Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about "Organic non-cellulose fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, triglyceride, and optionally acid. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, triglyceride, and optionally acid, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous Structures and Methods for Making Same

PendingUS20170009401A1Easy to optimizeOrganic non-cellulose fibresPaper/cardboardFiberPolymer science

Fibrous structures and more particularly fibrous structures containing a plurality of hydroxyl polymer fibrous elements, for example hydroxyl polymer filaments, such that the fibrous structures exhibit improved surface properties compared to known fibrous structures and methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Water stable compositions and articles comprising starch and methods of making the same

Thermoplastic polymer compositions comprising starch and articles made therefrom are water stable or may be rendered so. One method of making water stable thermoplastic compositions comprises the steps of mixing destructured starch with polyhydric alcohol and acid, and forming an ester condensation reaction product from at least a portion of the polyhydric alcohol and acid. In some embodiments, a pre-polymer formed from the ester condensation reaction may be provided as a pre-polymer that is mixed with the starch.

Owner:THE PROCTER & GAMBLE COMPANY

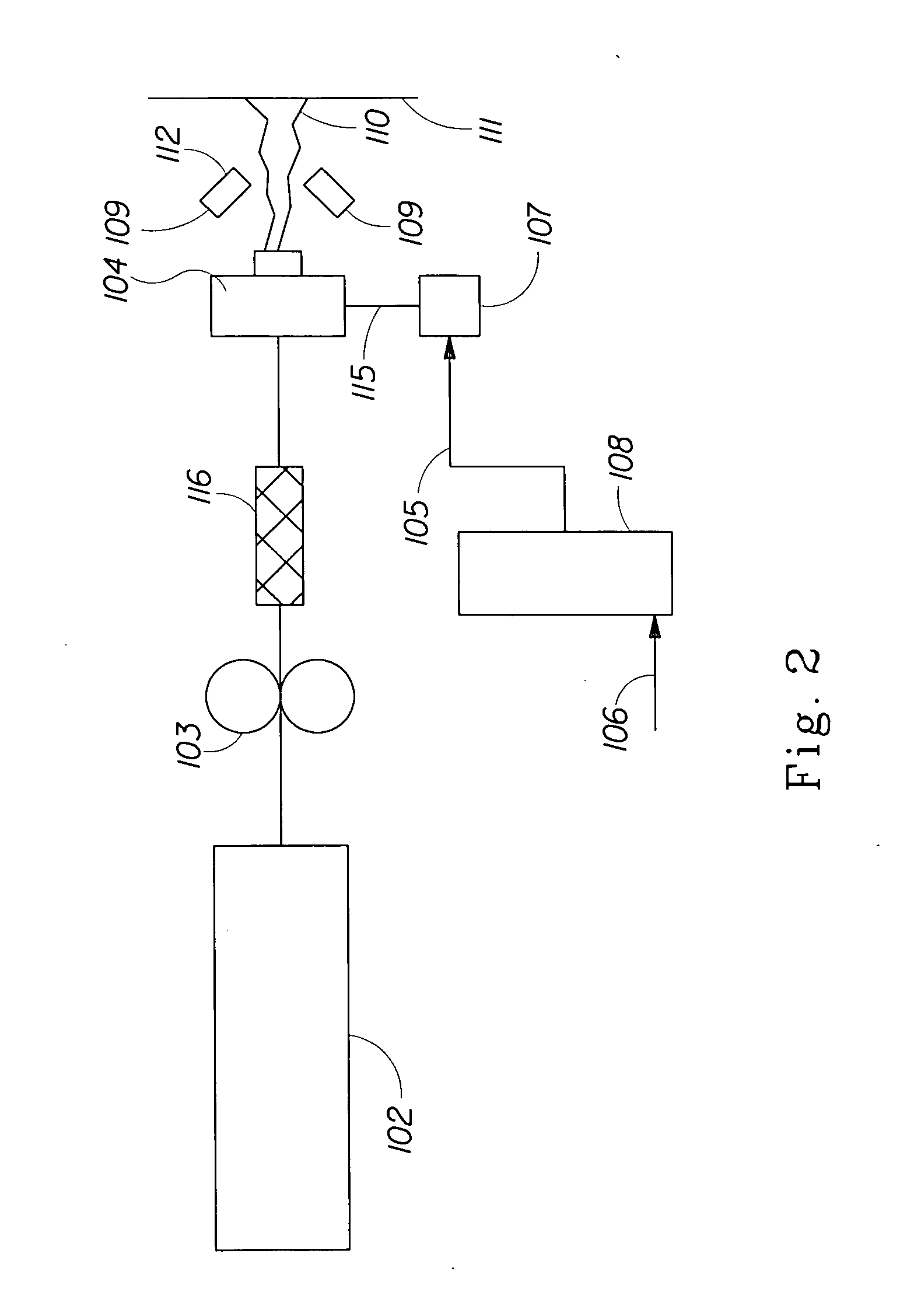

Dispersible and degradable synthetic fiber spunlace nonwoven fabric and preparation method thereof

ActiveCN105463703ANo pollutionGuaranteed dry and wet strengthOrganic non-cellulose fibresPaper/cardboardNatural fiberSynthetic fiber

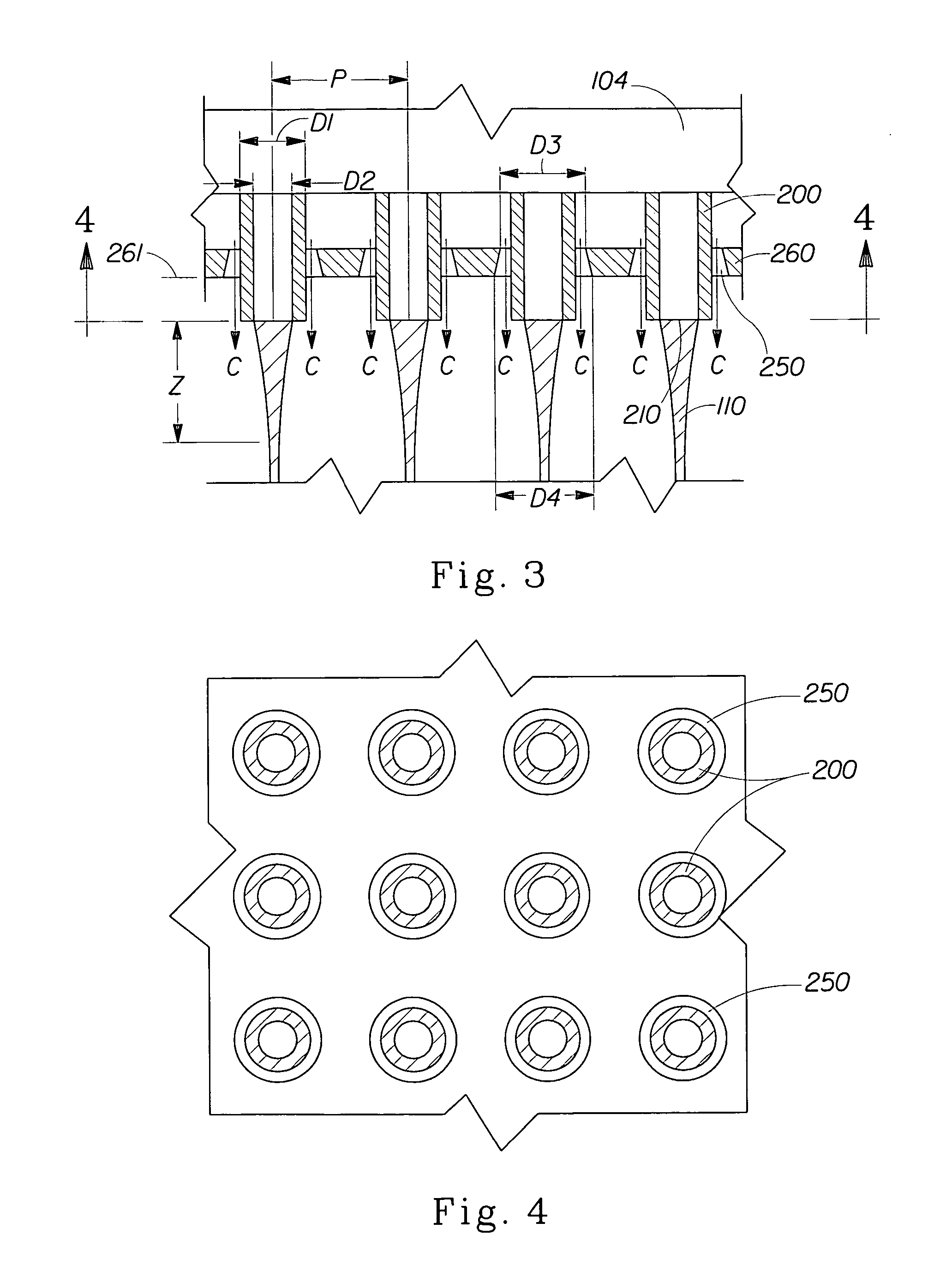

The invention discloses a dispersible and degradable synthetic fiber spunlace nonwoven fabric and a preparation method thereof and belongs to the technical field of nonwoven products and preparation thereof. According to the preparation method, 50-95% of natural cellulose fibers and 5-50% of artificial cellulose fibers are selected; the natural cellulose fibers are smashed through a hydraulic smashing machine and then ground through a large-taper refiner and a double-disk grinder to obtain natural cellulose fiber paste; the artificial cellulose fibers are decomposed into artificial cellulose fiber suspension liquid for use; the natural cellulose fiber paste is sent into a primary flushing tank and a secondary flushing tank; the artificial cellulose fiber suspension liquid is sent into an inclined wire flow box to form a uniform fiber net; after water on the fiber net is absorbed, the fiber net is transferred into a pre-spunlace area on the lower portion of the flow box for pre-spunlace; the fiber net is punctured by high-pressure squirt cutters and rebounds, and fibers are entangled. Pollution to a human body and the environment is not caused; fracture resistance and tear resistance of the spunlace nonwoven fabric are improved; better anti-static performance and anti-microbial performance are achieved; water dispersibility is good; the fibers are distributed uniformly.

Owner:SUZHOU MESON NONWOVEN TECH

Water stable compositions and articles comprising starch and methods of making the same

Thermoplastic polymer compositions comprising starch and articles made therefrom are water stable or may be rendered so. One method of making water stable thermoplastic compositions comprises the steps of mixing destructured starch with polyhydric alcohol and triglyceride, and forming a transesterification reaction product from at least a portion of the polyhydric alcohol and triglyceride.

Owner:THE PROCTER & GAMBLE COMPANY

Water stable fibers and articles comprising starch, and methods of making the same

InactiveUS20070079945A1Improve water stabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, acid, and optionally triglyceride. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, acid, and optionally triglyceride, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

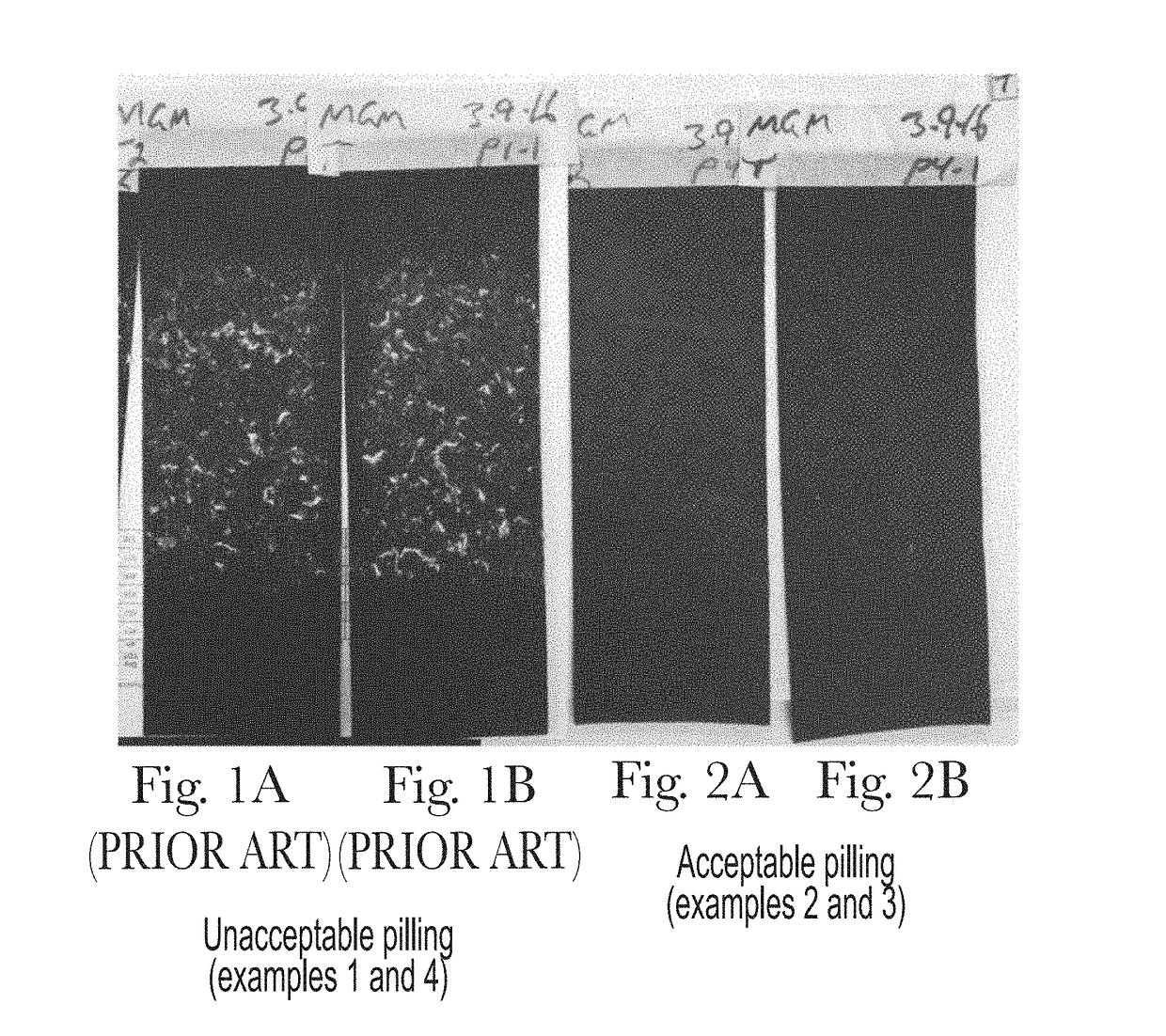

Hybrid Fiber Compositions and Uses in Containerboard Packaging

ActiveUS20140093704A1Cellulosic pulp after-treatmentNon-fibrous pulp additionCardboardFiber composition

The present invention relates to a containerboard packaging material comprising at least one non-wood alternative pulp material wherein said non-wood alternative pulp material is present in an amount of from about 5% to about 100% and wherein said material replaces at least a portion of conventional fiber materials.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polysaccharide structures comprising an unsubstituted polysaccharide and processes for making same

ActiveUS20060134412A1Organic non-cellulose fibresMonocomponent cellulose artificial filamentFiberPolysaccharide

Polysaccharides, more particularly, polysaccharide structures, especially fibers, comprising an unsubstituted polysaccharide, webs comprising such polysaccharide structures and processes for making such polysaccharide structures and / or webs are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Poly alpha-1,3-glucan fibrids and uses thereof and processes to make poly alpha-1,3-glucan fibrids

ActiveUS20180119357A1Organic non-cellulose fibresPlastic/resin/waxes insulatorsCrystallographyPolymer science

The disclosure relates to poly alpha-1,3-glucan fibrids and methods for making them. Also disclosed uses for the fibrids, including paper-making and use as an emulsifier.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Paper for painting and calligraphy and manufacturing process of paper for painting and calligraphy

ActiveCN106283837AWith flame retardant effectImprove waterproof performanceOrganic non-cellulose fibresWater-repelling agents additionHigh volume manufacturingPolyvinyl alcohol

The invention provides paper for painting and calligraphy. The paper for painting and calligraphy is prepared from, by weight, 10-30 parts of bamboo pulp, 50-80 parts of herba junci setchuensis pulp, 5-20 parts of wood pulp, 5-15 parts of water-soluble polyvinyl alcohol fibers, 5-20 parts of silk, 0.01-1 part of starch adhesive and 0.001-0.5 part of a waterproof agent. The starch adhesion is prepared from starch, carbamido resin, sodium bromide, ammonium chloride and water. The invention further discloses a manufacturing process of the paper for painting and calligraphy. By addition of the starch adhesive according to a specific formulation, the paper for painting and calligraphy has flame-retardant and fireproof effects; due to addition of the silk, light weight, thinness and softness of the paper are achieved; by spraying of the waterproof agent, water resistance of the paper is improved. The manufacturing process is suitable for large-batch production, and operation efficiency is improved.

Owner:ZHEJIANG VOCATIONAL COLLEGE OF COMMERCE

Multi-ply Fibrous Structures

Owner:THE PROCTER & GAMBLE COMPANY

Tissue product with silk fibers and method of making the same

InactiveUS20060108082A1Natural cellulose pulp/paperOrganic non-cellulose fibresMaterials scienceSilk fiber

A tissue product comprising a plurality of first fibers and a plurality of silk fibers and a method of making the tissue product wherein the silk fibers are a different color than the color of the first fibers, as assessed by the human naked eye.

Owner:THE PROCTER & GAMBLE COMPANY

Structures comprising an association agent and processes for making same

ActiveUS20060134411A1Organic non-cellulose fibresMonocomponent cellulose artificial filamentFiberPolysaccharide

Polysaccharides and / or hydroxyl polymers, more particularly, structures, especially fibers, comprising a polysaccharide and / or hydroxyl polymer and an association agent, fibrous structures comprising such structures and processes for making such structures and / or fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous Structures Different Fibrous Elements

PendingUS20170284025A1Improve surface propertiesTransportation and packagingArtificial filament washing/dryingFiberPolymer science

Owner:THE PROCTER & GAMBLE COMPANY

Production method of oil-proof food wrap paper

The invention discloses a production method of oil-proof food wrap paper. The production method includes the steps of subjecting polylactic acid fibers to modified treatment; preparing modified polylactic acid fibers into an aqueous solution, heating and regulating a pH value; adding sodium alginate and microcrystalline cellulose for ultrasonic treatment prior to stirring so as to obtain a polylactic acid fiber solution; adding xylanase into pulp and beating so as to obtain mixed pulp; conducting papermaking, namely diluting the polylactic acid fiber solution obtained from modified treatment of the polylactic acid fibers, adding the diluted polylactic acid fiber solution into the diluted mixed pulp with mixing evenly, adding chitosan, microfibrillated cellulose and silica sol and conducting dewatering pressing so as to obtain a wet paper web; preparing a carboxymethyl chitosan solution and a cationic guar gum solution, mixing the two solutions, and subjecting the wet paper web to surface sizing in the papermaking step so as to obtain the oil-proof food wrap paper. The oil-proof food wrap paper produced from a natural polymer assistant is simple in production method, safe and nonhazardous, and has excellent oil-proof performance and high surface strength.

Owner:SHAANXI UNIV OF SCI & TECH

Dispersion processing aids for the formation of a leather material

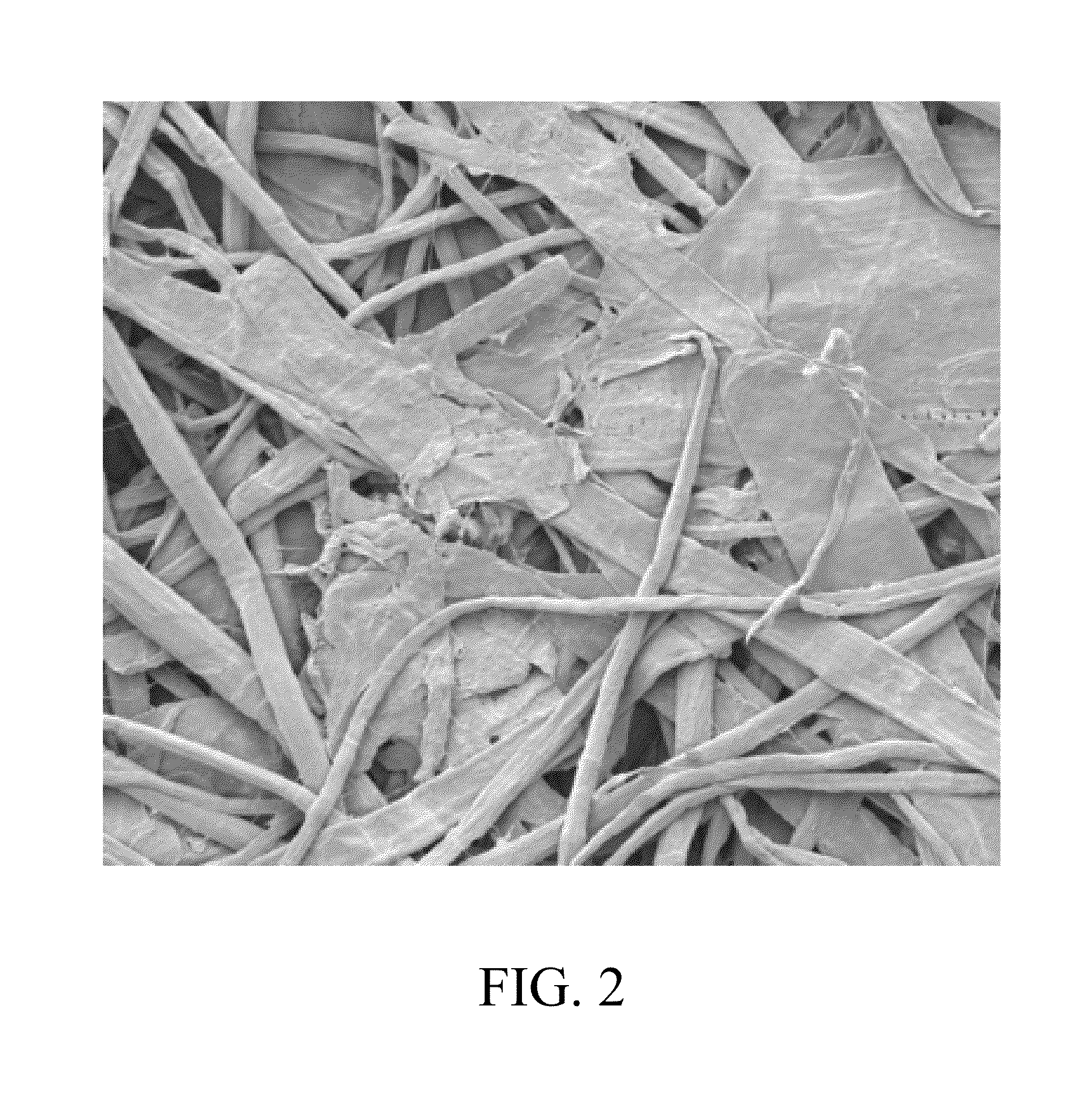

ActiveUS10138595B1Accelerates the dehydration processFacilitate physically manipulatingOrganic non-cellulose fibresComposite leathersFiberEngineering

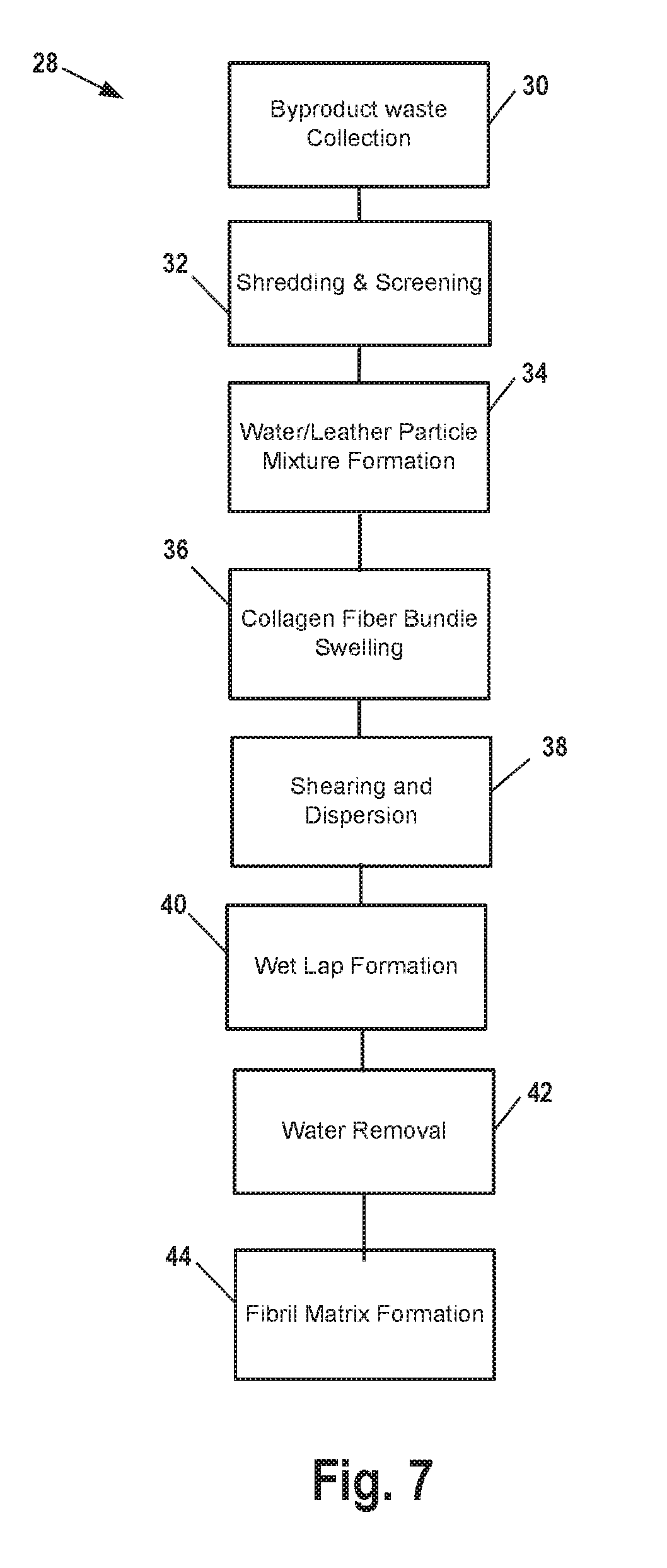

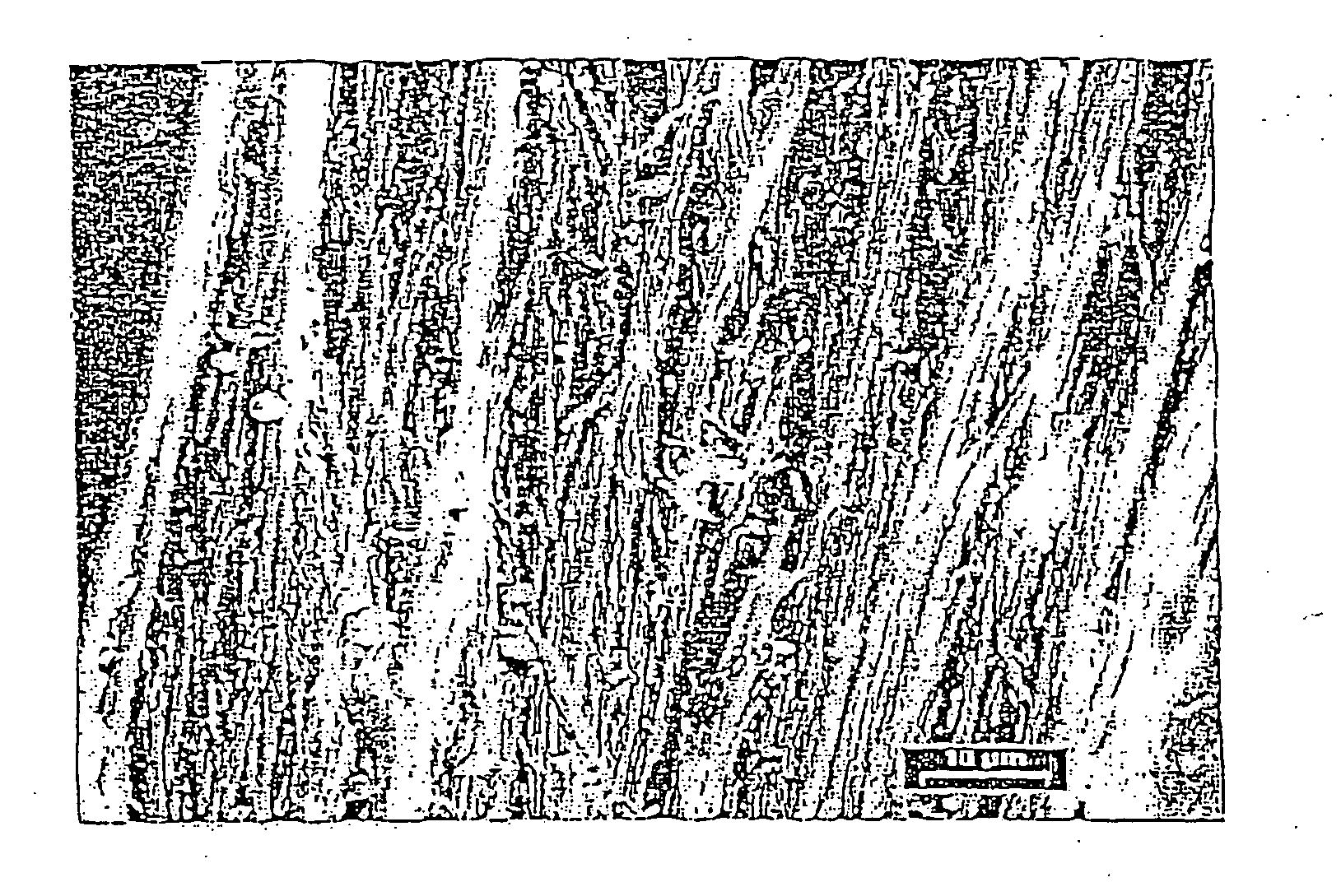

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

Polysaccharide structures comprising an unsubstituted polysaccharide and processes for making same

Owner:PROCTER & GAMBLE CO

Method for preparing chitosan fiber paper-based material based on wet paper-making technology

InactiveCN109235105AImprove physical strengthTensile strength can be adjustedPulp properties modificationOrganic non-cellulose fibresChemical industryFiber

The invention discloses a method for preparing a chitosan fiber paper-based material based on a wet paper-making technology. The method comprises the following steps: adding a chitosan fiber materialinto deionized water and an acid or alkali solution of alkene, performing pretreatment, cleaning the pretreated fiber and performing pulping treatment; and diluting the fiber pulp obtained through pulping to obtain fiber suspension, and performing dehydrating and drying treatment by a paper-making former to prepare a chitosan fiber paper base material; or according to the requirements, performingdipping or surface coating treatment on the prepared chitosan fiber paper base material and drying again to obtain a material needing special application. The method is simple and convenient to operate, low in cost and convenient in industrialized product; the production cost of the chitosan material can be greatly reduced; and wide application prospect in the aspects of medical treatment, daily-use chemical industry and special materials is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Sheet forming binder, container, sheet forming apparatus, sheet forming method, and powder set

Owner:SEIKO EPSON CORP

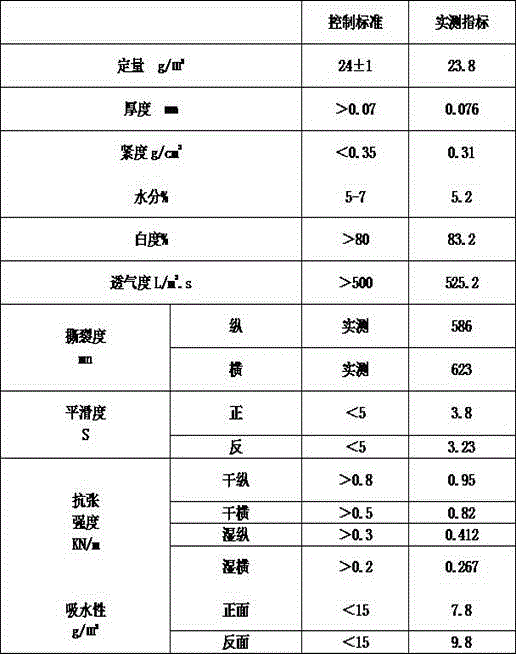

Breathable medical adhesive tape base material and manufacturing method thereof

ActiveCN106012658AIntertwinedSoft and bulky textureOrganic non-cellulose fibresWater-repelling agents additionPolyesterFiber

The invention relates to the field of base materials of medical supplies, in particular to a breathable medical adhesive tape base material and a manufacturing method thereof. The manufacturing method of the breathable medical adhesive tape base material comprises the following steps: (1) carrying out mild pulping treatment on wood pulp fibers, increasing degree of beating by 2-8 degrees of SR, mixing the wood pulp fibers with polyester fibers and water-soluble fibers, and adding a wet strength agent in mixed fibers; (2) manufacturing paper by using the mixed fibers through a cylinder paper machine or an inclined wire machine, carrying out enhancement through surface sizing, and drying and reeling to obtain finished products, wherein the mass percents of the wood pulp fibers, the polyester fibers and the water-soluble fibers respectively account for 50-75%, 20-45% and 1-5% of the mass percent of fibers in breathable medical adhesive tape paper, and the sum of the mass percents of the various components is 100%. A manufacturing process of the method is simple, and the prepared medical adhesive tape base material has the characteristics of high strength, good flexibility, high bulk, high breathability, good evenness and easiness in tearing.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, acid, and optionally triglyceride. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, acid, and optionally triglyceride, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:NODA ISAO +3

Production of pulp and materials utilizing pulp from fibrous proteins

A pulp material that comprises a fibrous protein fiber is suitable for incorporation into paper or paper composites. The fibrous protein of the fibrous protein fiber is typically a keratin, fibrin, collagen, or elastin. Preferably, the fibrous protein is a collagen, such as a β-keratin. The β-keratin can be obtained from avian feathers, such as chicken feathers. The pulp material can further comprise at least one additive such as mordants. dyes. binders. foaming agents. hardeners. chemical sizing agents, fillers. wetting agents. plant fibers, or animal fibers. The pulp material can be treated with a crosslinking agent or an oxidizing agent. Other aspects of the invention include a biodegradable polymer comprising the pulp material and a filter comprising the pulp material. Still another aspect of the invention is a composite material comprising: (1) the pulp material; and (2) a fiber selected from the group consisting of an animal fiber and a plant fiber. Still another aspect of the invention is a multilayer material comprising: (1) a first layer that is the pulp material; and (2) a second layer including a material selected from the group consisting of paper and a biopolymer.

Owner:LICATA CARLO

Method for wet-making filter tip rod paper by using PLA fiber

ActiveCN110528335AEasy to processUniform indexSurface covering paperNon-fibrous pulp additionFiberVitrification

The invention provides a method for wet-making filter tip rod paper by using PLA fiber. The method comprises the following steps: (1) performing beating treatment on a fiber material containing polylactic acid; (2) diluting the above-mentioned mixed slurry, adding an auxiliary agent, then carry out forming treatment on a net, and then performing net section, pressing dehydration, and drying treatment to obtain dry paper sheets; and (3) coiling and cutting the dry page sheets in turn to obtain the filter tip rod paper. The filter tip rod paper is easy to process and form, has uniform indexes and good quality stability, and also has a good cooling effect. In addition, the fiber raw materials used in the method are all degradable, and green and environment-friendly, the glass transition temperature is low, and the cooling effect is good. The process is simple and practicable, the cost is low, production efficiency is high, and the filter tip rod paper with excellent properties and good smoking experience can be obtained.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Stacking-assembled reinforced paper base as well as preparation method and application thereof

ActiveCN107524043AImprove physical performanceRich chargeOrganic non-cellulose fibresPaper/cardboardFiberPaper based

The invention discloses a stacking-assembled reinforced paper base as well as a preparation method and an application thereof. The preparation method of the paper base comprises the following steps: (1) mixing nanocellulose with water to obtain a nanocellulose suspension; (2) hydrolyzing chitin with an acid to obtain a nano-chitin whisker suspension; (3) adding a Na2SO4 solution and the nano-chitin whisker suspension obtained in the step (2) to coniferous wood paper pulp, regulating pH, and performing stirring and deposition to obtain composite fibers I; (4) adding the Na2SO4 solution and the nanocellulose suspension obtained in the step (1) to the composite fibers I obtained in the step (3), regulating pH, stirring the mixed solution, and depositing a second layer on the composite fibers I to obtain composite fibers II; (5) repeating the step (3) and the step (4), and making paper from the stacking-assembled composite fibers to obtain the stacking-assembled reinforced paper base. The obtained stacking-assembled reinforced paper base can be applied to the field of special paper, food packaging or antibacterial materials.

Owner:SOUTH CHINA UNIV OF TECH

Methods for producing ultrafine fiber and ultrafine fiber-containing sheet, sheet obtained thereby, and resin composite comprising laminated resins

ActiveUS20170183820A1Low linear thermal expansion coefficientFlexibilityPaper/cardboardIdentification meansPhosphoric acidMachining process

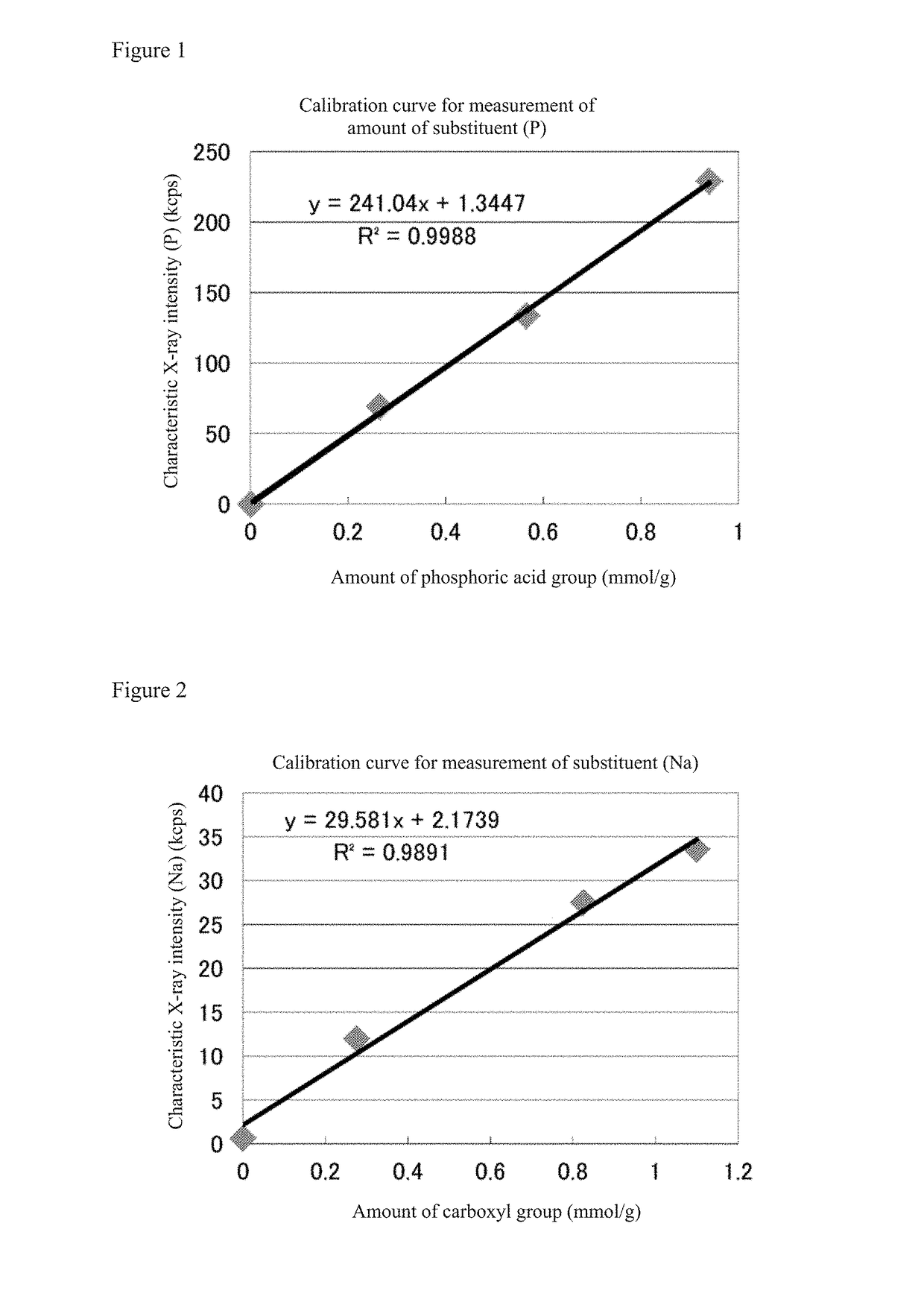

An object of the present invention is to provide a method for producing an ultrafine fiber-containing sheet with suppressed yellowing. Another object of the present invention is to provide an efficient method for eliminating an introduced substituent, and a composite sheet comprising an organic layer and / or an inorganic layer laminated on the obtained sheet. The present invention provides a method for producing an ultrafine fiber-containing sheet, comprising (a) introducing a substituent having electrostatic and / or steric functionality to a fiber raw material to obtain substituent-introduced fiber; (b) machine-processing the substituent-introduced fiber obtained in the step (a) to obtain substituent-introduced ultrafine fiber; (c) preparing a sheet from the substituent-introduced ultrafine fiber obtained in the step (b); and (d) eliminating at least a portion of introduced substituents from the sheet obtained in the step (c). In a preferred aspect, the substituent having electrostatic and / or steric functionality is a phosphoric acid-derived group, and the method may further comprise, after the step (a) and before the step (c), the step of (e) changing the degree of neutralization of the substituent-introduced fiber or the substituent-introduced ultrafine fiber.

Owner:OJI HLDG CORP

Slurry for drum paper of horn

ActiveCN108978326AHigh strengthHigh elastic modulusOrganic non-cellulose fibresWater-repelling agents additionGlass fiberSlurry

The invention discloses slurry for drum paper of a horn. The slurry is prepared from the following components: wood pulp cellulose, cotton fibers, natural silk, wool fibers, bulletproof fibers, nano cellulose, special fibers, glass fibers, coal ash, phenolic resin, hydroxyethyl cellulose, a flow aid and filter aid, a dye, a sizing agent and a dispersant polyoxyethylene (PEO). The slurry is specifically prepared by the following steps: first, defibering and dispersing the wood pulp cellulose, cotton fibers, nano cellulose and the like to prepare mixed fiber slurry; then adding the chemical reagents; making paper through a paper machine; and then preparing the drum paper for the horn containing nano cellulose by means of follow-up and conventional preparation methods of the drum paper. The drum paper prepared by mixing the three fibers has excellent rigidity, soft performance and relatively high Young modulus, so that the clearness of high audio in the drum paper is improved greatly andthe service life of the drum paper is prolonged greatly.

Owner:SOUTH CHINA UNIV OF TECH

Waste leather treatment method

ActiveCN107287975AEasy to handleIncrease profitMonocomponent protein artificial filamentOrganic non-cellulose fibresFiberBacillus licheniformis

The invention discloses a waste leather treatment method. The method comprises steps as follows: (1), leather pretreatment: cleaned leather is soaked in acid liquor and then is cleaned and spin-dried, and the leather is cut into pieces and subjected to coarse grinding for standby application; (2), beating: the ground leather is soaked in alkali liquor for 3-5 h at the temperature of 30-40 DEG C, then the leather is soaked in an aqueous solution containing bacillus subtilis and bacillus licheniformis for fermentation, the leather and bacterium-containing water are put in a beater and subjected to beating, and pasty collagenous fibers are obtained; (3), wringing and stretching: the pasty collagenous fibers are laid on a pass-type wringing machine and wrung by the pass-type wringing machine, and the moisture content of the wrung collagenous fibers is 80%; (4), papermaking: the wrung collagenous fibers are added to softwood pulp, and paper is made. The bacillus subtilis and the bacillus subtilis are adopted for fermenting the leather, so that the extraction rate of the collagenous fibers can be increased, the leather treatment effect is good, the utilization value is high, and no secondary pollution is produced.

Owner:台州中知英健机械自动化有限公司

Medical paper towel for disinfection and sterilization

InactiveCN108103847AImprove antibacterial propertiesImprove the bactericidal effectOrganic non-cellulose fibresSpecial paperFiberPolyvinyl alcohol

The invention discloses a medical paper towel for disinfection and sterilization. The medical paper towel is prepared from the following raw materials: paper pulp, cationic starch, cotton fibers, acetate fibers, silks, a wet strength agent, an antimicrobial agent, chitosan, sodium alginate and polyvinyl alcohol. The medical paper towel for disinfection and sterilization provided by the invention has good antibiosis, sterilization and disinfection effects, effectively avoids infection and also has favorable comfort and softness.

Owner:HEFEI C&P NONWOVEN PROD

Multi-ply fibrous structures

ActiveUS20220090329A1Organic non-cellulose fibresSpecial paperMechanical engineeringMaterials science

Owner:PROCTER & GAMBLE CO

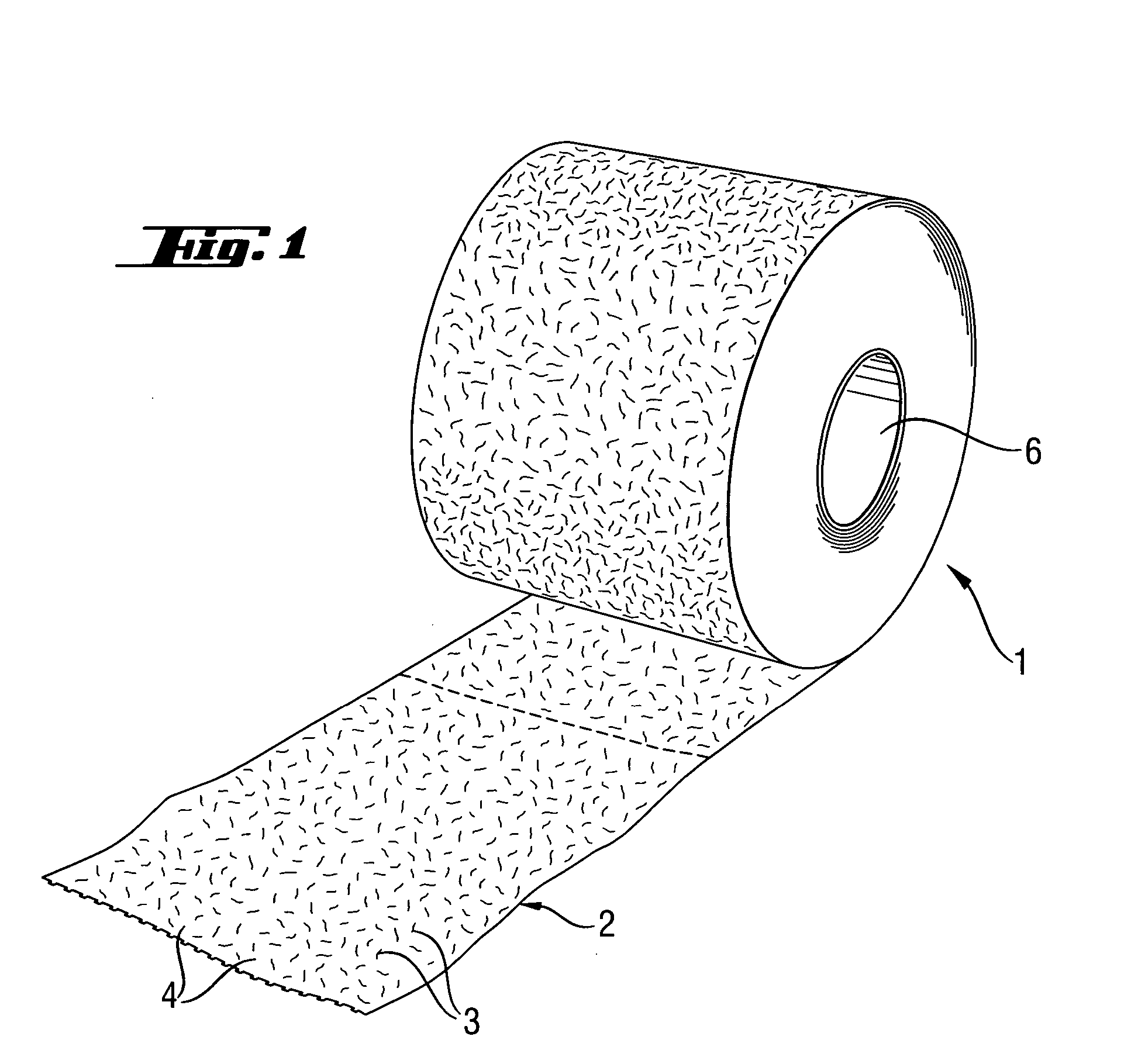

Toilet Tissue Comprising a Non-Clingy Surface

ActiveUS20210123190A1High water/moisture contentIncrease moisture contentOrganic non-cellulose fibresPaper/cardboardBiomedical engineeringAnatomy

Owner:THE PROCTER & GAMBLE COMPANY

Popular searches

Filament/thread forming Monocomponent polyolefin artificial filament Yarn Thin material handling Monocomponent polyesters artificial filament Artificial filament chemical after-treatment Monocomponent polyamides artificial filament Absorbent pads Woven fabrics Conjugated synthetic polymer artificial filaments

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com