High shock-resistant, wear-resistant sport shoe sole material and manufacturing method thereof

A technology for sole materials and sports shoes, applied in the directions of soles, footwear, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

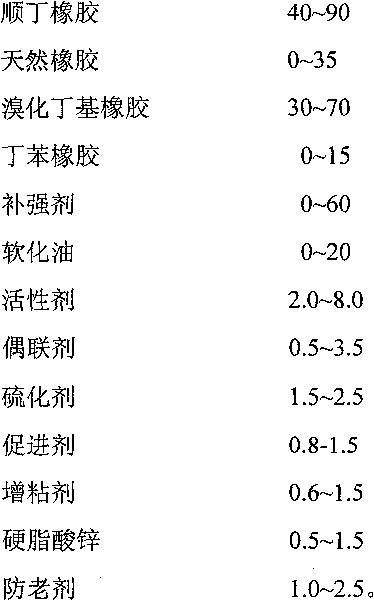

Method used

Image

Examples

Embodiment 1

[0040] The composition (mass ratio) is: 100 parts of BIIR, 50 parts of white carbon black, 5.0 parts of PEG, 5.0 parts of paraffin oil, 2.0 parts of sulfur, 8.0 parts of magnesium oxide (MgO), 1.5 parts of DM, 0.5 parts of M, 0.5 parts of TMTM, Zinc oxide 4.0 parts, zinc stearate 1.0 parts.

[0041] Weigh according to the above ratio, mix according to the above process, and measure the engineering vulcanization time of the mixed rubber at 150°C by a rotorless rheometer. 90 for 1127s. Then molded under the condition of 150 ℃. Place the sample at room temperature 22.0°C for more than 24 hours to test its hardness (ShoreA) 59, and the relative density is 1.19g / cm 3 ;According to the QB / T2884-2007 standard, the DIN wear is 246mm 3 ; According to the GB1040 standard, the tensile strength is 13.1MPa, and the elongation at break is 743%; according to the GB / T 3903.12-2005 standard, the right-angle tear strength is 35N / mm. According to the dynamic viscoelastic performance test, th...

Embodiment 2

[0043] The composition (mass ratio) is: 100 parts of BR, 50 parts of white carbon black, 1.5 parts of DEG, 3.0 parts of PEG, 3.0 parts of coupling agent Si-6, 5.0 parts of naphthenic oil, 1.5 parts of sulfur, 0.9 parts of NS, oxidation 3.0 parts of zinc, 2.0 parts of zinc stearate, 1.0 part of tackifier, 1.0 part of anti-aging agent RD, 1.0 part of anti-aging agent 4020, 1.0 part of microcrystalline wax.

[0044] Weigh according to the above ratio, mix according to the above process, and measure the engineering vulcanization time of the mixed rubber at 150°C by a rotorless rheometer. 90 for 1461s. Then molded under the condition of 150 ℃. Place the sample at room temperature at 22.0°C for more than 24 hours to test that its hardness (ShoreA) is 65, and the relative density is 1.15g / cm 3 ;According to the QB / T2884-2007 standard, the DIN wear is 52mm 3 ; According to the GB 1040 standard, the tensile strength is 11.8MPa, and the elongation at break is 692%; according to the G...

Embodiment 3

[0046] The composition (mass ratio) is: 70 parts of BIIR, 30 parts of BR, 50 parts of white carbon black, 4.5 parts of PEG, 50.9 parts of coupling agent Si-7, 1.85 parts of sulfur, 0.3 parts of NS, 0.35 parts of TMTM, 3.6 parts of zinc oxide, 5.6 parts of magnesium oxide, 1.3 parts of zinc stearate, 0.5 parts of tackifier, 0.5 parts of anti-aging agent 4010A, and 0.5 parts of microcrystalline wax.

[0047] Weighing according to the above ratio, mixing according to the above process, measured by the rotorless rheometer, the engineering positive vulcanization time t90 of the compounded rubber is 694s at 150°C. Then molded under the condition of 150 ℃. Place the sample at room temperature at 22.0°C for more than 24 hours to test that its hardness (ShoreA) is 63, and the relative density is 1.17g / cm 3 ;According to the QB / T2884-2007 standard, the DIN wear is 273mm 3 ; According to the GB1040 standard, the tensile strength is 13.4MPa, and the elongation at break is 673%; accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com