Application of catalyst with multiple active components for preparing 1,3-propanediol by hydrogenolysis of glycerin

An active component, glycerol hydrogenolysis technology, applied in heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of catalyst deactivation, impurity tolerance Problems such as power difference to achieve the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

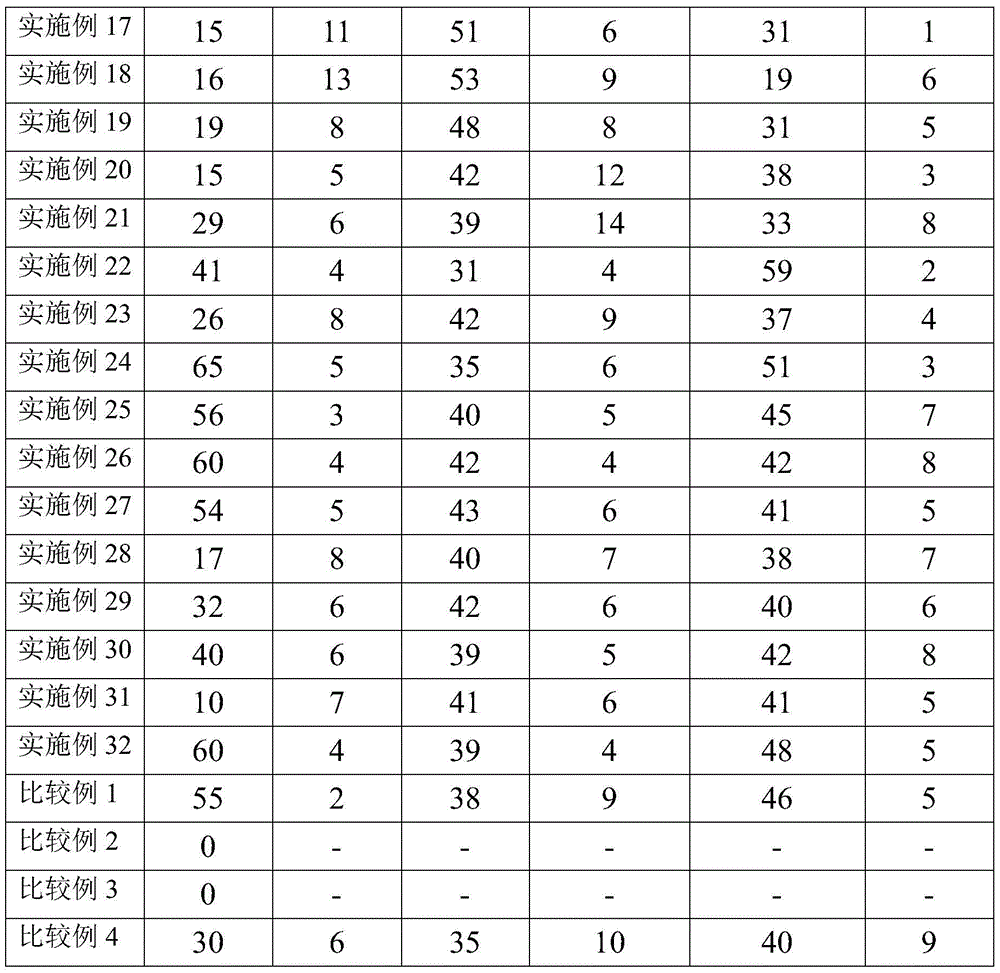

Examples

Embodiment 1

[0025] The catalyst used is WO 3 -Al 2 o 3 The carrier (the mass fraction of tungsten oxide is 20%) loads active components platinum and lanthanum oxide. Catalyst composition is Pt%=5wt%, La%=0.5wt%, the rest is WO 3 -Al 2 o 3 carrier. WO 3 -Al 2 o 3 The carrier is prepared by wet impregnation method, and the specific preparation steps include: a) Impregnate the precursor solution of tungsten oxide (ammonium metatungstate or ammonium paratungstate aqueous solution) on the alumina by wet method, the impregnation time is 18h, and dry in an oven at 120°C For more than 10 hours, calcined at 900°C for 10 hours in a muffle furnace to obtain a composite carrier of tungsten oxide-alumina, which is denoted as WO 3 -Al 2 o 3 . b) Immerse an equal volume of chloroplatinic acid solution into WO 3 -Al 2 o 3 On the carrier, impregnate overnight, dry in an oven at 120°C for 12h, and calcinate in a muffle furnace at 500°C for 10 hours to obtain Pt / WO 3 -Al 2 o 3 , the mass c...

Embodiment 2

[0027] Reverse the loading order of Pt and La, other conditions are the same as in Example 1, denoted as Pt / La 2 o 3 / WO 3 -Al 2 o 3 .

Embodiment 3

[0029] Simultaneous loading of Pt and La on the carrier WO 3 -Al 2 o 3 On, other conditions are identical with embodiment 1, denoted as Pt-La 2 o 3 / WO 3 -Al 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com