Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137 results about "Rhenium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rhenium(IV) oxide or rhenium dioxide is the inorganic compound with the formula ReO2. This gray to black crystalline solid is a laboratory reagent that can be used as a catalyst. It adopts the rutile structure.

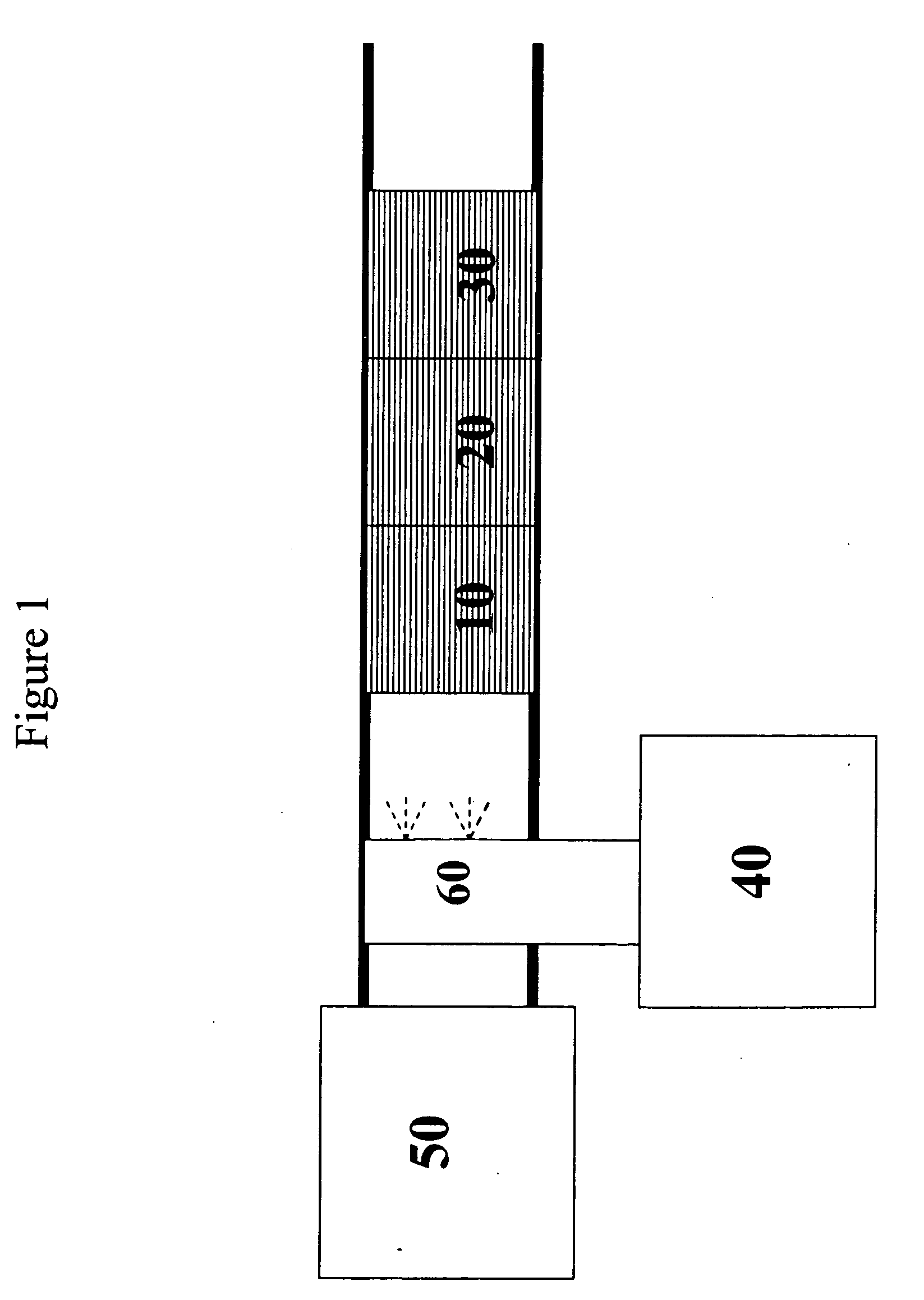

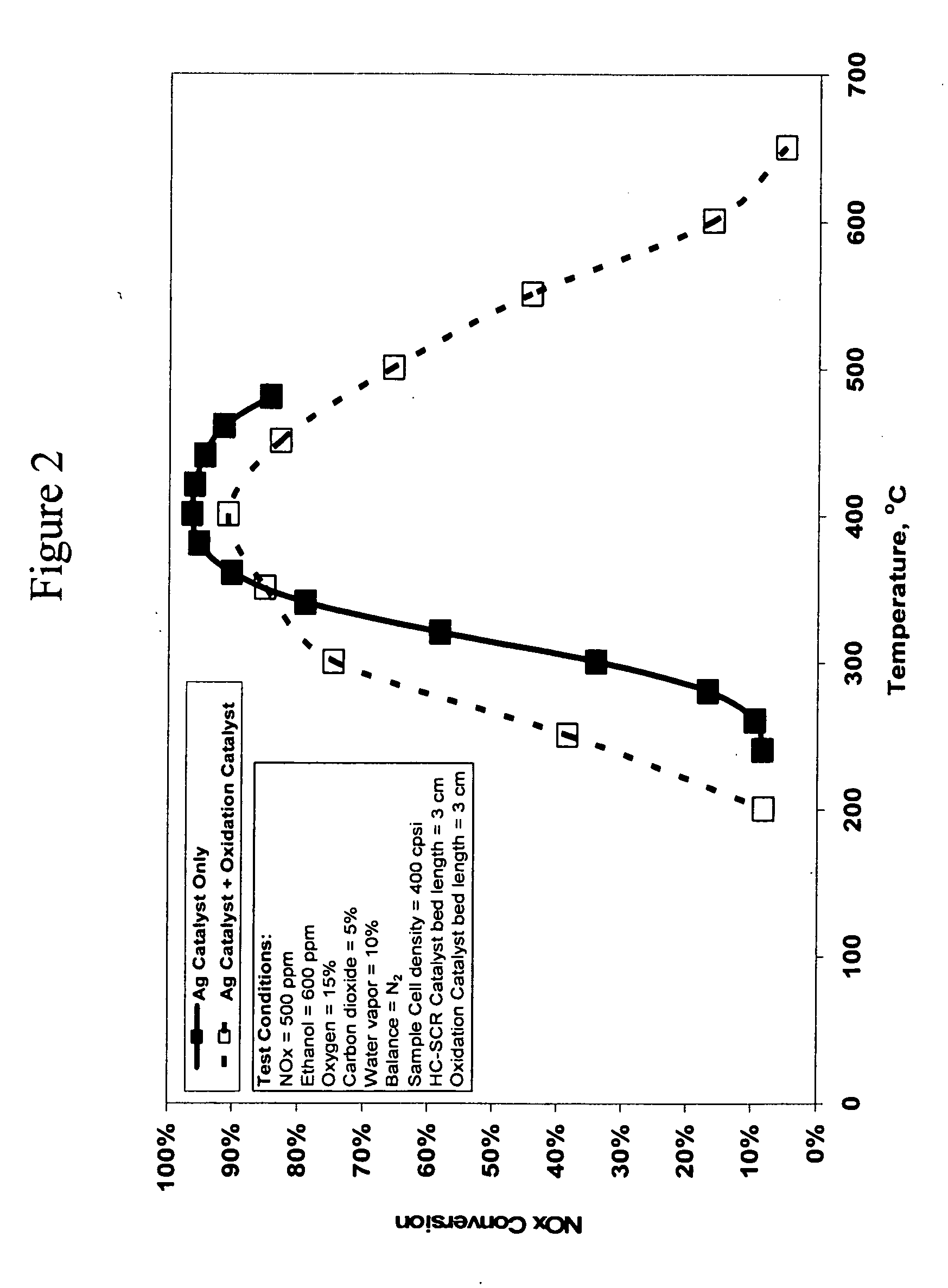

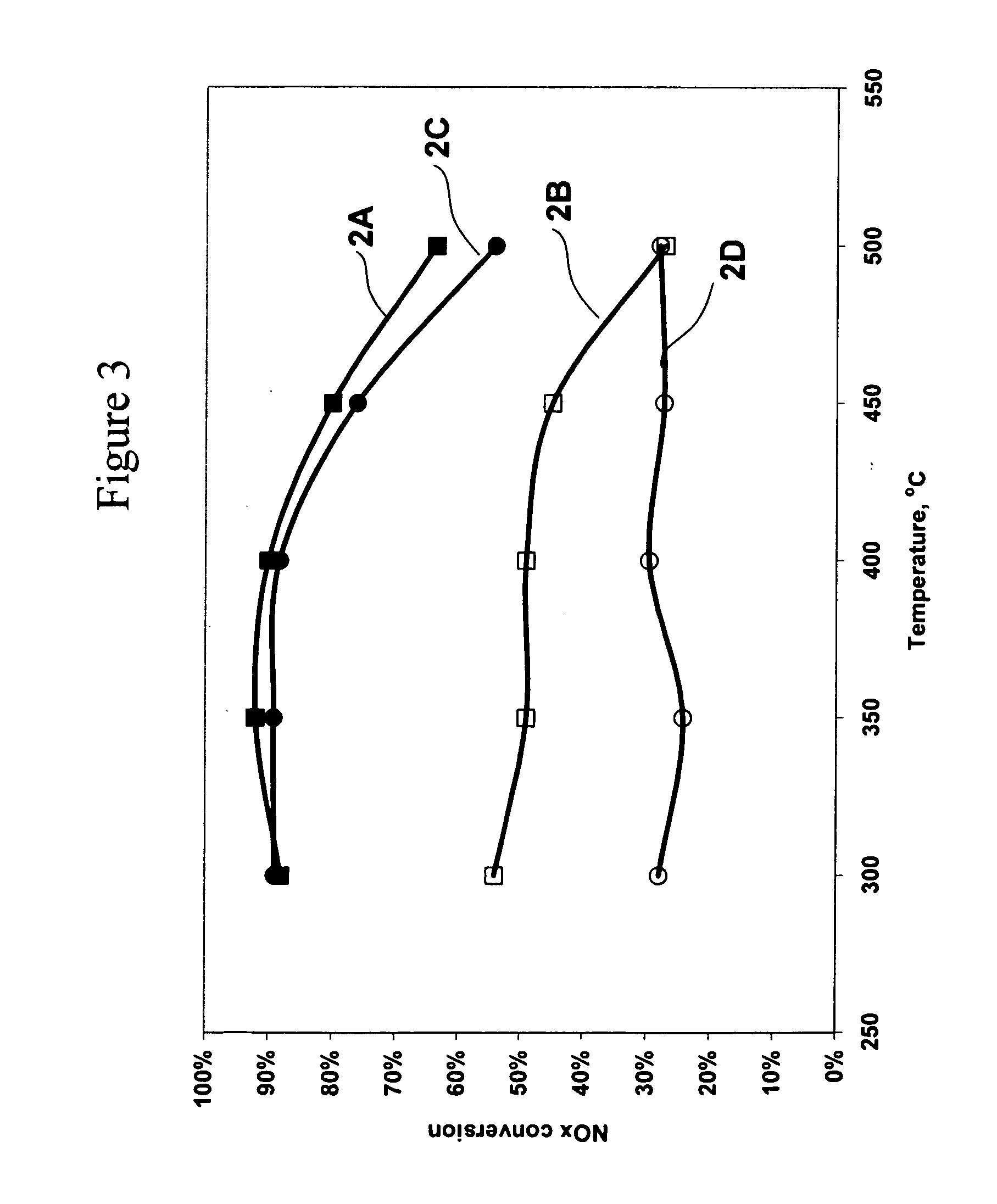

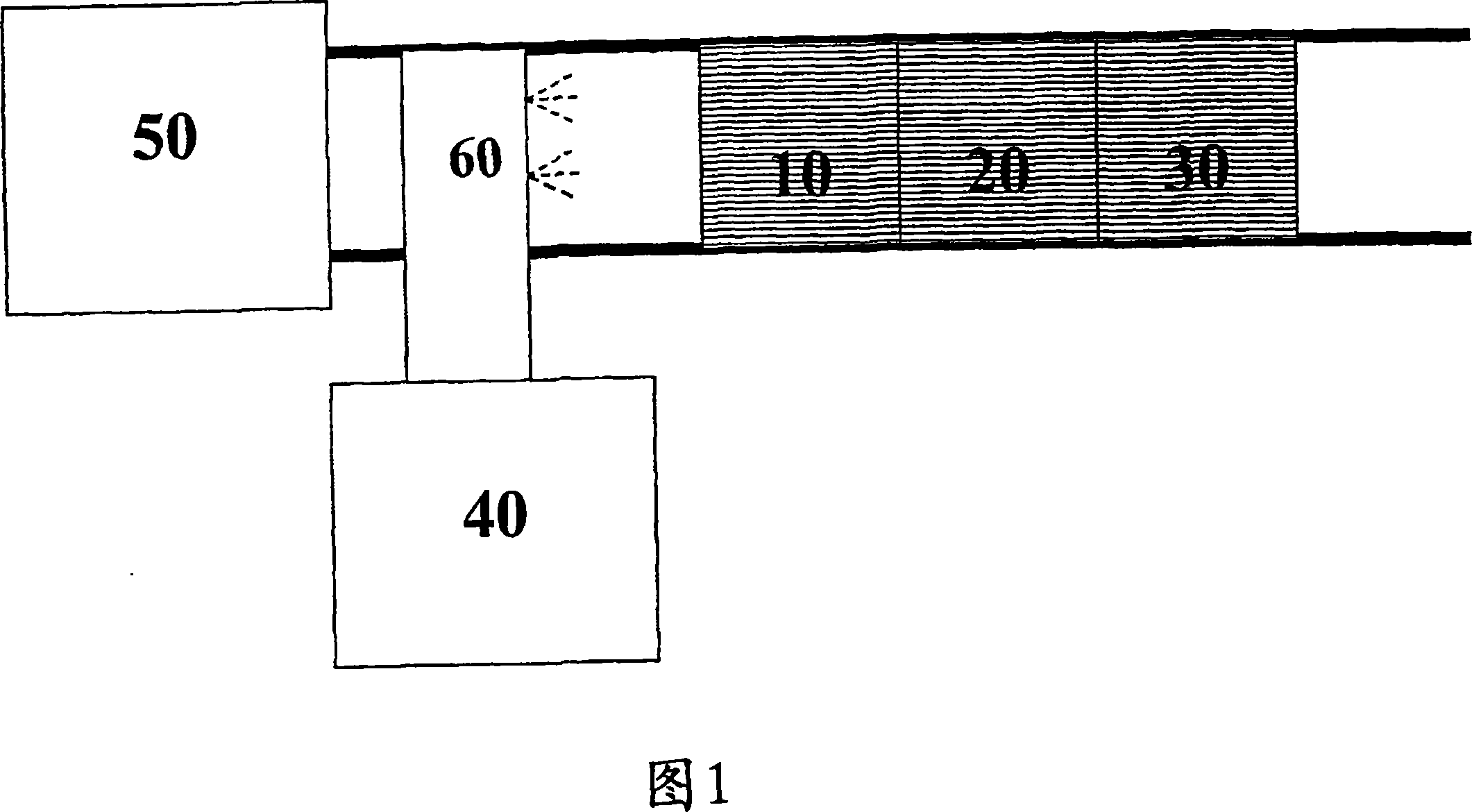

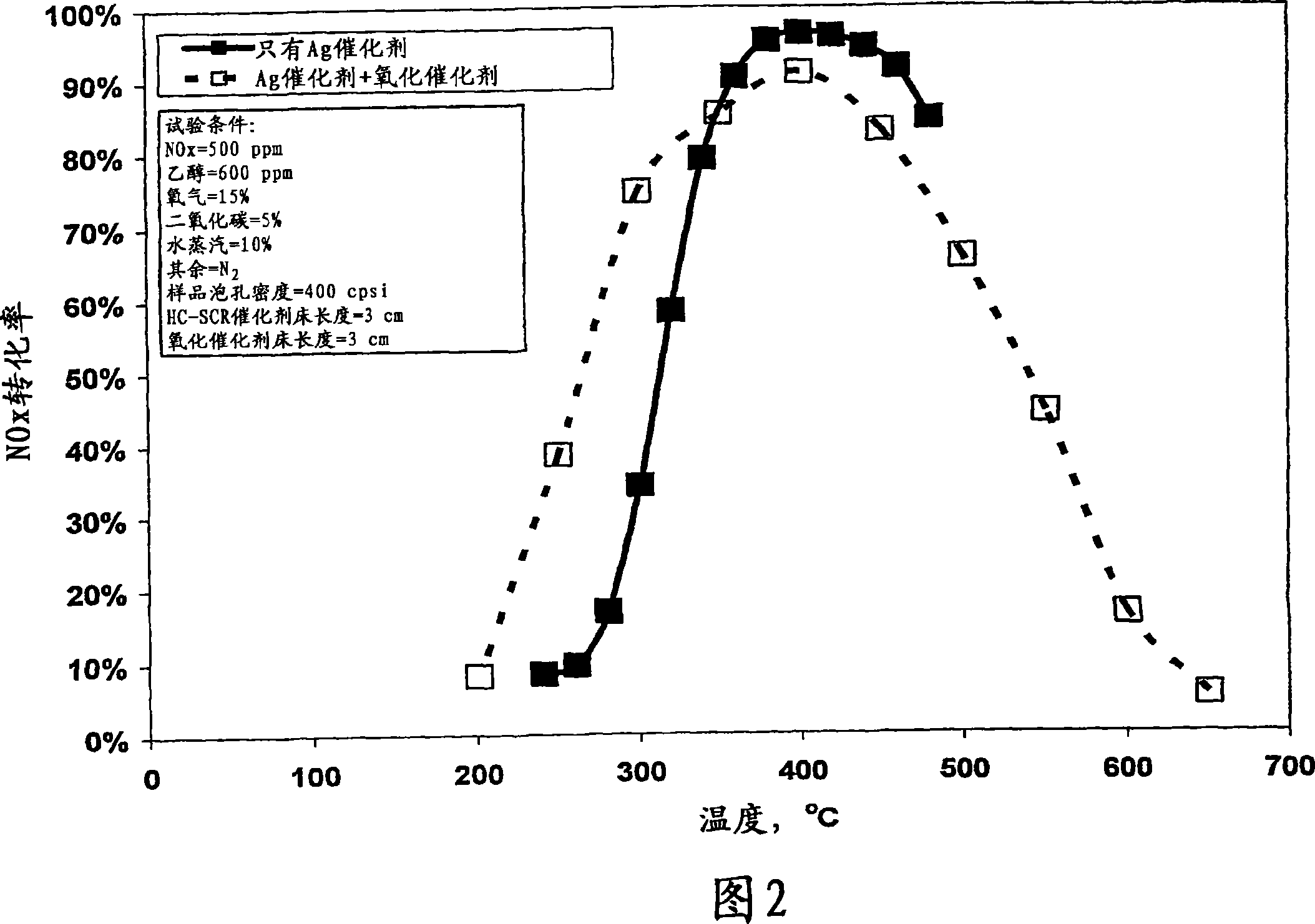

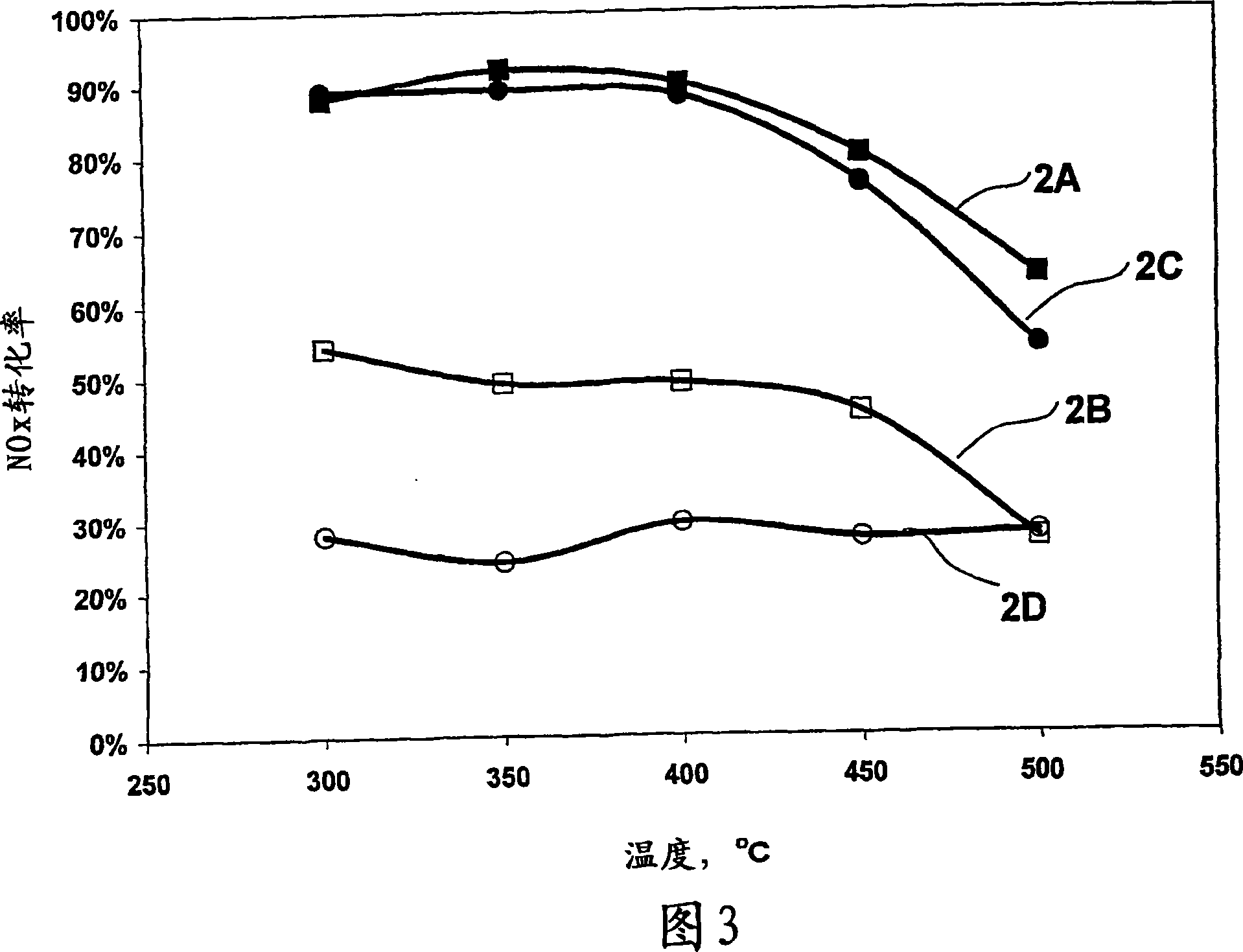

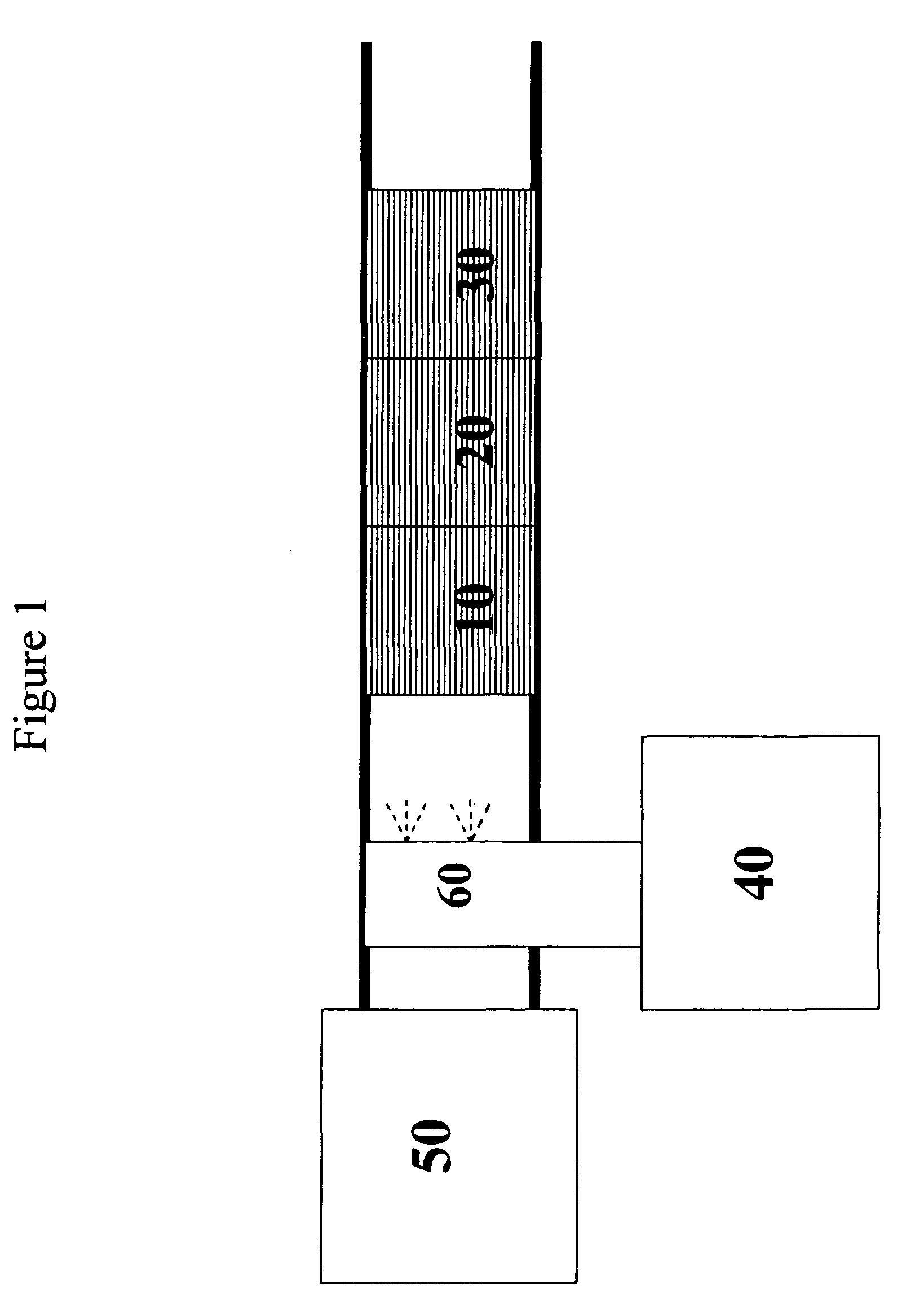

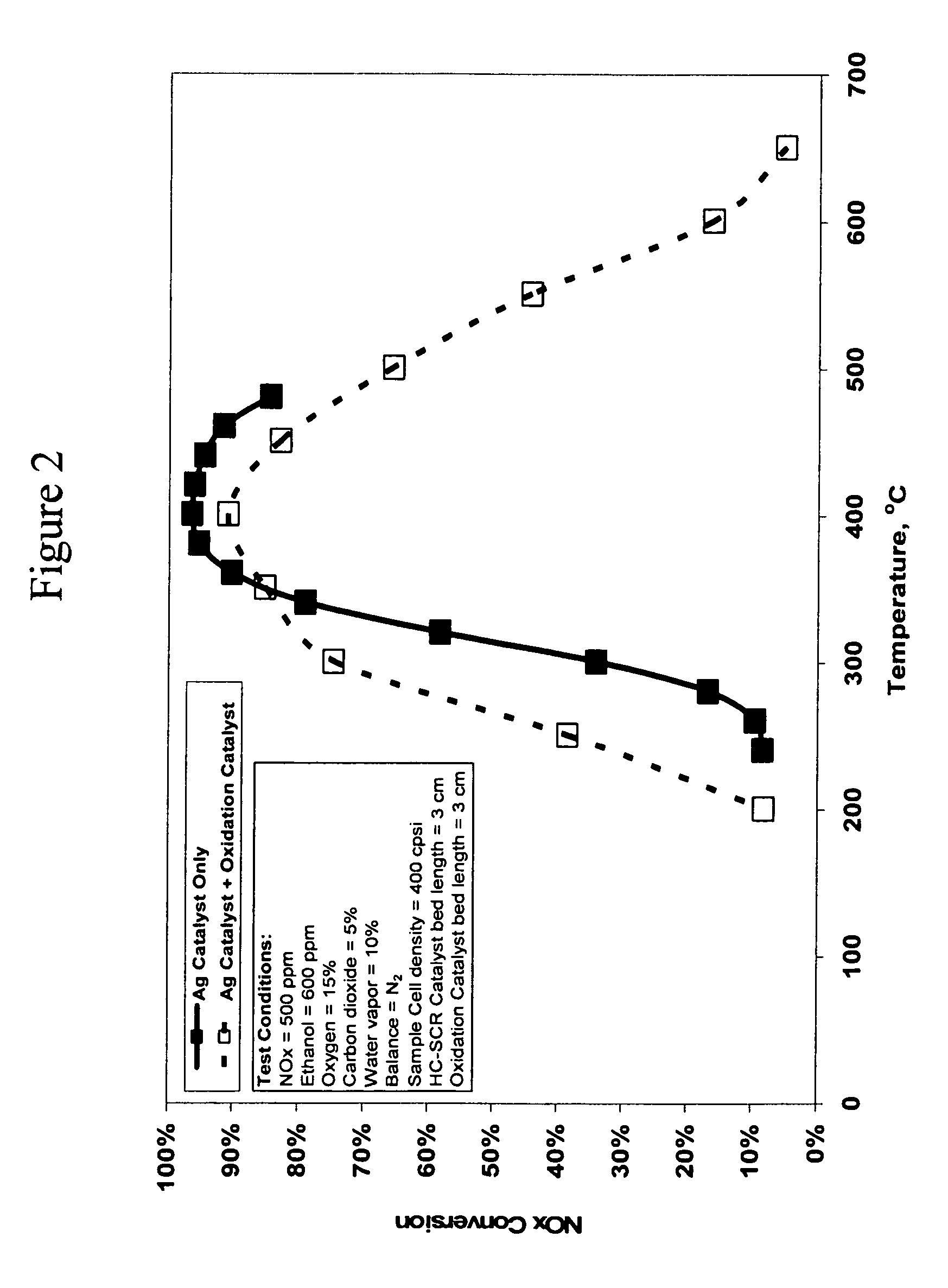

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

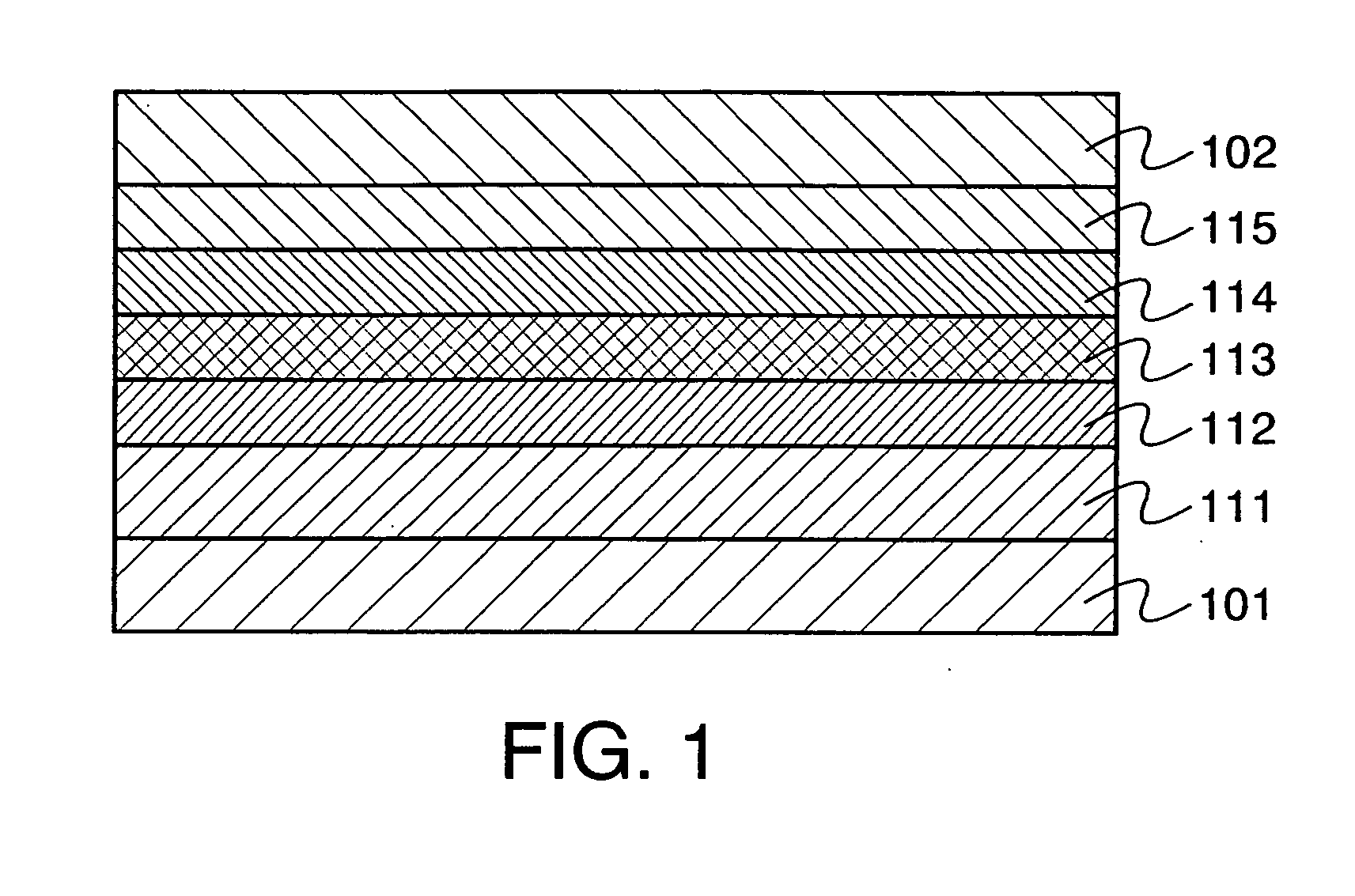

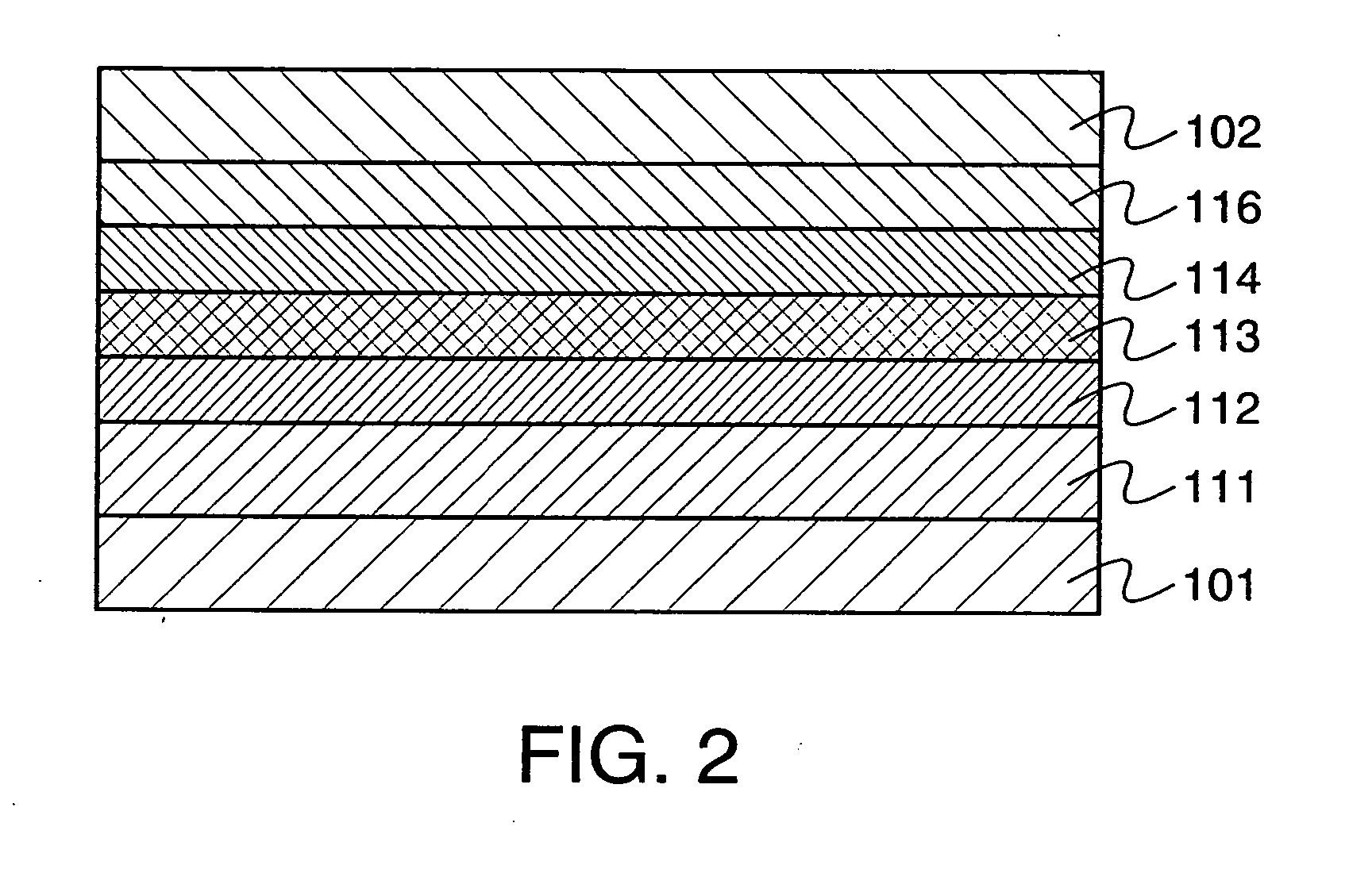

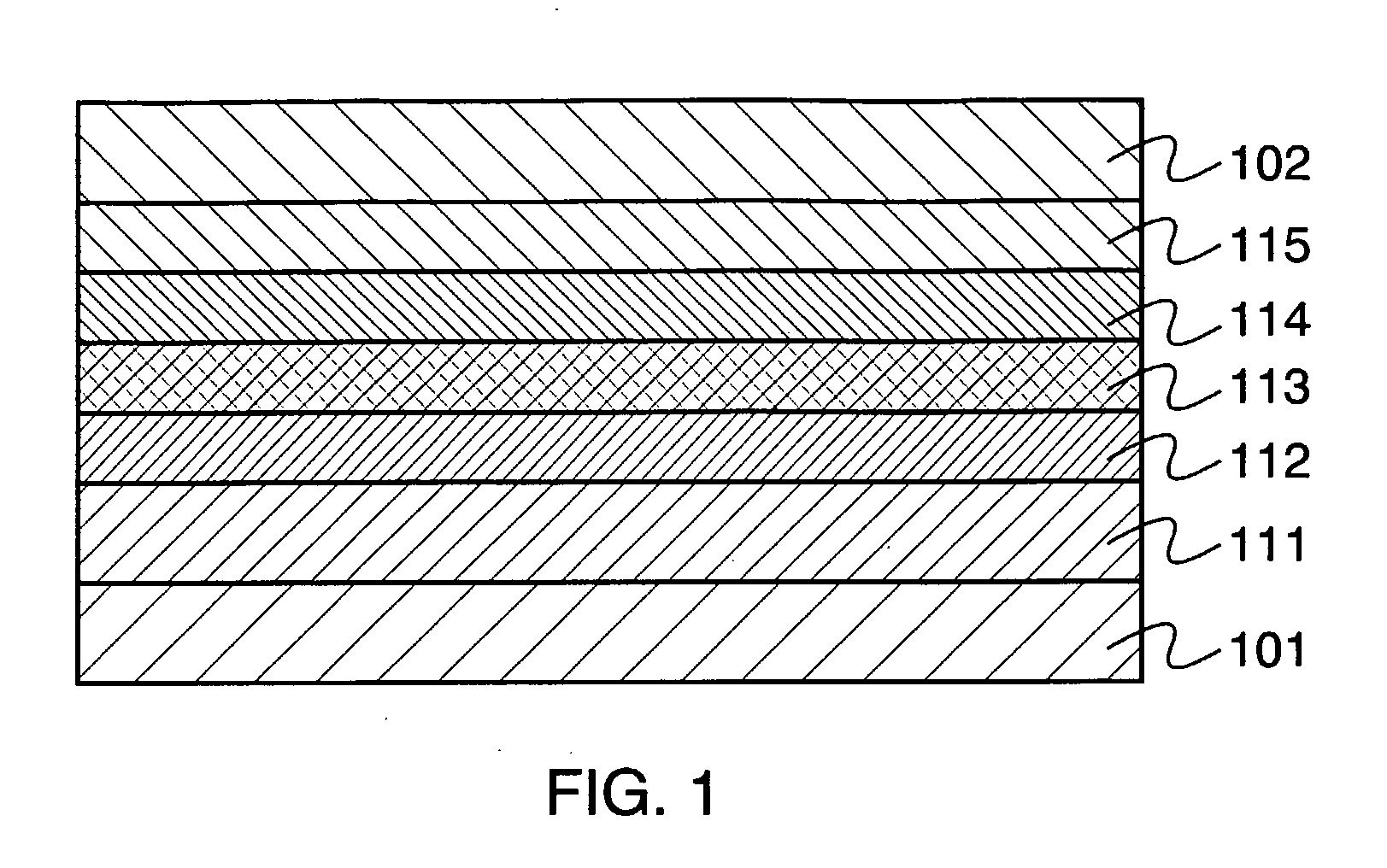

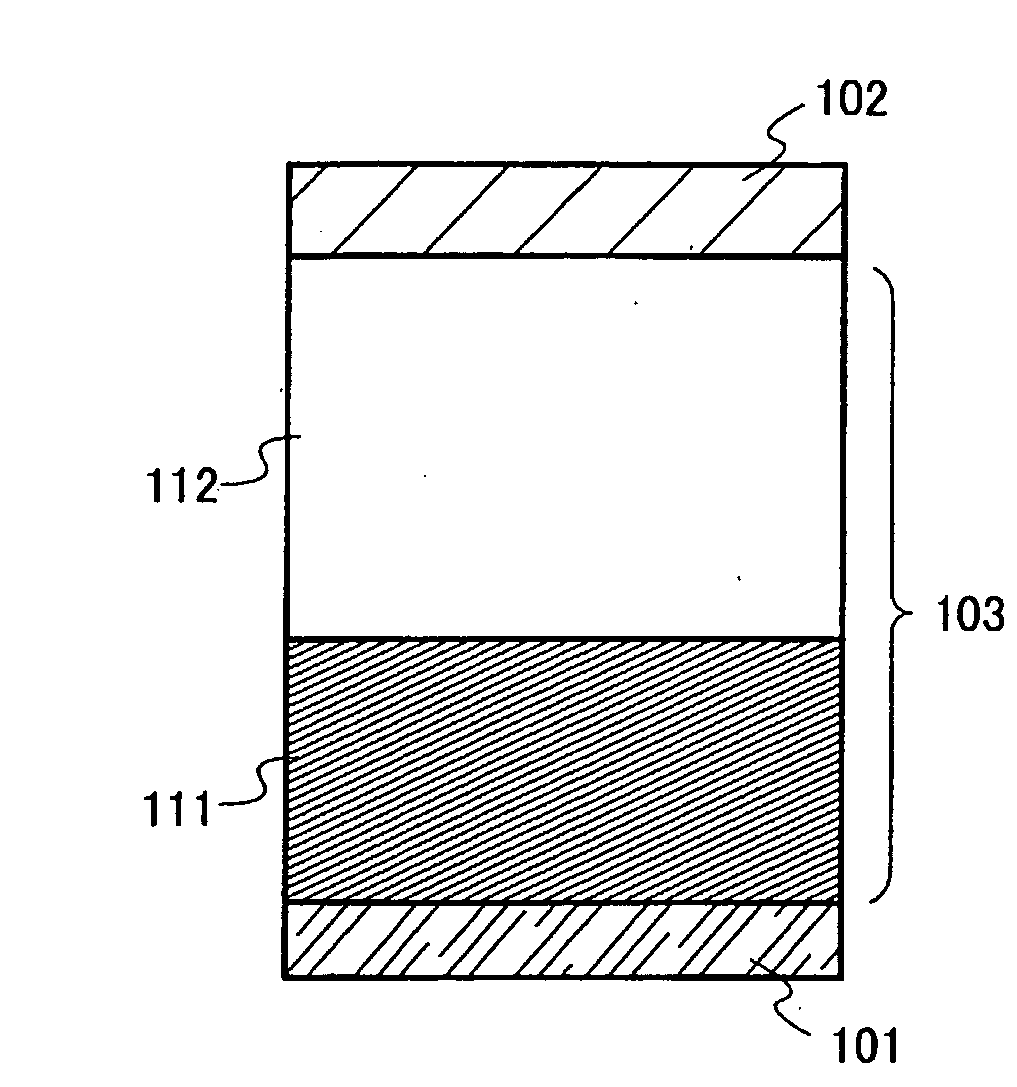

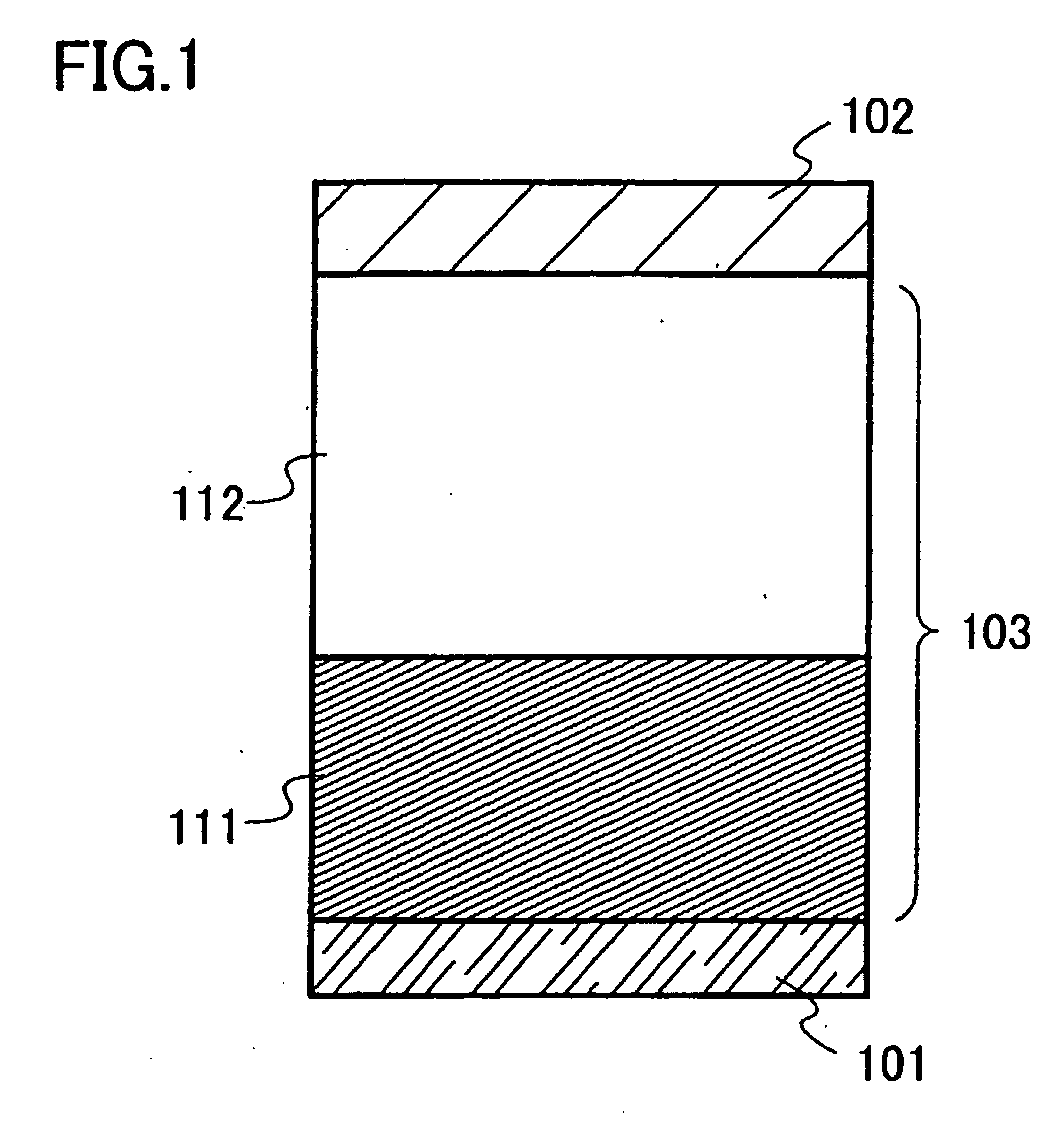

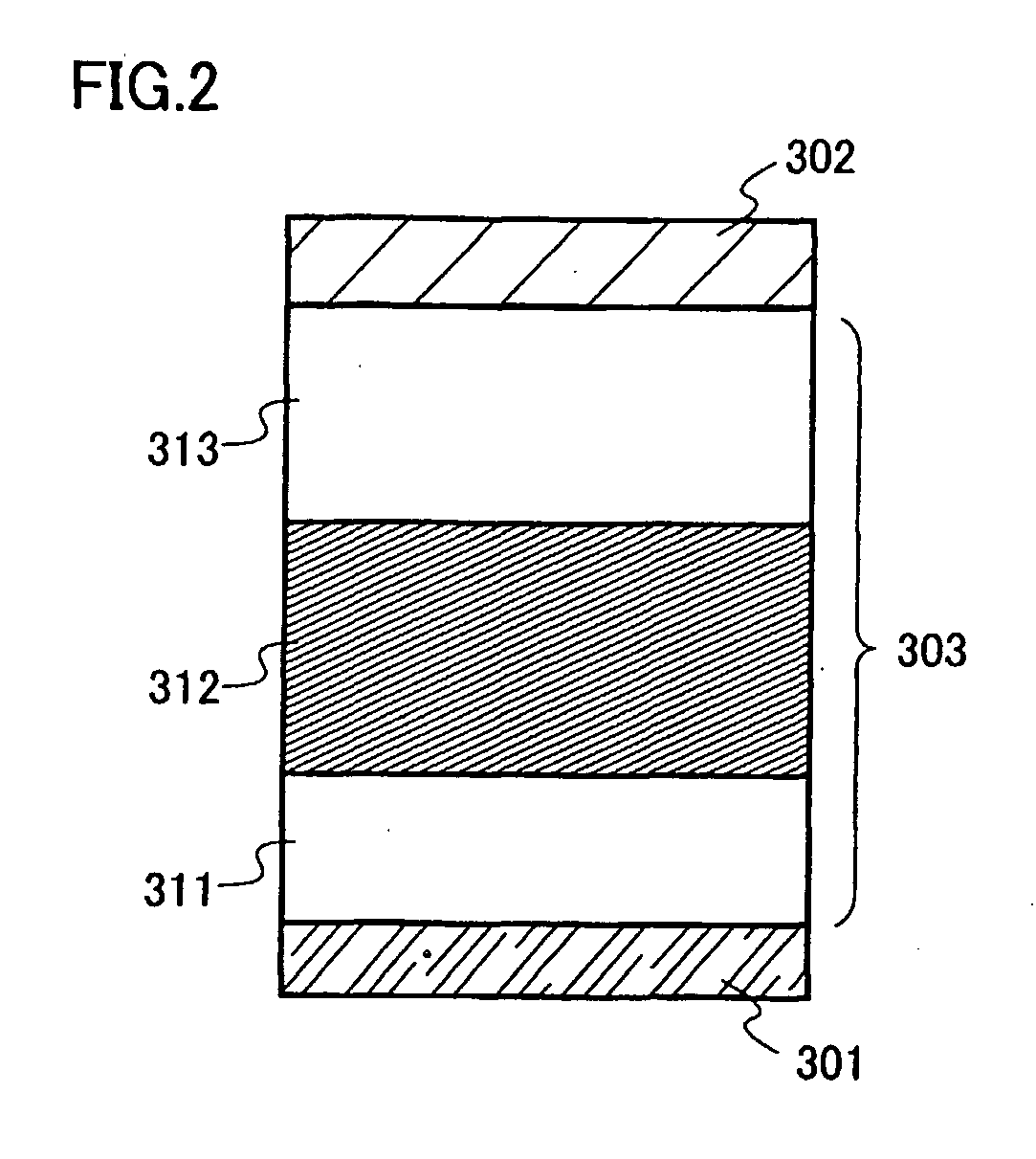

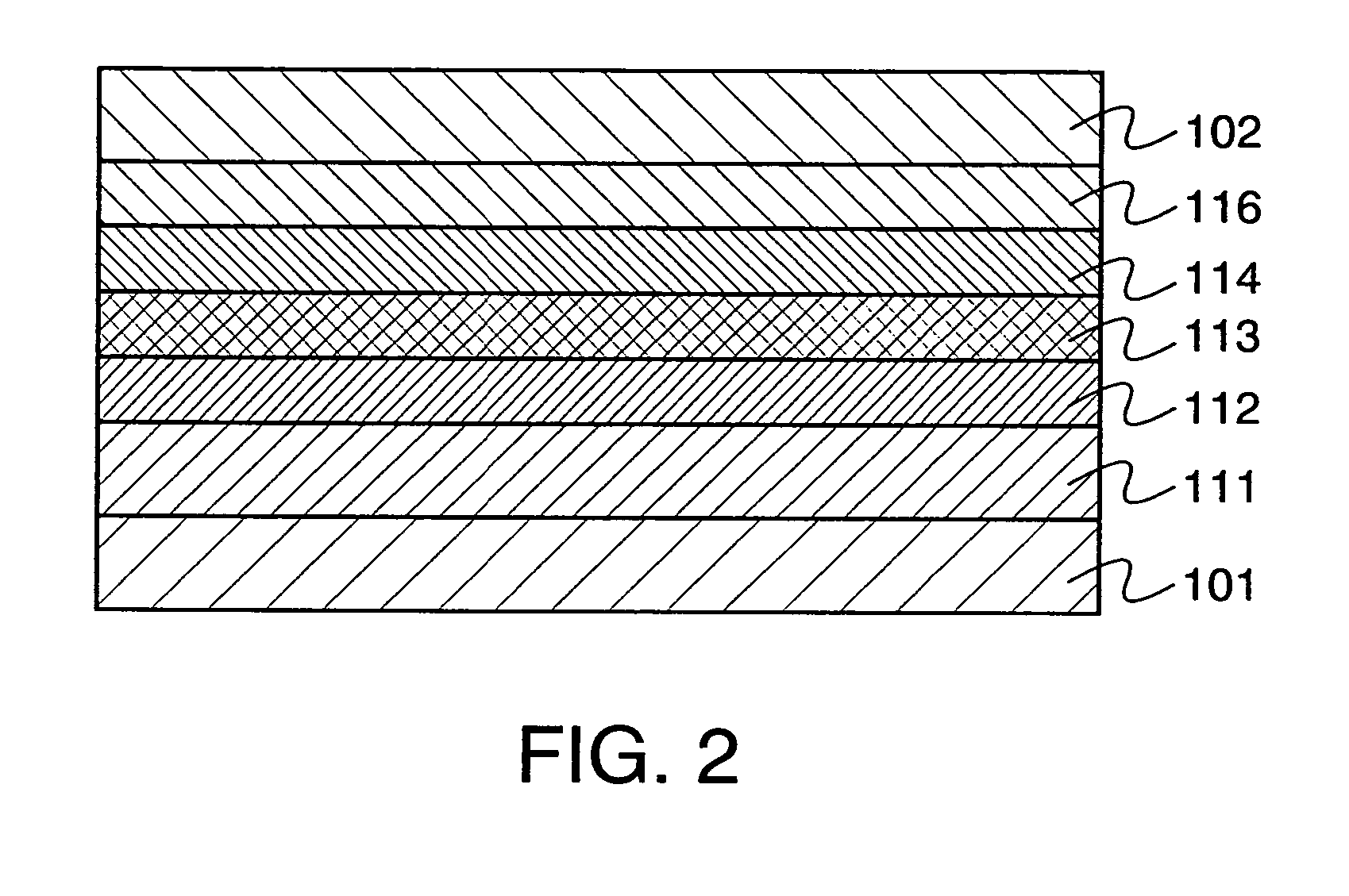

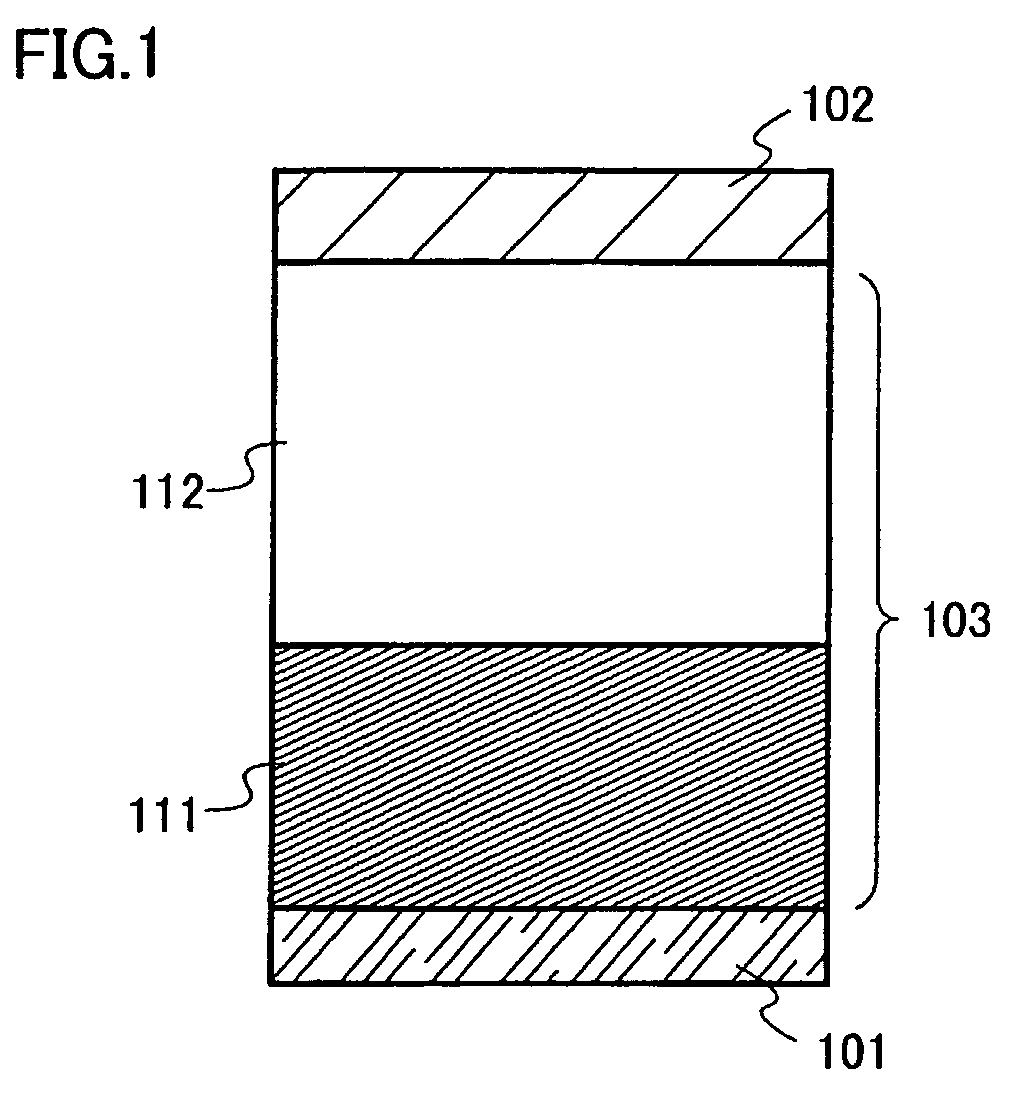

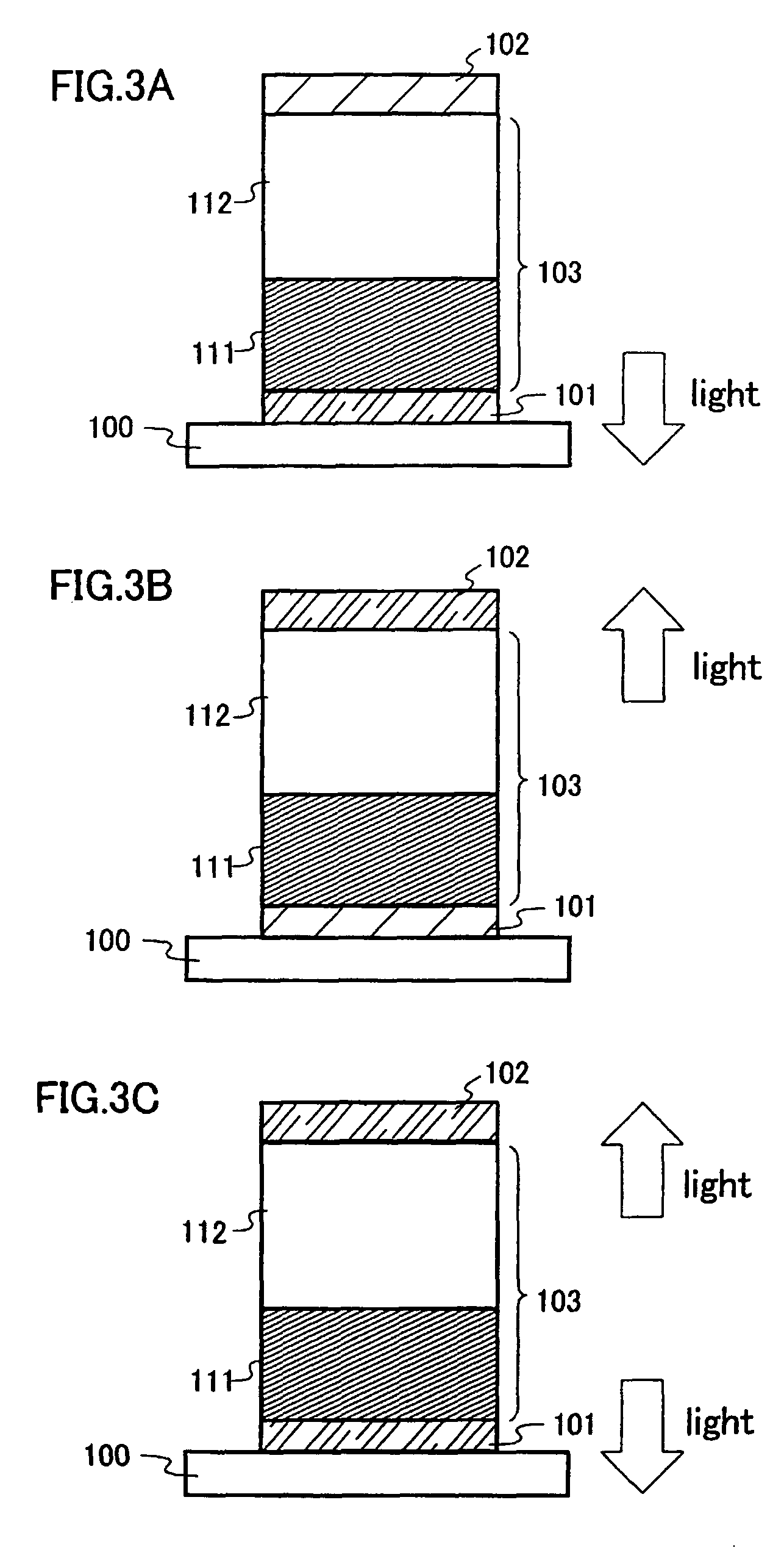

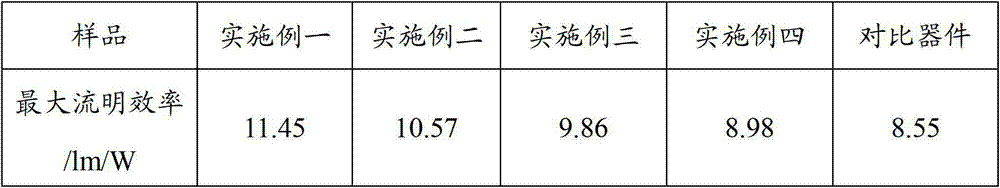

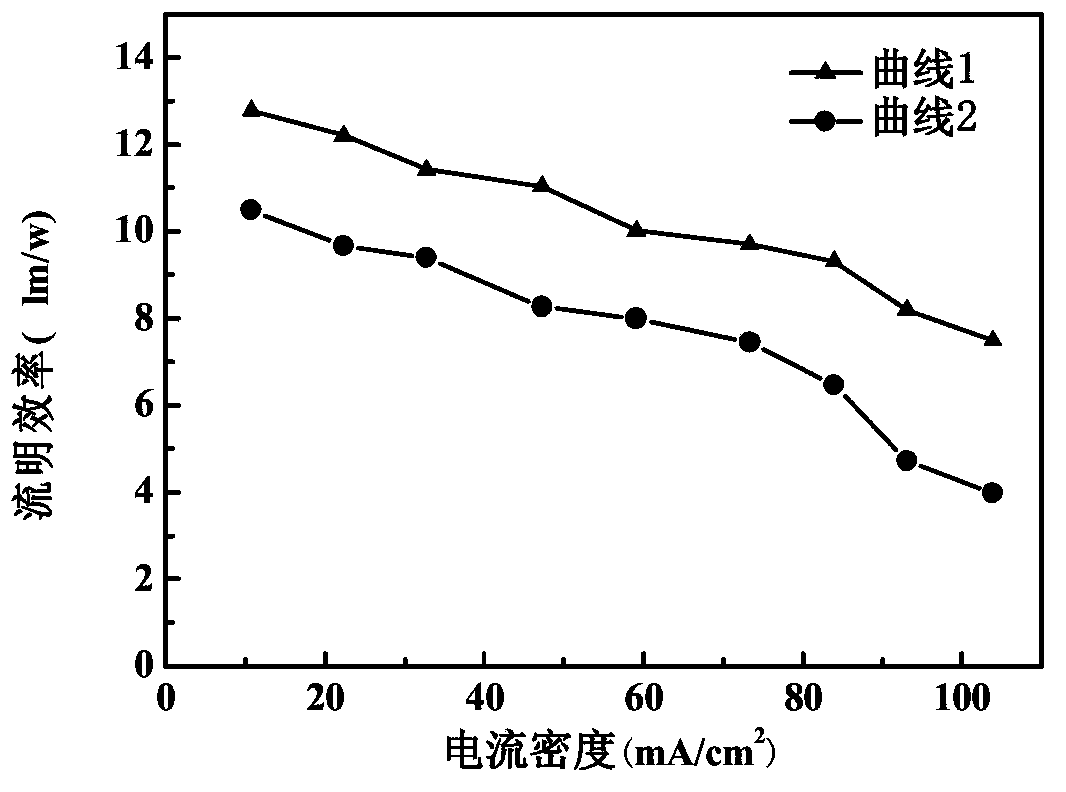

Light emitting device and electronic appliance using the same

InactiveUS20060292394A1Easy to changeDistanceDischarge tube luminescnet screensElectroluminescent light sourcesVanadium oxideOrganic compound

A light emitting device comprises a pair of electrodes and a mixed layer provided between the pair of electrodes. The mixed layer contains an organic compound which contains no nitrogen atoms, i.e., an organic compound which dose not have an arylamine skeleton, and a metal oxide. As the organic compound, an aromatic hydrocarbon having an anthracene skeleton is preferably used. As such an aromatic hydrocarbon, t-BuDNA, DPAnth, DPPA, DNA, DMNA, t-BuDBA, and the like are listed. As the metal oxide, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are preferably used. Further, the mixed layer preferably shows absorbance per 1 μm of 1 or less or does not show a distinct absorption peak in a spectrum of 450 to 650 nm when an absorption spectrum is measured.

Owner:SEMICON ENERGY LAB CO LTD

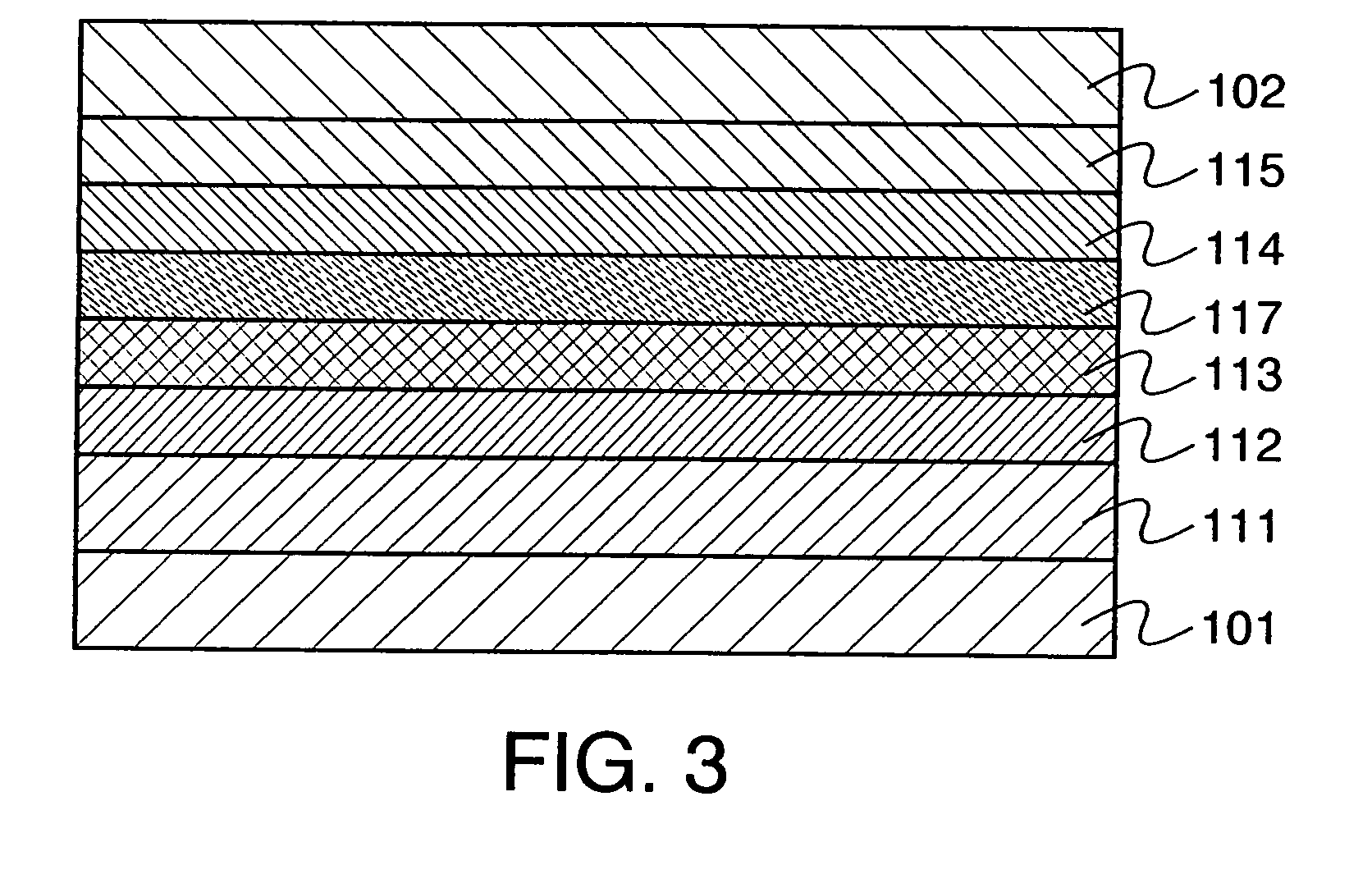

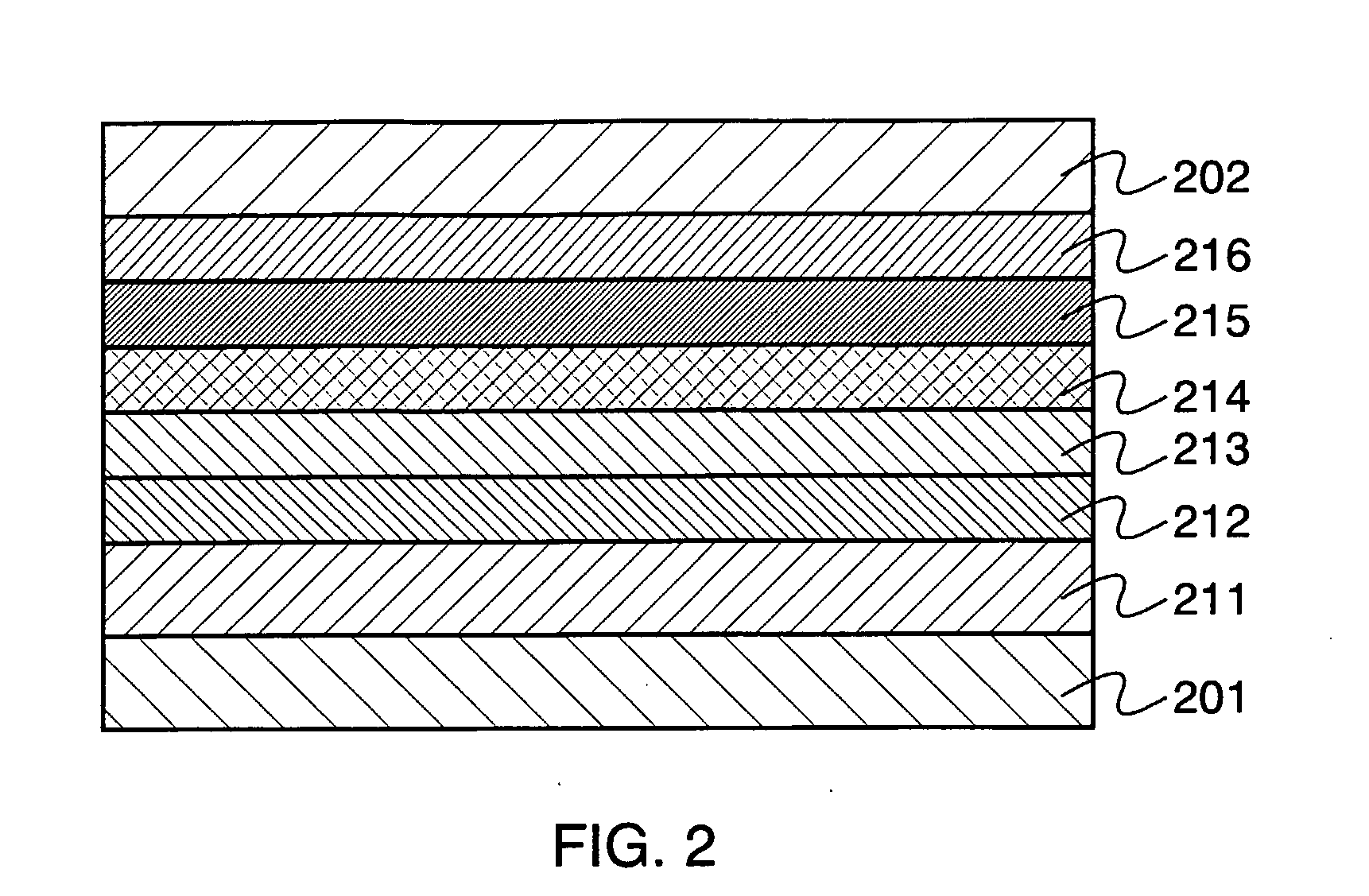

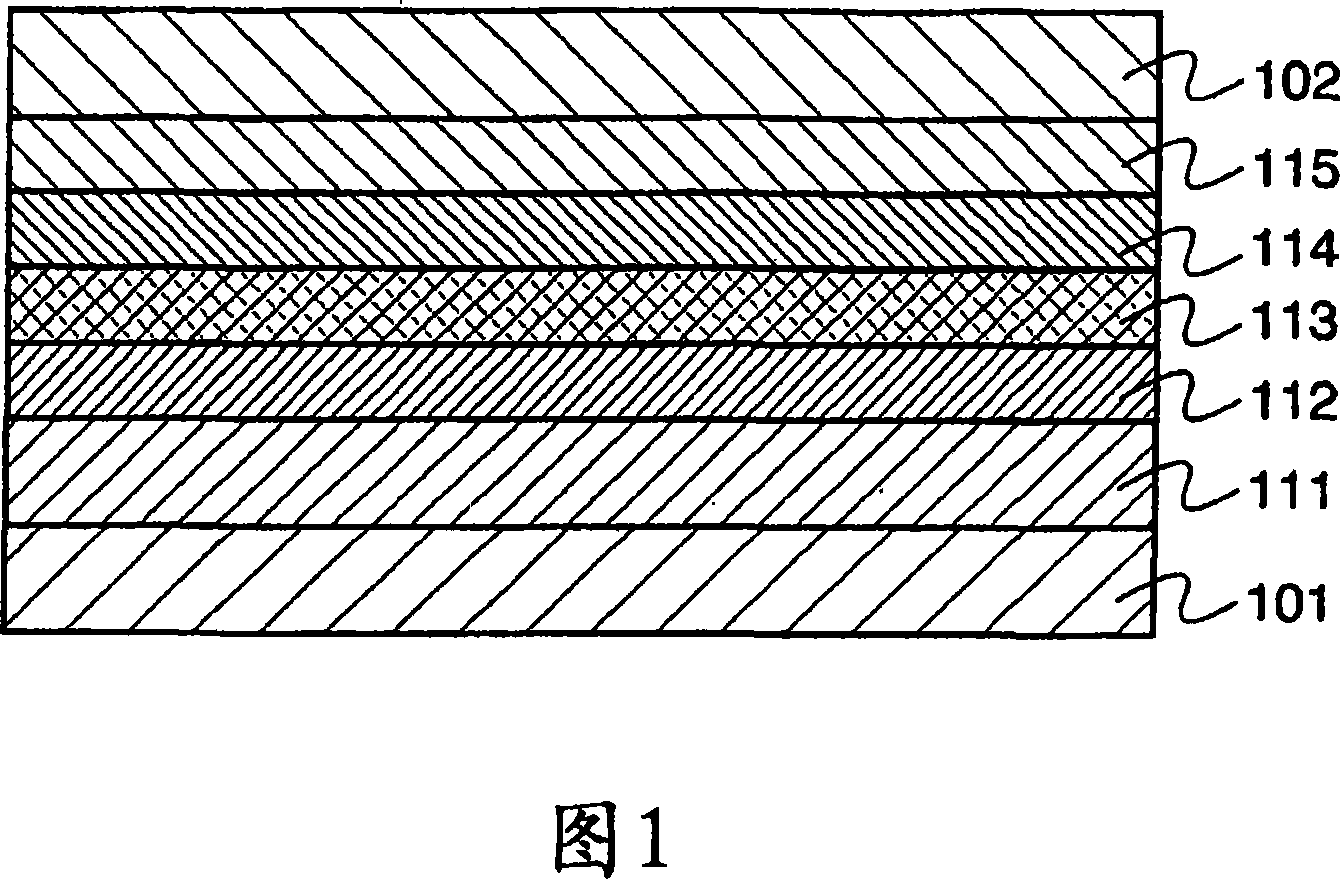

Light emitting element, light emitting device, and electronic device

InactiveUS20090026922A1Operation failureEasy to changeDischarge tube luminescnet screensLamp detailsVanadium oxideTert butyl

One aspect of the present invention is a light emitting element having a layer including an aromatic hydrocarbon and a metal oxide between a pair of electrodes. The kind of aromatic hydrocarbon is not particularly limited; however, an aromatic hydrocarbon having hole mobility of 1×10−6 cm2 / Vs or more is preferable. As such aromatic hydrocarbon, for example, 2-tert-butyl-9,10-di(2-naphthyl)anthracene, anthracene, 9,10-diphenylanthracene, tetracene, rubrene, perylene, 2,5,8,11-tetra(tert-butyl)perylene, and the like are given. As the metal oxide, a metal which shows an electron-accepting property to the aromatic hydrocarbon is preferable. As such metal oxide, for example, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are given.

Owner:SEMICON ENERGY LAB CO LTD

Application of catalyst with multiple active components for preparing 1,3-propanediol by hydrogenolysis of glycerin

ActiveCN106883098AImprove conversion rateHigh selectivityHeterogenous catalyst chemical elementsPreparation by OH group eliminationCobalt oxideChemistry

The invention relates to a catalyst for preparing 1,3-propanediol by hydrogenolysis of glycerin as well as a preparation method thereof. The catalyst comprises a tungsten oxide-aluminum oxide (WO3-Al2O3) composite carrier and active components which comprise any one selected from ruthenium, rhodium, palladium, iridium and platinum (marked as A) and any one selected from gold, silver, copper, nickel, sodium oxide, lithium oxide, potassium oxide, magnesium oxide, gallium oxide, zinc oxide, iron oxide, molybdenum oxide, lanthanum oxide, zirconium oxide, cobalt oxide, rhenium oxide, tin oxide, and manganese oxide (marked as a component B). The prepared catalyst can be used for generating 1,3-propanediol by hydrogenolysis of glycerin at a certain hydrogen pressure and temperature with high conversion rate and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

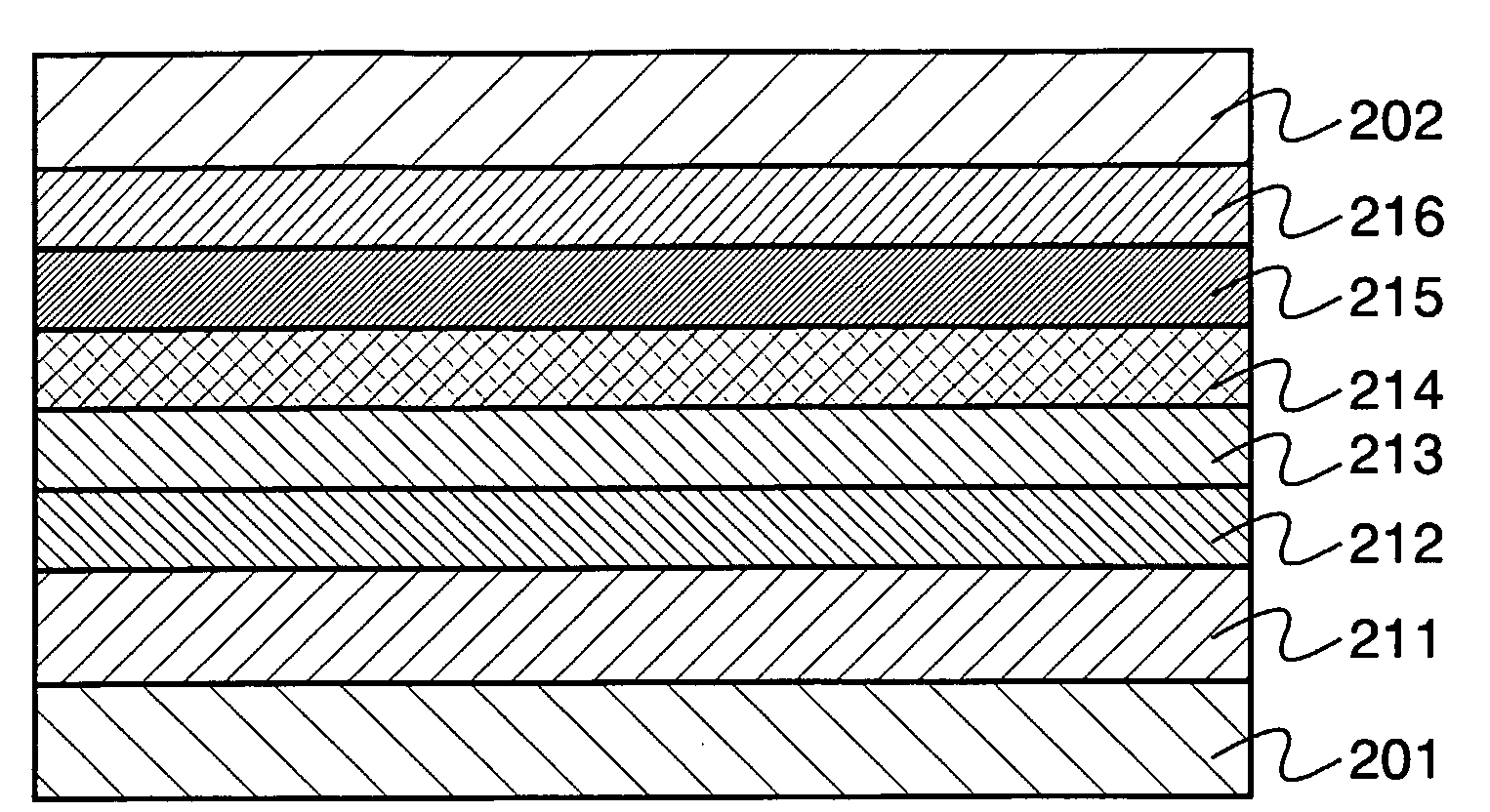

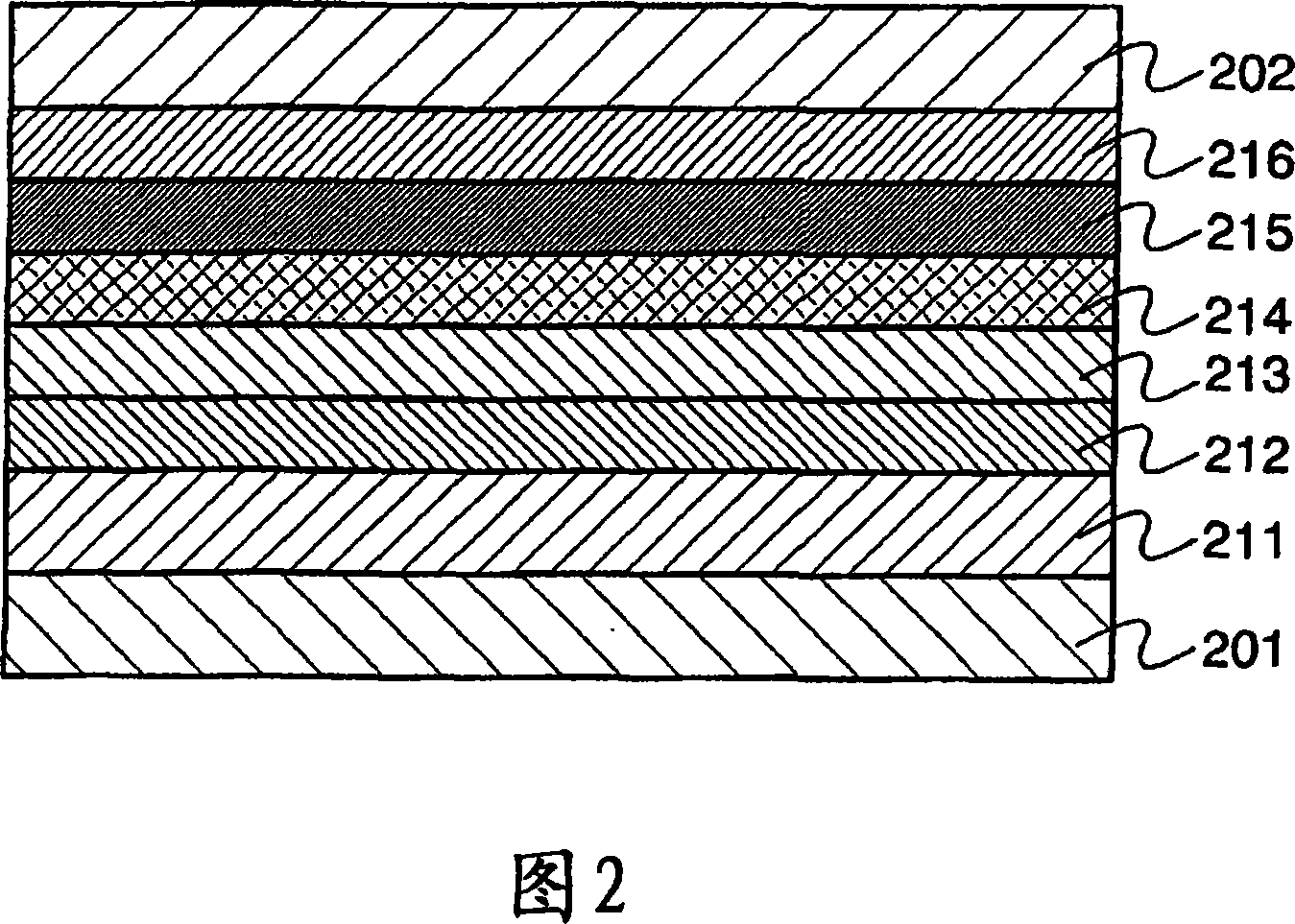

Composite Material, Light Emitting Element and Light Emitting Device

ActiveUS20080191611A1Maintain good propertiesGood property of carrier injectionOrganic chemistryDischarge tube luminescnet screensInorganic compoundOrganic compound

An object of the present invention is to provide a composite material formed of an organic compound and an inorganic compound, and has an excellent carrier transporting property, an excellent carrier injecting property to the organic compound, as well as excellent transparency. A composite material of the present invention for achieving the above object is a composite material of an organic compound represented in the general formula below, and an inorganic compound. For the inorganic compound, an oxide of a transition metal, preferably an oxide of a metal belonging to groups 4 to 8 of the periodic table, in particular vanadium oxide, tantalum oxide, molybdenum oxide, tungsten oxide, rhenium oxide, and ruthenium oxide, can be used.

Owner:SEMICON ENERGY LAB CO LTD

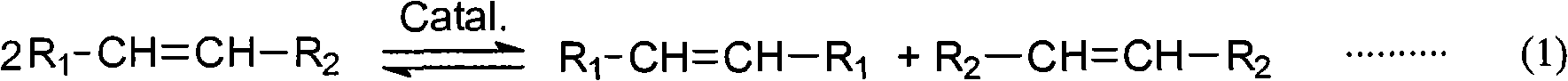

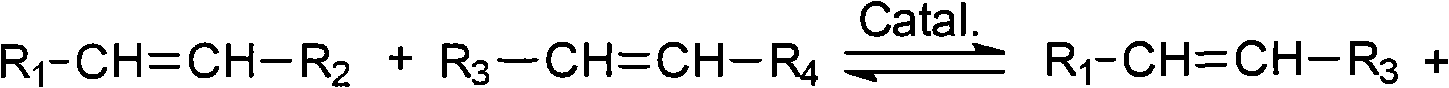

Method for preparing propylene through C4 disproportionation

ActiveCN102372572AToxic reductionAdjust the ratioHydrocarbon by metathesis reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureDisproportionation

The invention relates to a method for preparing propylene through C4 disproportionation and mainly solves the problems of the past technologies such as the consumption of ethylene and low catalyst activity. In the technical scheme in the method, C4 is used as the raw material and the method comprises the following step: under the conditions that the reaction temperature is 300-520 DEG C, the reaction pressure is 0-2MPa and the weight space velocity is 1-10h<-1>, the raw material passes through a catalyst bed to generate propylene. The catalyst used in the method comprises the following components in parts by weight: 4-30 parts of at least one of tungsten oxide, molybdenum oxide and rhenium oxide and 70-96 parts of SiO2 carrier. By adopting the technical scheme, the problems can be better solved and the method can be used in the propylene industrial production adopting C4 disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

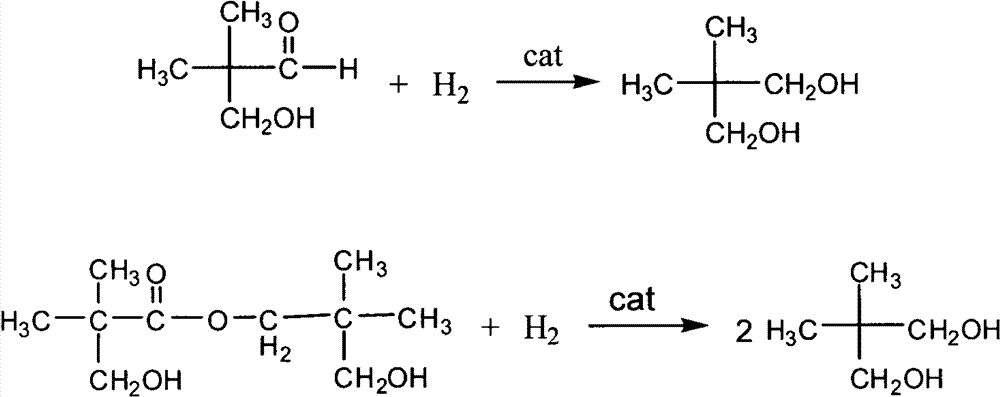

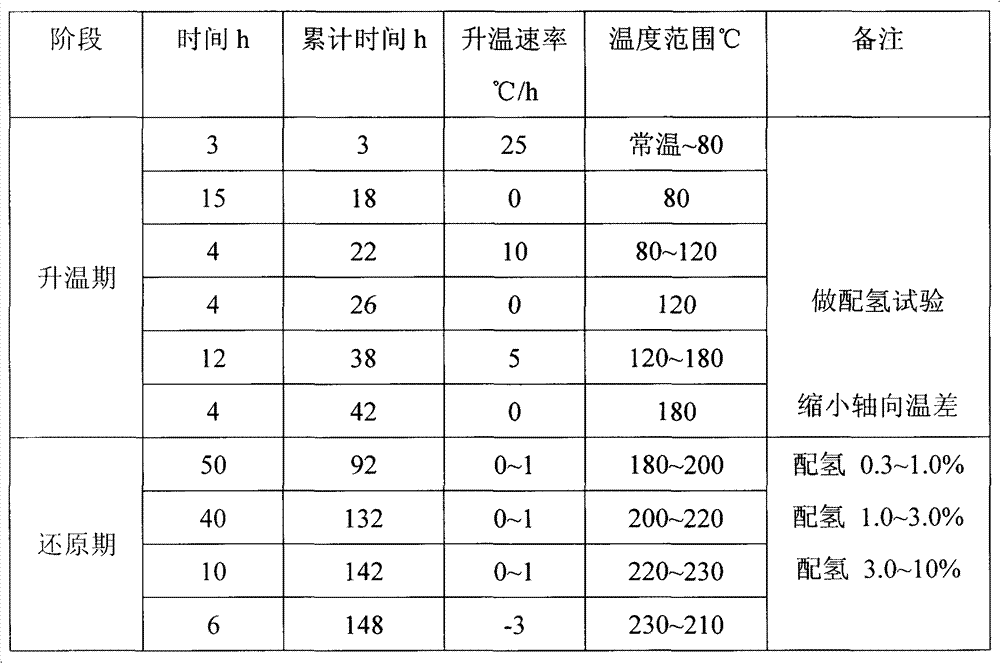

Catalyst for preparing neopentyl glycol by hydrogenation and preparation method of catalyst

ActiveCN102728370AImprove hydrogen absorption performanceIncrease the number of contactsOrganic compound preparationHydroxy compound preparationPolymer scienceCopper oxide

The invention relates to a catalyst for preparing neopentyl glycol (NPG) by hydrogenation and a preparation method of the catalyst. Based on the total weight of the catalyst, the catalyst contains 15-50wt% of copper oxide, 10-30wt% of zinc oxide, 20-40wt% of alumina, 1-15wt% of one or two or three kinds of titanium oxide, zirconium oxide or hafnium oxide. In addition, 0.1-1wt% of rhenium oxide is also added. The catalyst is prepared by a co-precipitation method, then the mixed gas of hydrogen and nitrogen is used to reduce and activate the catalyst for preparing NPG by hydrogenation. With the adoption of the catalyst provided by the invention, the raw material of hydrogenation has high conversion, and the NPG has high selectivity.

Owner:WANHUA CHEM GRP CO LTD +1

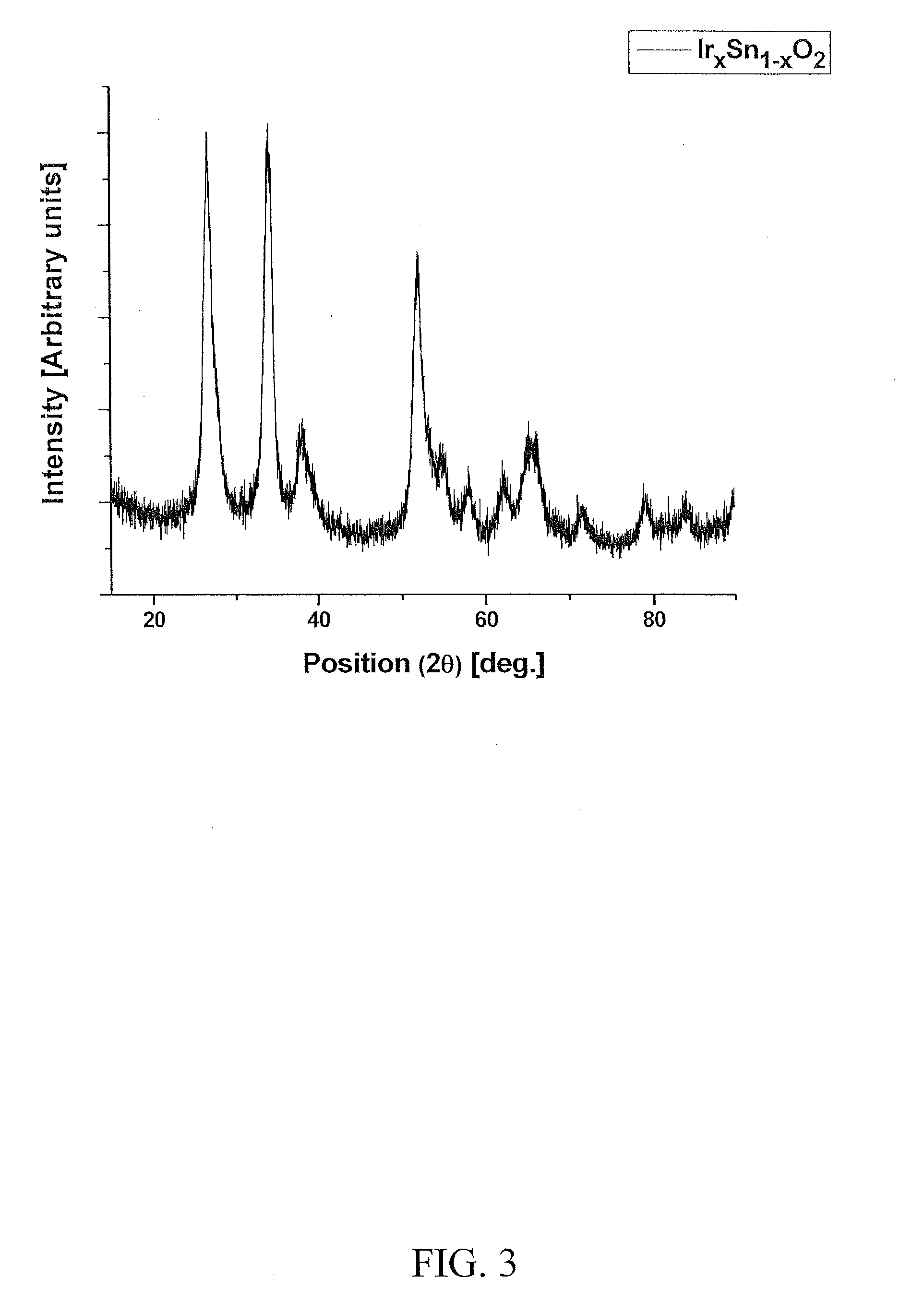

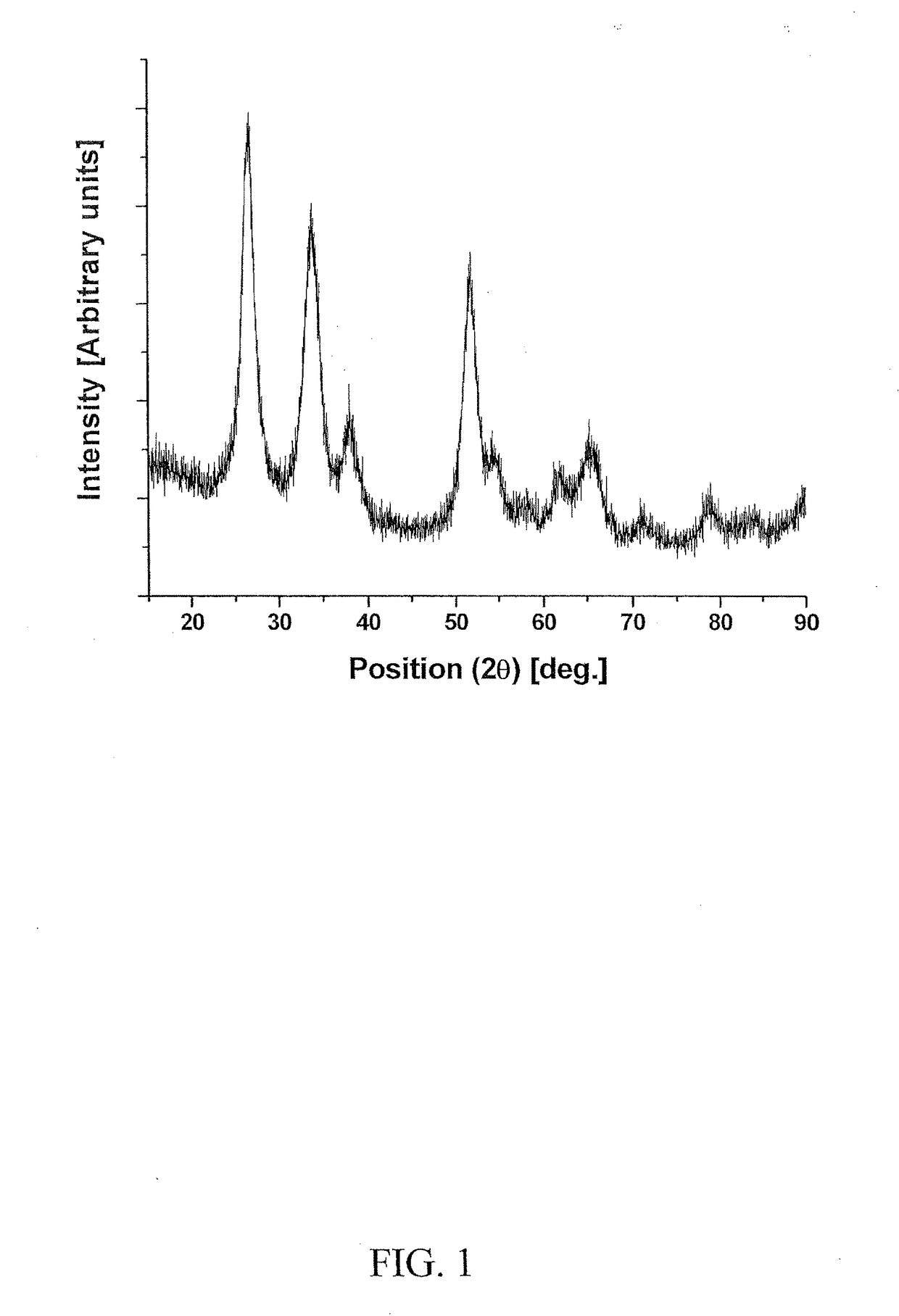

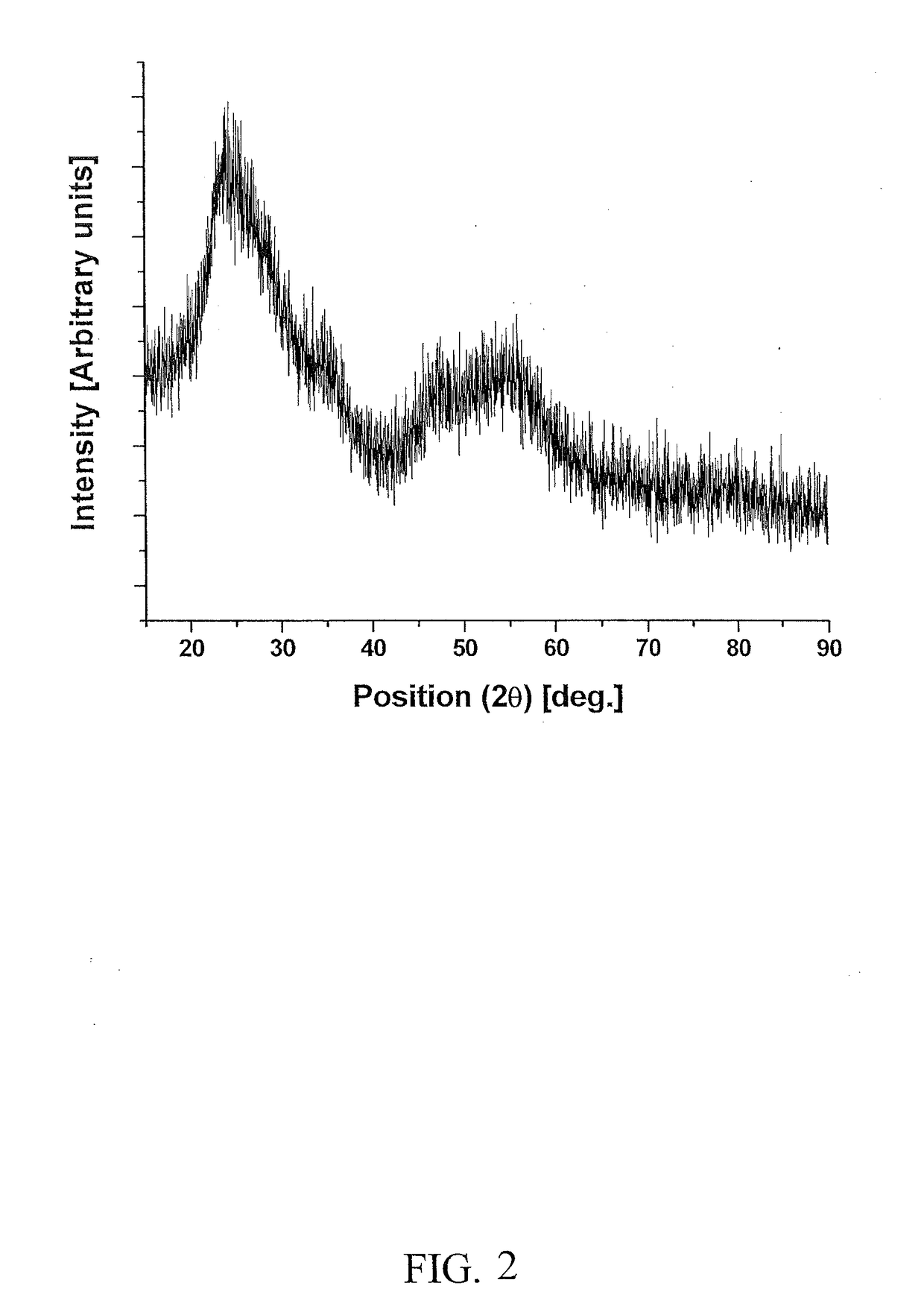

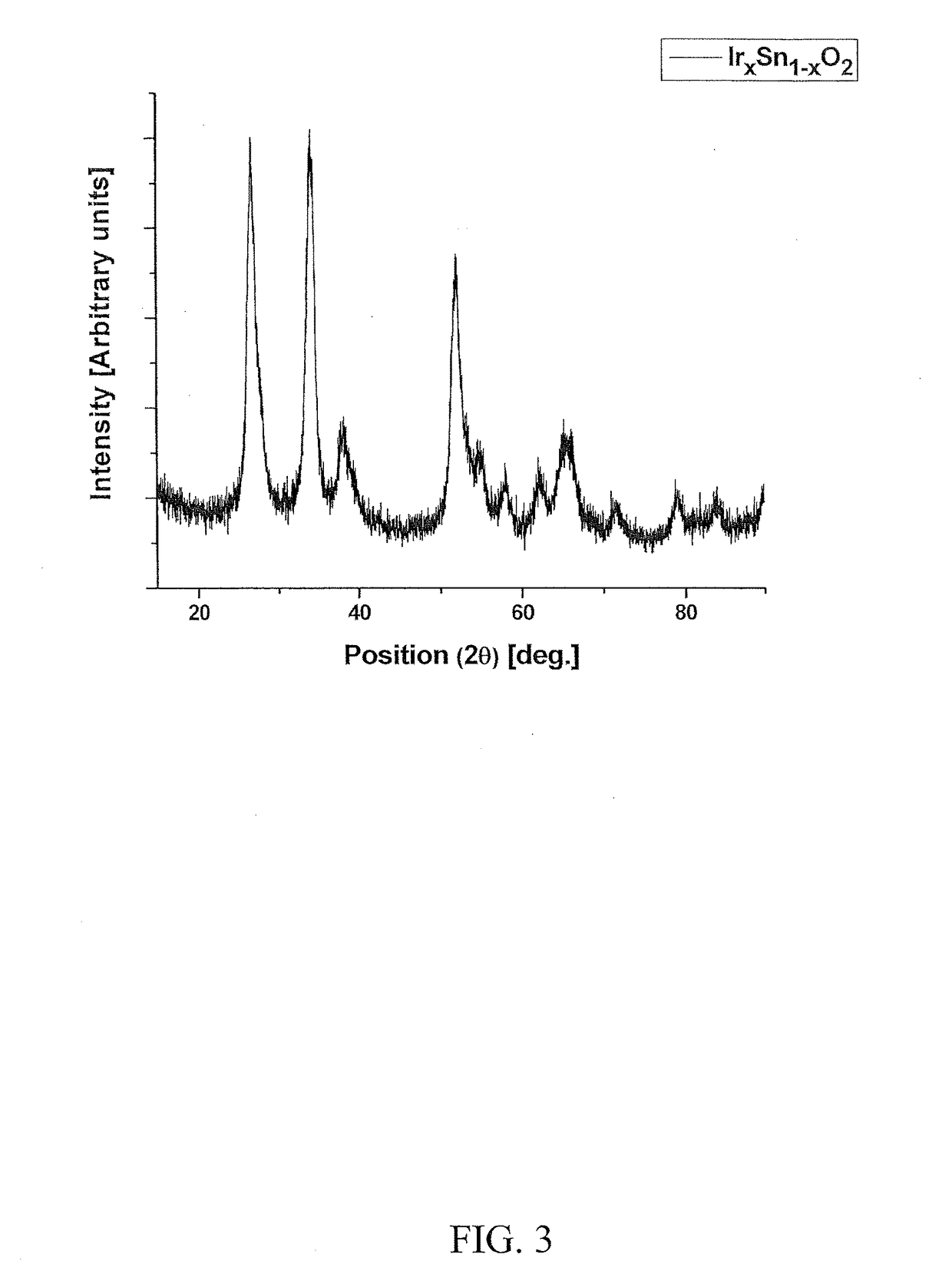

Non-noble metal based electro-catalyst compositions for proton exchange membrane based water electrolysis and methods of making

The invention provides electro-catalyst compositions for an anode electrode of a proton exchange membrane-based water electrolysis system. The compositions include a noble metal component selected from the group consisting of iridium oxide, ruthenium oxide, rhenium oxide and mixtures thereof, and a non-noble metal component selected from the group consisting of tantalum oxide, tin oxide, niobium oxide, titanium oxide, tungsten oxide, molybdenum oxide, yttrium oxide, scandium oxide, cooper oxide, zirconium oxide, nickel oxide and mixtures thereof. Further, the non-noble metal component can include a dopant. The dopant can be at least one element selected from Groups III, V, VI and VII of the Periodic Table. The compositions can be prepared using a surfactant approach or a sol gel approach. Further, the compositions are prepared using noble metal and non-noble metal precursors. Furthermore, a thin film containing the compositions can be deposited onto a substrate to form the anode electrode.

Owner:UNIVERSITY OF PITTSBURGH

Light emitting device and electronic appliance using the same

InactiveUS8017252B2Avoid mutationReduce stepsOrganic chemistryDischarge tube luminescnet screensAbsorbanceVanadium oxide

A light emitting device comprises a pair of electrodes and a mixed layer provided between the pair of electrodes. The mixed layer contains an organic compound which contains no nitrogen atoms, i.e., an organic compound which dose not have an arylamine skeleton, and a metal oxide. As the organic compound, an aromatic hydrocarbon having an anthracene skeleton is preferably used. As such an aromatic hydrocarbon, t-BuDNA, DPAnth, DPPA, DNA, DMNA, t-BuDBA, and the like are listed. As the metal oxide, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are preferably used. Further, the mixed layer preferably shows absorbance per 1 μm of 1 or less or does not show a distinct absorption peak in a spectrum of 450 to 650 nm when an absorption spectrum is measured.

Owner:SEMICON ENERGY LAB CO LTD

Light emitting element, light emitting device and electronic apparatus

ActiveCN101203968ANot easy to crystallizeReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingVanadium oxideTert butyl

Owner:SEMICON ENERGY LAB CO LTD

Non-noble metal based electro-catalyst compositions for proton exchange membrane based water electrolysis and methods of making

ActiveUS20170233879A1Shorten the timeReduced service lifeCellsMaterial nanotechnologyElectrolysisTitanium oxide

The invention provides electro-catalyst compositions for an anode electrode of an acid mediated proton exchange membrane-based water electrolysis system. The compositions include a noble metal component selected from the group consisting of iridium oxide, ruthenium oxide, rhenium oxide and mixtures thereof, and a non-noble metal component selected from the group consisting of tantalum oxide, tin oxide, niobium oxide, titanium oxide, tungsten oxide, molybdenum oxide, yttrium oxide, scandium oxide, cooper oxide, zirconium oxide, nickel oxide and mixtures thereof. Further, the non-noble metal component can include a dopant. The dopant can be at least one element selected from Groups III, V, VI and VII of the Periodic Table. The compositions can be prepared using any solution based methods involving a surfactant approach or a sol gel approach. Further, the compositions are prepared using noble metal and non-noble metal precursors. Furthermore, a thin film containing the compositions can be deposited onto a substrate to form the anode electrode.

Owner:UNIVERSITY OF PITTSBURGH

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

ActiveCN101137439ADispersed particle separationCatalyst activation/preparationPtru catalystManganese oxide

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:TANAKA PRECIOUS METAL IND

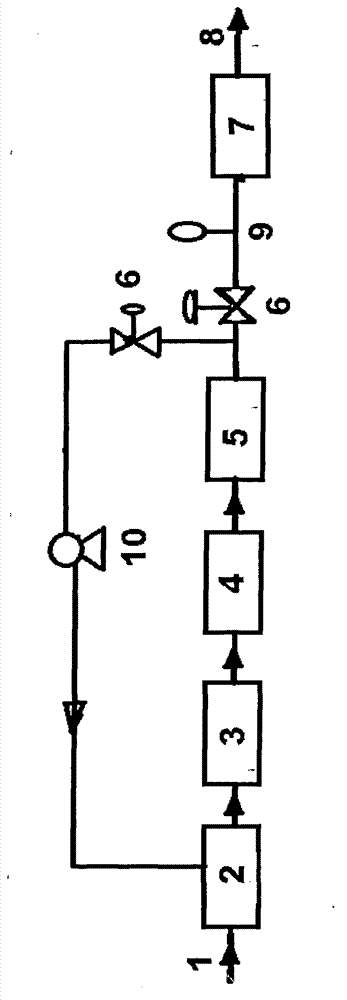

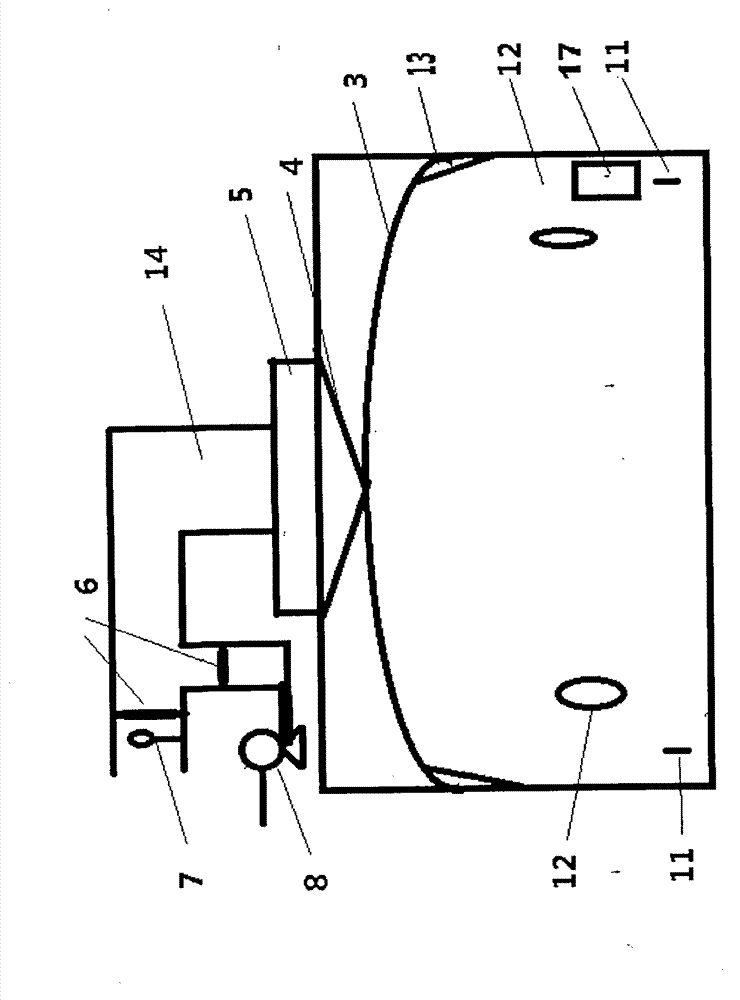

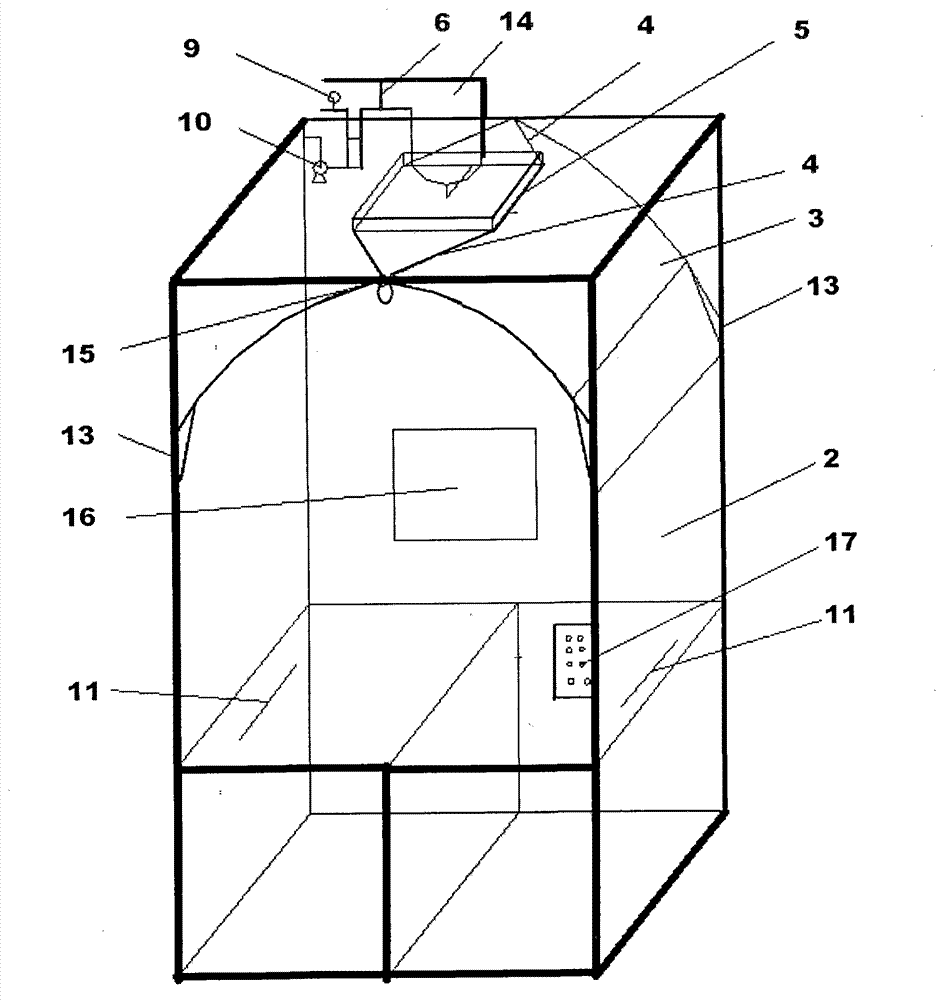

Energy-saving waste gas treatment method and apparatus thereof

InactiveCN103706232AReduce resistanceLarge adsorption capacityIon-exchange process apparatusDispersed particle separationFiberActivated carbon

The invention belongs to the field of waste gas treatment, and specifically discloses an energy-saving waste gas treatment method and an apparatus thereof. According to the energy-saving waste gas treatment method, in a fuming cupboard, the waste gas is successively subjected to ion exchange resin membrane absorption, and photocatalytic decomposition and absorption of an activated carbon fiber adsorbed layer and a mixed catalyst of nano pucherite and rhenium oxide; and part of the processed waste gas is reused using a booster pump. The apparatus comprises an electric control system, an ion exchange resin membrane, the activated carbon fiber adsorbed layer, a photocatalytic device, a ventilation system, a waste gas recycling system, and a drainage system; the energy-saving waste gas treatment apparatus comprises the ion exchange resin membrane, the activated carbon fiber adsorbed layer, and the nano photocatalytic device which are connected successively. The energy-saving waste gas treatment method and the apparatus can be widely used in treatment of various waste gas and fuming cupboards of laboratories.

Owner:MEIZHOU JINCHUAN MEDICAL WASTE CENTIZED TREATMENT CO LTD

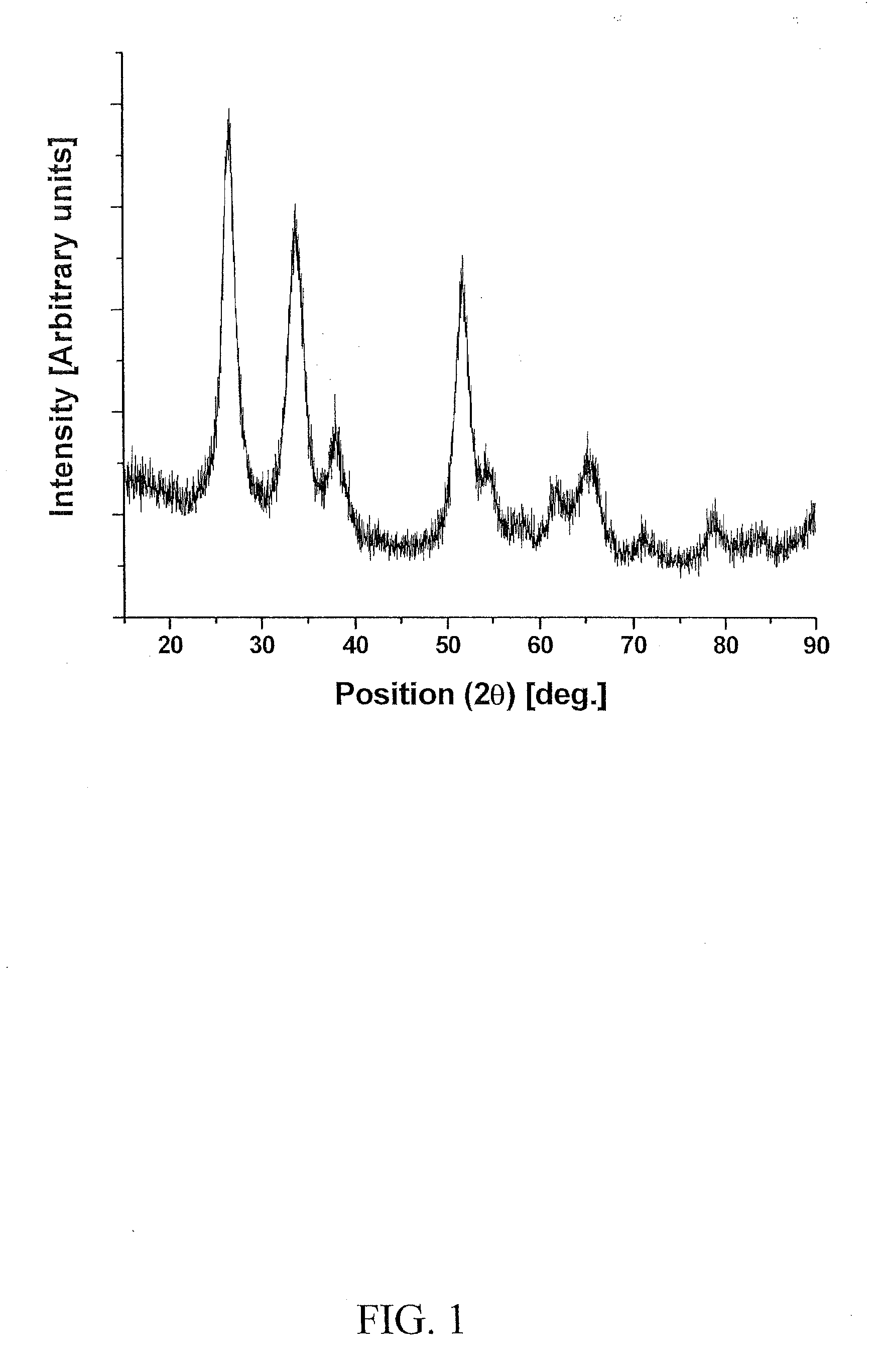

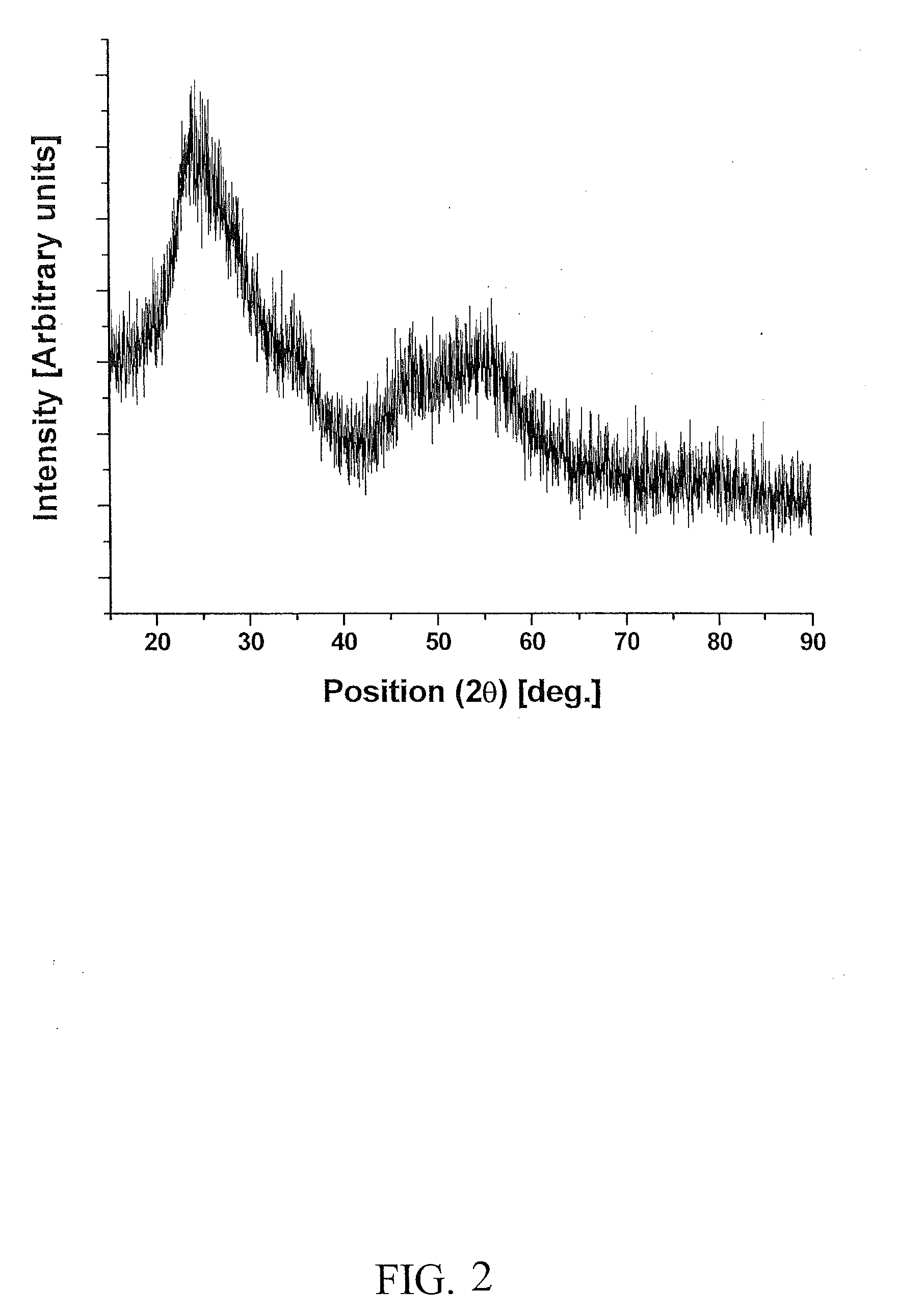

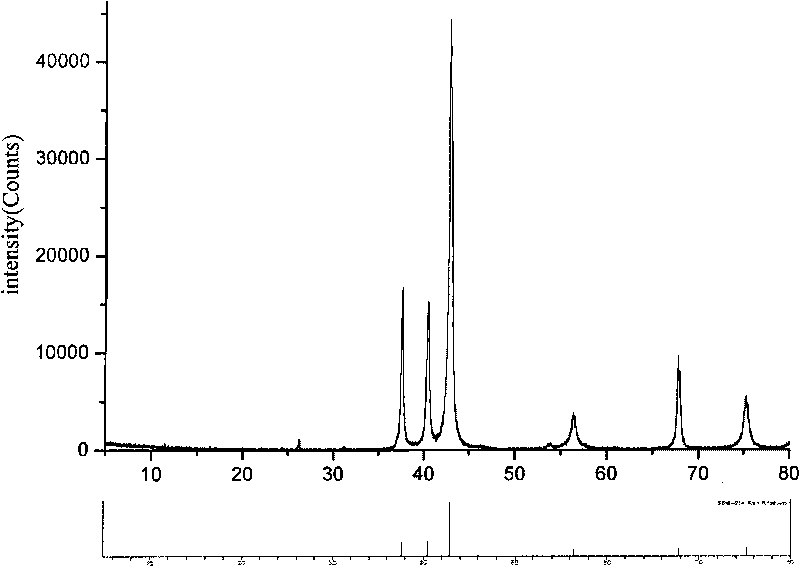

Preparation method of superfine rhenium powder

InactiveCN101700574ALower decomposition temperatureLow reduction temperatureVolumetric Mass DensityCrystallinity

The invention discloses a preparation method of superfine rhenium powder, taking high-purity ammonium rhenate as a raw material and comprising the following steps: heating the high-purity ammonium rhenate at an oxidizing atmosphere to decompose into high valence rhenium oxide Re2O7; and then reducing Re2O7 by H2 or CO to obtain superfine rhenium powder. The superfine rhenium powder obtained by the method of the invention has the advantages of low impurity content, sphere or sphere-like structure, even particle size distribution, high crystallinity, low oxygen content, good fluidity, high tap density and the like.

Owner:CENT SOUTH UNIV +1

Composite material, light emitting element and light emitting device

ActiveUS8420227B2Maintain good propertiesHigh transparencyDischarge tube luminescnet screensLamp detailsInorganic compoundVanadium oxide

An object of the present invention is to provide a composite material formed of an organic compound and an inorganic compound, and has an excellent carrier transporting property, an excellent carrier injecting property to the organic compound, as well as excellent transparency. A composite material of the present invention for achieving the above object is a composite material of an organic compound represented in the general formula below, and an inorganic compound. For the inorganic compound, an oxide of a transition metal, preferably an oxide of a metal belonging to groups 4 to 8 of the periodic table, in particular vanadium oxide, tantalum oxide, molybdenum oxide, tungsten oxide, rhenium oxide, and ruthenium oxide, can be used.

Owner:SEMICON ENERGY LAB CO LTD

Chromium carbide copper-based contact material for low-voltage electric appliance, and processing method for chromium carbide copper-based contact material

The invention discloses a chromium carbide copper-based contact material for low-voltage electrical appliances, which is characterized in that the composition of the contact material is: 0.1%-10% chromium carbide, 0.1%-5% alloy metal, 0.1% ~10% rare earth oxides, and the balance is copper; the alloy metal is one or two or a combination of two or more of aluminum, lanthanum, cerium, yttrium, nickel, chromium, zirconium, niobium, vanadium, and tungsten , the rare earth oxide is one or a combination of two or more of rhenium oxide, lanthanum oxide, cerium oxide, yttrium oxide, yttrium oxysulfide, samarium oxide, and zirconia. The low-voltage electrical contact made of the above materials not only has excellent welding resistance, wear resistance and oxidation resistance, but also can be used safely for a long time. In addition, the present invention also provides a chromium carbide copper-based contact for low-voltage electrical appliances The processing method of the material.

Owner:仙居县南大合金科技有限公司

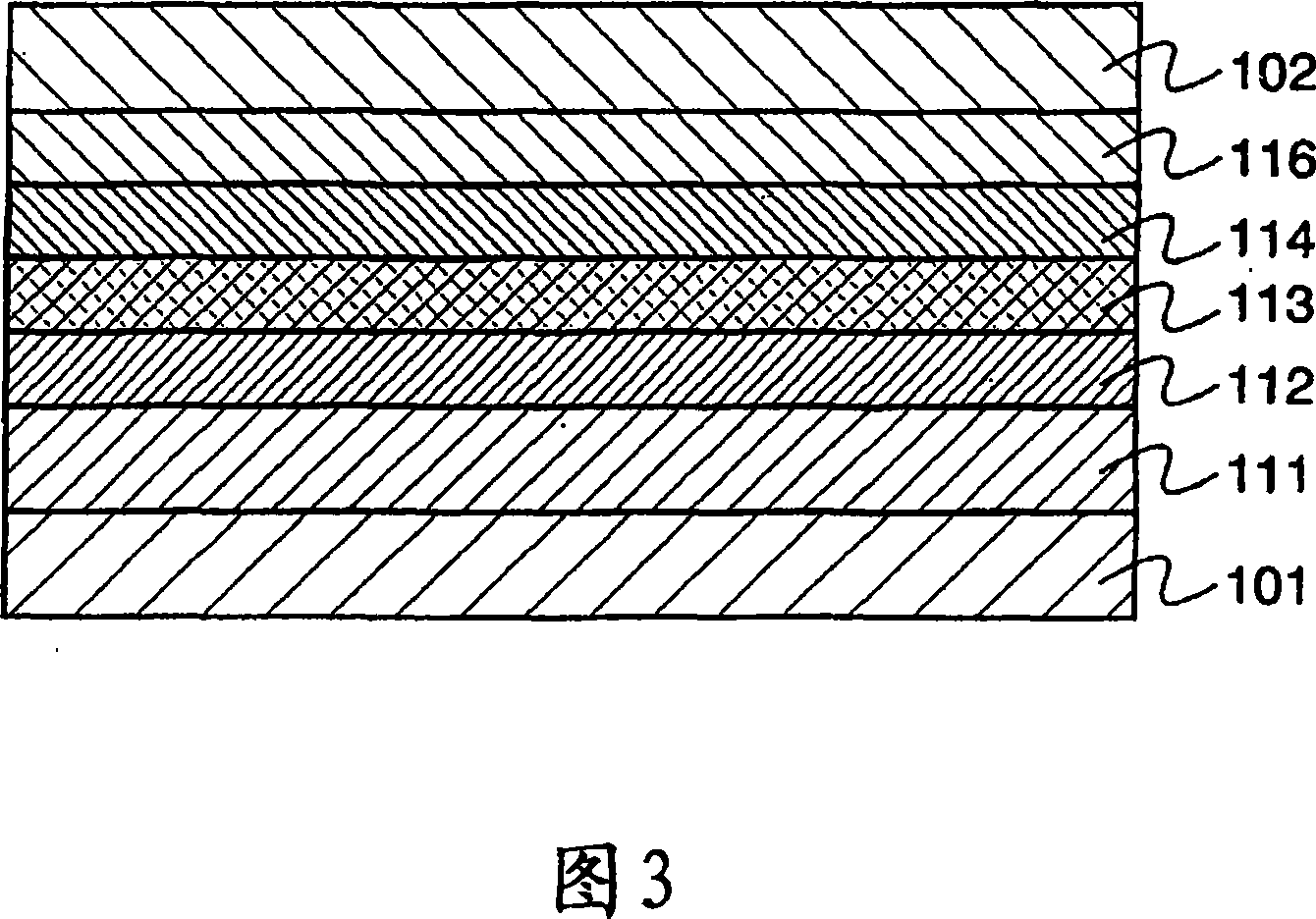

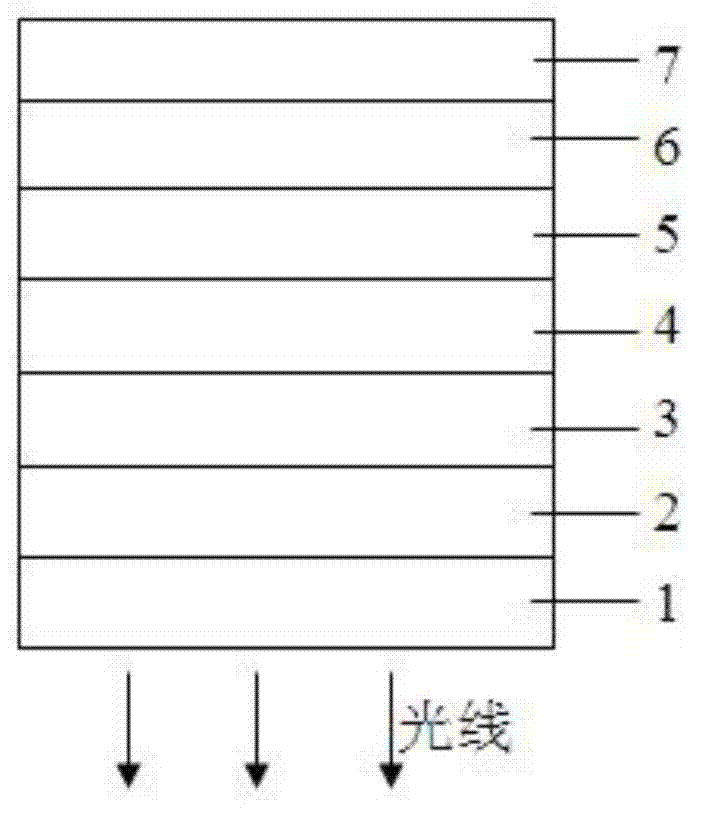

Organic electroluminescence device and manufacturing method thereof

InactiveCN103928622ALower work functionBlocking quenchingSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerDecomposition

The invention provides an organic electroluminescence device and a manufacturing method thereof. The organic electroluminescence device comprises a conductive anode substrate, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transmission layer, an electron injection layer and a cathode which are stacked sequentially, wherein the hole injection layer is made of a mixture of rhenium oxide and zinc oxide, the hole injection layer further contains the binder polytetrafluoroethylene, the hole injection layer is of a nanometer netty structure, and the bore diameter of the nanometer netty structure is 100 nm - 150 nm. According to the organic electroluminescence device, the hole transmission layer is manufactured through mixture of rhenium oxide, azo substances, zinc oxide and polytetrafluoroethylene, the binder polytetrafluoroethylene enables the cohesiveness between the hole injection layer and adjacent layers to be improved, decomposition of the azo substances enables the nanometer netty structure of the hole injection layer to be formed, the hole transmission rate and the photoelectric conversion efficiency of the device can be improved, the manufacturing method is simple, and application prospects are good.

Owner:STATE GRID CORP OF CHINA +1

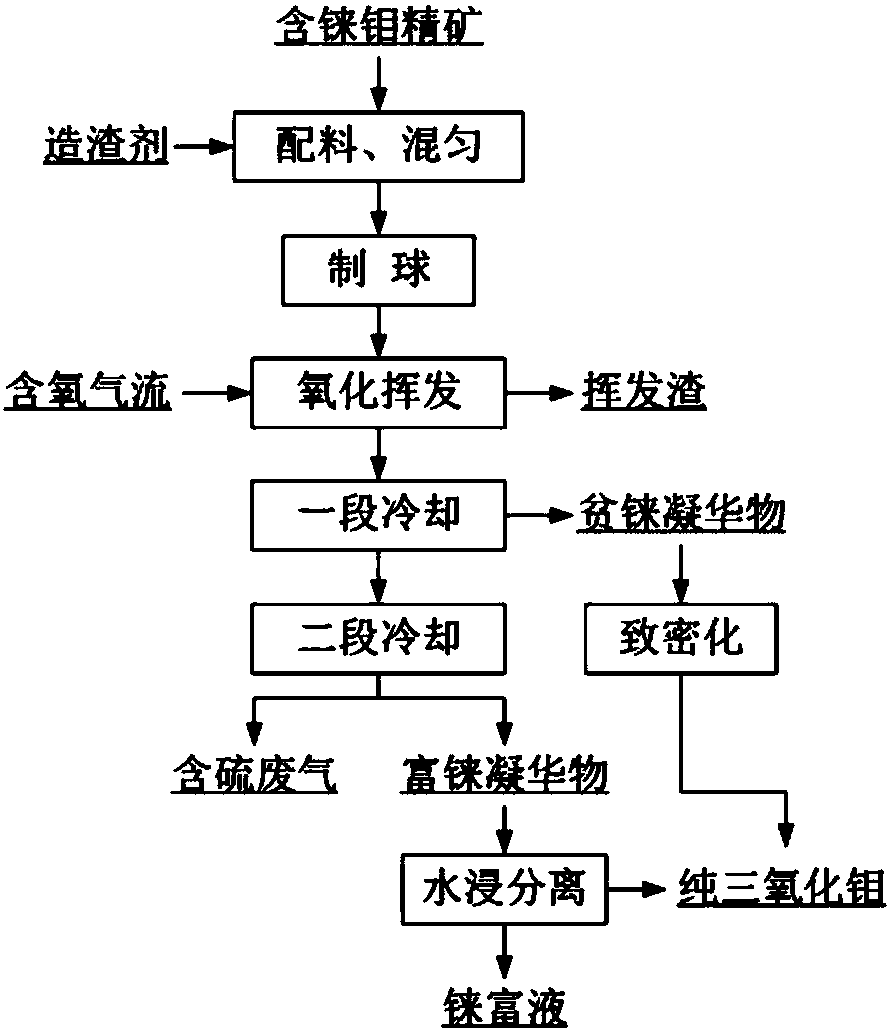

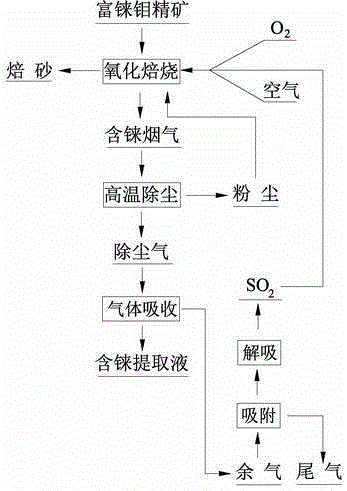

Method of concentrate volatilization containing molybdenum-rhenium, and water leaching and separation of molybdenum-rhenium

The invention discloses a method of concentrate volatilization containing molybdenum-rhenium, and water leaching and separation of the molybdenum-rhenium. The concentrate containing the molybdenum-rhenium is used as a raw material, a slagging agent is added and mixed to make a pellet, then the pellet is heated to 900-1150 DEG C, an oxygen-containing flow is supplied to produce a mixed vapor comprising a molybdenum oxide and a rhenium oxide, two-stage cooling separation is carried out to obtain a condensation product, water immersion treatment is carried out on the rhenium-rich condensation product, the rhenium is separated into the water immersion liquid, and the rest part is the pure molybdenum trioxide product. According to the method, molybdenum and rhenium are volatilized together through high-temperature oxidation roasting, and molybdenum and rhenium are separated through the water leaching, the method has the advantages of being efficient in production, simple in process, good inequipment adaptability, high in product additional value and the like, and the method is suitable for industrial application.

Owner:CENT SOUTH UNIV

Zirconium carbide copper-based contact material for low-voltage electric appliances and processing method thereof

InactiveCN106024432AImprove welding resistanceImprove wear resistanceContactsYttrium oxide sulfideLow voltage

The invention discloses a zirconium carbide copper-based contact material for low-voltage electric appliances. The zirconium carbide copper-based contact material is characterized in that the contact material is prepared from the following components in percentages by weight: 1% to 5% of zirconium carbide, 0.1% to 5% of alloy metals, 0.1% to 10% of rare earth oxides and the balance of copper, wherein the alloy metals comprise one or the combination of two or more than two of aluminum, lanthanum, cerium, yttrium, nickel, chromium, zirconium, niobium, vanadium and tungsten; and the rare earth oxides comprise one or the combination of two or more than two of rhenium oxide, lanthanum oxide, cerium oxide, yttrium oxide, yttrium oxide sulfide, samarium oxide and zirconium oxide. A low-voltage electric appliance contact prepared from the materials is high in welding resistance, wear resistance and oxidation resistance, and can be safely used for a long time. Moreover, the invention also provides a processing method of the zirconium carbide copper-based contact material for the low-voltage electric appliances.

Owner:仙居县南大合金科技有限公司

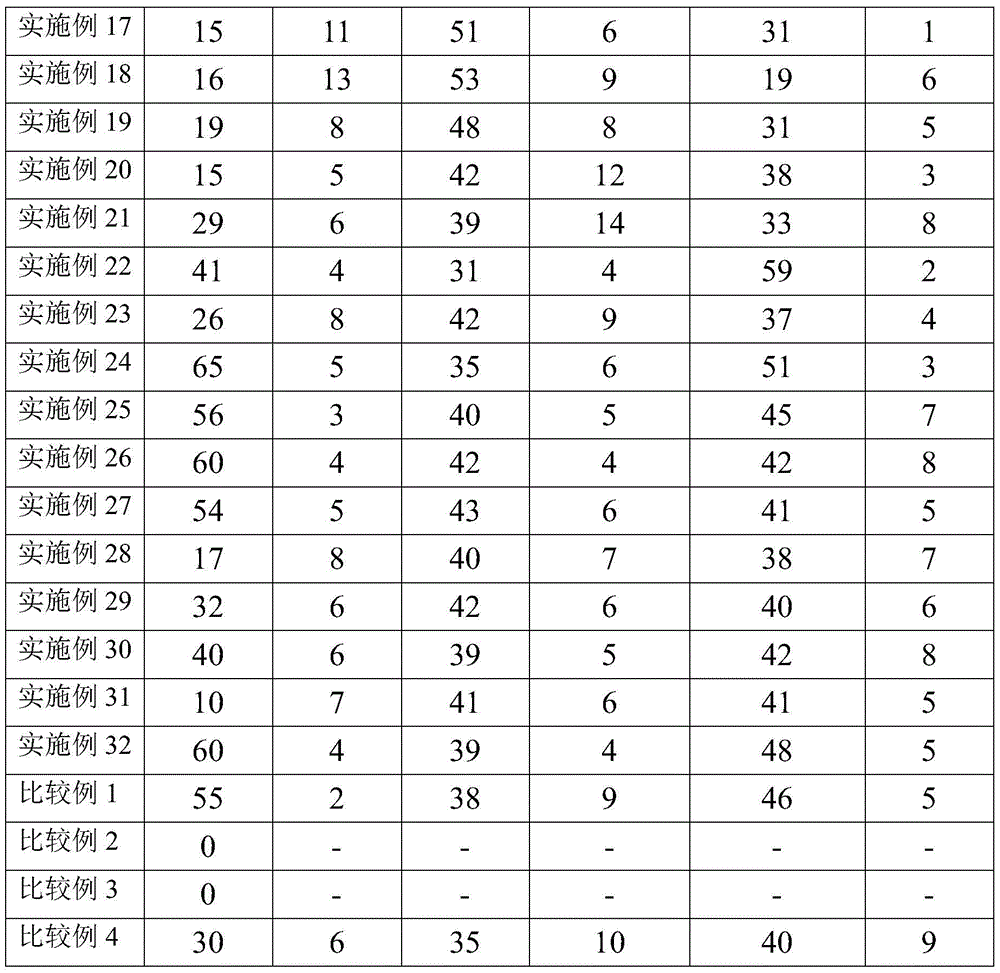

Nickel-rhenium alloy powder and conductor paste containing the same

InactiveUS20100021735A1No deterioration of electric propertyInhibition lossSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSurface oxidation

A nickel-rhenium alloy powder comprising nickel as a main component, 0.1 to 10% by weight of rhenium, and having an average particle size of 0.05 to 1.0 μm is provided. The nickel-rhenium alloy powder has a surface oxide film containing a nickel oxide and a rhenium oxide, and the amount of oxygen in the surface oxide film is 0.1 to 3.0% by weight relative to the total weight of the powder. The nickel-rhenium alloy powder is suitable, in particular, for forming internal electrode layers of a multilayer ceramic electronic component. The obtained powder is homogeneously mixed and dispersed in an organic vehicle, together with other additives as needed, to prepare a conductor paste. The surface oxide film allows bringing the sintering shrinkage behavior of electrode layers and ceramic layers closer to each other when the nickel-rhenium alloy powder is used, in particular, for forming internal electrodes of a multilayer ceramic electronic component. Moreover, there occurs no electrode spheroidizing caused by oversintering. and thus thinner, dense internal electrodes having excellent continuity can be formed.

Owner:SHOEI CHEM IND CO LTD

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

Method for manufacturing rhenium-containing alloy powder, rhenium-containing alloy powder, and conductor paste

InactiveUS7503959B2Easy to getObtained and stablyTransportation and packagingMetal-working apparatusElectrical conductorGas phase

Metal particles that can be alloyed with rhenium are dispersed as a main component in a gas phase, a rhenium oxide vapor is made to be present around these particles, the rhenium oxide is reduced, and the rhenium precipitated on the surface of the main component metal particles as a result of this reduction is diffused under a high temperature into the main component metal particles, which gives a rhenium-containing alloy powder including the main component metal and rhenium. The powder thus obtained preferably contains 0.01 to 50 wt % rhenium, has an average particle size of 0.01 to 10 μm, and is made into a conductor paste by being uniformly mixed and dispersed in an organic vehicle along with other additives as needed.

Owner:SHOEI CHEM IND CO LTD

Soft magnetic ferrite high in magnetic permeability and saturation induction density

The invention discloses soft magnetic ferrite high in magnetic permeability and saturation induction density. The soft magnetic ferrite comprise main ingredients and subsidiary ingredients, wherein the main ingredients comprise, by Moore, 52.5-54% of ferric oxide, 36-37.5% of manganese oxide and 10-12.5% of zinc oxide; the total mass of the main ingredients serves as the basis, and the subsidiary ingredients comprise 100-300 ppm of indium oxide, 300-500 ppm of yttrium oxide, 400-800 ppm of magnesium oxide, 150-300 ppm of niobium oxide, 400-600 ppm of cobaltous oxide, 100-200 ppm of bismuth oxide, 200-500 ppm of vanadium oxide, 100-500 ppm of titanium dioxide, 20-80 ppm of rhenium oxide, 100-200 ppm of copper oxide, 50-150 ppm of zirconium oxide, 20-70 ppm of stannic oxide, 50-200 ppm of tungsten carbide and 500-800 ppm of silicon dioxide.

Owner:ZHONGDE ELECTRONICS

Organic electroluminescence device and preparation method thereof

InactiveCN104347811AImprove luminous efficiencyLower electron barrierSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionSilicon oxide

The invention relates to an organic electroluminescence device and a preparation method thereof. The organic electroluminescence device comprises an anode conductive substrate, a hole injection room, a hole transmission layer, a luminous layer, an electronic transmission layer, an electron injection layer and a cathode which are sequentially stacked, wherein the cathode comprises sodium salt layer, a doping layer and a metallic sulfide layer which are sequentially stacked on the electron injection layer; the material of the sodium salt layer is sodium carbonate, sodium fluoride, sodium chloride or sodium bromide; The material of the doping layer comprises rhenium oxide, a passivation material and metal; the rhenium oxide is rhenium heptoxide, rhenium dioxide, rhenium trioxide or rhenium sesquioxide; the passivation material is silicon oxide, aluminum oxide, nickelous oxide or copper oxide; the metal is magnesium, strontium calcium or ytterbium; the material of the metallic sulfide room is zinc sulfide, cadmium sulfide, magnesium sulfide or copper sulphide. The organic electroluminescence device is high in luminous efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

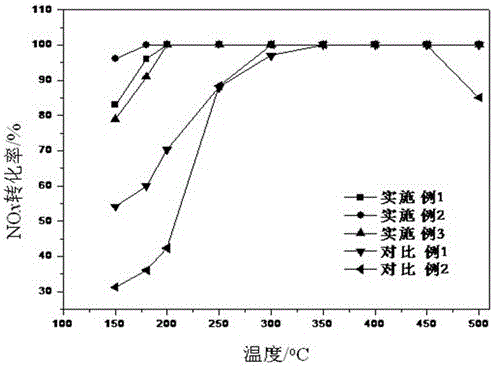

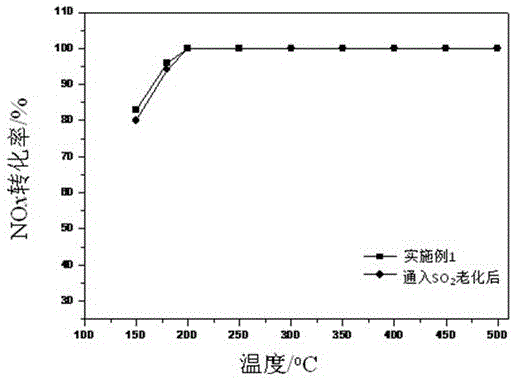

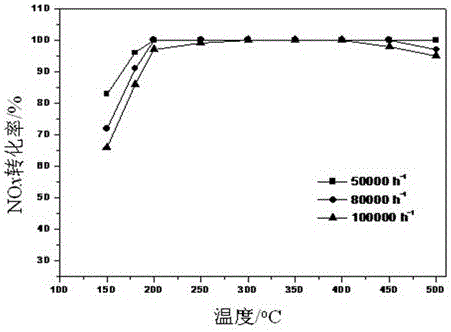

Rare earth-based SCR catalyst for diesel oil vehicle and preparation method of rare earth-based SCR catalyst

ActiveCN106799234AImprove low temperature performanceWide operating temperature windowGas treatmentInternal combustion piston enginesCeriumHafnium

The invention relates to a rare earth-based SCR catalyst for a diesel oil vehicle and a preparation method of the rare earth-based SCR catalyst. According to the catalyst, cordierite honeycomb ceramic is taken as a carrier and is coated with coating layer slurry, and the coating layer slurry mainly contains rare earth-based powder, a binder, an additive and water; and the rare earth-based powder contains the following four active components: the first active component is one or more of cerium-niobium composite oxide, cerium-tin composite oxide, cerium-yttrium composite oxide and cerium-lanthanum composite oxide, the second active component is one or more of manganese-samarium composite oxide, zirconium-hafnium composite oxide, zinc-erbium composite oxide, iron-copper composite oxide, copper-hafnium composite oxide and zirconium-aluminum composite oxide, the third active component is rhenium oxide, and the fourth active component is titanium-tungsten powder. The rare earth-based SCR catalyst has the advantages that the low temperature performance is good, an operation temperature window is wide, and the conversion rate of NOx reaches above 70% at 150 DEG C, is more than 90% at 180 DEG C and is 100% at 200-500 DEG C.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for manufacturing rhenium-containing alloy powder, rhenium-containing alloy powder, and conductor paste

Metal particles that can be alloyed with rhenium are dispersed as a main component in a gas phase, a rhenium oxide vapor is made to be present around these particles, the rhenium oxide is reduced, and the rhenium precipitated on the surface of the main component metal particles as a result of this reduction is diffused under a high temperature into the main component metal particles, which gives a rhenium-containing alloy powder including the main component metal and rhenium. The powder thus obtained preferably contains 0.01 to 50 wt % rhenium, has an average particle size of 0.01 to 10 mum, and is made into a conductor paste by being uniformly mixed and dispersed in an organic vehicle along with other additives as needed.

Owner:SHOEI CHEM IND CO LTD

Method for manufacturing wheel mold

The invention discloses a method for manufacturing a wheel mold; a wheel mold material has the chemical composition by the mass percentage: 3.5-3.8% of carbon, 1.9-2.0% of silicon, 1-1.3% of nickel, less than 1% of copper, 0.5-0.7% of manganese, 0.35-0.5% of molybdenum, 0.35-0.5% of chromium, less than 0.08% of titanium, less than 0.08% of zirconium, less than 0.02% of sulfur, less than 0.02% of phosphorus, less than 0.02% of rhenium, less than 0.02% of scandium, and the balance iron. Micro titanium oxide and nano zirconium carbide are used as reinforcement phases, and micro-nano compositing is realized, so the strength, toughness and hardness of the material can be improved at the same time, and the mechanical properties and the use performance of the material are significantly improved; with composite addition of rhenium oxide and scandium oxide, the material has rather high aging resistance and defect resistant ability, the grain phase transformation critical size is relatively large, and requirements on the fineness of raw materials are relatively low, so that the material has better comprehensive performance. The wheel mold has ideal oxidation resistance, refined austenite grains, heat radiation and fatigue resistance through reasonable selection of the chemical elements and amount.

Owner:SHANDONG HEZE ZHENHUA PRECISION MOLD

Lead-free glass powder for solar batteries and pure silver paste

InactiveCN107032623AGood chemical stabilityImprove thermal stabilityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationDispersityHeat stability

The invention discloses lead-free glass powder for solar batteries. The lead-free glass powder is prepared from bismuth oxide, antimony oxide, zinc oxide, boracic acid, silicon oxide, rhenium oxide and strontium oxide. The invention further discloses pure silver paste containing the lead-free glass powder. Products of the lead-free glass powder are uniform in granule and good in dispersity, and the softening point is between 420 DEG C and 480 DEG C; components of zinc oxide, silicon oxide and boron oxide can improve the chemical stability and heat stability of glass, and the boron oxide component can further reduce the thermal expansion coefficient of the glass powder; bismuth oxide serves as a redox active additive, the stability of the antimony oxide component in the glass powder preparation is promoted, and the precipitation of metal bismuth is avoided; besides, the preparation method of the glass powder is simple in process, glass prepared from the glass powder is small in granule size and uniform in performance, better sintering of conductive silver powder can be further promoted, so that an electrode is more compact, the good ohmic contact is formed, the series resistance is reduced, and therefore the efficiency of battery pieces is improved, and the service life of the battery pieces is prolonged.

Owner:JIANGSU RUIDE NEW ENERGY TECH

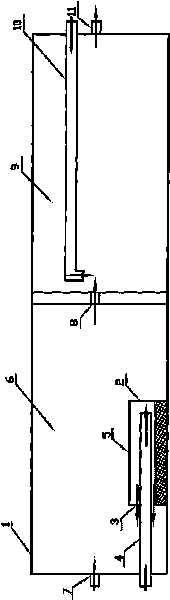

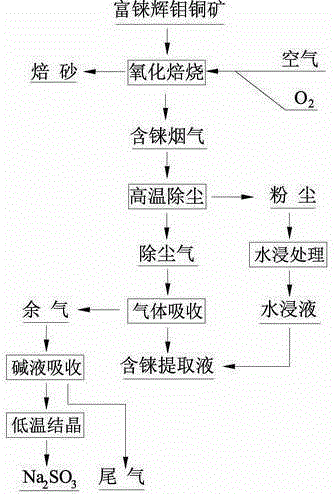

Rhenium extracting method

ActiveCN105219980AImprove efficiencyIncrease the volatilization rate of rheniumExhaust gasRhenium oxide

The invention relates to the technical field of rhenium recycling, in particular to a rhenium extracting method. The proposed rhenium extracting method uses a rhenium-contained ore as a raw material, adopts steps of oxidizing roasting of the rhenium-contained ore, high-temperature dust removal of roasting smoke and rhenium oxide gas absorption to obtain rhenium-contained extracting solution, and realizes safe exhaust of tail gas through a residual gas treatment step. Through improvement of a boiling furnace body and reasonable control of oxidizing roasting, dust removal and gas absorption process conditions, the oxidizing roasting efficiency of the rhenium-contained ore and the rhenium volatilization rate are improved, the roasting dust quantity is reduced, and the production efficiency is improved; a dust removing mode and a gas absorption system are improved to reduce the loss of the rhenium-contained smoke in the dust removal and gas absorption process; the whole recovery rate of extracting rhenium by the oxidizing roasting mode is improved; and the problems of low rhenium oxidizing roasting efficiency and low rhenium volatilization rate in the boiling furnace and high rhenium loss in the dust removal and gas absorption process in the rhenium extraction by a conventional oxidizing roasting mode are solved.

Owner:洛阳双罗铼材料科技有限公司

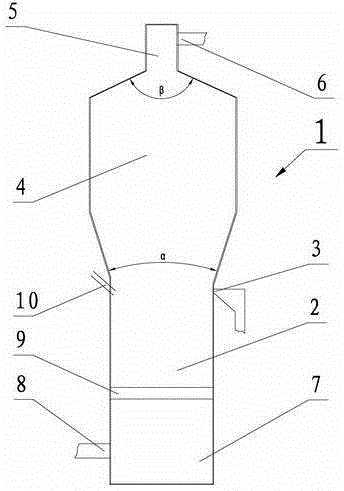

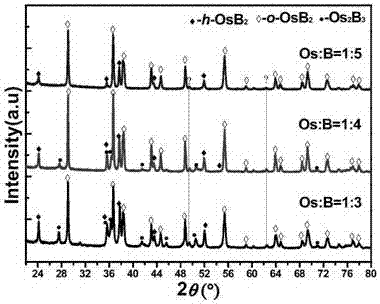

Novel ternary osmium-rhenium diboride (Os<1-x>Re<2>B<2>) hard material and preparation method thereof

The invention discloses a transition metal osmium-rhenium diboride (Os<1-x>Re<2>B<2>) material with high hardness and wear resistance and a preparation method thereof and belongs to the field of inorganic non-metallic hard materials. According to the technical scheme, the method comprises the following steps: by adopting a mechanical and chemical method and high-energy ball mill equipment, and taking high-purity osmium (Os) powder, rhenium (Re) powder and boron (B) powder as raw materials, synthesizing osmium-rhenium diboride powder at a room temperature; and carrying out dense sintering on the synthesized osmium-rhenium diboride powder under an argon protection atmosphere by using a high-temperature sintering technology to obtain a high-density and high-hardness bulk material. The transition metal osmium-rhenium diboride (Os<1-x>Re<2>B<2>) material has the characteristics that the osmium-rhenium diboride powder is synthesized at the room temperature and the osmium-rhenium diboride (Os<1-x>Re<2>B<2>) bulk material of a hexagonal structure with high-temperature stability is prepared. The prepared osmium-rhenium diboride material can be applied to industrial uses, such as cutting tools and grinding.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com