Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Guaranteed machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of spinning stoste with cellulose base fibre

InactiveCN1818160AImprove protectionGood for healthArtificial filaments from viscoseCELLULOSE FLOURCellulose fiber

The invention opened a preparing method of the cellulose fibre spinning stock solution. The solvent is the intermixture of the [BMIM]Cl and the [BMIM]BF4. The cellulose dissolves in the solvent after breaking up to get the uniform and transparent liquid. So it can save the energy, decrease the pollution and improve the quality of the stock solution.

Owner:DONGHUA UNIV

Glass mould material of alloy cast iron and preparation method thereof

A glass mould material of the alloy cast iron and a preparation method thereof belong to the technical field of the glass mould material. The mould material comprises the following chemical components by weight percent: 3.49-3.65% of carbon, 1.9-2.1% of silicon, 1-1.3% of nickel, 0.5-0.7% of manganese, less than 0.16% of sulfur, less than 0.3% of phosphorus, less than 0.08% of titanium, 0.36-0.5%of molybdenum, 0.36-0.6% of chromium, less than 0.05% of vanadium, less than 1% of copper, less than 0.02% of rhenium and the balance iron. By using the technical scheme, as the selection of chemicalelements and the element contents are reasonable, the alloy cast can has ideal oxidation resistance, heat dissipation performance and fatigue resistance and fine austenite grains and the generation of D-type graphite can be improved so as to increase the heat dissipation performance of the product; by using the preparation method provided by the invention, D-type graphite can be generated, the heat dissipation performance of the product can be ensured, and metal elements can be uniformly distributed in the matrix through solid solution, thus preventing metal elements from returning to the outside of the matrix and forming alloy carbide, and ensuring the machinability of the mould.

Owner:CHANGSHU JIANHUA MOLD TECH

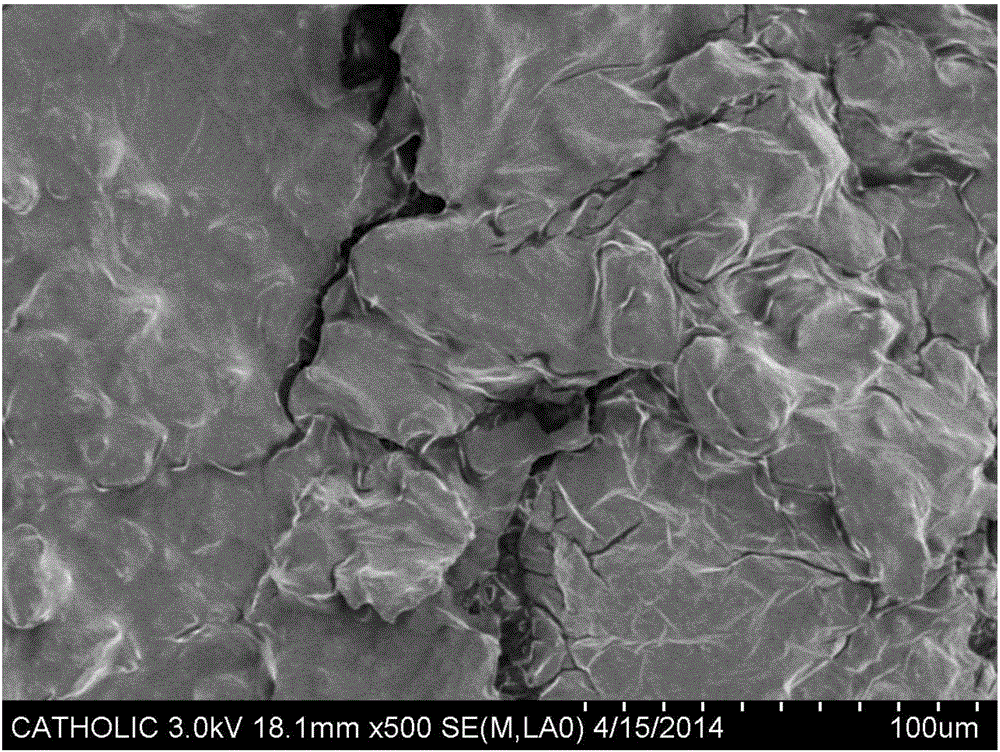

Rare earth magnesium alloy micro arc oxidation green ceramic film preparation method

InactiveCN101187049AGood corrosion resistanceGuaranteed machinabilityAnodisationMicro arc oxidationHardness

The invention belongs to the technical field of magnesium alloy surface treatment, and relates to a process for preparing green ceramic membrane by micro-arc oxidation of a rare earth magnesium alloy. Using oil removaling, cleaning, washing, micro-arc oxidation coloring, hole sealing and drying for the surface of the rare earth magnesium alloy, thereby obtaining a series of ceramic membranes whose color are uniform and are from light green, medium green to dark green and are oxidized by micro-arc of SJDM-1 rare earth magnesium alloy. The ceramic membrane which is prerared through the process has an excellent wear resistance and hardness, at the same time the machinability of the ceramic membrane is further guaranteed, and the ceramic membrane has the characteristics of uniform colors, color diversity and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Production process for stainless steel damping composite board

InactiveCN101905558AGuaranteed surface qualityImprove the shock and noise reduction effectSynthetic resin layered productsLaminationMetallurgyComposite plate

The invention discloses a production process for a stainless steel damping composite board, which comprises the following steps of: firstly, preheating a hot galvanizing cold-rolled steel sheet; secondly, rolling and adhering a macromolecular damping adhesive film on the preheated hot galvanizing cold-rolled steel sheet by using a film coating roller; thirdly, rolling and combining the stainless steel sheet on the macromolecular damping adhesive film by a sheet coating roller, heating the whole sheet body by a pressing roller at the same time and further performing rolling and adhesion to realize stable solidification; and finally, cooling the whole sheet body by using forced air cooling and rolling the cooled sheet to obtain the stainless steel damping composite board, wherein the stainless steel sheet is a surface plate, the hot galvanizing cold-rolled steel sheet is a base plate and the macromolecular damping adhesive film is a middle layer; the preheating temperature of the hot galvanizing cold-rolled steel sheet is 80 to 120 DEG C; the temperature of the film coating roller is 120 to 150 DEG C; the temperature of the sheet coating roller and the pressing roller is 170 to 220 DEG C; and the composite board is cooled to 20 to 30 DEG C by the forced air cooling. The process has the advantages that: the production is simple; the cost is low; and the product uses few stainless steel, has a high strength, and can damp and reduce noises and be produced continuously with low cost and high production process.

Owner:XUCHANG AUSTAR AUTOMATION EQUIP

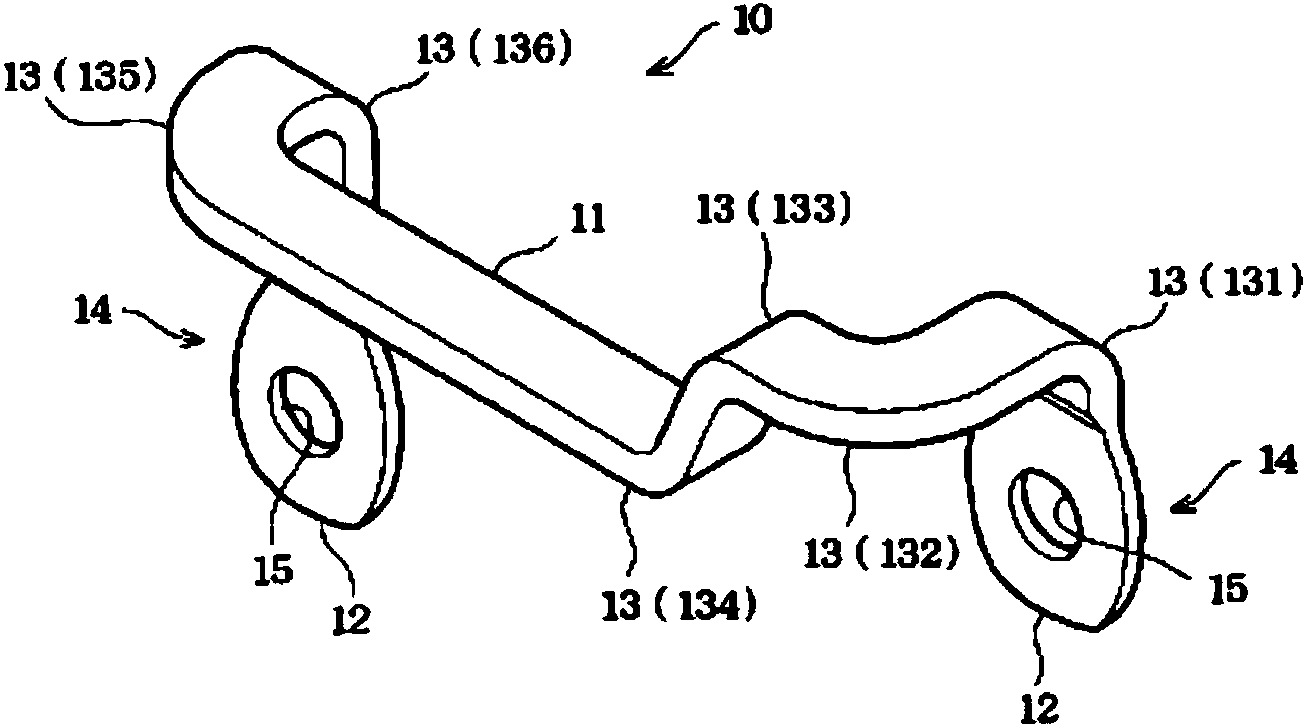

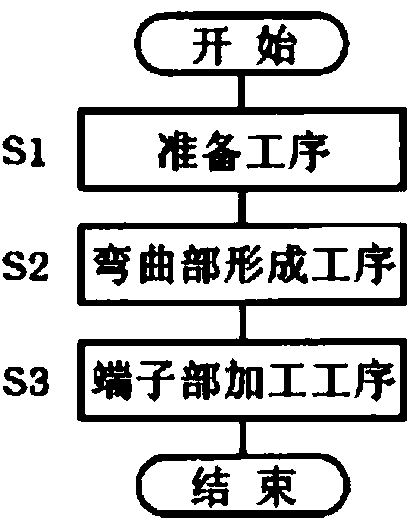

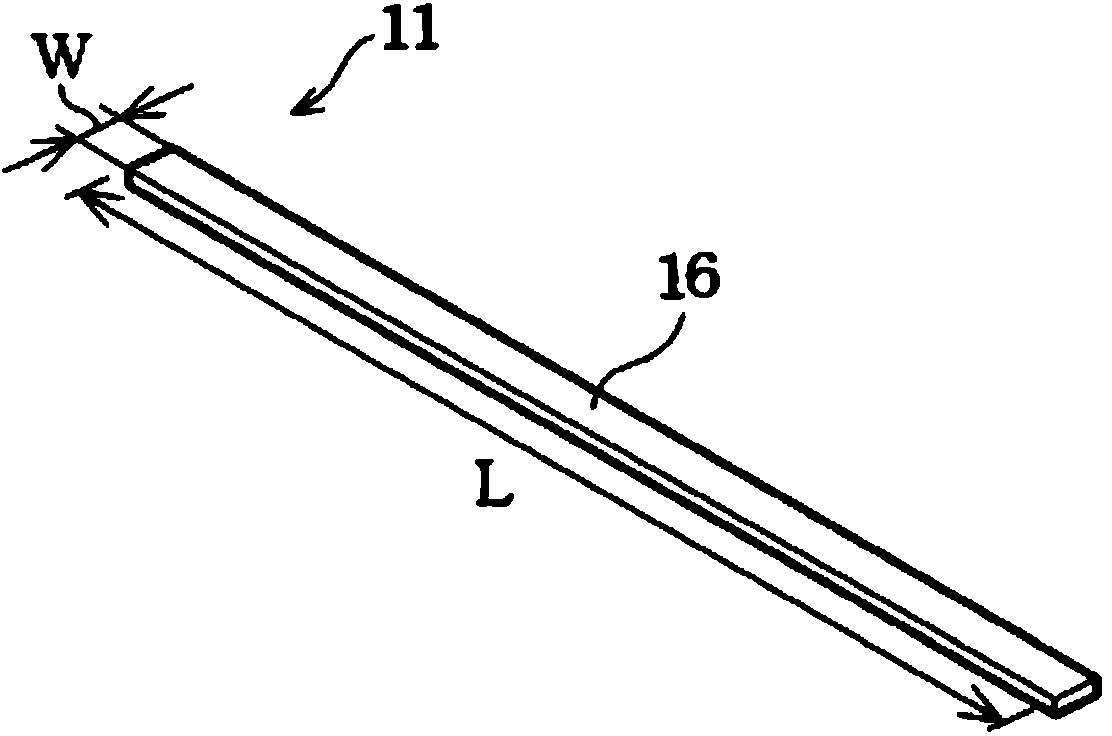

Bus bar and method for manufacturing bus bar

InactiveCN103392281ASuppresses the phenomenon of boundary heatingReduced conductive cross-sectional areaCoupling device connectionsBus-bar/wiring layoutsHardnessMechanical engineering

A bus bar includes a body having at least one bent portion and a plate-shaped or bar-like terminal located on at least one end of the body and formed of a material identical with a material of the body integrally with the body in a seamless manner. The terminal has a higher hardness than the bent portion.

Owner:TOGO SEISAKUSYO CORP

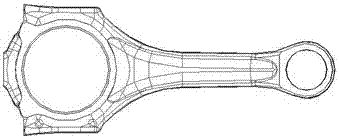

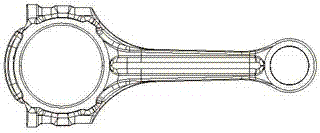

High-strength non-quenched and tempered steel material suitable for connection rod

The invention relates to a high-strength non-quenched and tempered steel material suitable for a connection rod. The high-strength non-quenched and tempered steel material is characterized by comprising chemical elements of C, Si, Mn, P, S, Cr, V, N, Mo, Ni and the balance Fe and unavoidable impurities, wherein the element mass percents are as follows: C is 0.42%-0.50%, Si is 0.40%-0.70%, Mn is 0.90%-1.20%, P is 0.020% or less, S is 0.045%-0.075%, Cr is 0.20% or less, V is 0.10%-0.20%, N is 0.010%-0.020%, Ni is 0.2% or less, Mo is 0.10% or less, and the element mass percent is about 96.80%-98.10%; after the steel material is forged at the temperature of 1,250 DEG C into a test sample with the diameter phi being 30 mm and air-cooled, the mechanical performance data requirements of the non-quenched and tempered steel material are as follows: RP0.2 is larger than or equal to 700 MPa, Rm is larger than or equal to 1,000 MPa, A is larger than or equal to 10 %, and Z is larger than or equal to 25 %. After the steel material is forged, the strength level exceeds 1,000 MPa, the steel material has good toughness, swelling performance and machining performance, and the swelling connection rod manufactured and produced through the material has a relatively-high fatigue safety factor and accordingly has good application prospects.

Owner:CHINA FIRST AUTOMOBILE

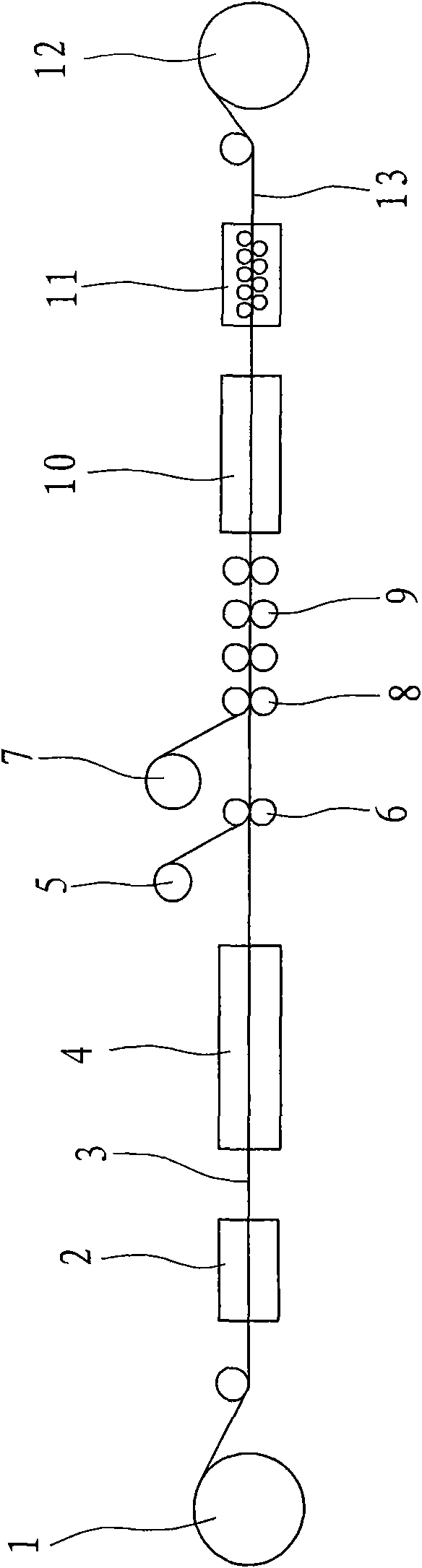

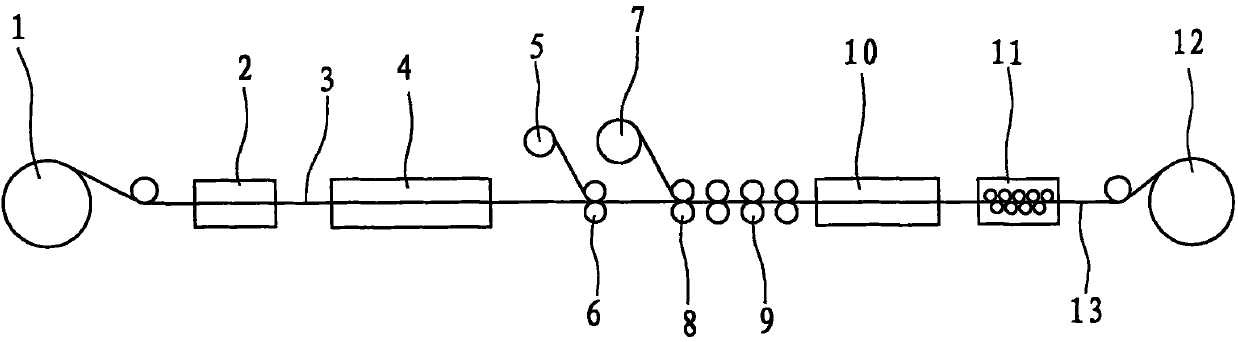

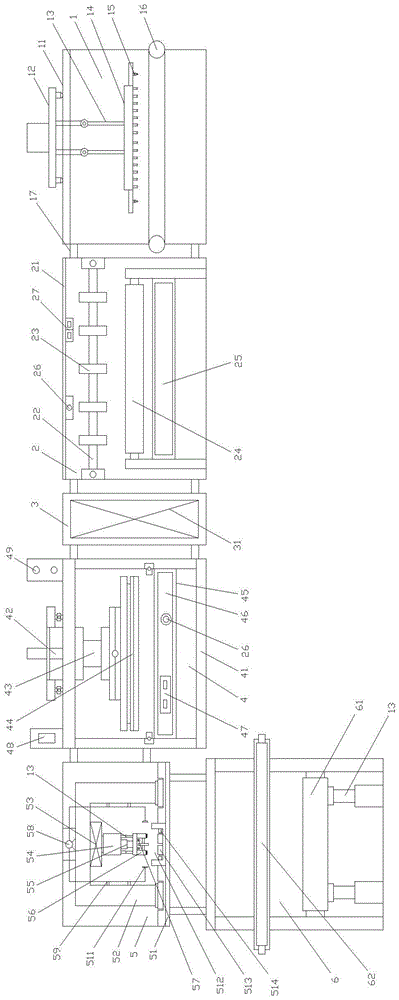

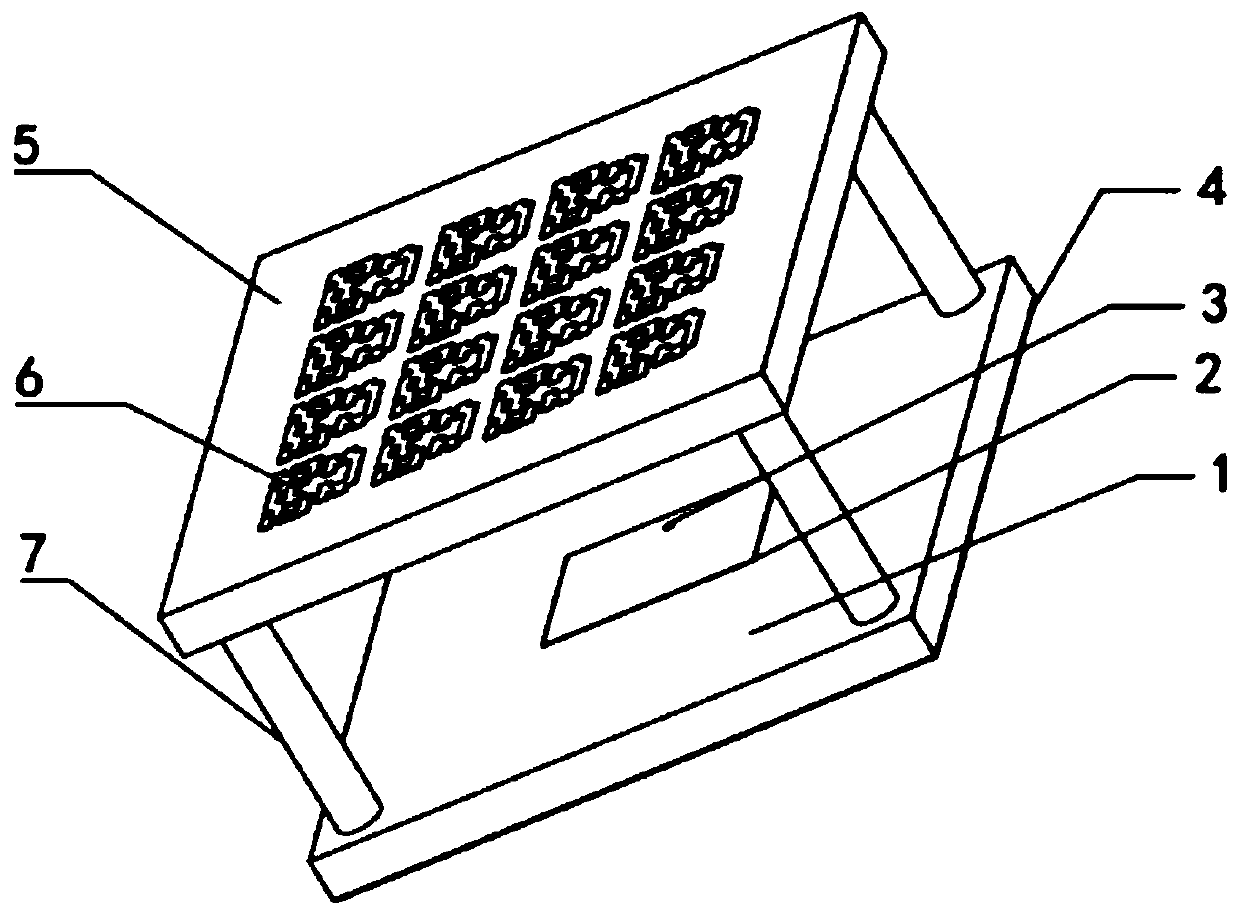

Ceiling wet-process production line

ActiveCN105538876AQuality improvementImprove performanceLamination ancillary operationsLaminationProduction lineProcess equipment

The invention discloses a ceiling wet-process production line which comprises an automatic feeding mechanism, wherein the automatic feeding mechanism is connected with a glue rolling mechanism through an automatic conveyor belt; the glue rolling mechanism is connected with a composite mechanism through the automatic conveyor belt; a dust collector is also arranged in the composite mechanism; the composite mechanism is connected with a hot pressing mechanism through the automatic conveyor belt; the hot pressing mechanism is connected with a cutting mechanism through the automatic conveyor belt; the cutting mechanism is connected with a reserve tank through the automatic conveyor belt. The ceiling wet-process production line disclosed by the invention is simpler in processes, high in degree of automation and time and labor saving, and greatly improves the working efficiency; meanwhile, the cooperation among all the production line processes is compact, the environment configured on process equipment is further improved, and the production and processing quality of products is improved to the maximum extent.

Owner:ANHUI ANJIAN AUTO SKYLIGHT TECH CO LTD LUAN CITY

A kind of high-strength and high-conductivity cucrzrmg series copper alloy wire material and preparation method thereof

ActiveCN108060323BHigh strengthIncrease the number ofConductive materialMetal/alloy conductorsPower flowIngot casting

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

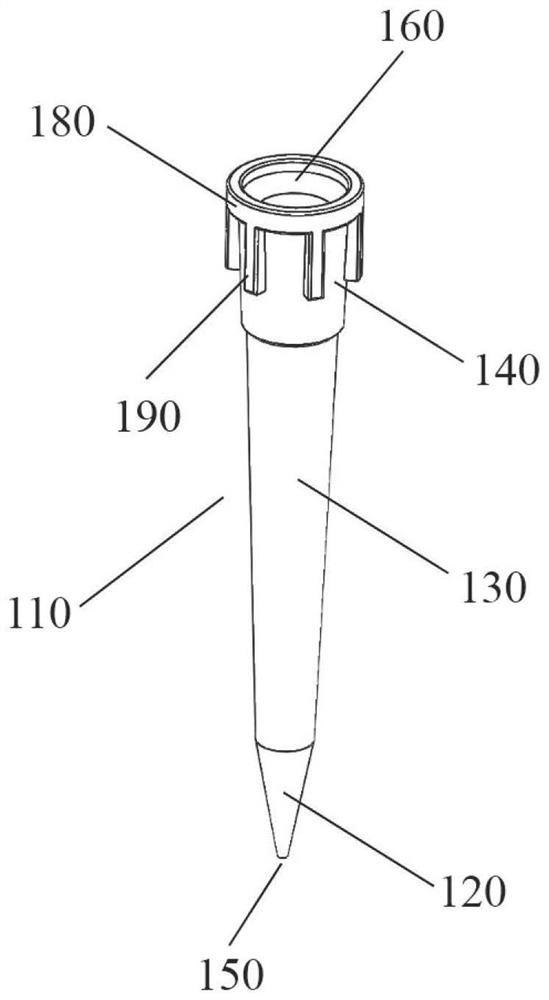

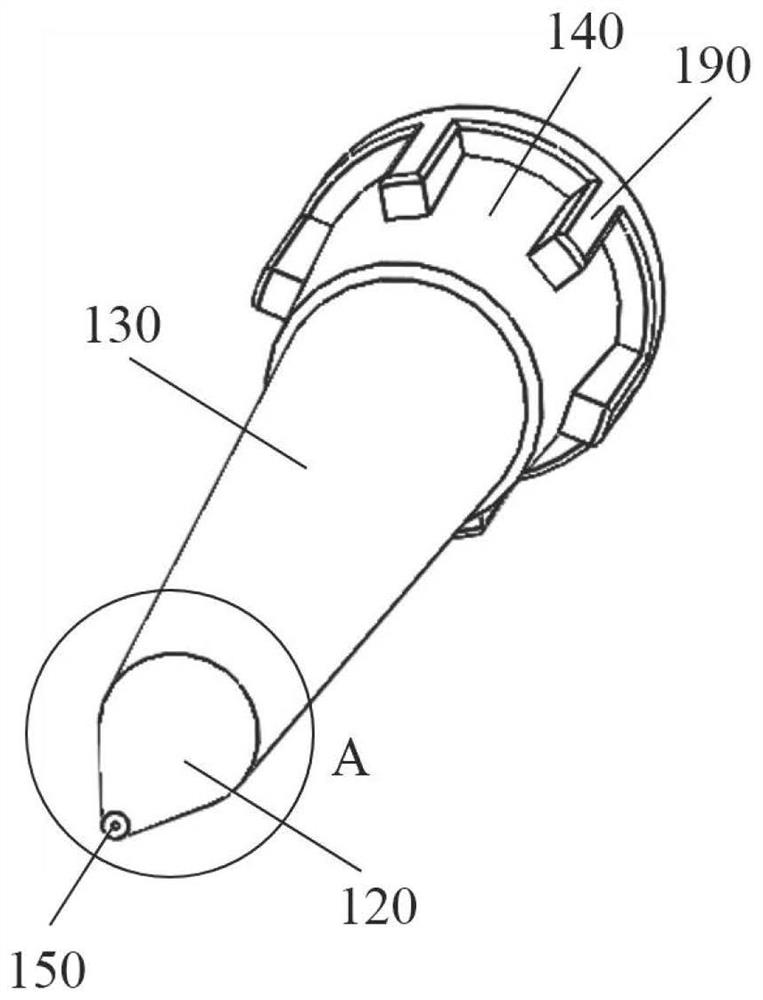

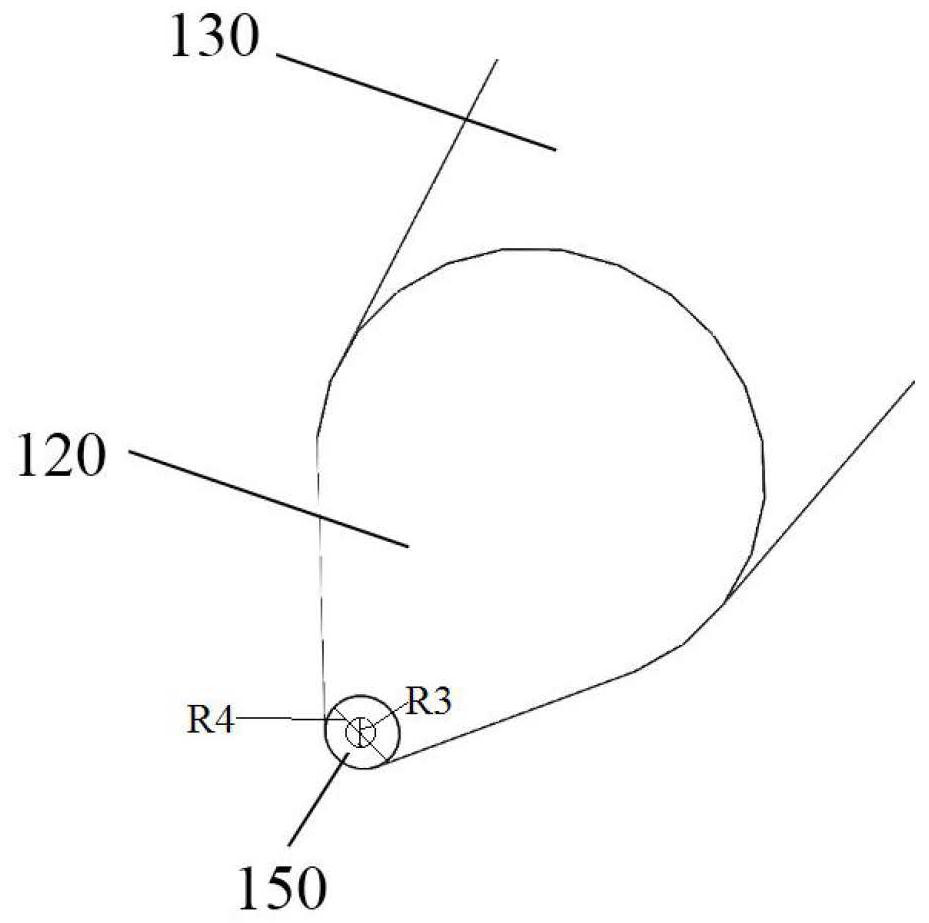

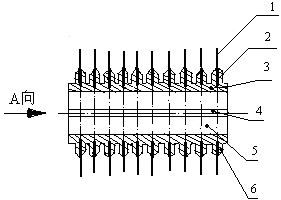

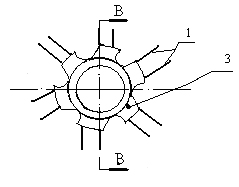

Sample adding needle for preparing micro-droplets and preparation method of micro-droplets

ActiveCN112439470AReliable generationGuaranteed rigidityBurettes/pipettesFluid controllersReciprocating motionInjection moulding

The invention discloses a sample adding needle for preparing micro-droplets. The sample adding needle comprises a liquid storage part and a liquid discharge part which are integrally formed in an injection molding mode and are communicated with each other, the liquid storage part is a circular truncated cone with the radial size gradually decreased in the direction towards the liquid discharge part, and the liquid discharge part is a circular truncated cone with the radial size gradually decreased in the direction away from the liquid storage part. The taper of the liquid storage part is C1, the taper of the liquid discharge part is C2, and C1 is smaller than or equal to C2. The wall thickness of the liquid storage part is D1, the wall thickness of the liquid discharge part is D2, and D1 is greater than D2. According to the sample adding needle for preparing micro-droplets, when the micro-droplets are prepared through the sample adding needle, the sample adding needle does periodic reciprocating motion with changed speed in oily liquid, so that the sample solution is subjected to periodic shearing force of the oily liquid at a liquid discharge opening, further, the sample solutionin the sample adding needle enters the oily liquid, and the generation of micro-droplets with uniform size and controllable volume is realized.

Owner:MACCURA MEDICAL INSTR CO LTD

Preparation method of polyvinyl alcohol based water-soluble nonwoven fabric

ActiveCN106012293AGood compatibilityImprove mechanical propertiesConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer scienceWater soluble

The invention relates to a preparation method of a polyvinyl alcohol based water-soluble nonwoven fabric, belonging to the technical field of textiles and chemical fibers. The polyvinyl alcohol based water-soluble nonwoven fabric is prepared by utilizing water and polyoxyethylene to synergistically plastify polyvinyl alcohol and carrying out melt spinning, online drafting and direct web forming. The preparation method is simple and pollution-free, is low in cost and has a wide range of application and high application value. The nonwoven fabric has a broad market application prospect in the fields of costume embroidery, disposable medical health care products, and the like.

Owner:大连天马可溶制品有限公司

Integrated crushing tooth of grading crusher and manufacturing method thereof

InactiveCN102000620AExtended service lifeHigh initial hardnessFoundry moulding apparatusGrain treatmentsAlloyHardness

The invention discloses the integrated crushing tooth of a grading crusher and a manufacturing method thereof, which is characterized in that the integrated crushing tooth takes alloy high manganese steel as a main raw material and adopts an integrated lost foam casting process; the center of the integrated crushing tooth (3) is provided with a tooth roller hole (5) with a key slot (4); the outer wall of the integrated crushing tooth (3) is provided with an outer circular tooth (6); and a hard alloy bar (2) is cast on the outer circular tooth (6). The integrated crushing tooth manufactured by the invention has the advantages of good strength and toughness, and higher hardness and abrasion resistance, can carry out the cutting machining and is suitable for manufacturing the crushing tooth of a tooth sleeve type grading crusher.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Biologically-synthesized resin capable of controlling interfacial compatibility and application thereof

InactiveCN105949811AControl Interface CompatibilityImprove interface compatibilityUltimate tensile strengthSynthetic resin

The invention discloses biologically-synthesized resin capable of controlling interfacial compatibility and application thereof and relates to biologically-synthesized resin and application thereof. The biologically-synthesized resin is prepared by, by weight percentage, 30-50% of resin, 0.5-5% of compatilizer, 0.5-3% of lubricating agent, 0.5-3% of oxidant and the balance of filler. The biologically-synthesized resin can be used for preparing degradable materials. By the preparation method of the biologically-synthesized resin, the surface appearance of biomass micro-powder can be controlled, good interfacial compatibility between the biomass micro-powder and a nonpolar resin base can be achieved, good moistening and interfacial combination between the biomass micro-powder and the nonpolar resin base can be achieved, interface combination strength is increased, internal defects of biologically-synthesized resin products are reduced, interface thickness is controlled, occlusion of the resin base on the surface and inside biomass is reduced, and the mechanical strength, stability, machinability, flexibility and ductility of the biologically-synthesized resin products are guaranteed.

Owner:王育钦

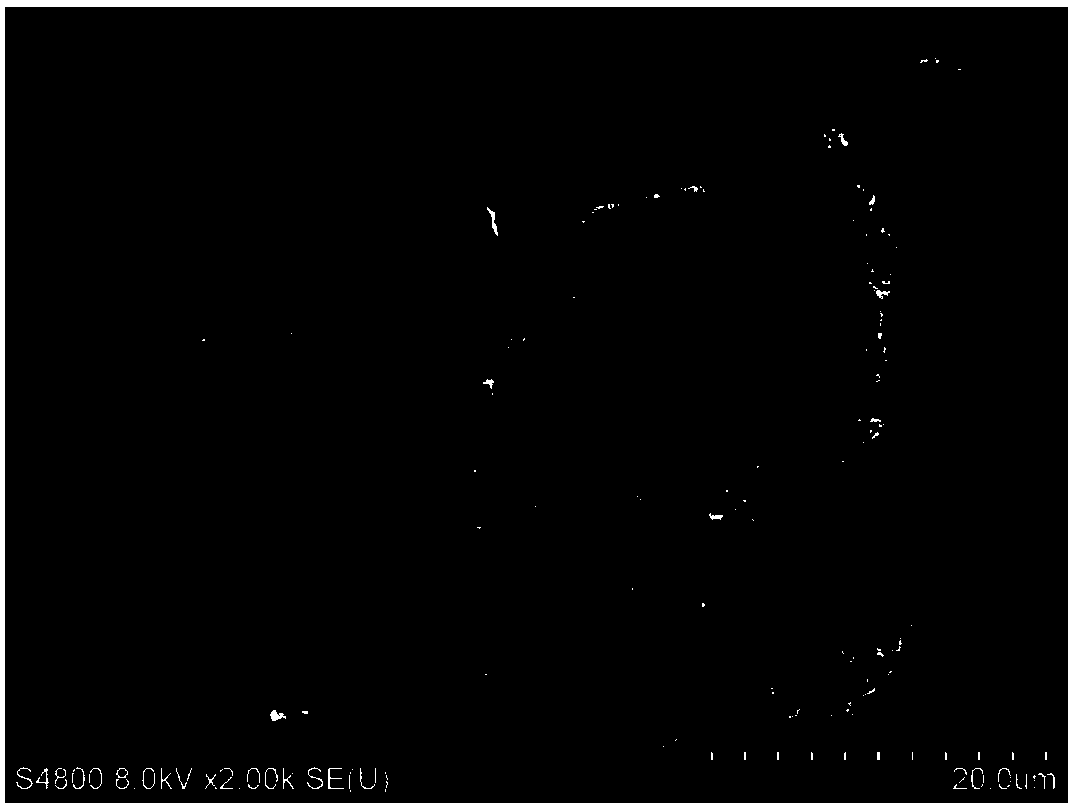

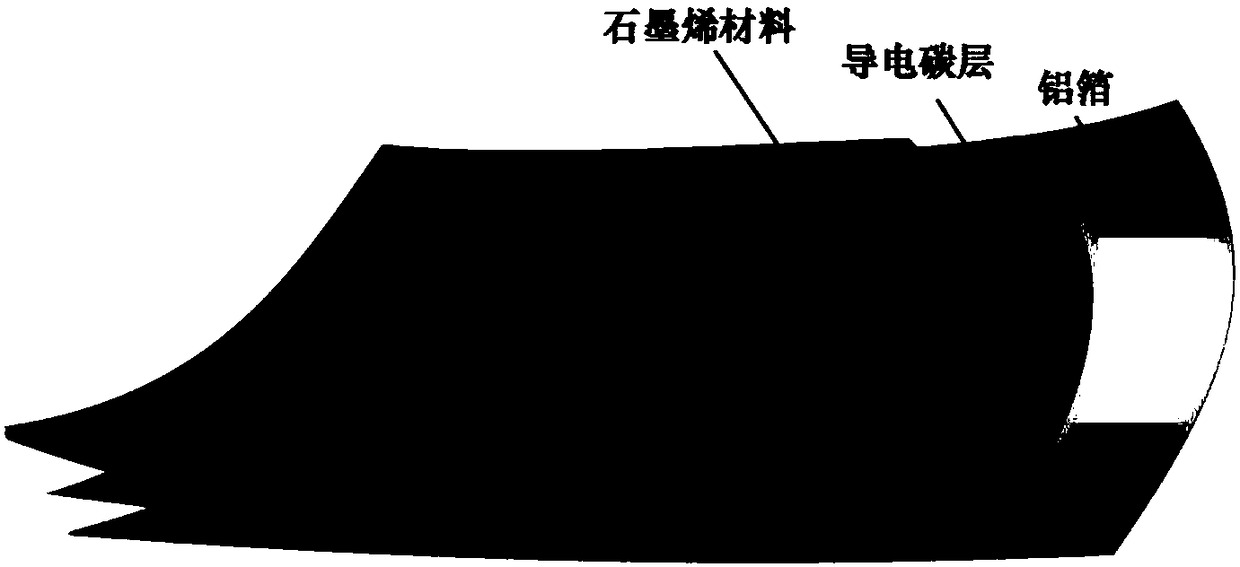

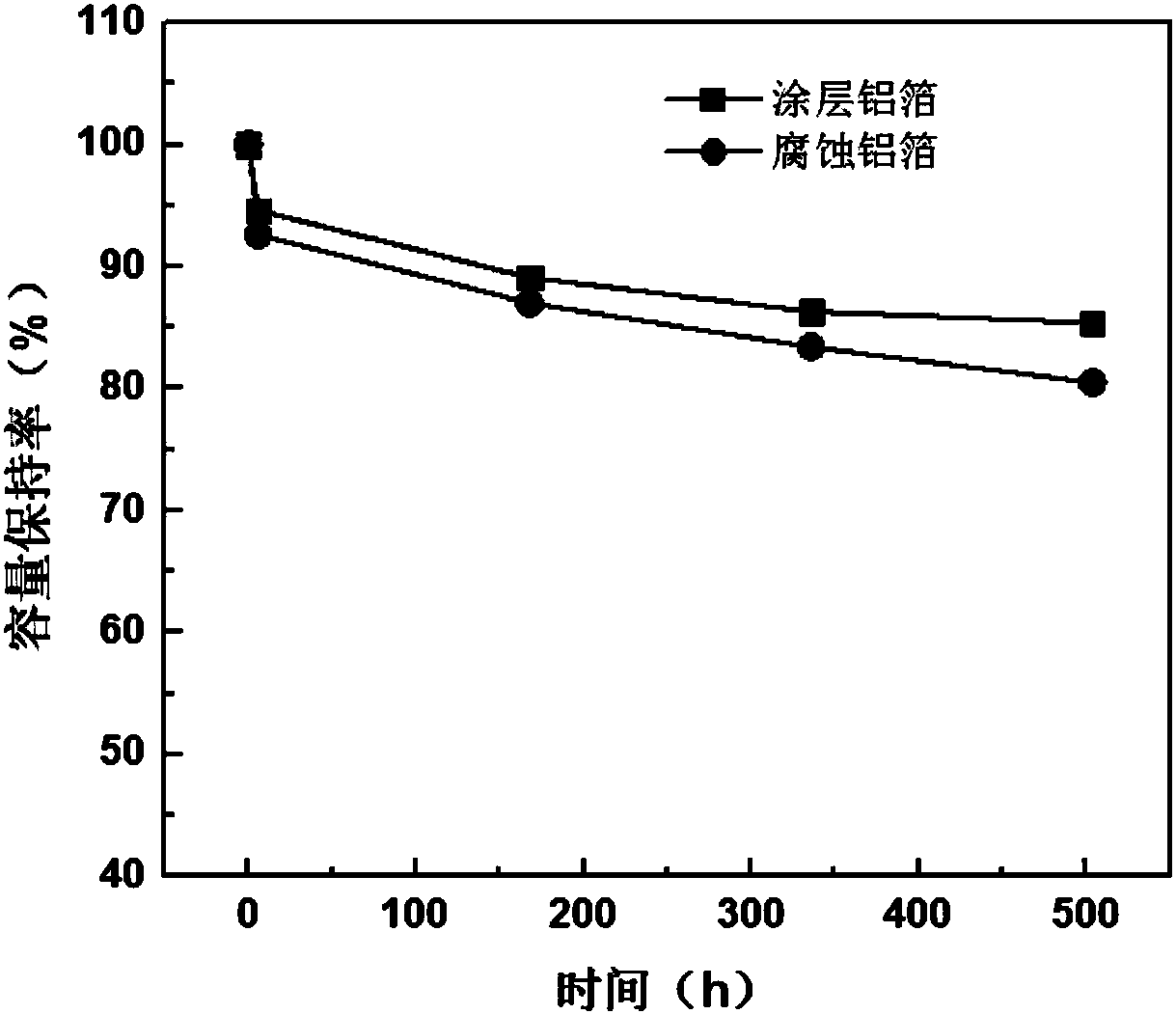

Low internal resistance and high power graphene super capacitor electrode sheet and manufacturing method

InactiveCN108470635ALarge specific surface areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureInternal resistanceNew energy

The invention relates to a graphene super capacitor electrode sheet, especially relates to a low internal resistance and high power graphene super capacitor electrode sheet and a manufacturing methodand belongs to the new energy storage device technology field. The graphene electrode sheet comprises a current collector and a graphene electrode slurry. The graphene electrode slurry comprises, by weight, 75-93% of graphene, 2-10% of conductive agent and 5-15% of binder. The current collector is a coating aluminum foil. The thickness of the graphene electrode sheet is 100-200 microns, and a surface density is 0.5-0.7g / cm<3>. The super capacitor graphene electrode sheet has characteristics of a low internal resistance, high power and the like.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

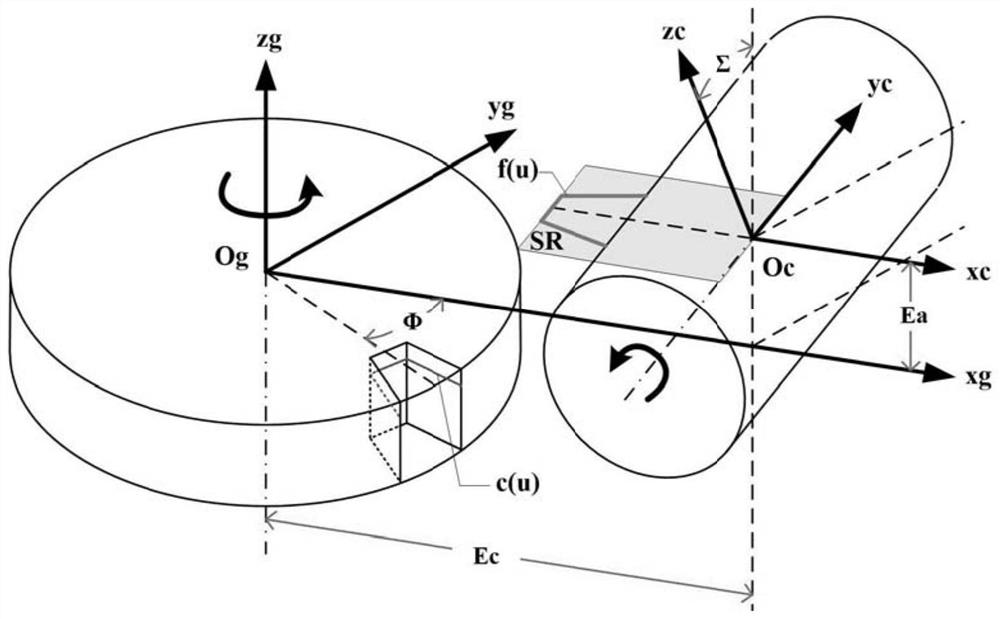

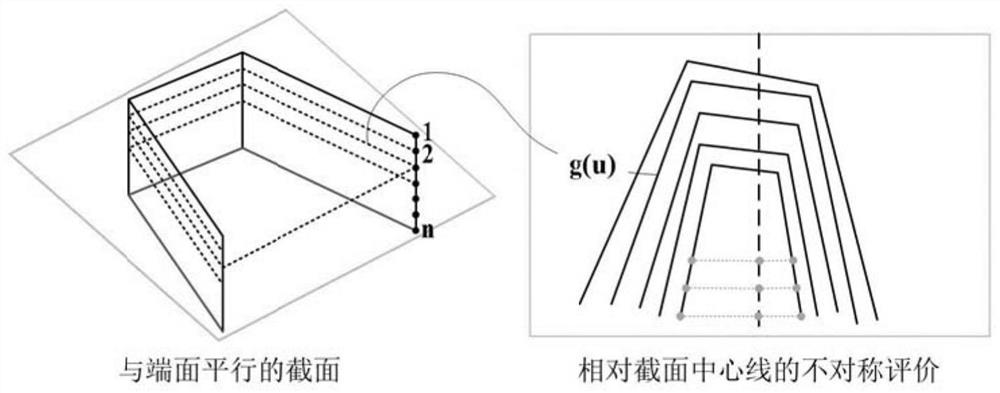

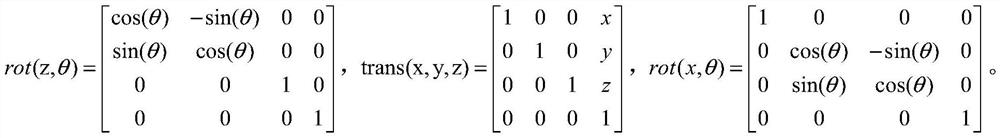

Blade type design method of gear workpiece end face continuous equidistant chamfering cutting tool

ActiveCN114101807ACalculation stableUniversalGear teeth manufacturing toolsGear teethGear wheelGear tooth

The invention discloses a blade design method of a gear workpiece end face continuous equidistant chamfering cutting tool, which comprises the following specific steps of: giving an included angle variable initial value phi between a gear tooth groove end face profile center line and a gear workpiece static coordinate system X axis; the angle theta c of the cutting tool rotating relative to the initial position when the cutting tool rotates around the rotation axis of the cutting tool is obtained through the installation parameters of the cutting tool and the gear workpiece, the variable initial value phi of the included angle and the transmission ratio i, and a transformation matrix Mcg and an inverse matrix Mgc from a cutting tool moving coordinate system to a gear workpiece moving coordinate system are obtained; a cylindrical gear tooth groove chamfering edge space curve c (u) is obtained, points on the gear tooth groove chamfering space curve c (u) are transformed to a cutting tool rake face SR through the transformation matrix Mcg, a cutting edge curve f (u) is obtained, and the cutting tool is machined through the obtained cutting edge curve f (u); the cutting tool with the designed cutting edge can ensure that chamfering structure cutting can be accurately carried out on the end face profile of the cylindrical gear under specified installation parameters and motion parameters.

Owner:XI AN JIAOTONG UNIV

Glass mould material of alloy cast iron and preparation method thereof

A glass mould material of the alloy cast iron and a preparation method thereof belong to the technical field of the glass mould material. The mould material comprises the following chemical components by weight percent: 3.49-3.65% of carbon, 1.9-2.1% of silicon, 1-1.3% of nickel, 0.5-0.7% of manganese, less than 0.16% of sulfur, less than 0.3% of phosphorus, less than 0.08% of titanium, 0.36-0.5%of molybdenum, 0.36-0.6% of chromium, less than 0.05% of vanadium, less than 1% of copper, less than 0.02% of rhenium and the balance iron. By using the technical scheme, as the selection of chemicalelements and the element contents are reasonable, the alloy cast can has ideal oxidation resistance, heat dissipation performance and fatigue resistance and fine austenite grains and the generation of D-type graphite can be improved so as to increase the heat dissipation performance of the product; by using the preparation method provided by the invention, D-type graphite can be generated, the heat dissipation performance of the product can be ensured, and metal elements can be uniformly distributed in the matrix through solid solution, thus preventing metal elements from returning to the outside of the matrix and forming alloy carbide, and ensuring the machinability of the mould.

Owner:CHANGSHU JIANHUA MOLD TECH

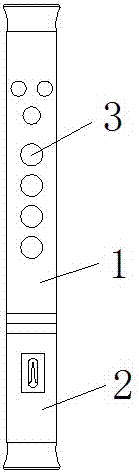

Dismountable musical instrument Bawu with high intonation adjustability and manufacturing process thereof

InactiveCN106935230AReduce the difficulty of playingGuaranteed machinabilityWind musical instrumentsEngineeringAcoustics

The invention discloses a dismountable musical instrument Bawu with high intonation adjustability. The musical instrument Bawu comprises a Bawu pipe body and a sound mouth that is in sliding connection with the Bawu pipe body; and the connection part between the sound mouth and the Bawu pipe body is sealed. Sound holes are formed in the Bawu pipe body; and decoration heads are installed at the two ends of the Bawu pipe body. According to the dismountable musical instrument Bawu and the manufacturing process thereof, compared with the prior art, the musical instrument Bawu has the following beneficial effects: the musical instrument Bawu is made of a blood wood material, so that workability of the density and dimension of the Bawu can be guaranteed and the playing sensitivity can be improved and the playing difficulty of the player is reduced; once any intonation deviation occurs, the pipe body length is adjusted by moving the tone adjusting port, and after fine toning, the accurate tone tuning effect is realized; and dismounting becomes convenient and the process becomes simple.

Owner:JIAMUSI UNIVERSITY

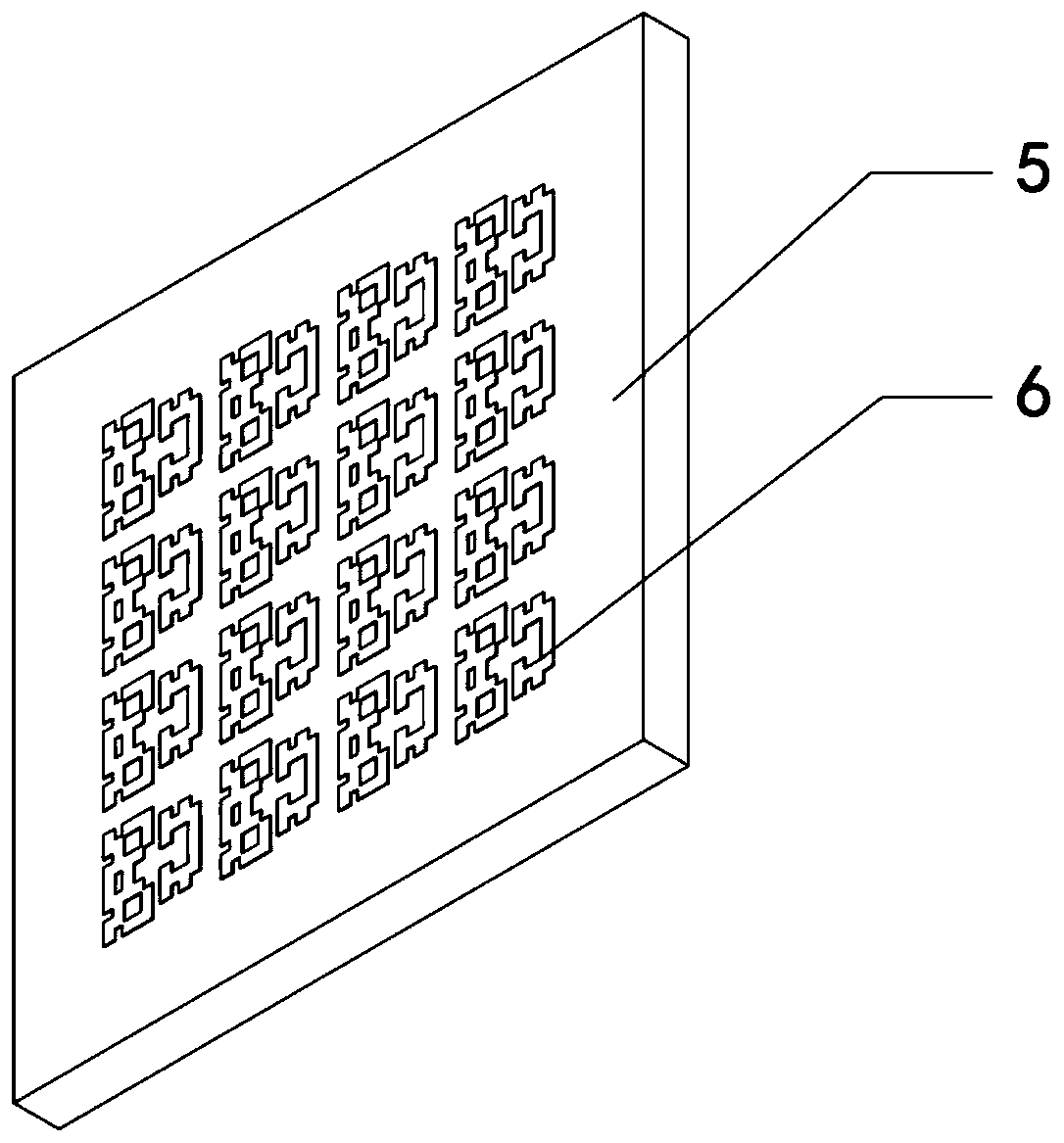

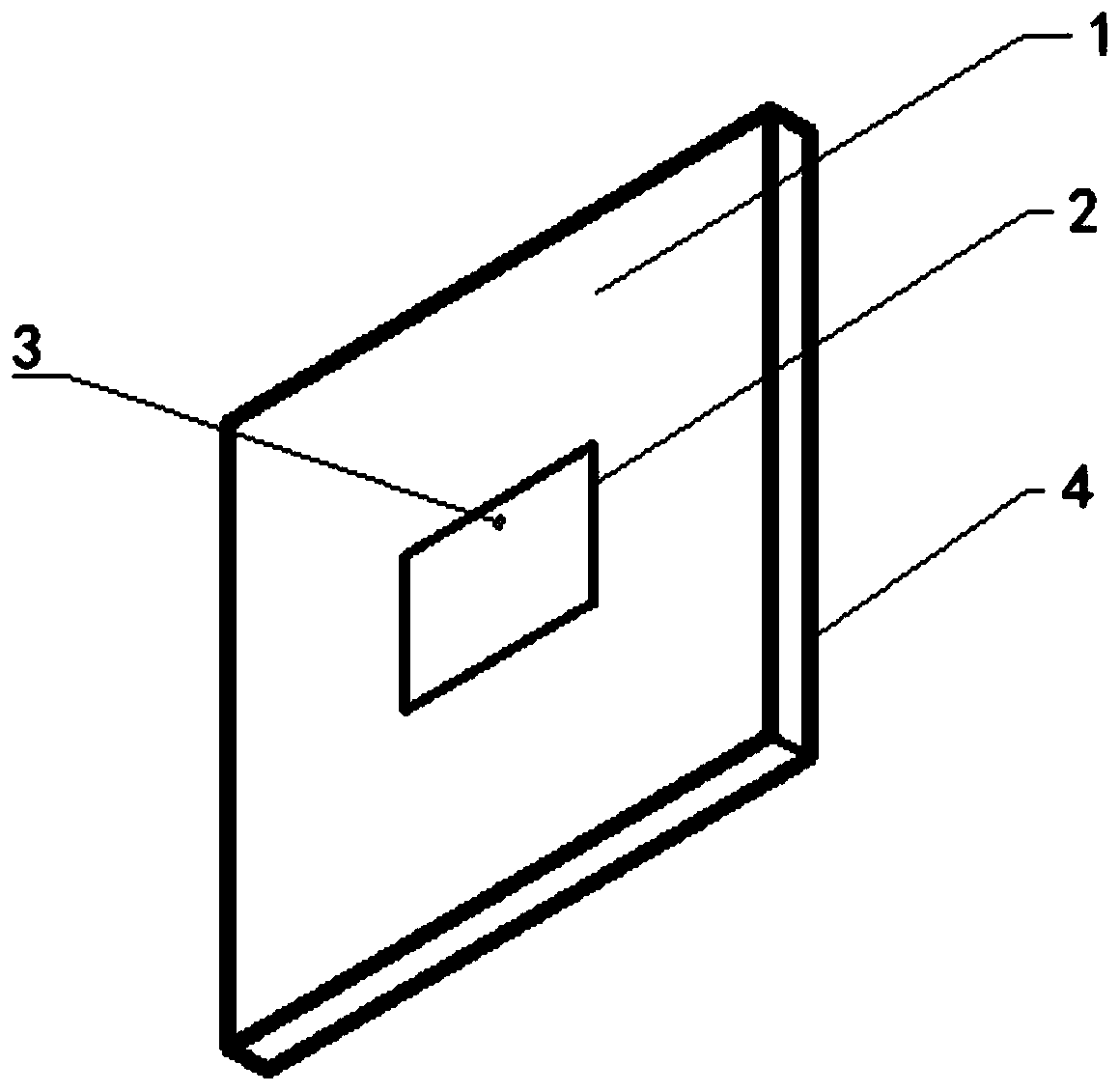

K-waveband metamaterial coating microstrip antenna based on topological optimization and design method

ActiveCN110247177ALow costSimple structureRadiating elements structural formsAntenna earthingsAntenna designCoaxial line

The invention discloses a K-waveband metamaterial coating microstrip antenna based on topological optimization and a design method. The microstrip antenna comprises an antenna substrate. The lower surface of the antenna substrate is provided with a metal grounding plate. A microstrip patch is arranged in the middle of the upper surface; a coaxial line feed probe is arranged on the microstrip patch; an antenna coating substrate is arranged above the antenna substrate in parallel. The antenna substrate and the antenna coating substrate are connected through a pillar. Wherein a plurality of metamaterial elements are etched on the antenna coating substrate, the metamaterial elements are of an array arrangement structure, each metamaterial element is dispersed into a square grid structure, each grid corresponds to one design element xi, and a set X of all the design elements xi forms a topological structure of the metamaterial elements. According to the invention, the problem of difficult matching of the metamaterial element and the microstrip antenna in the antenna design process is solved, and the antenna has the advantages of simple structure, convenient preparation and high gain.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

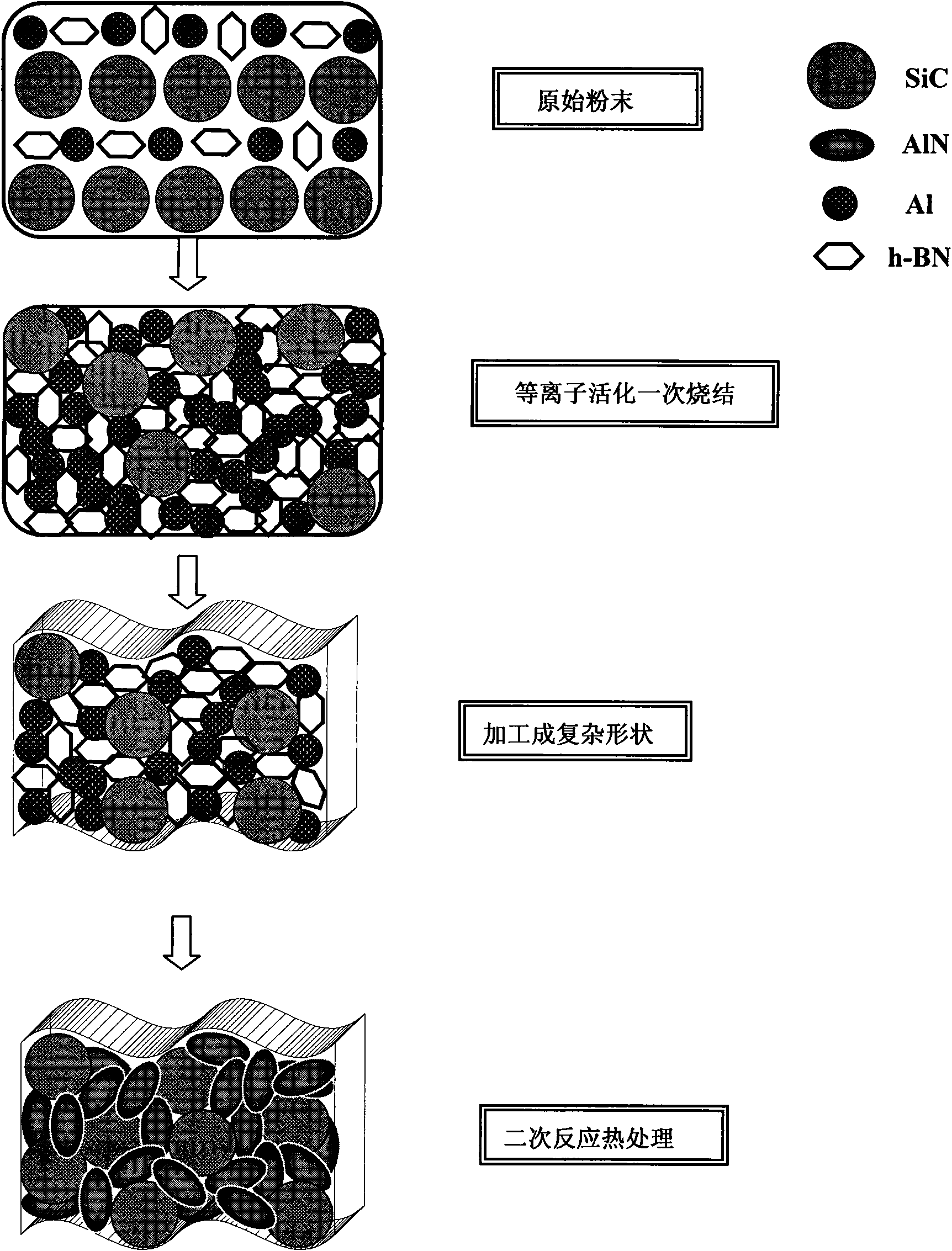

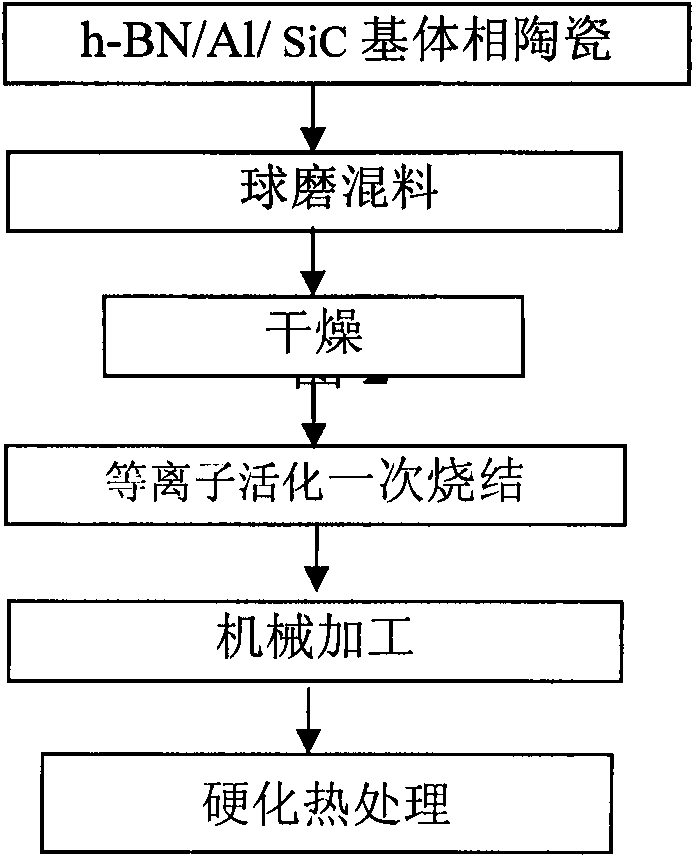

Method for preparing processable BN complex phase ceramic capable of improving later-stage hardness

The invention discloses a method for preparing a processable BN complex phase ceramic capable of improving the later-stage hardness, which comprises the following steps: adding active metals of aluminum or titanium and the like into the BN complex phase ceramic, and obtaining a compact sintered body through one-step sintering, wherein the hardness of the material is lower at that time, and the material can be processed into products with different shapes conveniently by adopting a common mechanical cutting method; and performing secondary heat treatment on the products so that the BN and the aluminum (titanium) generate a new hard ceramic phase in situ so as to greatly improve the hardness of the final products. The method has simple and easy technological processes and short sintering time. Besides, the method well solves the conflict between the processability and the hardness of the ceramic, and not only ensures the processability of the ceramic, but also keeps good characteristic of hardness of the ceramic.

Owner:XI AN JIAOTONG UNIV

Production of spinning stoste with cellulose base fibre

InactiveCN100334270CImprove protectionGood for healthArtificial filaments from viscoseCELLULOSE FLOURCellulose fiber

The invention opened a preparing method of the cellulose fibre spinning stock solution. The solvent is the intermixture of the [BMIM]Cl and the [BMIM]BF4. The cellulose dissolves in the solvent after breaking up to get the uniform and transparent liquid. So it can save the energy, decrease the pollution and improve the quality of the stock solution.

Owner:DONGHUA UNIV

A kind of preparation method of water-soluble nonwoven fabric based on polyvinyl alcohol

ActiveCN106012293BGood compatibilityImprove mechanical propertiesConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolyvinyl alcohol

The invention relates to a preparation method of a polyvinyl alcohol based water-soluble nonwoven fabric, belonging to the technical field of textiles and chemical fibers. The polyvinyl alcohol based water-soluble nonwoven fabric is prepared by utilizing water and polyoxyethylene to synergistically plastify polyvinyl alcohol and carrying out melt spinning, online drafting and direct web forming. The preparation method is simple and pollution-free, is low in cost and has a wide range of application and high application value. The nonwoven fabric has a broad market application prospect in the fields of costume embroidery, disposable medical health care products, and the like.

Owner:大连天马可溶制品有限公司

Ultra-thin flexible circuit board blind hole machining method

InactiveCN103796434AGuaranteed machinabilityEasy to processPrinted circuit manufactureManufacturing cost reductionMicrometer

The invention discloses an ultra-thin flexible circuit board blind hole machining method. A raw material is a double-face flexible circuit board which comprises a face A flexible circuit board body, a face B flexible circuit board body and an insulating film attached to the position between the face A flexible circuit board body and the face B flexible circuit board body. The machining method includes the following steps of (1) punching the face B flexible circuit board body and (2) punching the face A flexible circuit board body. During single-face blind hole machining, double-face blind hole machining and machining of a product with a copper thickness of 12 micrometers or smaller than 12 micrometers, good machining performance and quality guarantee can be guaranteed during laser machining or other manufacturing procedures, and accordingly machinability of the product is guaranteed; reliability and the yield of the product can be greatly improved, and manufacturing cost is reduced.

Owner:杨秀英

Glass lining steel plate good in fish scaling resistance and manufacturing method thereof

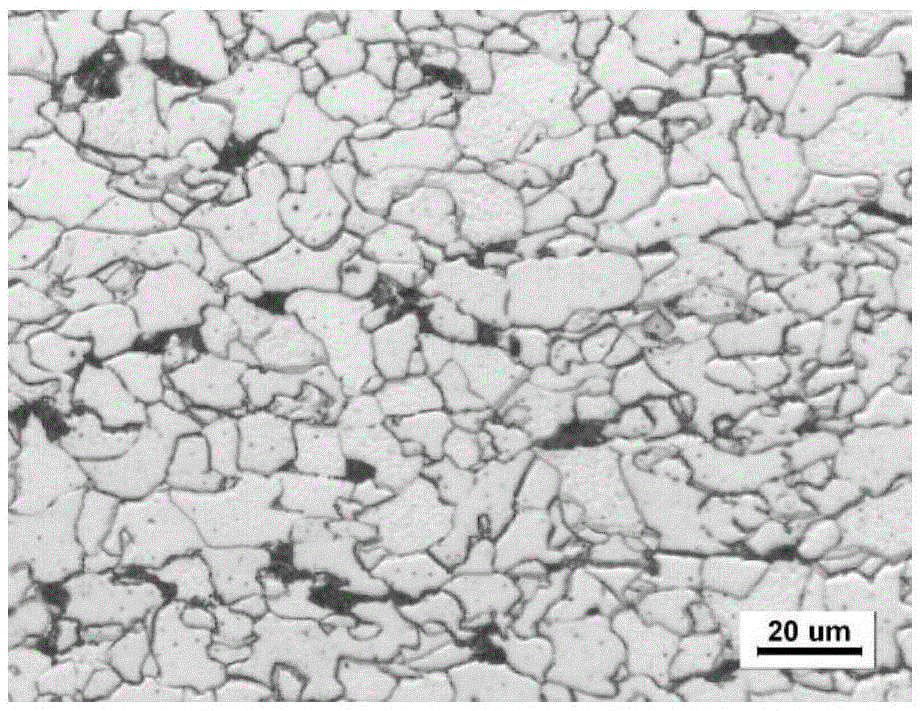

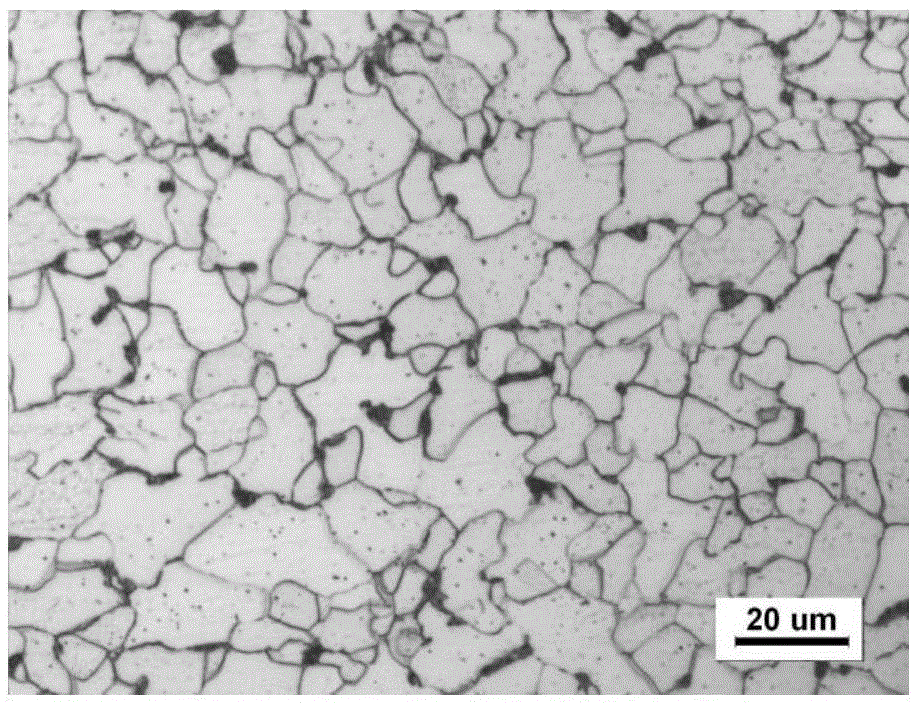

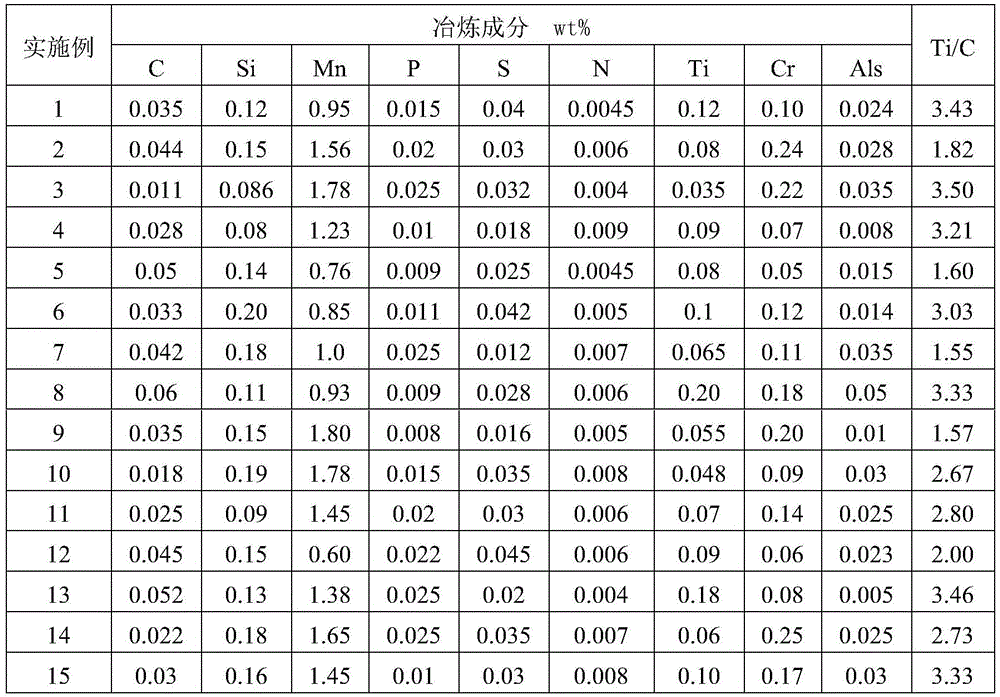

The invention provides a glass-lined steel plate with excellent anti-scale explosion performance and a manufacturing method thereof. The mass percentages of chemical components in the steel are: C: 0.011% to 0.060%, Si: 0.08% to 0.20%, and Mn: 0.60% to 1.8%, P≤0.025%, S: 0.010%~0.045%, N: 0.003%~0.009%, Ti: 0.035%~0.20%, Cr: 0.05%~0.25%, Als: 0.005%~0.050%, Ti / C: 1.5 to 3.5, and the rest are iron and unavoidable impurities. The continuous casting slab smelted according to the above composition ratio is heated to 1180-1250°C, and two-stage rolling is adopted. The rolling temperature in the rough rolling stage is ≥1100°C; 840 ~ 900 ℃, cumulative deformation ≥ 70%. After rolling, the steel plate is air-cooled or water-cooled to 600°C and slowly cooled in a pit. The obtained steel plate has excellent anti-scale explosion performance.

Owner:ANGANG STEEL CO LTD

Ink composition, organic light-emitting device using same, and manufacturing method therefor

ActiveCN111587275AGuaranteed machinabilityEnsure drying propertiesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceMaterials science

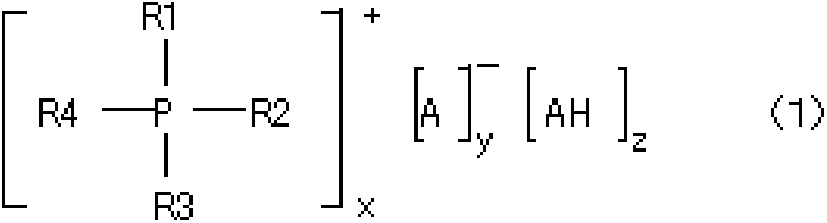

The present specification relates to: an ink composition comprising a first solvent represented by chemical formula 1 and a compound represented by chemical formula 2, or an ink composition comprisinga first solvent represented by chemical formula 1, a second solvent represented by chemical formula 3 or chemical formula 4, and a compound represented by chemical formula 2; an organic light-emitting device comprising the ink composition and a cured material thereof; and a manufacturing method therefor.

Owner:LG CHEM LTD

Spatial position forming method and device based on additive manufacturing

PendingCN114131925AImprove repair efficiencyImprove repair accuracyAdditive manufacturing apparatusAdditive manufacturing with solidsSpatial positioningEngineering

The invention discloses a spatial position forming method and device based on additive manufacturing, and the method comprises the steps: carrying out the additive forming of a positioning foundation on a positioning tool, carrying out the three-dimensional scanning of the positioning tool and the positioning foundation, obtaining complete three-dimensional data, carrying out the reverse modeling, and obtaining a spatial position according to the reverse modeling data and the positioning reference of the positioning tool. According to the method, the spatial position of the workpiece is quickly positioned by utilizing a spatial positioning method, the spatial position of a forming model is quickly and accurately obtained based on three-dimensional scanning, and a forming process of additive manufacturing is generated for quickly repairing and remanufacturing the workpiece, so that the repairing efficiency and the repairing precision of the part are greatly improved; therefore, the problem that precise positioning of the absolute position of the workpiece space is difficult to achieve through additive manufacturing equipment is solved, the method plays a crucial role in workpiece repairing and remanufacturing, grafting printing can be achieved on existing additive manufacturing equipment, the equipment does not need to be transformed, and the cost is reduced. According to the method, batched, rapid and accurate forming can be carried out at the specified spatial position of the part.

Owner:AECC AVIATION POWER CO LTD

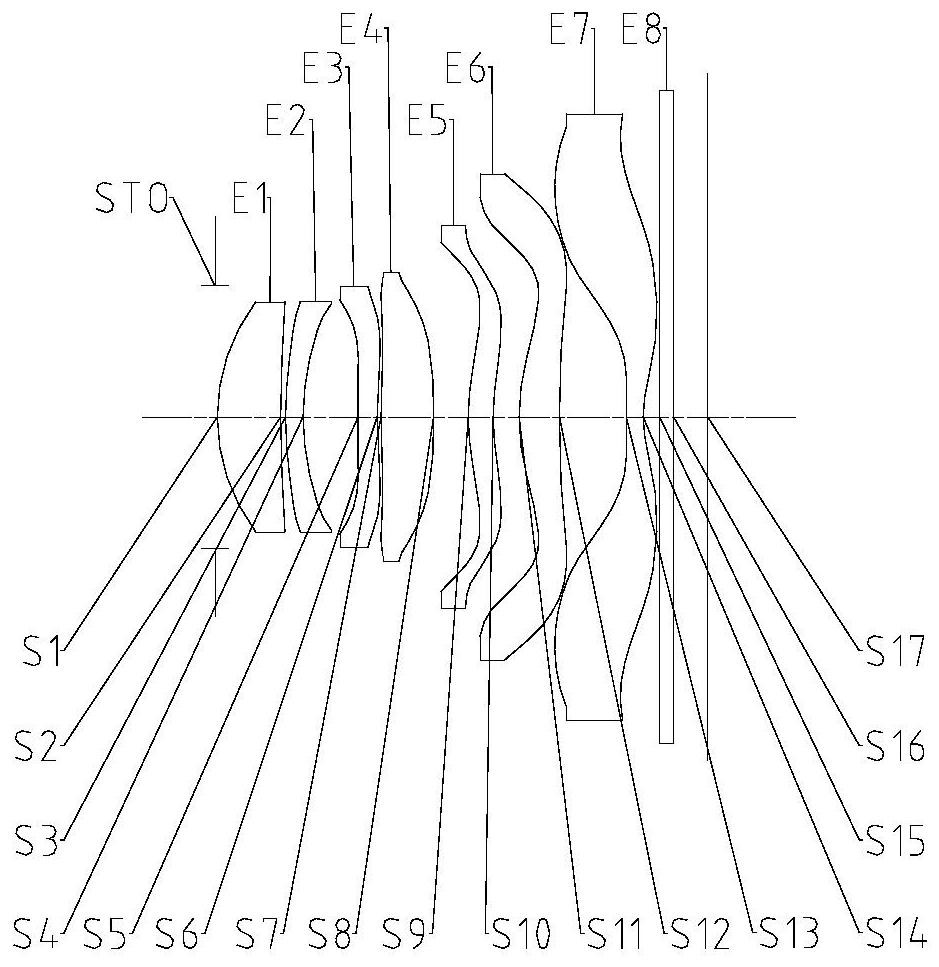

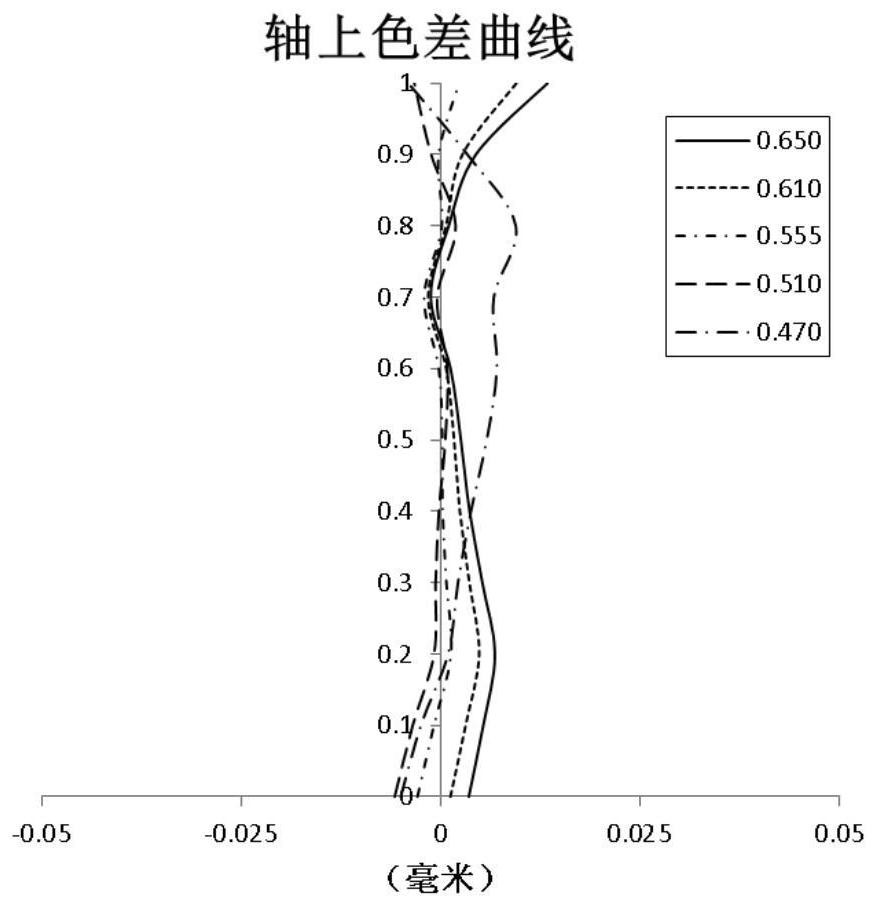

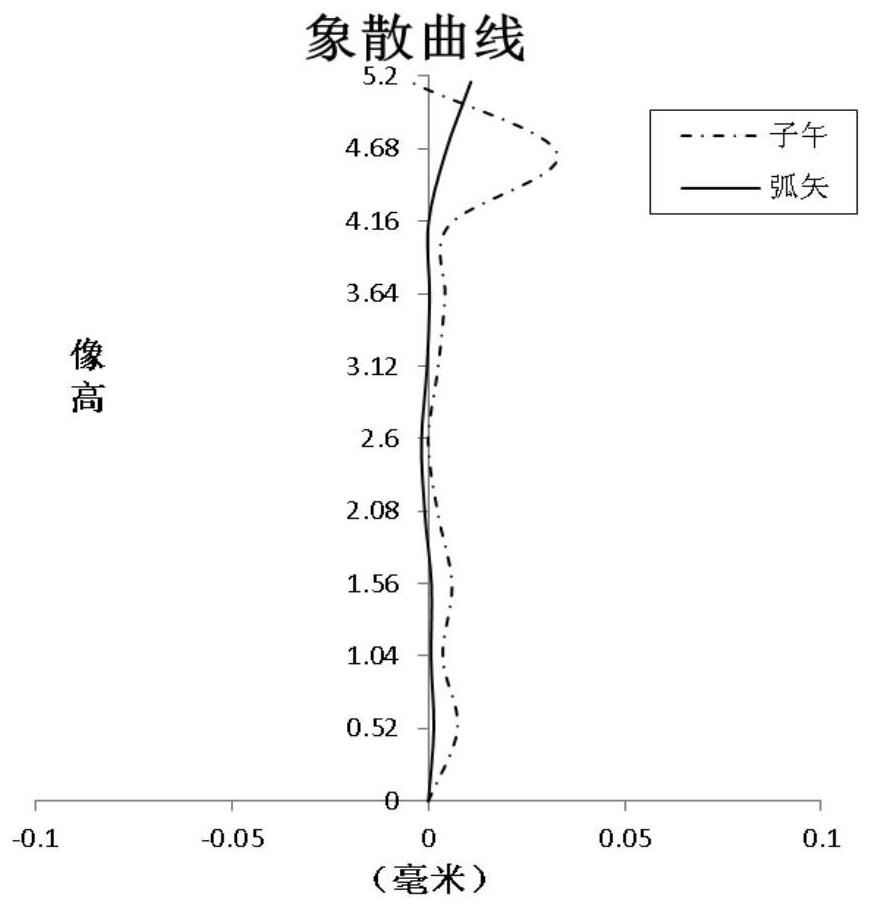

Optical imaging lens

ActiveCN113325545AGuaranteed structural strengthCompact structureOptical elementsOphthalmologyImaging quality

The invention provides an optical imaging lens. The optical imaging lens sequentially comprises from an object side to an image side along an optical axis, a variable diaphragm; a first lens; a second lens; a third lens; a fourth lens; a fifth lens, wherein the object side surface of the fifth lens is a convex surface; a sixth lens; a seventh lens; wherein the central thickness CT1 of the first lens on the optical axis and the air interval T67 of the sixth lens and the seventh lens on the optical axis meet the condition that CT1 / T67 is less than 1.0; the distance T1 from the variable diaphragm of the maximum entrance pupil of the optical imaging lens to the image side surface of the first lens on the optical axis and the aperture value FNO1 corresponding to the maximum entrance pupil of the optical imaging lens meet the following condition of 0.5<T1 / FNO1<1.0. A problem that in the prior art, an optical imaging lens is poor in imaging quality is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

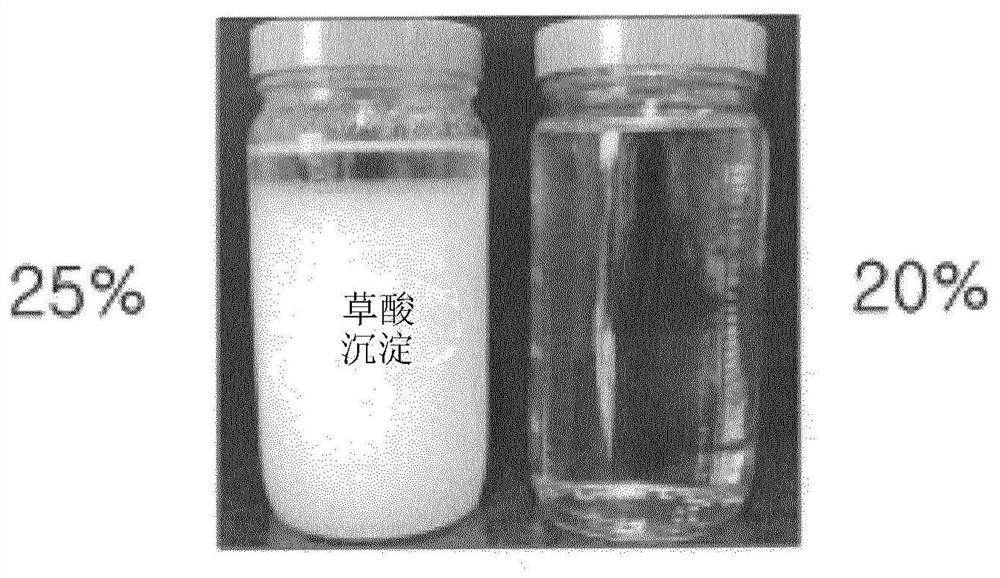

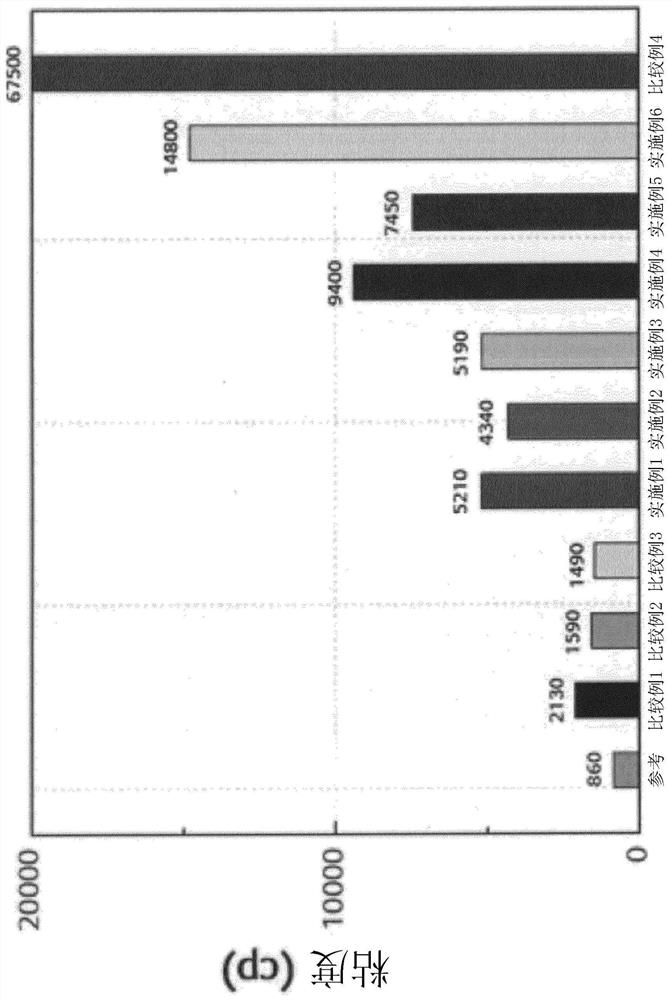

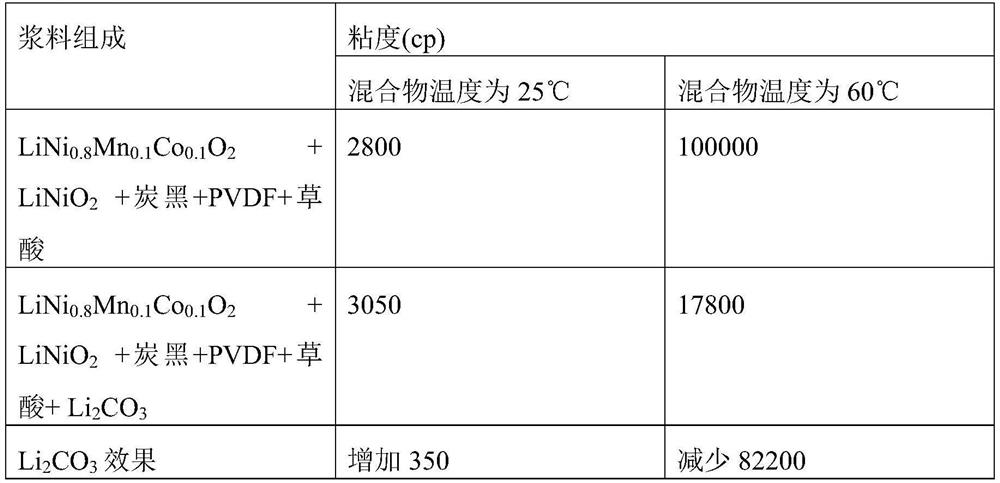

Positive electrode slurry comprising oxalic acid, method for manufacturing same, positive electrode for secondary battery, and secondary battery

ActiveCN111615767ALow viscosityAvoid condensationElectrode manufacturing processesPositive electrodesOXALIC ACID DIHYDRATEElectrical battery

Owner:LG ENERGY SOLUTION LTD

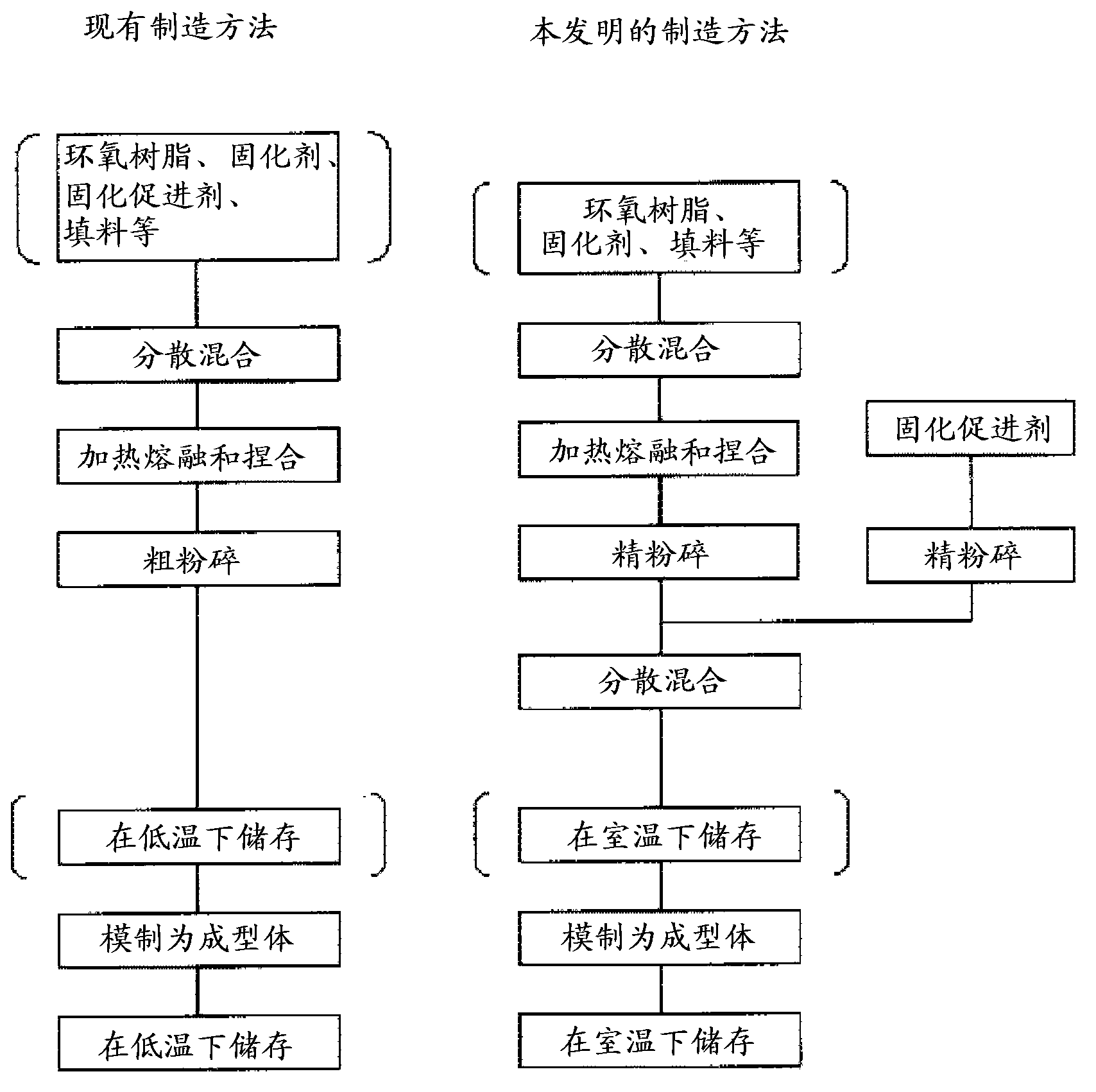

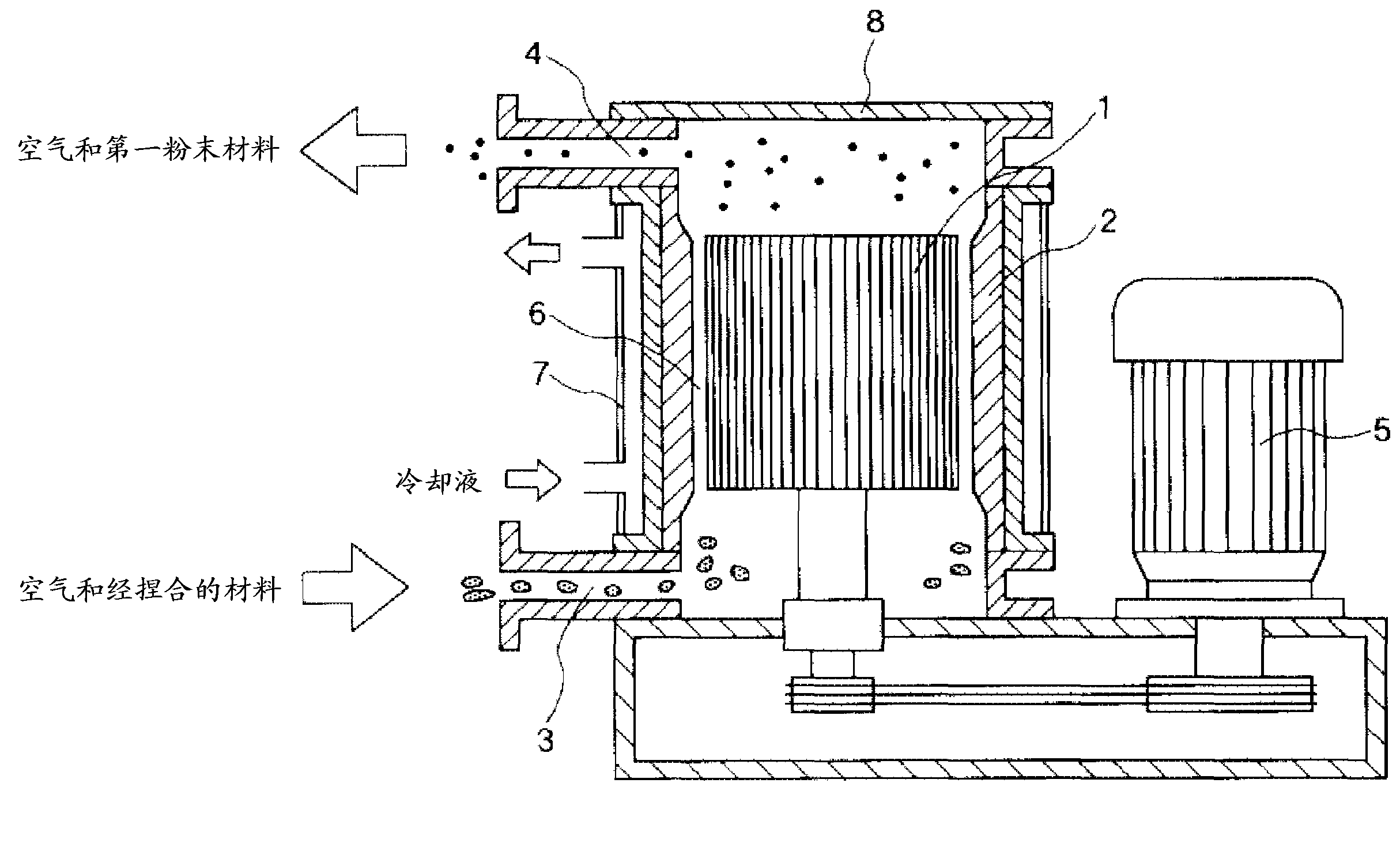

Resin molded product and process for producing same, resin composition and process for producing same, and electronic component device

ActiveCN103228709AExcellent long-term storage stabilityReduce storage costsSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureElectronic component

A process for producing a resin molded product according to the present invention is a process for producing a resin molded product that is made of a resin composition containing an epoxy resin, a curing agent, a curing accelerator, and an inorganic filler, the process involving: a kneading and crushing step of preparing a first powder by mixing, heating and melting, kneading, and crushing a first component that contains an epoxy resin, a curing agent, and an inorganic filler and that does not contain a curing accelerator; a pulverizing step of preparing a second powder by pulverizing a second component containing a curing accelerator; a mixing step of preparing a resin composition by dispersing and mixing the first powder and the second powder; and a molding step of molding a resin molded product by pressurizing the resin composition. Thus, it is possible to produce a resin molded product (particularly, resin tablets for sealing) having excellent long-term storability at room temperature and excellent curability and flowability.

Owner:SUMITOMO BAKELITE CO LTD

A method for processing blind holes in ultra-thin flexible circuit boards

InactiveCN103796434BGuaranteed machinabilityEasy to processPrinted circuit manufactureManufacturing cost reductionFlexible circuits

Owner:杨秀英

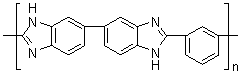

Isostatic pressing method for refractory polybenzimidazole

InactiveCN109605637AImprove mechanical propertiesImprove machinabilityAir atmosphereRoom temperature

The invention relates to an isostatic pressing method for refractory polybenzimidazole. The method includes steps of (1), cold isostatic pressing blank formation, specifically, polybenzimidazole molding powder is loaded into a flexible rubber sleeve in the air atmosphere and under a room temperature, and the flexible rubber sleeve is removed after pressing by a cold isostatic press to obtain the cold isostatic pressing blank; (2), packing sleeve welding and sealing, specifically, the cold isostatic pressing blank is put into a packing sleeve, a packing sleeve cover with a suction pipe is welded to the opening end of the packing sleeve, the packing sleeve is vacuumized through the suction pipe and then the suction pipe is sealed through a pair of hydraulic sealing pliers to obtain the workpiece to be pressed; and (3), hot isostatic pressing molding, specifically, the workpiece to be pressed is cooled to be 150 DEG C or below after being pressed by a hot isostatic press, and the packingsleeve is removed to obtain the refractory polybenzimidazole material. According to the method, the blank is obtained by adopting the cold isostatic pressing technology; sinter molding is competed through hot isostatic pressing technology at high temperature and high pressure; and the densification of the molding material is achieved by regulating and controlling the cooling rate after hot isostatic pressing to control the degree of crystallization of the polymer molecular chain.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

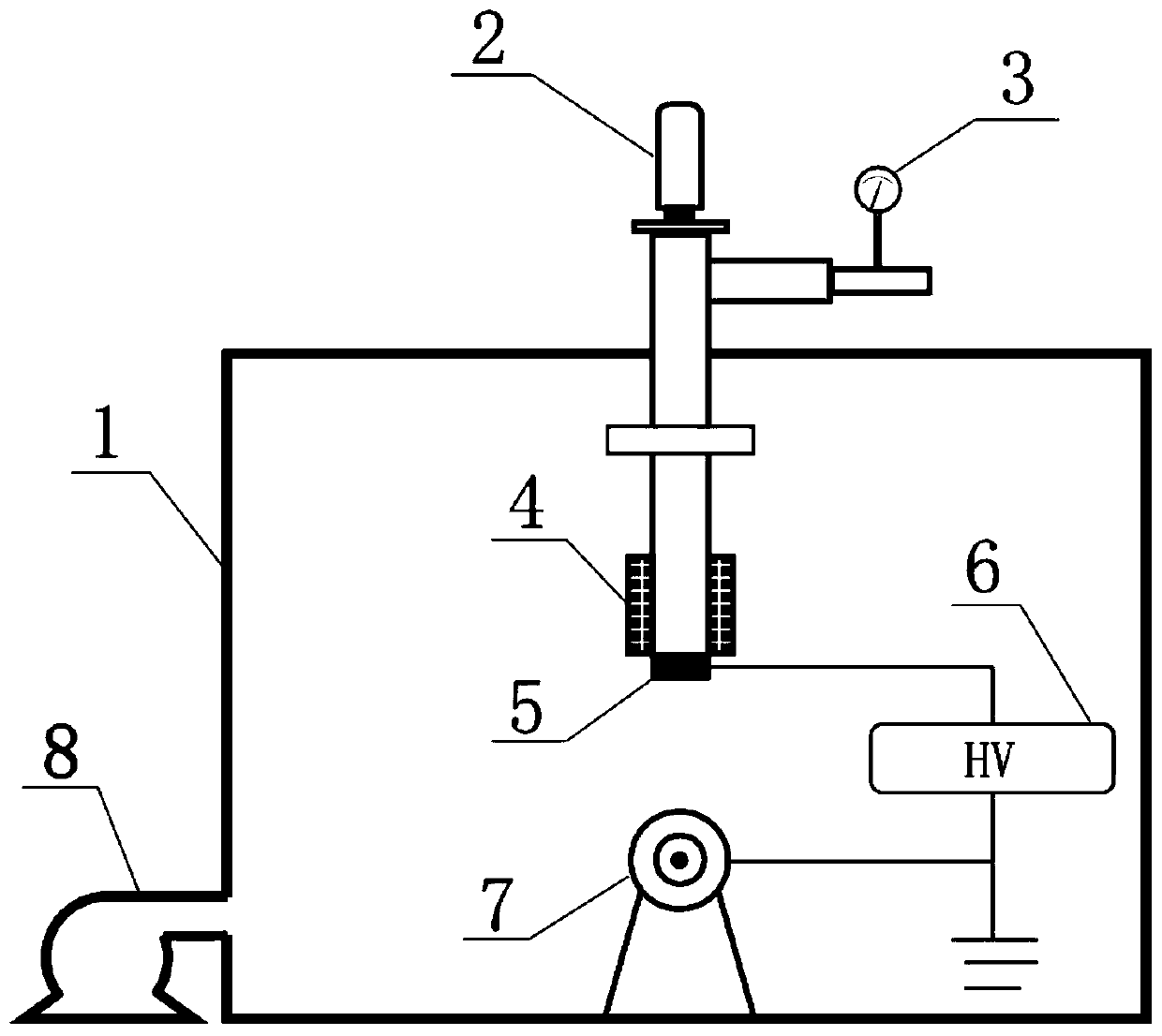

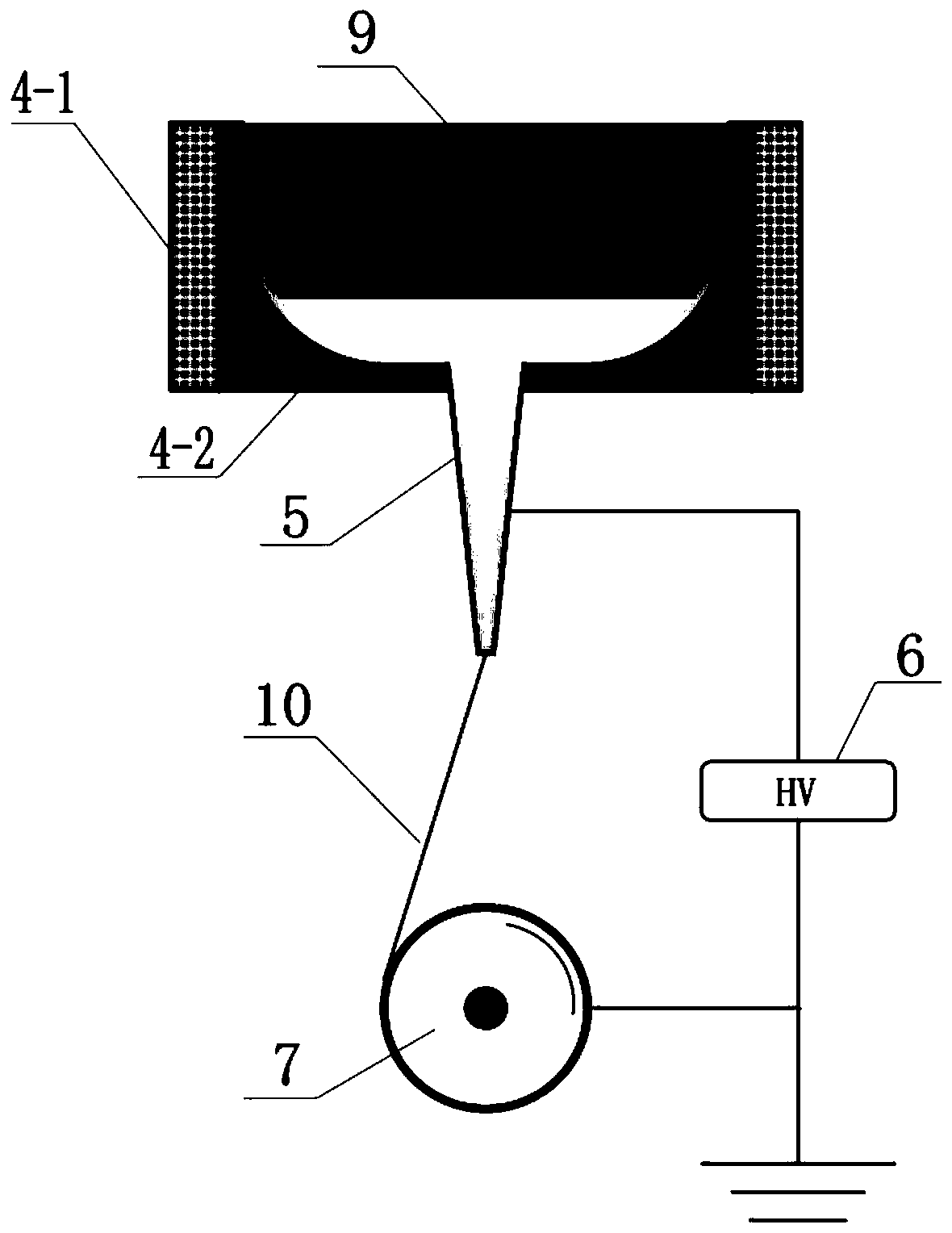

Electrostatic spinning method for melt

The invention provides an electrostatic spinning method for a melt. The method comprises the steps that S1, an inorganic material is heated to a molten state to form the melt; S2, the melt forms fibers through electrostatic spinning. The method is suitable for electrostatic spinning taking inorganic materials of high melting points as raw materials. The technology is simple in technical process, the orientation of the fiber product is high, and the preparation process is environmentally friendly.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com