Stereoscopic offset printing ink prepared by using waste vegetable oil foots as well as preparation method and application of stereoscopic offset printing ink

A technology of waste vegetable oil and offset printing ink, applied in the direction of ink, application, household utensils, etc., can solve the problem of not having a three-dimensional effect, achieve the effect of solving poor drying, improving adhesion fastness, and achieving zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

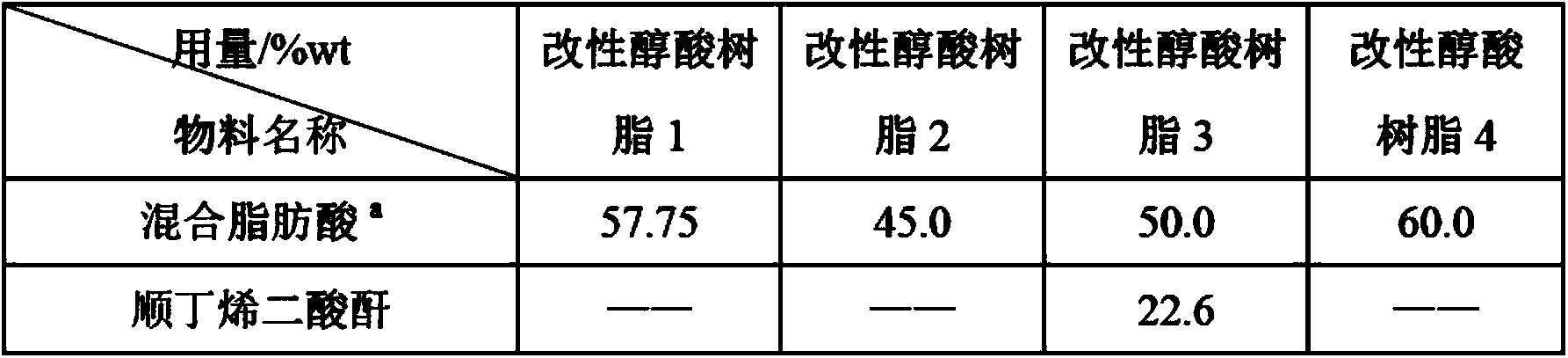

preparation example Construction

[0035] The preparation method of the three-dimensional offset printing ink prepared with waste vegetable oil foot, comprises the following steps:

[0036] 1) Weigh essential linseed oil, rosin modified phenolic resin, dimer acid polyamide resin, modified alkyd resin and fatty acid methyl ester, heat up, after the resin is dissolved, then raise the temperature to 230-235°C, keep warm for 0.5- 1 hour to get the resin binder;

[0037] 2) Add pigments, fillers, and aluminum gelling agent to the resin binder and stir to disperse. Use a three-roller machine to grind the uniformly dispersed material to a fineness of 1-10 μm. Finally, add wax powder to disperse evenly to obtain the product.

[0038] The pigment is at least one of magenta, lisol scarlet, phthalocyanine blue, benzidine yellow, permanent yellow, carbon black, and titanium dioxide.

[0039] The filler is at least one of calcium carbonate, caustic calcium, barium sulfate and talcum powder.

[0040] The aluminum gelling a...

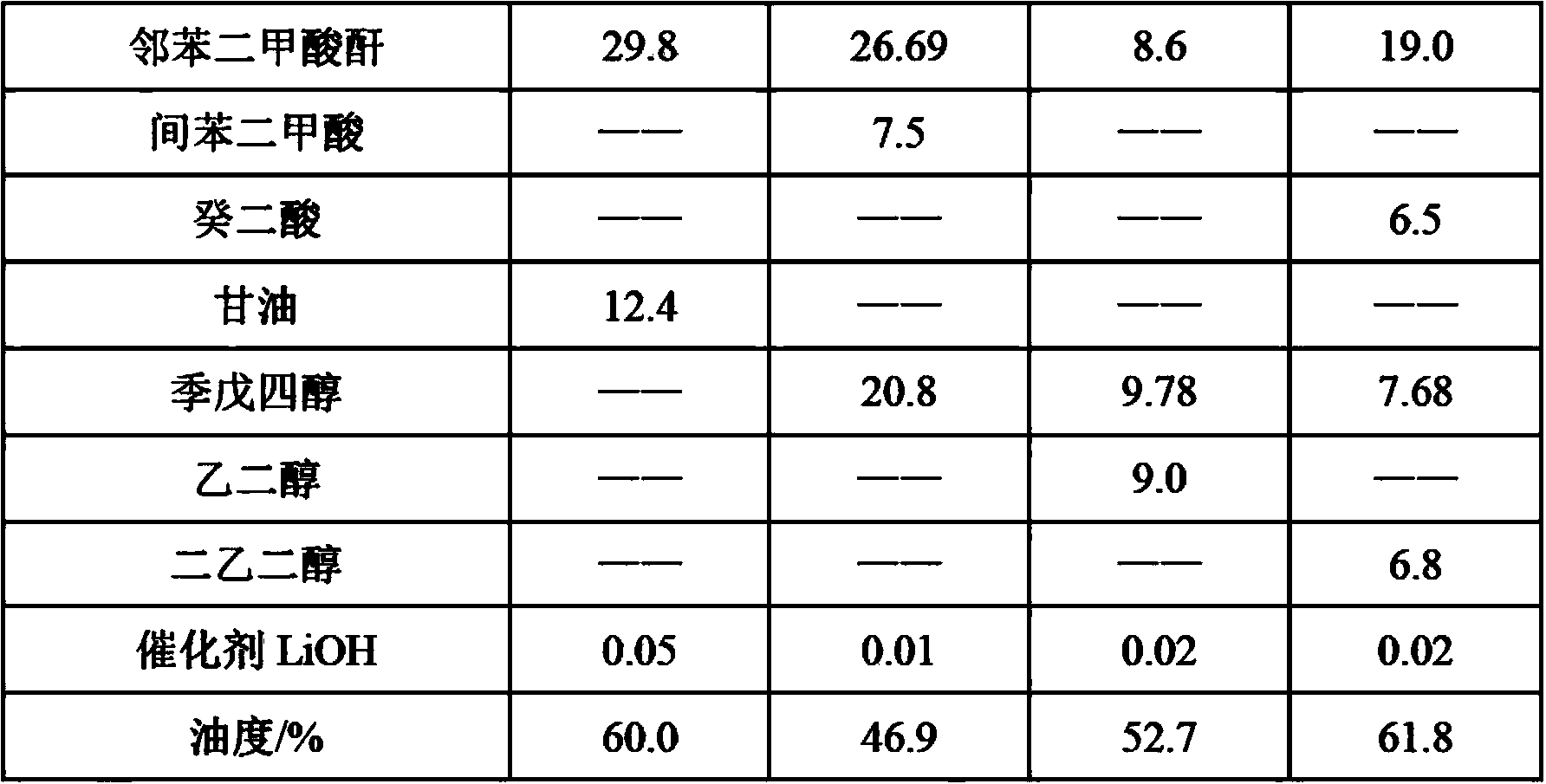

Embodiment 1

[0059] Three-dimensional offset printing ink, its formula composition is as follows:

[0060] Table 2: Formulation composition of three-dimensional offset printing ink

[0061]

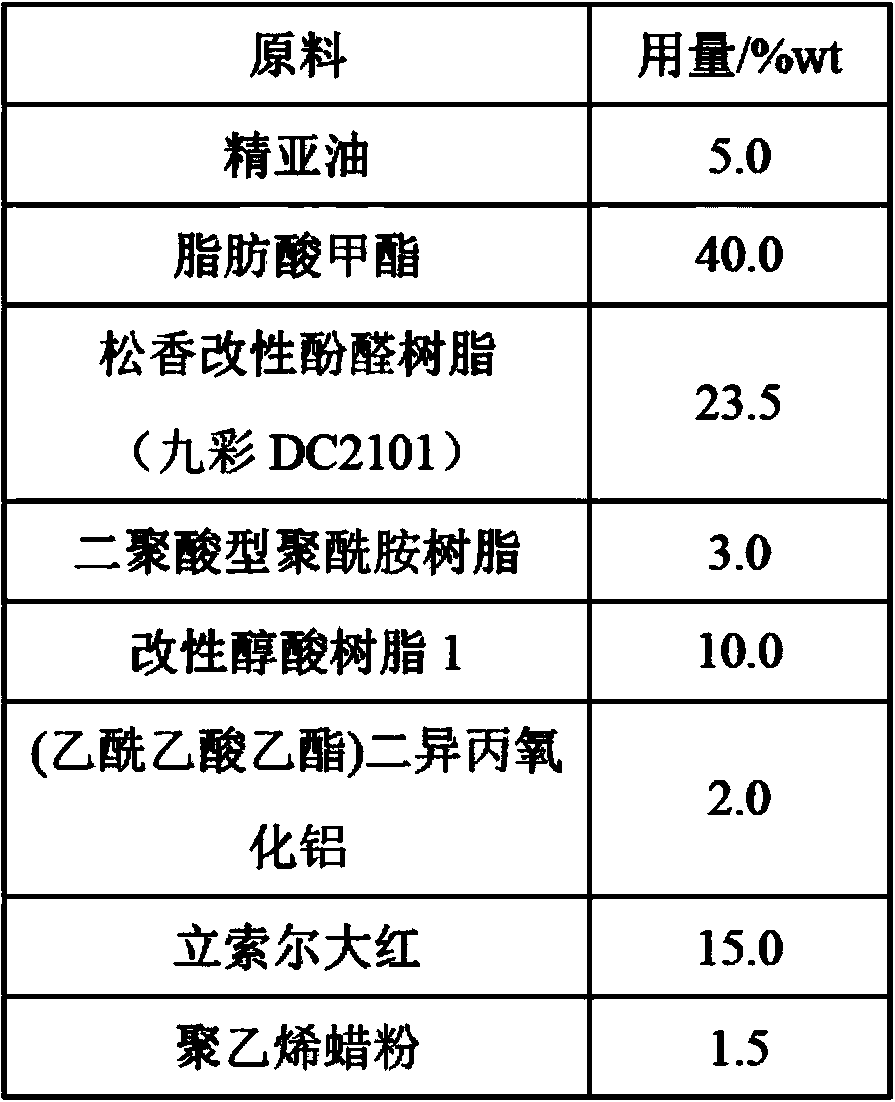

Embodiment 2

[0063] Three-dimensional offset printing ink, its formula composition is as follows:

[0064] Table 3: Formulation composition of three-dimensional offset printing ink

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com