Low temperature resistant polyamide thermosol adhesive and use thereof

A polyamide hot-melt adhesive and adhesive technology, which is applied in the direction of adhesives, etc., can solve the problems of low elongation and low temperature resistance of polyamide hot-melt adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

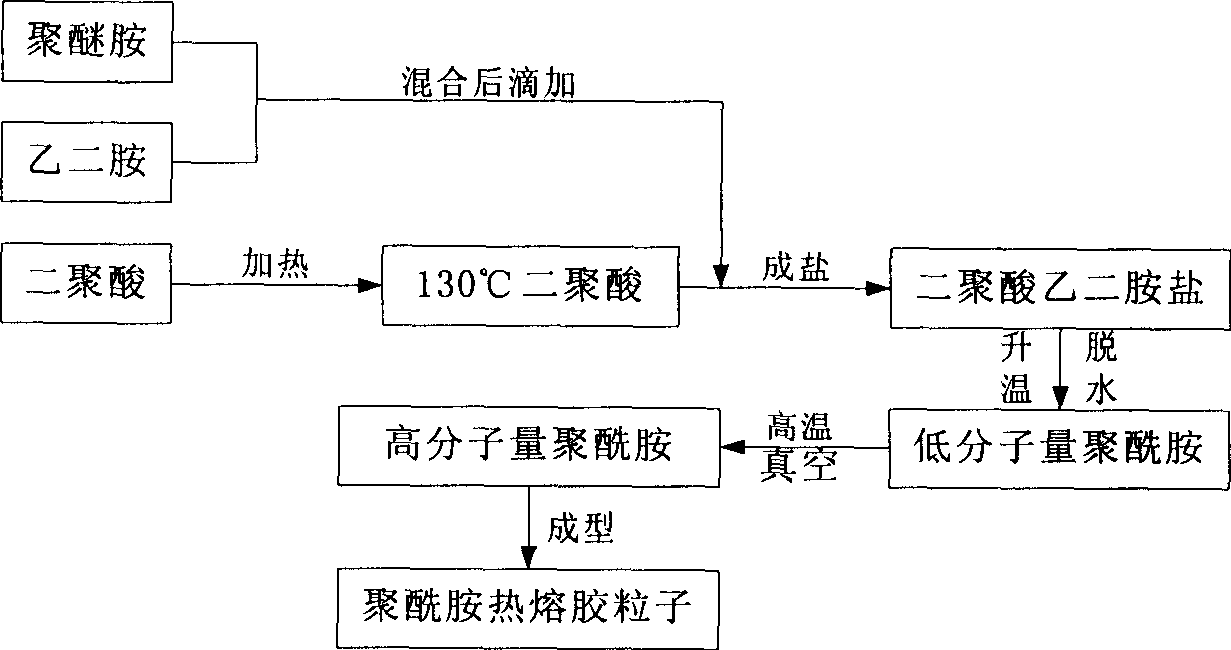

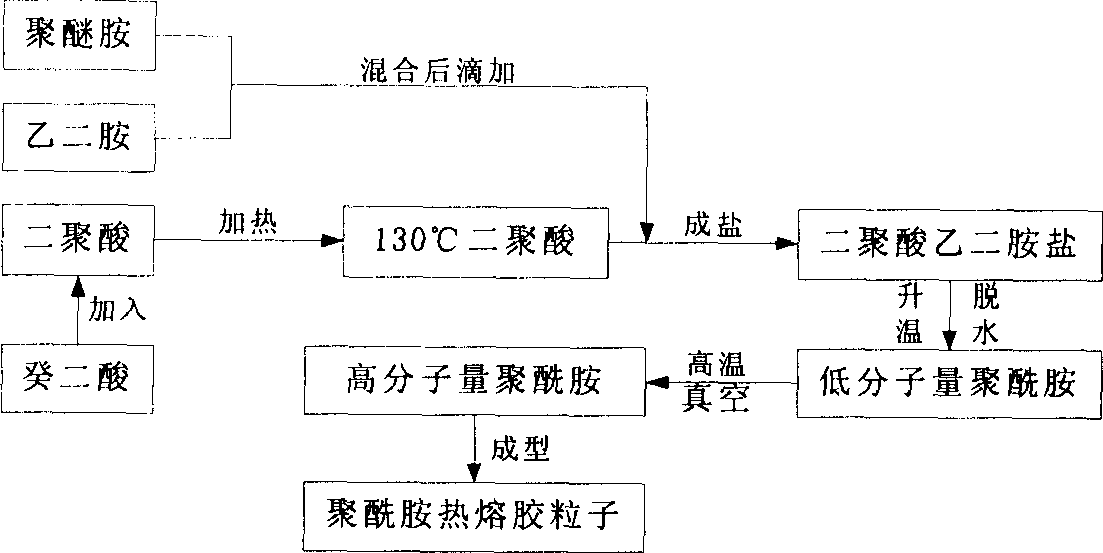

Method used

Image

Examples

Embodiment

[0035] The following examples are used to further illustrate the present invention, but it should be understood that these examples cannot be used to limit the protection scope of the present invention.

[0036] In the following examples, the performance parameters of the polyamide hot-melt adhesive of the present invention were determined as follows.

[0037] Softening point test:

[0038] On the SYP4202-I asphalt softening point tester, the test is carried out with reference to the standard GB / T15332-94.

[0039] Melt viscosity test:

[0040] The melt viscosity of the sample was tested with a Brookfield DV-E rotary viscometer, and 11.0 g of polyamide hot melt adhesive samples were weighed. During the test, the rotor of the model S27 was selected, the temperature was controlled at 160 ° C, and the rotational speed was constantly adjusted to make it The test value is within the linear range of 10% to 90%, and the measured value is recorded after stabilization.

[0041] Dete...

Embodiment 1

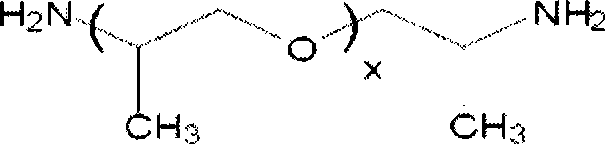

[0069] Add 334.8 grams of dimerized linoleic acid (purchased from Shanghai Huasheng Chemical Co., Ltd., brand GX92) into a 1000ml reaction bottle with a thermometer, a mechanical stirrer, a condenser tube and a nitrogen inlet tube, and in a 100ml constant pressure dropper Load 21.6g of ethylenediamine and 54.7g of polyetheramine D-230, blow in nitrogen, stir, and heat up. When the temperature in the reaction bottle reaches 130°C, add the mixed amine dropwise. The temperature is controlled at 130-140°C. After the addition, start to slowly heat up to about 230°C. During the heating process, water will distill out. When the reaction temperature reaches 230-240°C, use a vacuum pump to decompress and vacuumize. The vacuum degree is <100Pa. When the stirring power reaches a certain value, After the reaction was completed, the vacuum was removed, and the melt was poured on a tetrafluoro plate to obtain a yellow rubber strip (sample 8 in Table 1).

[0070] After drying at 50°C for 24 ...

Embodiment 2-11

[0072] Prepare in the same manner as Example 1, except that different polyetheramines are used in the system, such as D-400 and D-2000, and different ethylenediamine and polyetheramine ratios (sample in table 1 9-18).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com