urea as the nitrogen source. The resulting coated powder was shaped into a disc using the same method as in Example 1.

example 3

[0158] Example 3: Graphene reinforced tin composite material

[0159] In the experiment, 2 grams of 99.9% pure tin powder and 0.25 grams of HOPG and stainless steel balls were put into a resonance acoustic grinder (Lab Ram, Resodyn Company, Butte, Montana (Butte MT)) and processed 5 minute. Subsequently, the coated tin particles were compacted at room temperature, melted at 240°C, and solidified to form graphene-reinforced tin matrix composite discs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com