Steel sheet and enameled product

A technology of enamel products and steel plates, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of inability to obtain strength stably, unclear changes in tensile strength, uneven particle size, etc., and achieve excellent scale resistance and appearance Excellent, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

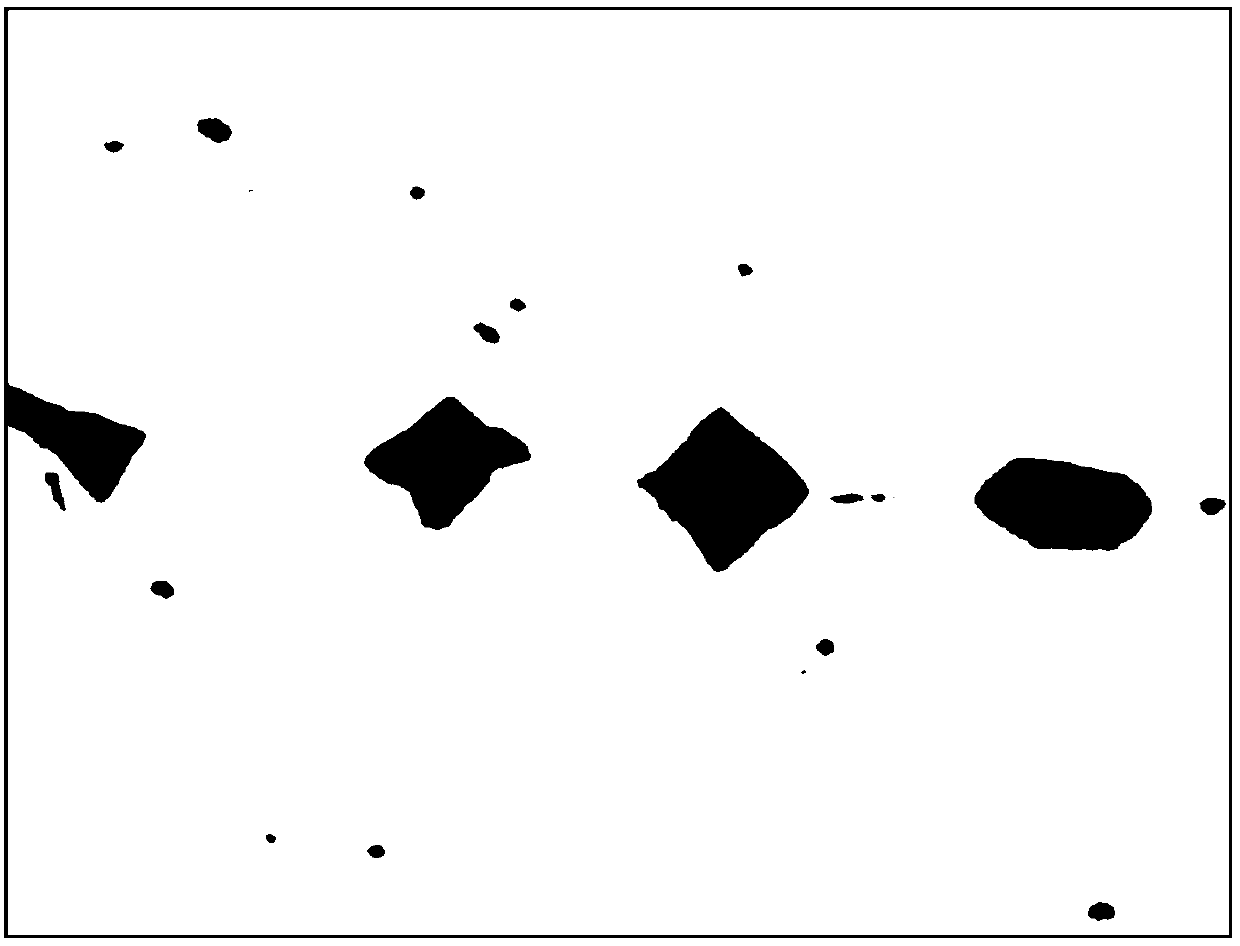

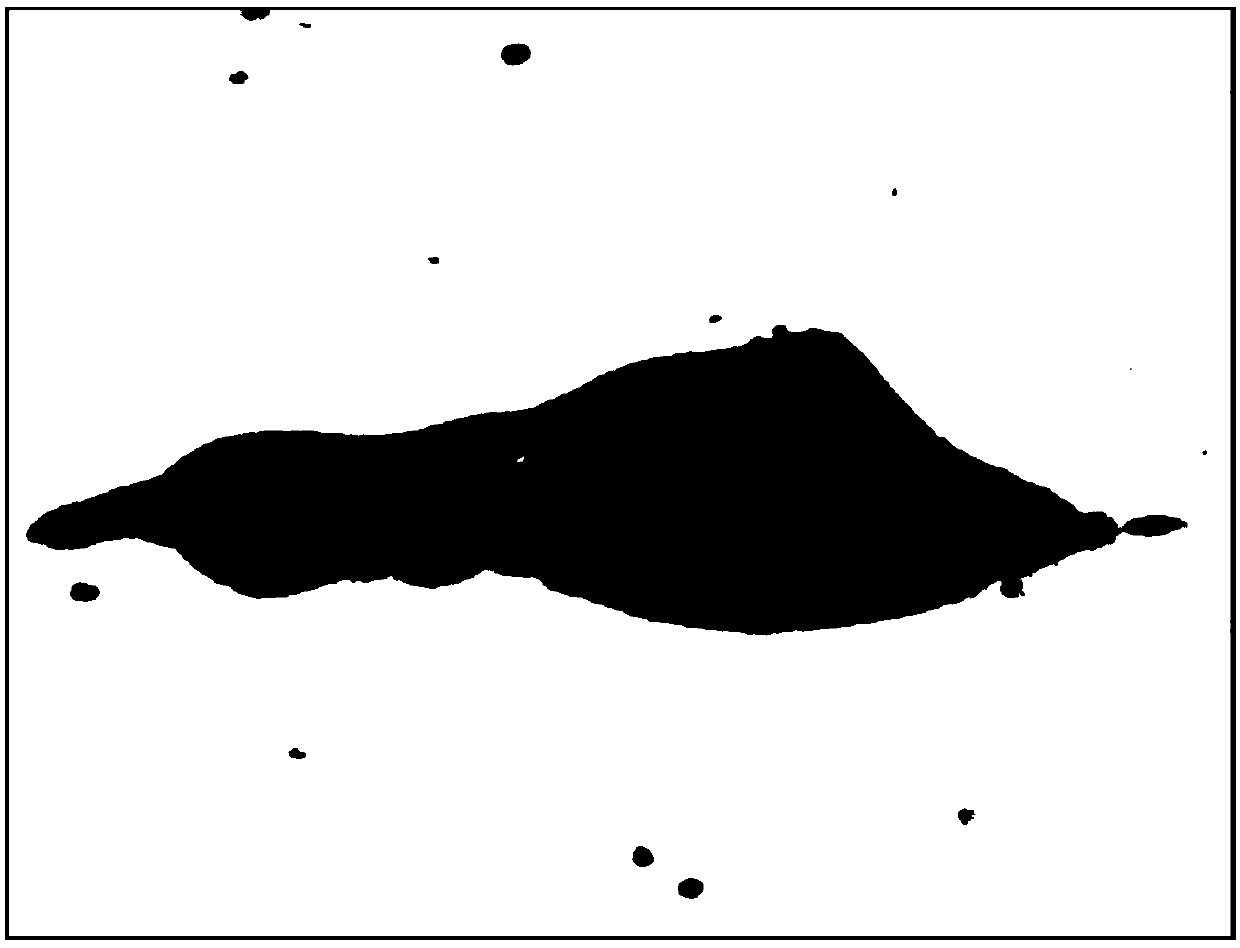

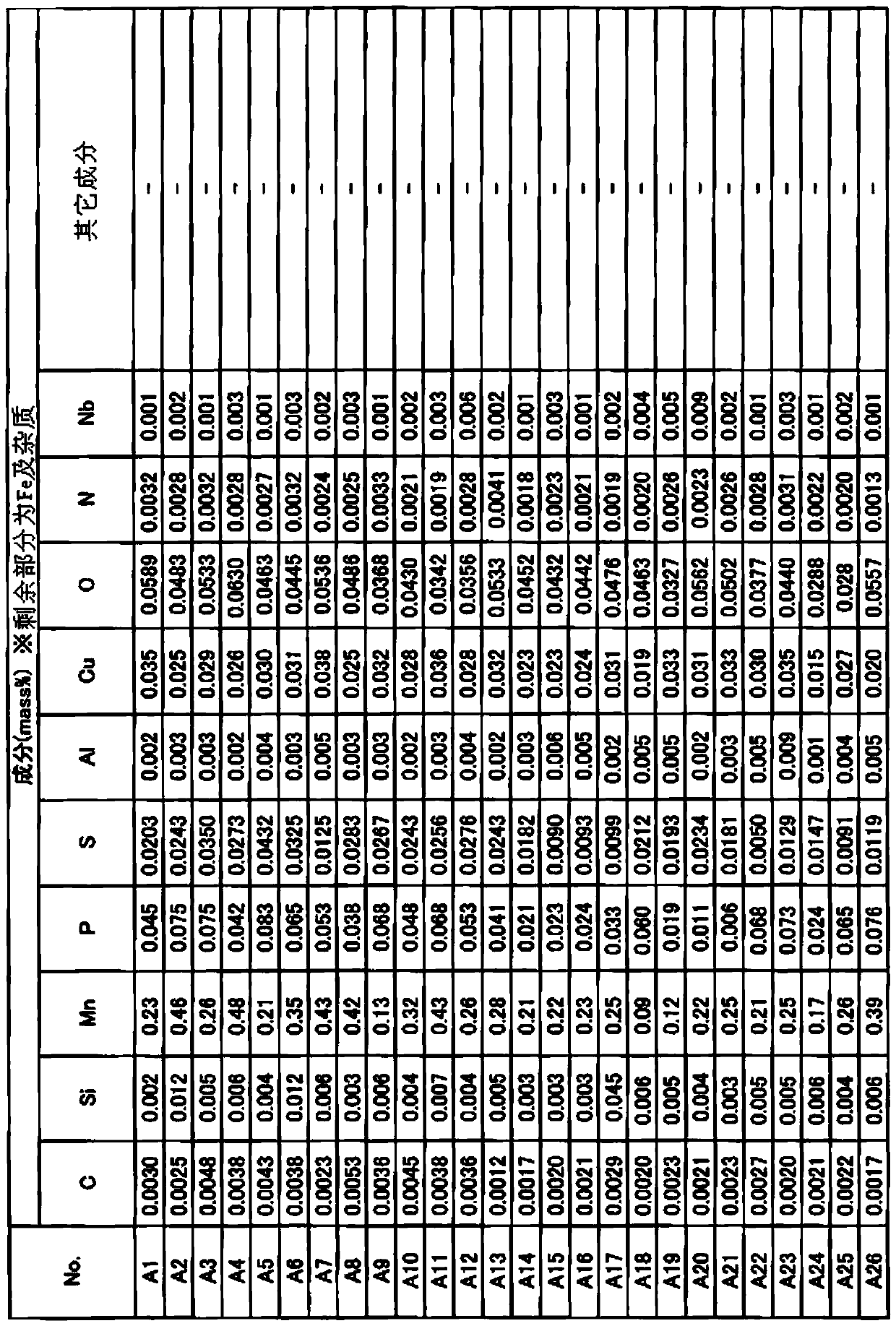

[0115] Steels having the composition shown in Table 1 and Table 2 were smelted in a converter, and then formed into slabs by continuous casting. The ΔT and casting speed in the mold during casting are shown in Table 3 and Table 4. Use electromagnetic stirring to control the cooling rate and dissolved oxygen in the range of 1200 to 1500°C according to the ranges in Table 3 and Table 4, and control the number of oxides. , density and oxygen content. Confirm the amount of dissolved oxygen (free oxygen) as described above. These slabs are heated in a heating furnace at a temperature of 1150° C. to 1250° C., hot rolled at a finish rolling temperature of 900° C. or higher, and coiled at 700° C. to 750° C. to form hot-rolled steel sheets. Then, after pickling, the rolling ratio of cold rolling was changed according to the ranges of Table 3 and Table 4 to form a cold-rolled steel sheet, and after performing continuous annealing at 780°C, temper rolling was performed to form a steel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com