Slow-recovery polyether polyol and preparation method thereof and slow-recovery foam and preparation method thereof

A technology of slow rebound polyether and polyether polyol, which is applied in the field of organic polymer synthesis, can solve the problems of no moist comfort, slow foam curing speed, and difficult adjustment of formula, so as to achieve good foam opening and improve Foam has good low-temperature flexibility and tensile tear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

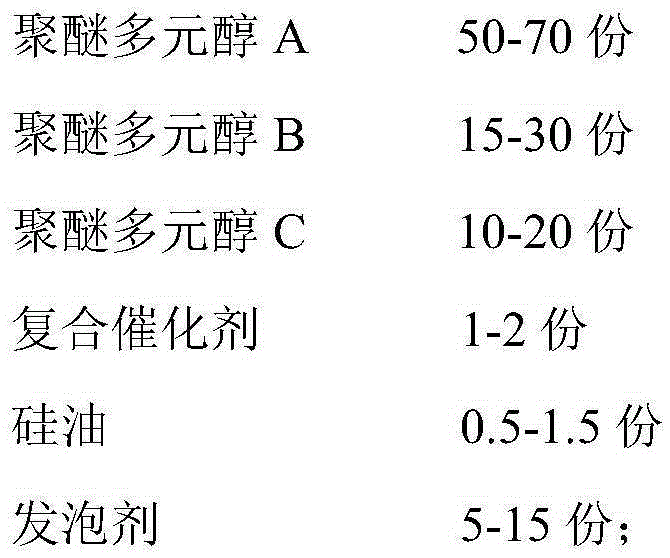

Method used

Image

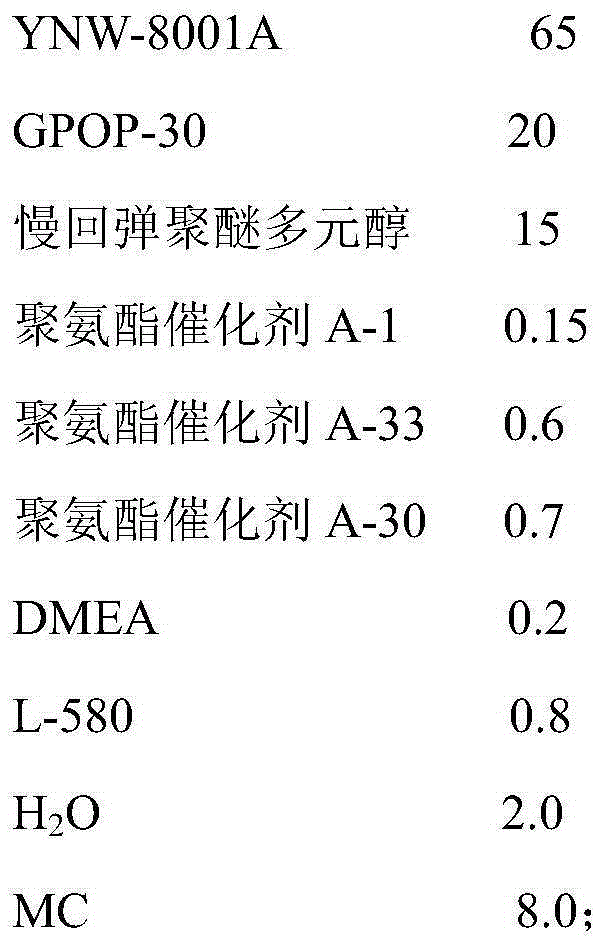

Examples

Embodiment 1

[0035] Slow resilience polyether polyol is a copolymer of propylene oxide and ethylene oxide with glycerol and sucrose as the initiator, wherein, in the polymerized monomer, propylene oxide accounts for 50wt%, and ethylene oxide accounts for 50wt% %.

[0036] The preparation method is as follows:

[0037] (1) Add 920g of glycerol, 142.5g of sucrose and 22.5g of KOH to the pressure-resistant reactor, and replace with nitrogen 3 times. After measurement, the oxygen content is 45ppm, and the temperature is raised to 100°C, vacuumed to -0.092MPa, and dehydrated Reaction 5h;

[0038] (2) Continuously add 3220g of propylene oxide and 3220g of ethylene oxide monomer into the pressure-resistant reaction kettle through a proportional adjustment mixer, and carry out polymerization reaction at 120°C. After the feeding is completed, continue to react for 2h; then vacuumize to -0.092 MPa, remove unreacted residual monomers, cool down to 90°C and transfer to post-treatment tank;

[0039]...

Embodiment 2

[0049] Slow resilience polyether polyol is a copolymer of propylene oxide and ethylene oxide with glycerol and neopentyl glycol as initiators, wherein propylene oxide accounts for 90wt% in the polymerized monomer, and ethylene oxide Alkanes accounted for 10wt%.

[0050] The preparation method is as follows:

[0051] (1) Add 920g of glycerol, 183.5g of neopentyl glycol and 20g of KOH to the pressure-resistant reactor, and replace it with nitrogen 4 times. It is measured that the oxygen content is 40ppm, the temperature is raised to 110°C, and the vacuum is pumped to -0.092MPa , dehydration reaction 7h;

[0052] (2) Continuously add 4997g of propylene oxide and 560g of ethylene oxide monomer into the pressure-resistant reaction kettle through the proportional adjustment mixer, and carry out polymerization reaction at 125°C. After the feeding is completed, continue to react for 2h; then vacuumize to -0.092 MPa, to remove unreacted residual monomers, cool down to 85°C and transf...

Embodiment 3

[0064] Slow resilience polyether polyol is a copolymer of propylene oxide and ethylene oxide with trimethylolpropane and sorbitol as the initiator, wherein propylene oxide accounts for 70wt% in the polymerized monomer, and epoxy Ethane accounts for 30 wt%.

[0065] The preparation method is as follows:

[0066] (1) Add 1340g of trimethylolpropane, 130g of sorbitol and 17.6g of NaOH into the pressure-resistant reactor, and replace it with nitrogen for 5 times. After measurement, the oxygen content is 28ppm, heat up to 110°C, and evacuate to -0.092MPa , dehydration reaction 8h;

[0067] (2) Continuously add 3100g of propylene oxide and 1300g of ethylene oxide monomer into the pressure-resistant reaction kettle through the proportional adjustment mixer, and carry out polymerization reaction at 130°C. After the feeding is completed, continue to react for 2h; then vacuumize to -0.092 MPa, to remove unreacted residual monomers, cool down to 80°C and transfer to post-treatment tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com