Device for printing a three dimensional cosmetic article from a build material comprising a cosmetic formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

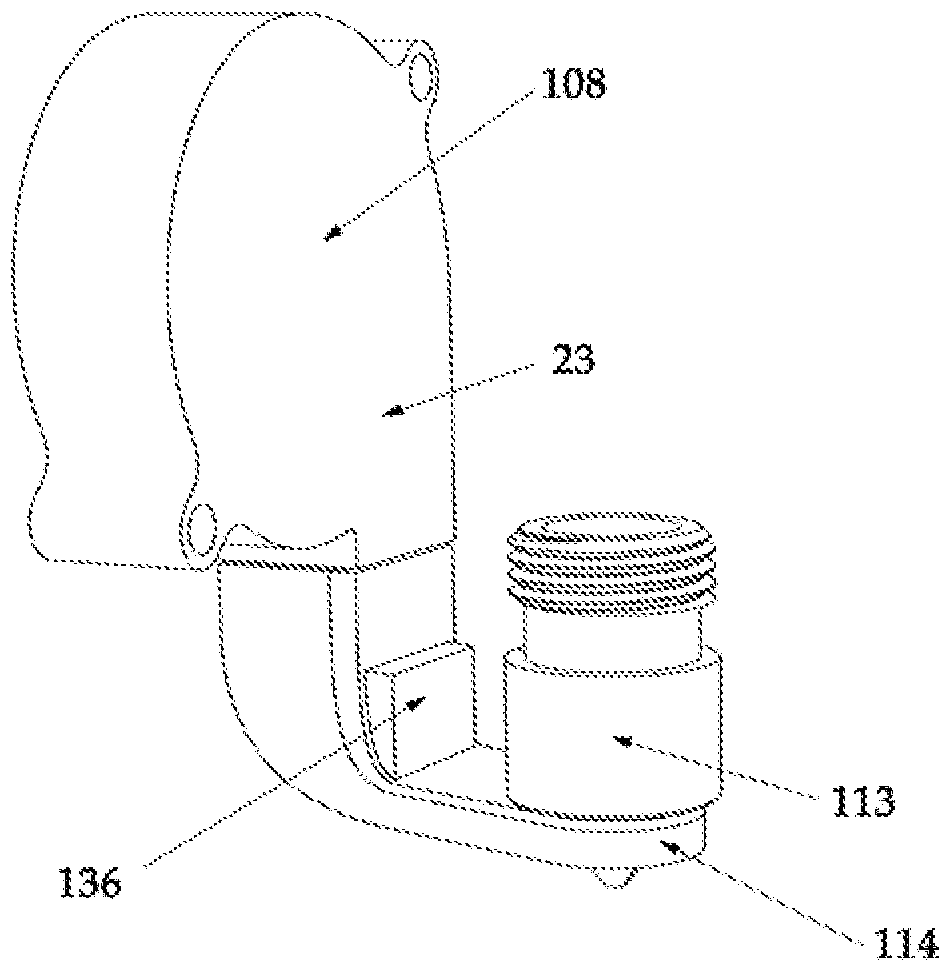

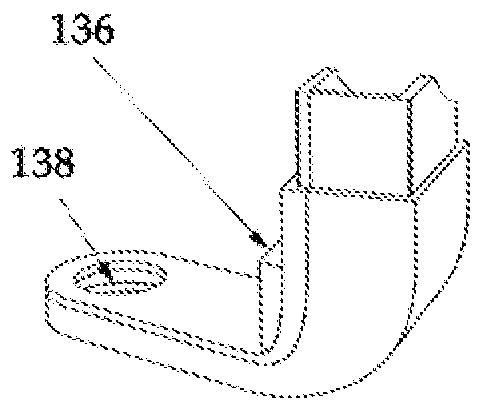

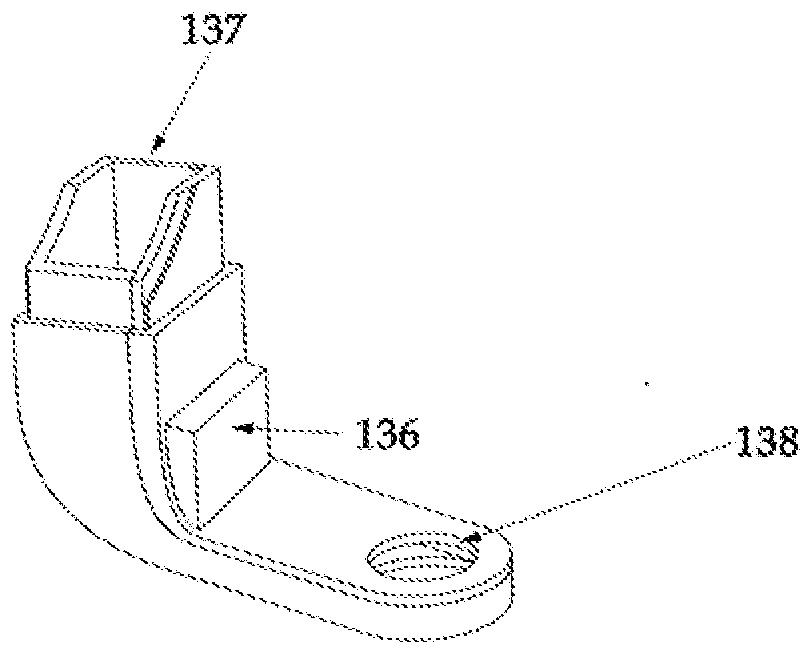

[0029] now refer to Figure 1 to Figure 15 , a device for printing a three-dimensional object from a build material comprising a cosmetic formulation is indicated generally at 2 . The printhead assembly 129 is supported on a base machine 130, such as a MakerBot Replicator2 or similar printer. The base machine has a positioning assembly (shown generally at 27 ) that includes a top frame rail 131 , an x-axis support platform 132 and a carriage rail 134 for supporting and positioning the printhead assembly 129 . Flexible wiring sheath 135 connects printhead assembly 129 to base machine 130 in electrical communication. Printhead assembly 129 includes extruder 4 having piston barrel 105 with inner wall 5 defining cylinder 6 . The cylinder 6 has a first end 7 and a second end 8 . The piston 104 is mounted in the first end 7 of the cylinder 6 such that the piston 104 can be advanced and retracted in the cylinder 6 . The piston 104 has a front wall 9 and a rear wall 10 connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com