Production process for stainless steel damping composite board

A production process, stainless steel technology, applied in the direction of synthetic resin layered products, layered products, lamination devices, etc., can solve the problems of low quality of the surface panel of the composite board, no shock absorption characteristics of the composite board, and low production efficiency. , to achieve the effect of obvious shock absorption and noise reduction, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

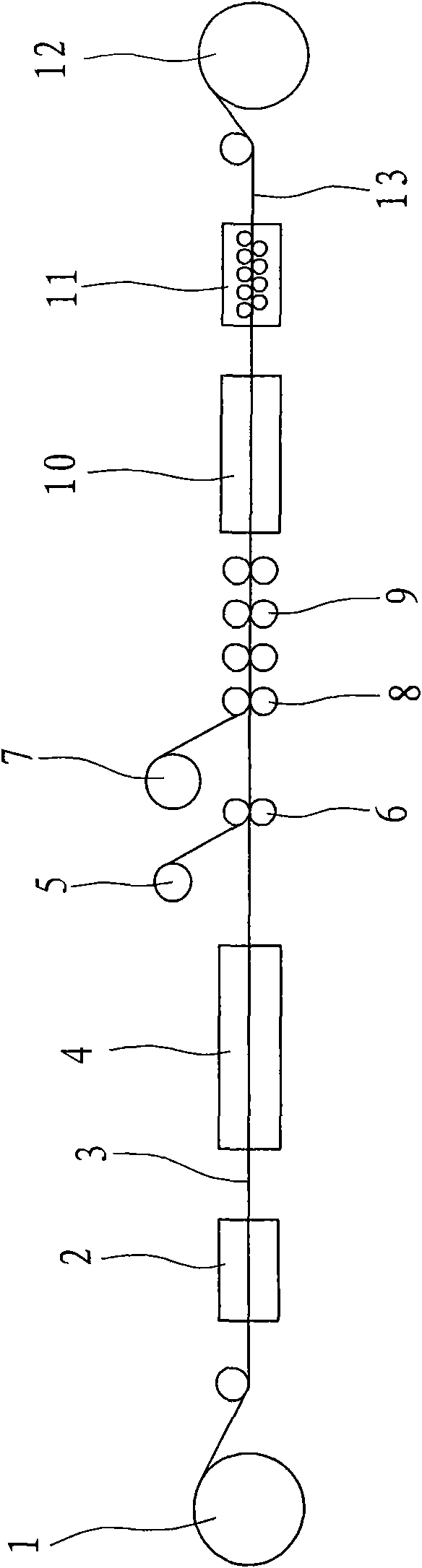

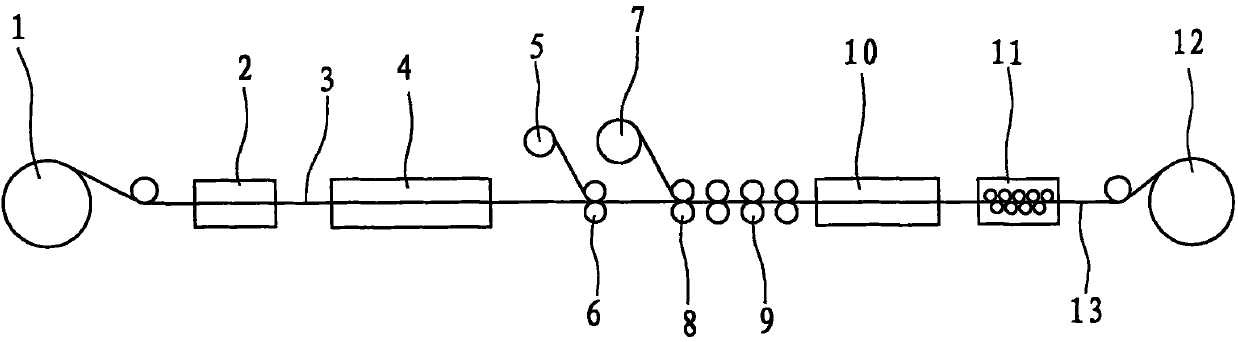

[0024] Production of 0.8mm stainless steel shock-absorbing composite panels (rolls). The panel is made of 0.15mm thick 304 stainless steel plate, the polymer damping adhesive film is made of 0.04mm, and the substrate is made of 0.6mm thick hot-dip galvanized cold-rolled steel plate. process such as figure 1 shown. The process parameters are: the preheating temperature is 100-105°C; the temperature of the coating roller (6) is 120-125°C; the temperature of the covering roller (8) is 160-165°C; ℃; the composite plate is forced to cool to 20-25°C by air cooling; the winding tension is 1250N.m, and the stainless steel shock-absorbing composite plate required by the present invention can be produced by adopting the above production process.

Embodiment 2

[0026] Production of 1.5mm stainless steel shock-absorbing composite panels (rolls). The panel is made of 0.3mm thick 304 stainless steel plate, the polymer damping adhesive film is made of 0.06mm, and the substrate is made of 1.2mm thick hot-dip galvanized cold-rolled steel plate. The technological process is as described above. The process parameters are: the preheating temperature is 100-110°C; the temperature of the laminating roller (6) is 130-140°C; the temperature of the covering roller (8) is 165-170°C; ℃; the composite board is forced to cool to 25-30℃ by air cooling; the winding tension is 1400N.m

Embodiment 3

[0028] Production of 3mm stainless steel shock-absorbing composite panels (rolls). The panel is made of 0.4mm thick 304 stainless steel plate, the polymer damping adhesive film is made of 0.08mm, and the substrate is made of 2.5mm thick hot-dip galvanized cold-rolled steel plate. The technological process is as described above. The process parameters are: the preheating temperature is 115-120°C; the temperature of the laminating roller (6) is 145-150°C; the temperature of the covering roller (8) is 175-180°C; ℃; the composite board is forced to cool to 30-35℃ by air cooling; the winding tension is 1500N.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com