Complex of metal and plastic and manufacturing method of complex

A composite and plastic material technology, applied in the field of metal and plastic composites and their manufacturing, can solve problems such as decreased bonding force, and achieve the effects of excellent impact resistance, simplified product structure, and excellent bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

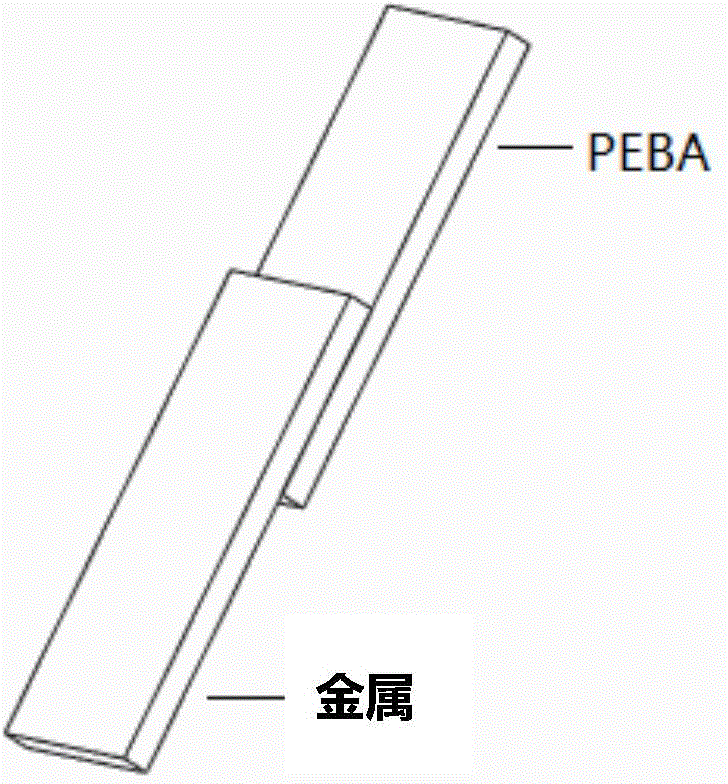

[0028] The preparation method of the metal-plastic composite of the present invention at least includes providing a metal component having the nano-scale concave-convex structure through chemical treatment on the bonding surface, and using the PEBA material to insert the metal component into the mold Implement the combined process.

[0029] According to an embodiment of the present invention, the selected metal material is preprocessed into a metal member (also called a metal member base material) of a designed shape and structure, and the bonding surface of the metal member is chemically treated to form the nanoscale concave-convex structure , can be realized according to conventional methods and existing reported implementations. For example, chemically etching (corroding) a pre-processed (not limited to machining, casting, forging, etc.) metal component base material in a set area to form a nanoscale concave-convex structure through acid and / or alkali treatment, or Combini...

Embodiment 1

[0042] 1. Pretreatment of metal components

[0043] 1) Preprocessing and treatment of metal substrates

[0044] Commercially available aluminum alloy plate A1100, 1.5mm thick, is processed into several rectangular sheets of 50mmx10mm, ground and polished, placed in a cleaning tank, washed with absolute ethanol, and then immersed in 40g / L sodium hydroxide aqueous solution, approx. Take it out for 2-3 minutes, rinse it with deionized water and dry it in the air to obtain a decontaminated and degreased aluminum alloy flake substrate.

[0045] 2) Surface etching of metal substrates

[0046] The aluminum alloy flake base material that has been decontaminated and degreased above is used as an anode and placed in an anodic oxidation tank containing 20 wt% sulfuric acid, electrolyzed at 20V and 18-20°C for 10min, and the aluminum alloy sheet is taken out and dried;

[0047] Soak the obtained aluminum alloy sheet in about 10wt% sodium carbonate solution (pH=12), soak at 20°C for 5-6m...

Embodiment 2

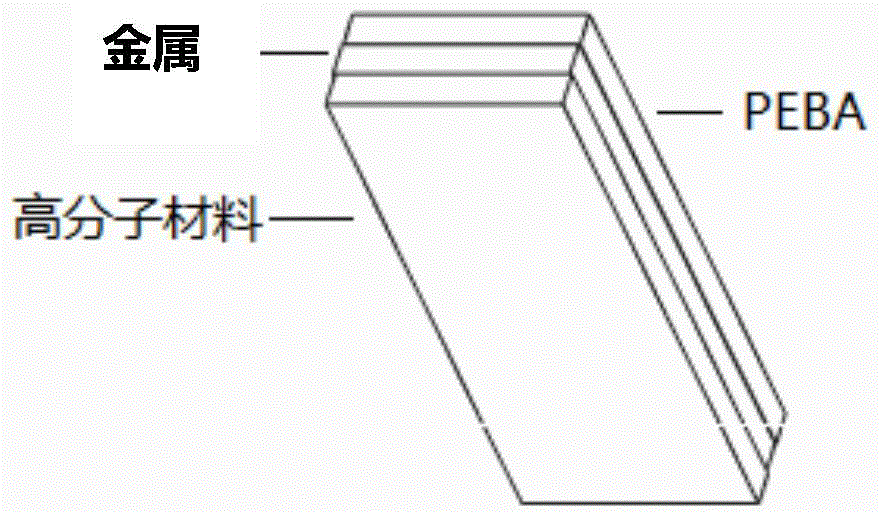

[0072] The selection and pretreatment of the metal substrate (aluminum alloy) are the same as in Example 1. The elastomer is commercially available Arkema4533. Using multiple injection molding processes, first obtain a composite body combining the metal substrate and the PEBA elastomer according to the method of Example 1. , and then use another polymer material: commercially available PPSTOSOSGX-120 (polyphenylene sulfide glass fiber reinforcement) injection molding again, so that the other side of the metal substrate is compounded with different plastic layers.

[0073] Choose different molds according to the needs, and obtain a composite body in which different bonding surfaces of the metal substrate are combined with plastic layers of different materials, such as figure 2 shown.

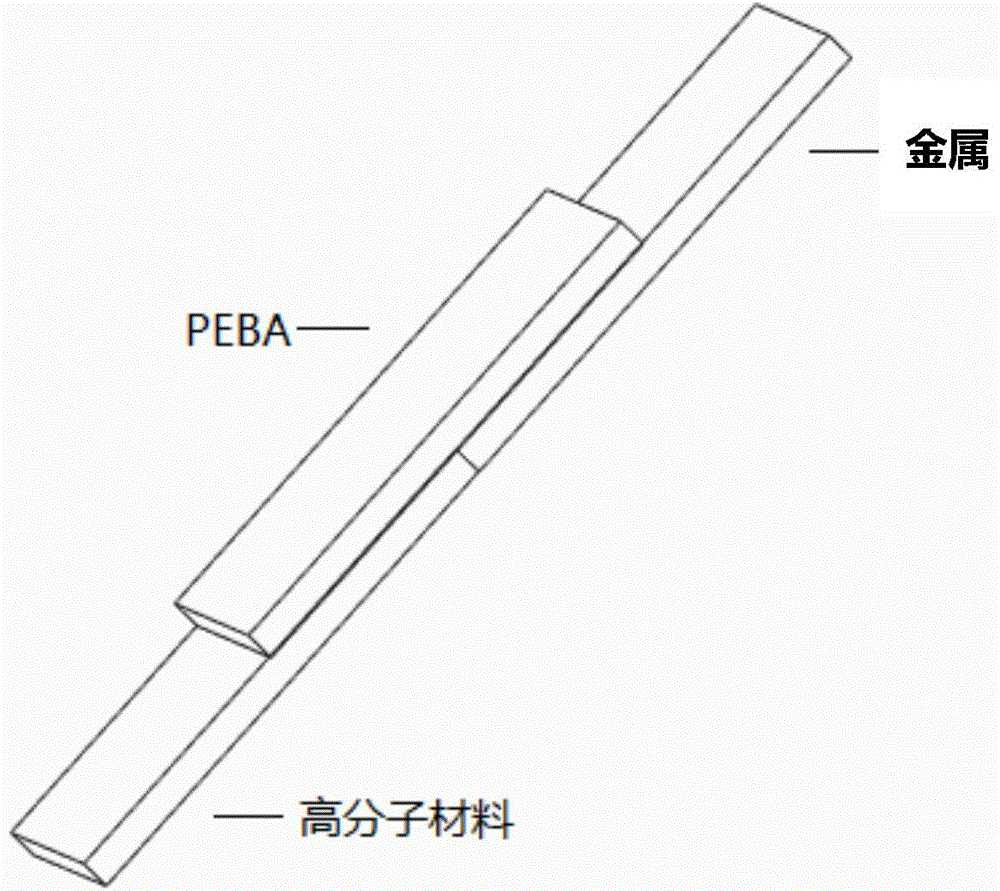

[0074] Similar operations such as image 3 As shown, different regions of a certain joint surface of the metal substrate are combined with composites of plastic layers of different materials th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com