Supported metal oxide double-active center ethylene-polymerization catalyst and its preparation method and use

A catalyst, supported technology, applied in the production of bulk chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

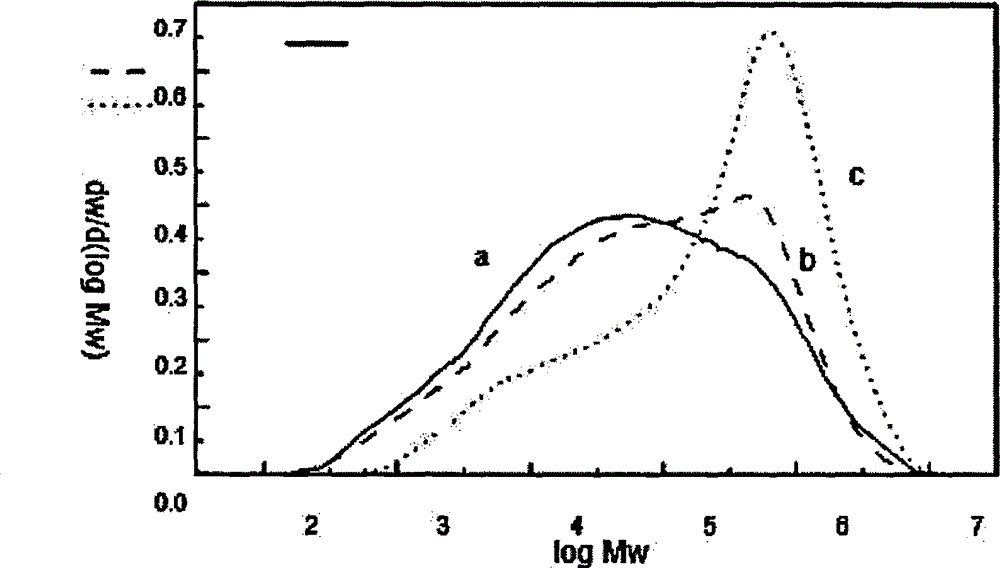

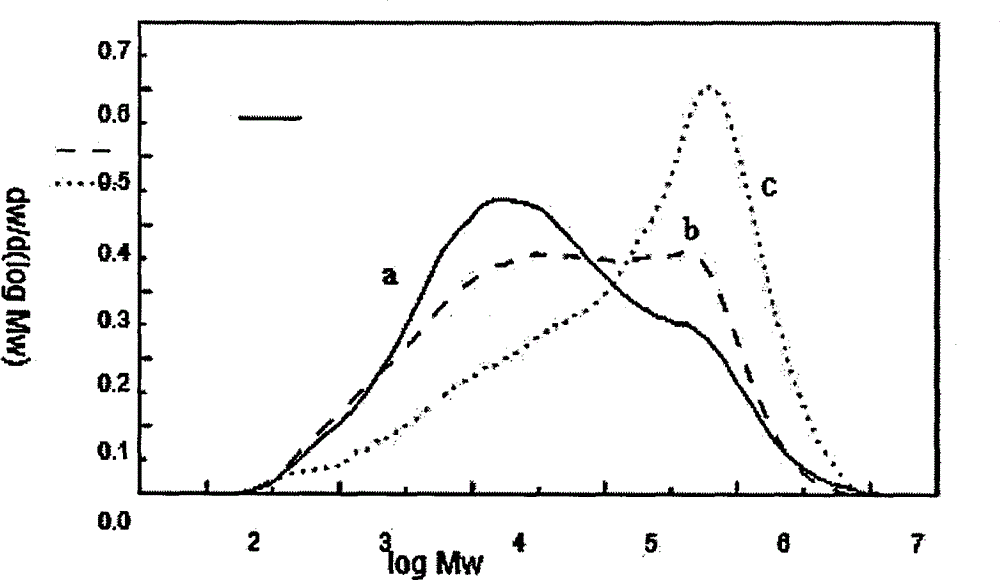

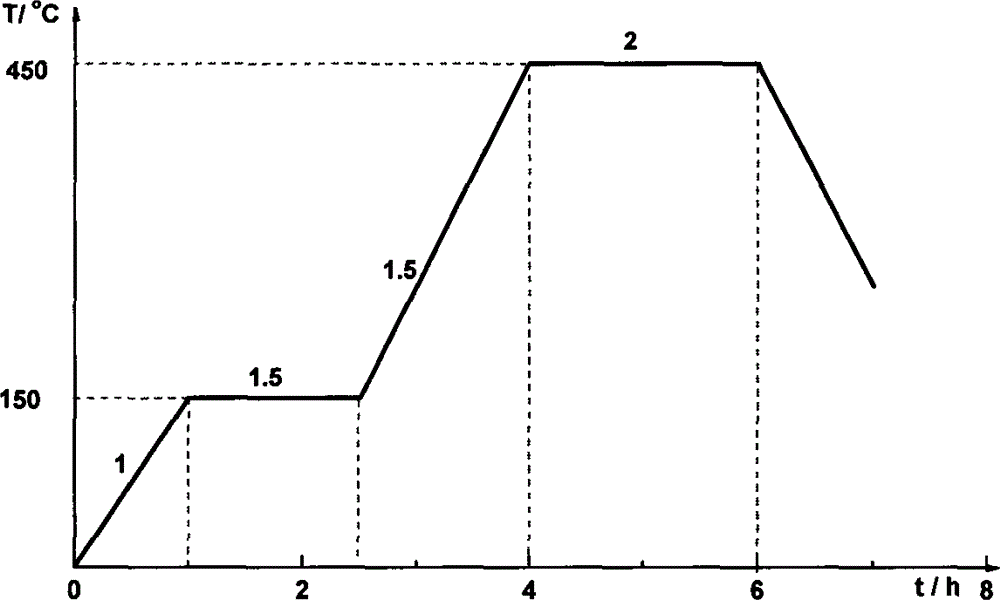

[0077] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) impregnated in an aqueous solution of vanadyl oxalate (V load is 0.48wt%), continuously stirred and impregnated in an oil bath at 40°C for 5h, then heated to 120°C for 5h, and then transferred to 120°C for oven drying for 6h; the impregnated The silica gel carrier of vanadyl oxalate is placed in a quartz fluidized bed for roasting and activation. The high-purity air is kept at 450°C for 4 hours, and the silica gel is finally cooled and transferred under nitrogen. The above roasting process is as follows: figure 1 shown. The obtained sample was impregnated with basic chromium acetate aqueous solution (0.5wt% Cr loading) again, after impregnating with continuous stirring at room temperature for 4 hours, dried at 120°C for 4 hours, and then transferred to a 120°C oven for 6 hours; the dried sample was placed in a quartz Carry out roasting activation in the fluidized bed, roast at 600°C in t...

Embodiment 2

[0079] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) immersed in an aqueous solution of basic chromium acetate and ammonium metavanadate (Cr load is 0.5wt%, V load is 0.48wt%), stirred and impregnated in an oil bath at 60°C for 4h, dried at 120°C for 4h, Then transferred to 120°C oven for drying for 6 hours; the dried sample was placed in a quartz fluidized bed for calcination and activation, kept in air at 500°C for 5 hours, and then cooled and transferred naturally under the protection of nitrogen to obtain the catalyst for storage until use.

Embodiment 3

[0081] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) impregnated in an aqueous solution of vanadyl sulfate (V load 0.16wt%), continuously stirred and impregnated at room temperature for 4h, dried at 120°C for 4h, and then transferred to a 120°C oven for 6h; the dried catalyst was placed in a quartz fluidized bed Roasting and activation were carried out in the oven, kept at 500°C for 4 hours in the air, and cooled naturally under the protection of nitrogen. The obtained sample was impregnated with basic chromium acetate solution (Cr load 0.5wt%) again, stirred and impregnated at room temperature for 4h, dried at 120°C for 4h, and then transferred to an oven for 6h; the dried sample was placed in a quartz fluidized bed for Roasting activation, in the air at 600°C, keep warm for 4h, and cool naturally under the protection of nitrogen, the roasting procedure is as follows figure 2 , the catalyst is obtained and stored for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com