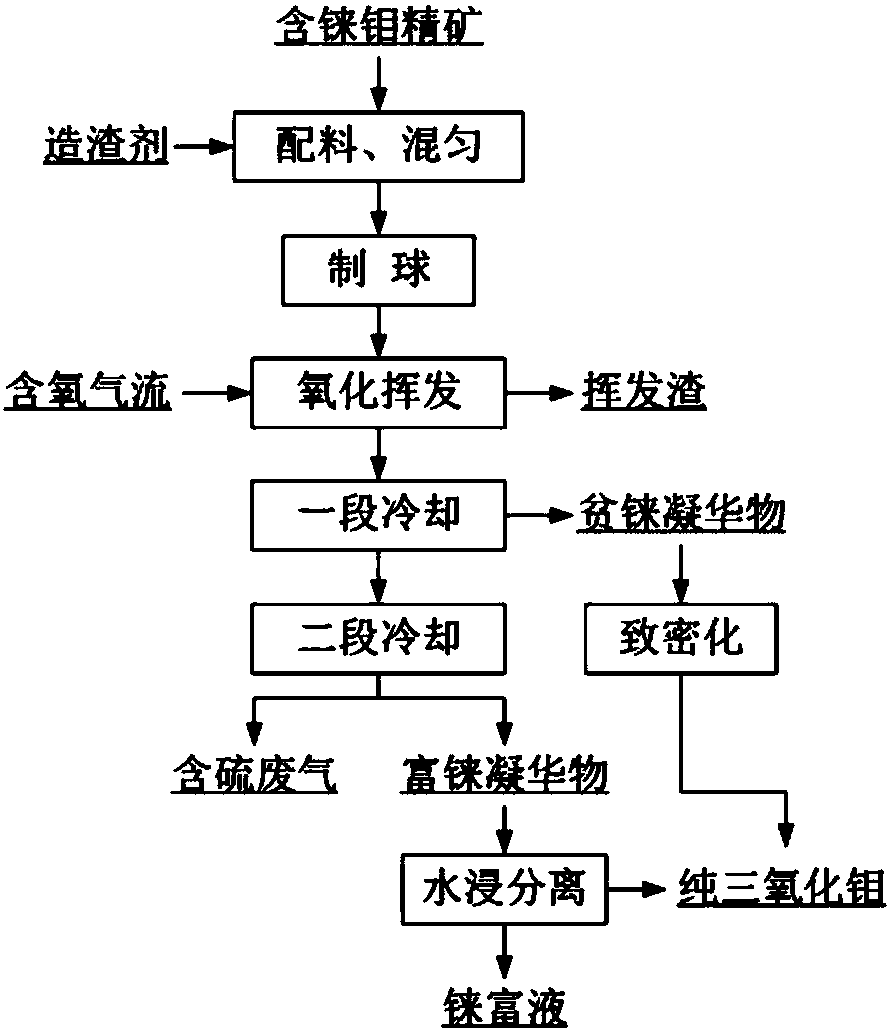

Method of concentrate volatilization containing molybdenum-rhenium, and water leaching and separation of molybdenum-rhenium

A molybdenum concentrate and water leaching technology, applied in the field of molybdenum-rhenium metallurgy, can solve the problems of high waste gas treatment cost, large equipment investment, and low rhenium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add molybdenum concentrate quality 50wt.% slagging agent (Al 2 o 3 40wt.%; SiO 2 10wt.%), obtain uniform green pellets with a diameter of 12mm and a water content of about 11% by pelletizing, and then cloth to a thickness of about 30mm. First let in 120°C low-temperature hot air for 10 minutes, then blow in 1050°C high-temperature hot air from bottom to top, and control the air volume per square meter at 280m 3 / h, the mixed steam is slowly cooled in the collection section, and the high-temperature hot air supply is stopped after 30 minutes. Through the analysis of the tailings, it can be concluded that the volatilization rate of Mo is 90.6%, and the volatilization rate of rhenium is higher than 99.9%. The average purity of molybdenum is higher than 99.9%. The sublimates in the cold section during work are taken below 500°C for water immersion separation. The liquid-solid ratio is 3, the water immersion temperature is 50°C, and the time is 40 minutes. The test resu...

Embodiment 2

[0023] Add molybdenum concentrate quality 50wt.% slagging agent (Al 2 o 3 40wt.%; SiO 2 10wt.%), obtain uniform green pellets with a diameter of 12mm and a water content of about 11% by pelletizing, and then cloth to a thickness of about 30mm. First let in 120°C low-temperature hot air for 10 minutes, then blow in 1100°C high-temperature hot air from bottom to top, and control the air volume per square meter at 300m 3 / h, the mixed steam is slowly cooled in the collection section, and the high-temperature hot air supply is stopped after 25 minutes. Through the analysis of tailings, it is concluded that the volatilization rate of Mo is 93.6%, and the volatilization rate of rhenium is higher than 99.9%. The average purity of molybdenum is higher than 99.9%. Take the sublimes in the cold section below 500°C during work, and carry out water immersion separation. The liquid-solid ratio is 3, the water immersion temperature is 50°C, and the time is 40 minutes. The test results ...

Embodiment 3

[0025] Add the slagging agent (Al 2 o 3 32wt.%; SiO 2 8wt.%), obtain uniform pellets with a diameter of 12mm and a moisture content of about 9% by making pellets, and then spread them to a thickness of about 30mm. First let in 120°C low-temperature hot air for 10 minutes, then blow in 1100°C high-temperature hot air from bottom to top, and control the air volume per square meter at 300m 3 / h, the mixed steam is slowly cooled in the collection section, and the high-temperature hot air supply is stopped after 25 minutes. Through the analysis of tailings, it is concluded that the volatilization rate of Mo is 89.4%, and the volatilization rate of rhenium is higher than 99.9%. The average purity of molybdenum is higher than 99.8%. Take the sublimes in the cold section below 500°C during work, and carry out water immersion separation. The liquid-solid ratio is 2. Add 5wt.% hydrogen peroxide to the immersion liquid, and the leaching temperature is 50°C. The test time is 40 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com