Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

A technology for reconstituting tobacco leaves and processing characteristics, applied in tobacco, tobacco preparation, application, etc., can solve the problems of film running, poor water holding capacity, large aroma loss, etc., achieve uniform width and length, improve sensory quality, and effective utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

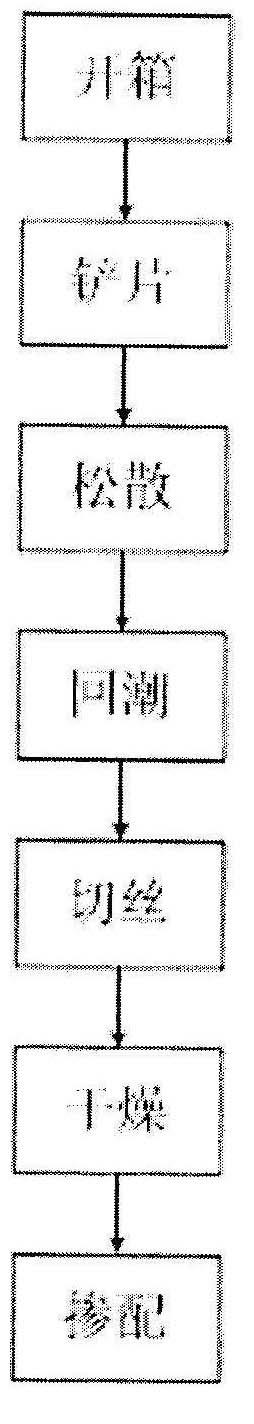

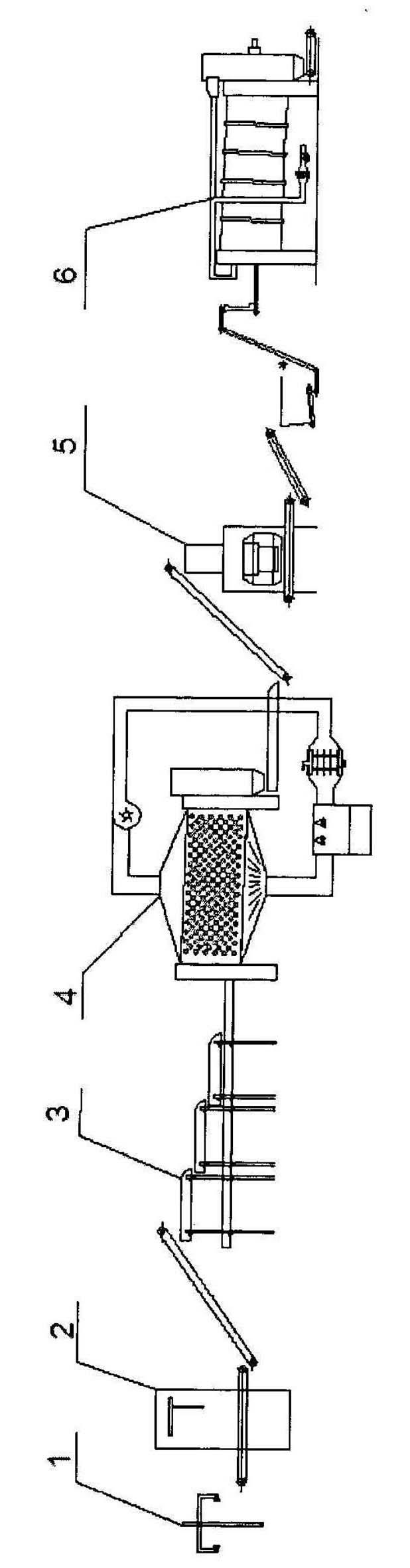

[0033] Such as figure 1 Shown: The present invention's independent silk-making process based on the processing characteristics of reconstituted tobacco leaves by papermaking method includes unpacking, shoveling, loosening, dampening, shredding, drying, and blending processes.

[0034] The individual silk-making process based on the processing characteristics of papermaking reconstituted tobacco leaves will be further described in conjunction with the following examples:

[0035] 1. Unpacking: use the unpacking machine to open the outer packaging of 150kg reconstituted tobacco leaves per box, and send the reconstituted tobacco leaves after removing the outer packaging to the shoveling process.

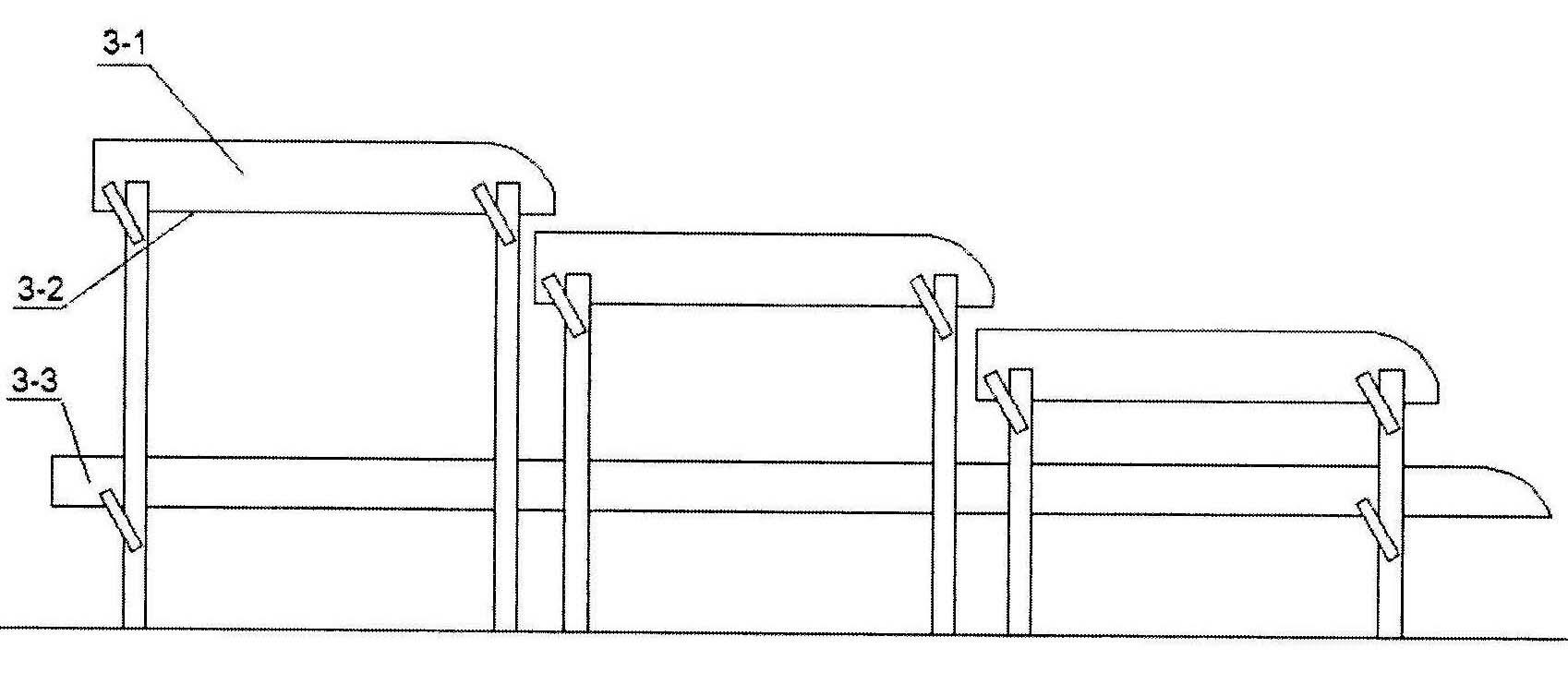

[0036] 2. Shoveling: Shovel the reconstituted tobacco block after removing the outer packaging along the direction of lamination, and each block is shoveled into 5 pieces, and each piece weighs about 30kg according to the weight of its packaging, and is transported to the loosening proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com