Glass lining steel plate good in fish scaling resistance and manufacturing method thereof

An anti-scale explosion and glass-lined technology, which is applied to the glass-lined steel plate with excellent anti-scale explosion performance and its manufacturing field, can solve the problems of increasing smelting difficulty, increasing process cost, long production cycle, etc., and achieve excellent anti-scale explosion performance , more tissue, even and fine tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

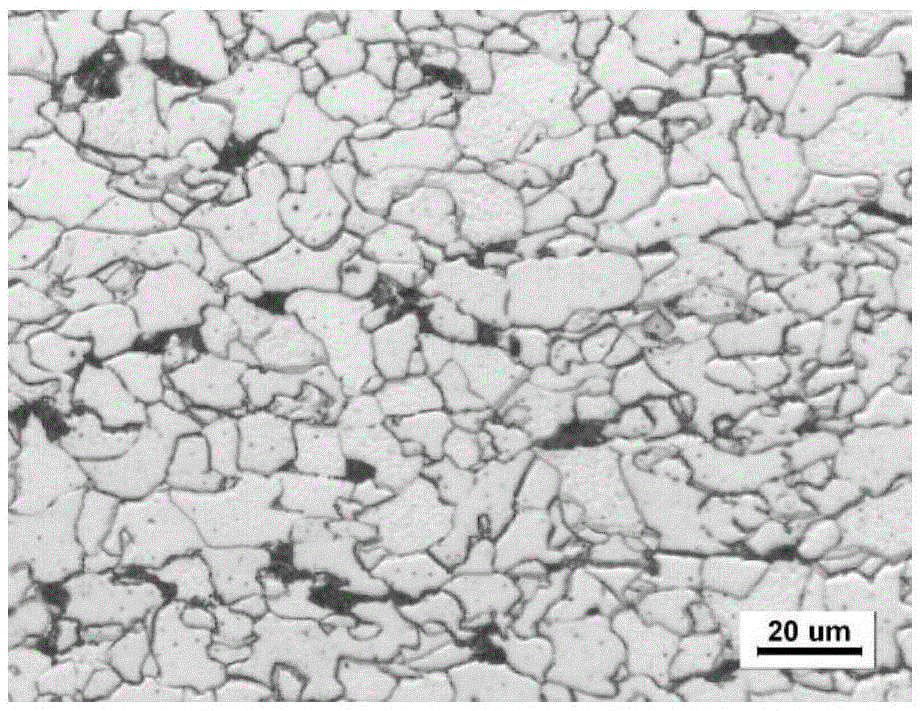

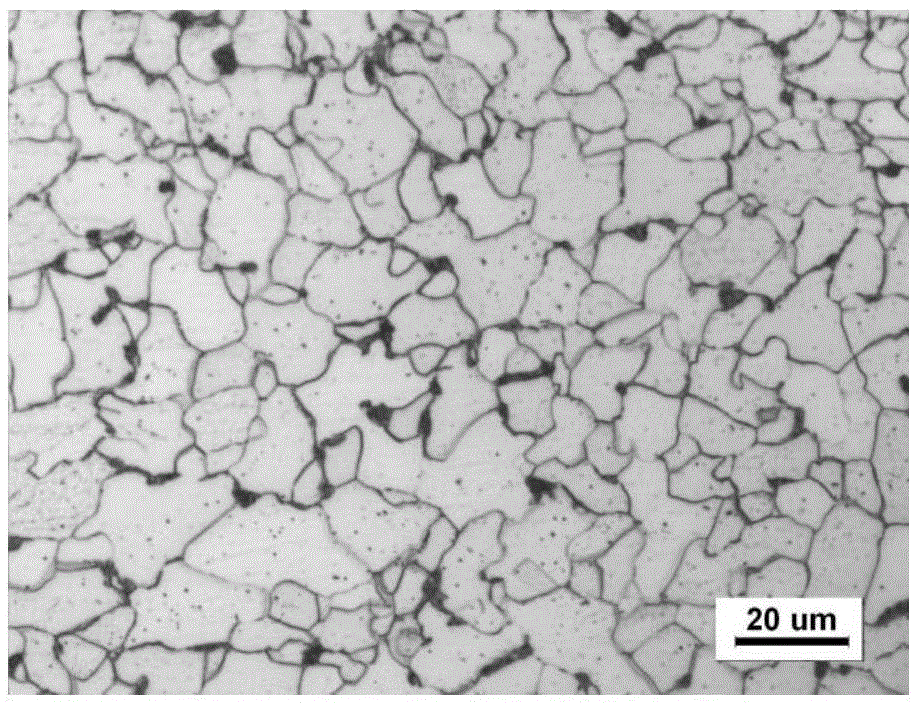

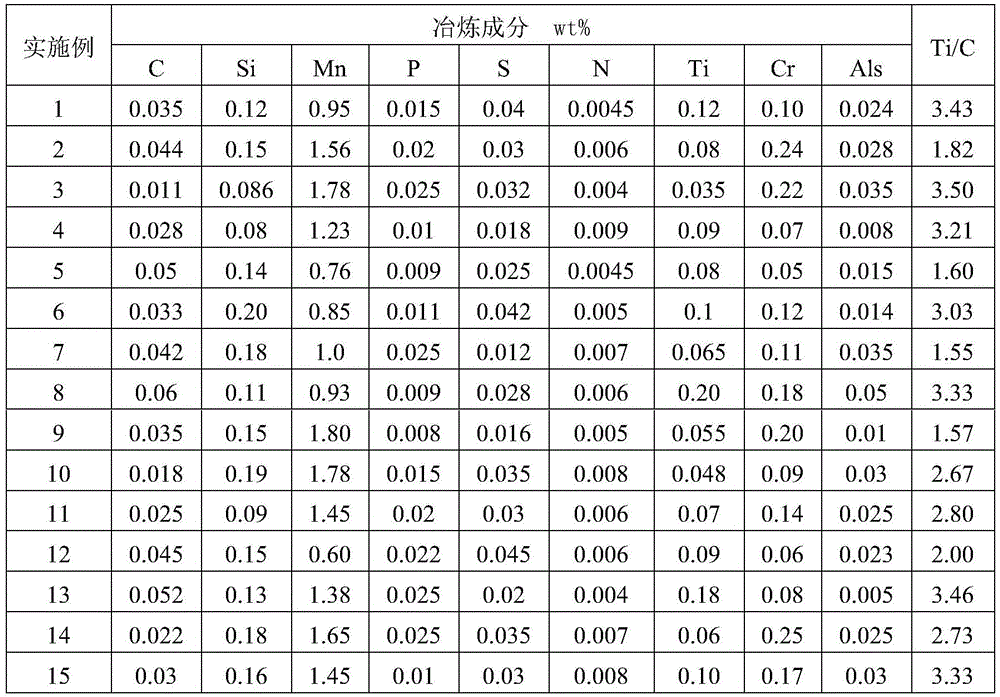

[0041] The invention provides a glass-lined steel plate with excellent anti-scale explosion performance and a manufacturing method thereof. The mass percentages of chemical components in the steel are: C: 0.011% to 0.060%, Si: 0.08% to 0.20%, and Mn: 0.60% to 1.8%, P≤0.035%, S: 0.010%~0.045%, N: 0.003%~0.009%, Ti: 0.035%~0.20%, Cr: 0.05%~0.25%, Als: 0.005%~0.050%, Ti / C: 1.5 to 3.5, and the rest are iron and unavoidable impurities. The continuous casting slab smelted according to the above composition ratio is heated to 1180-1250°C, and two-stage rolling is adopted. The rolling temperature in the rough rolling stage is ≥1100°C; 840 ~ 900 ℃, cumulative deformation ≥ 70%. After rolling, the steel plate is air-cooled or water-cooled to 600°C and slowly cooled in the pit.

[0042] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com