Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about "Composite leathers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

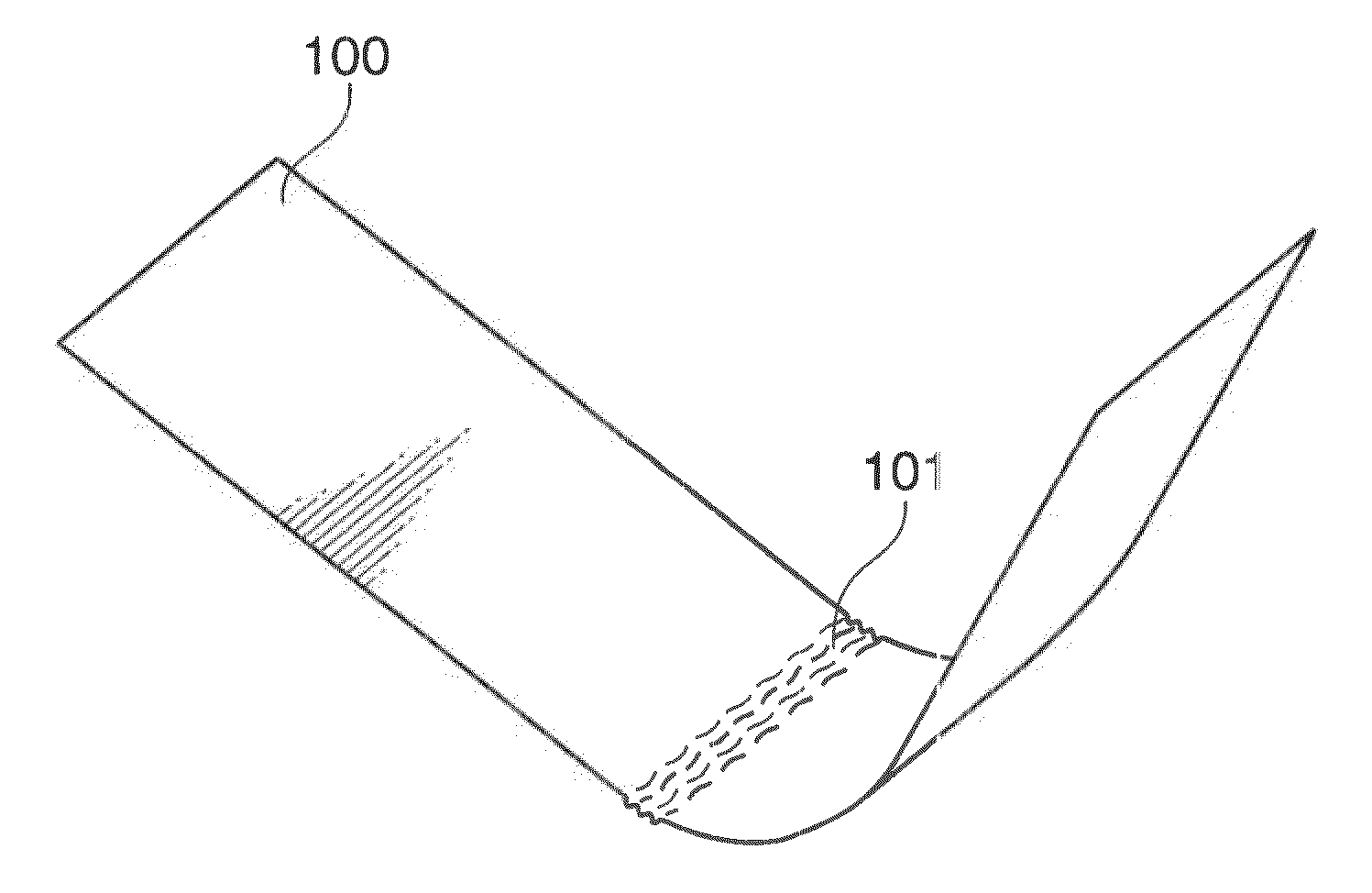

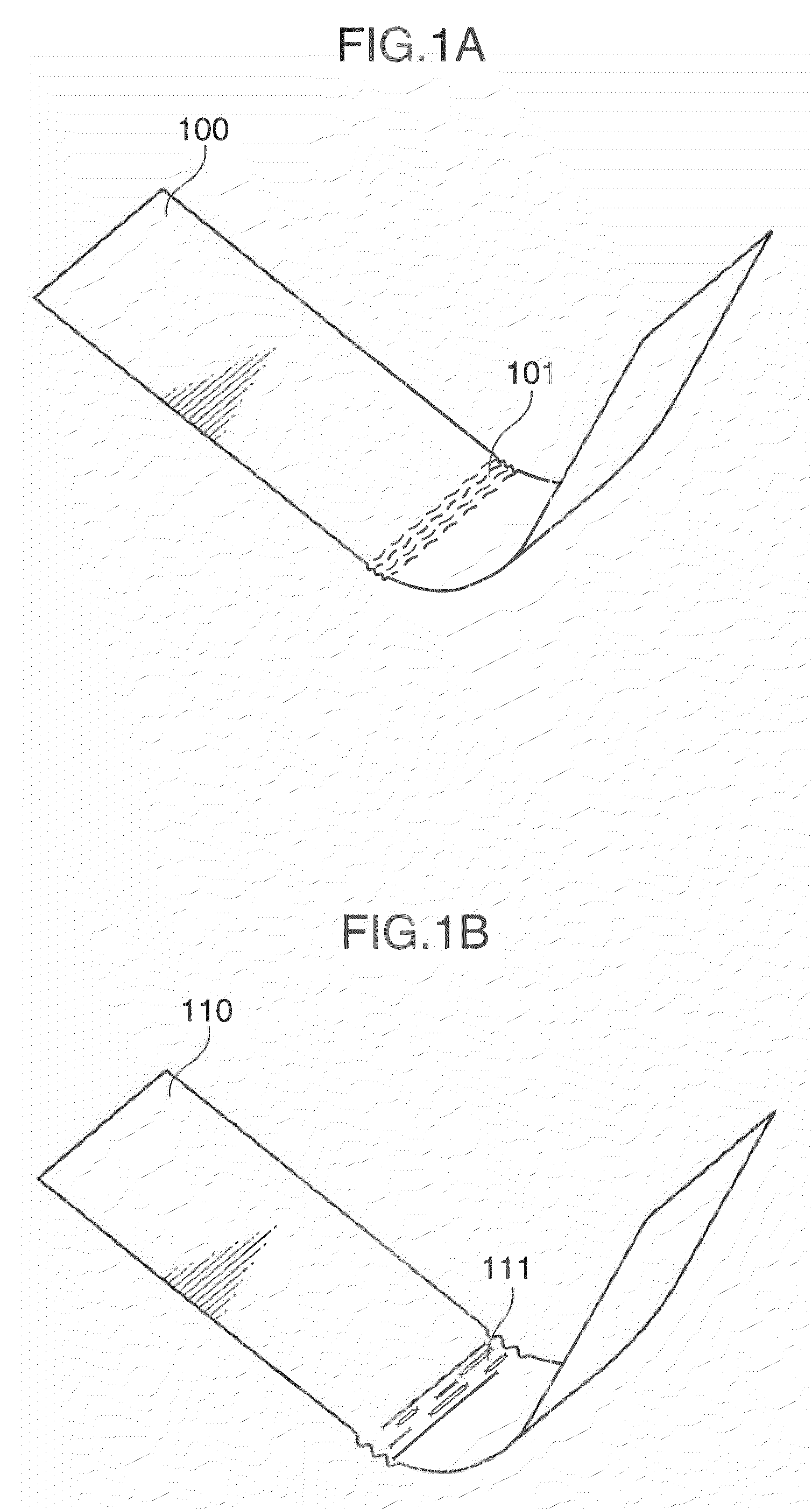

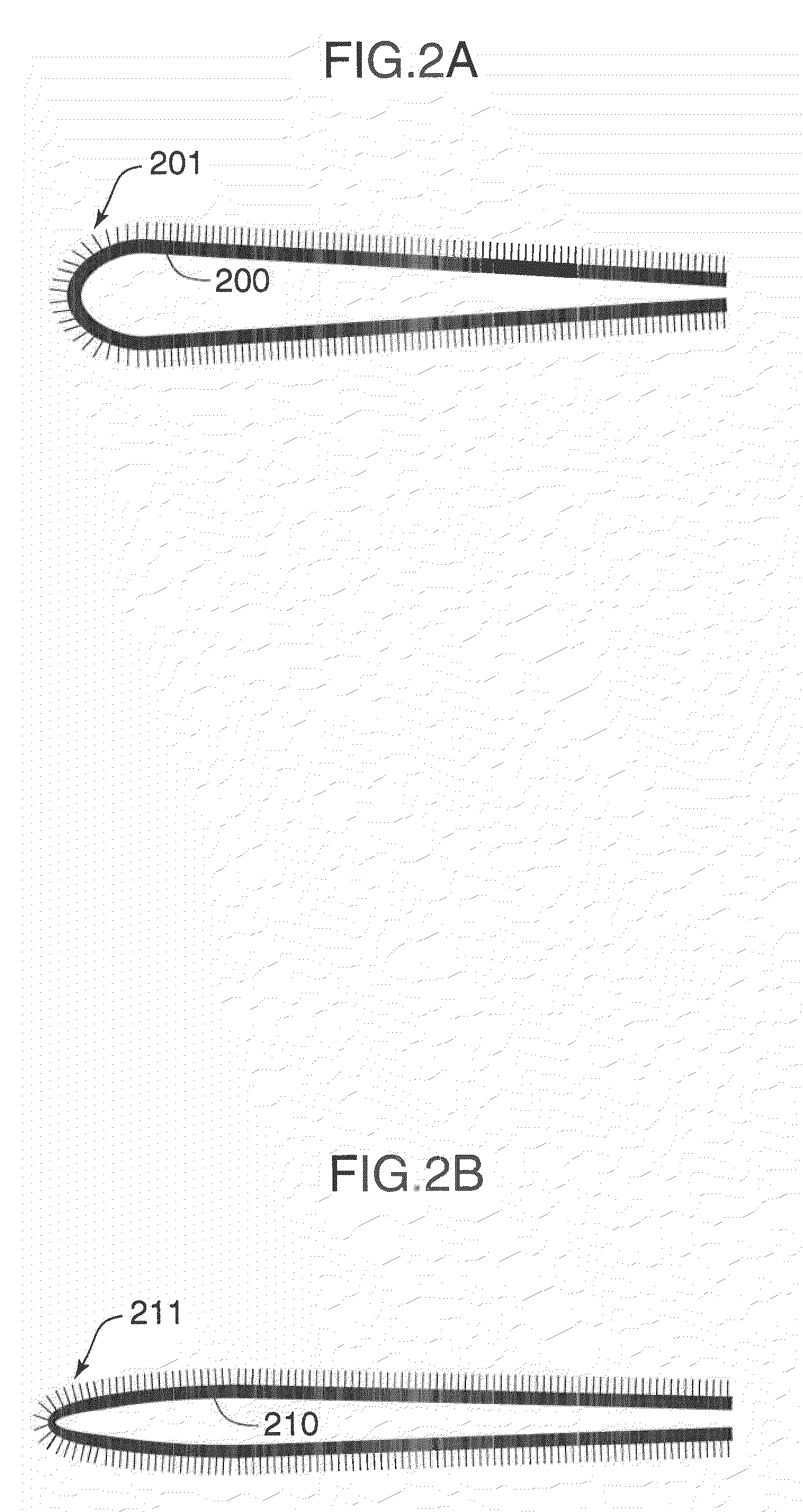

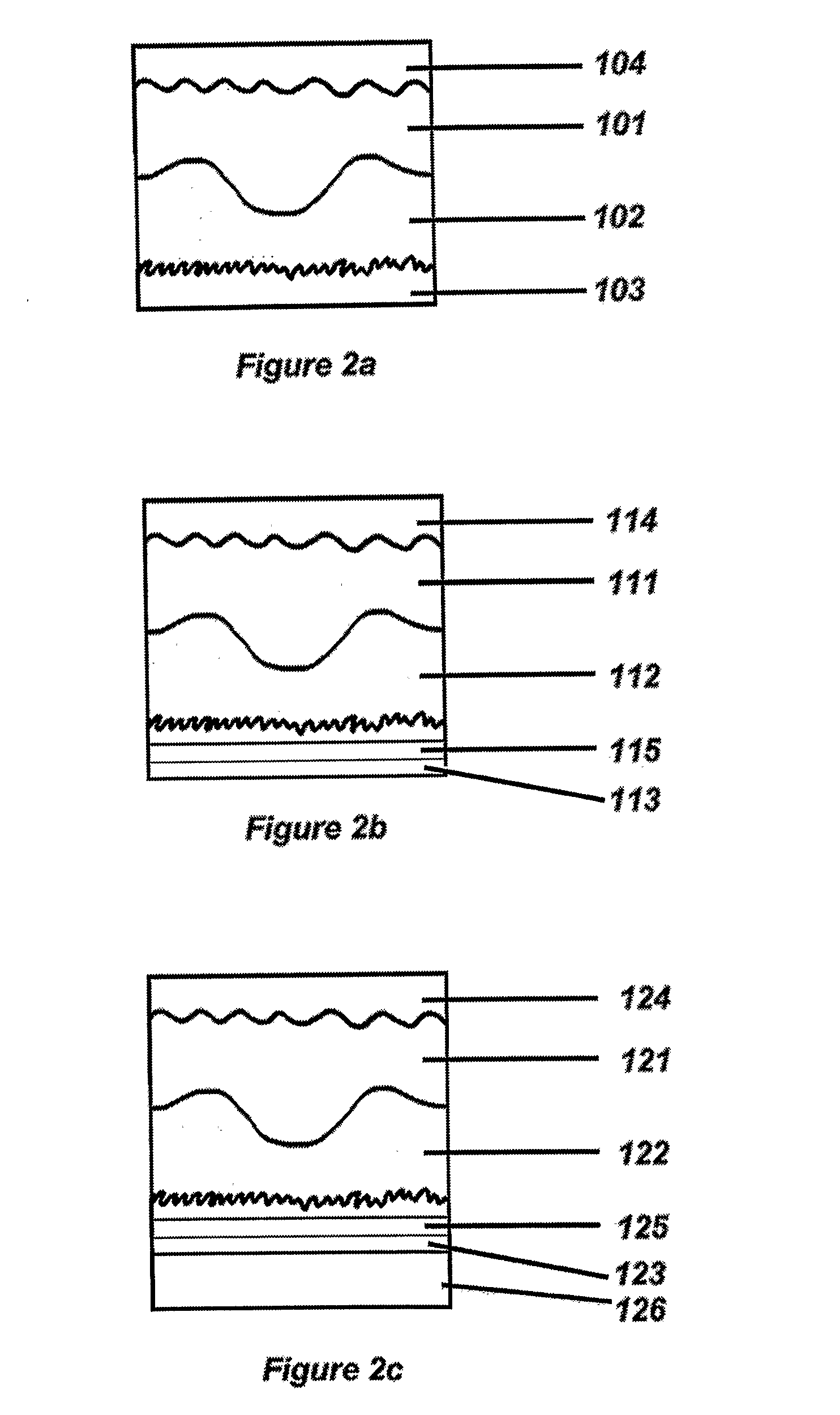

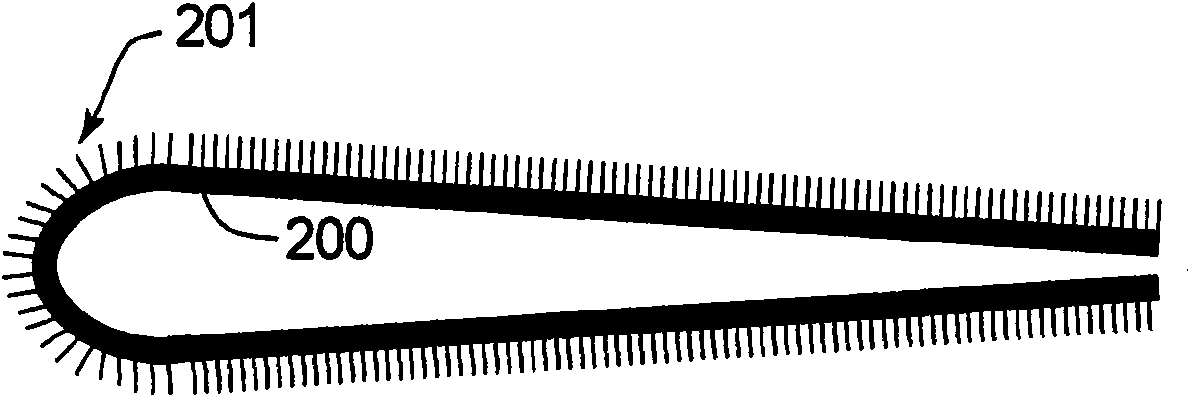

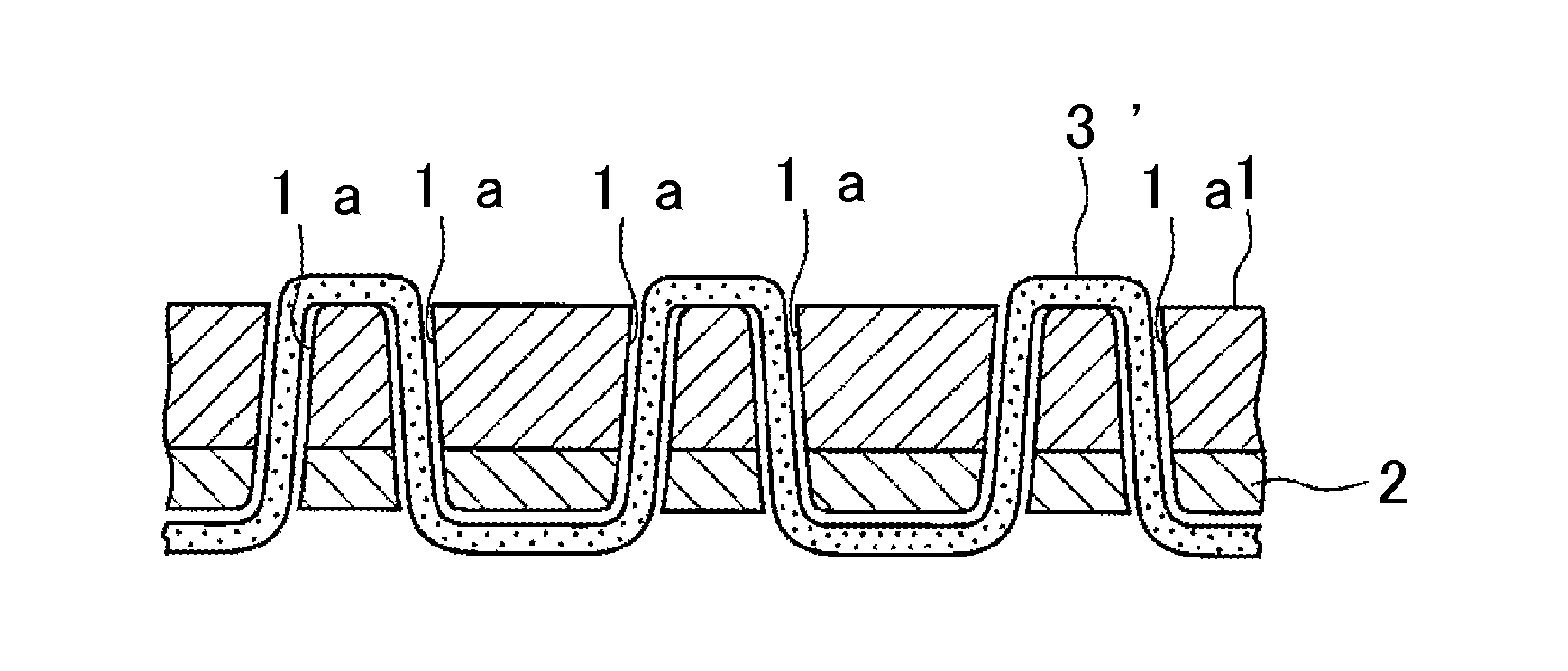

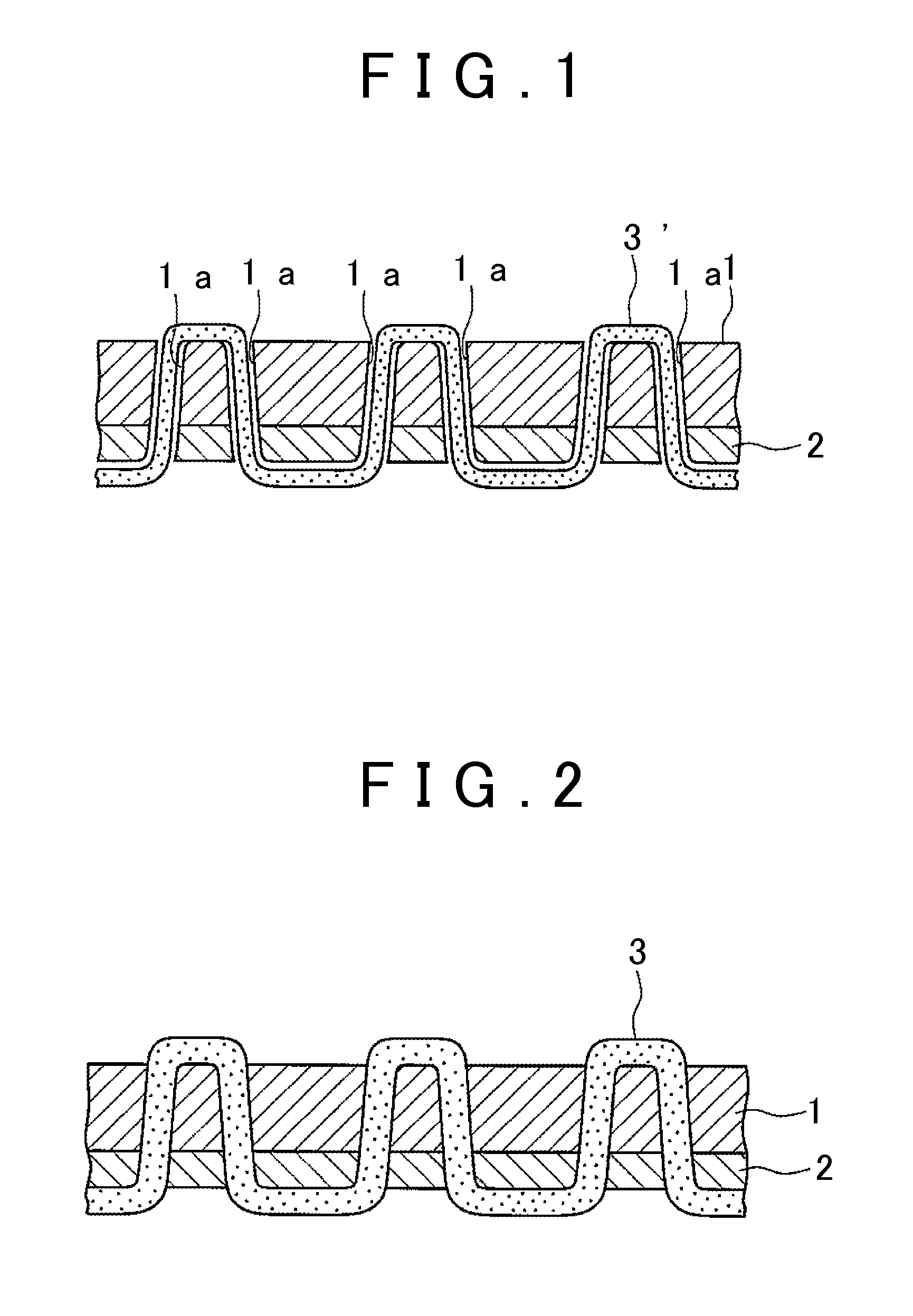

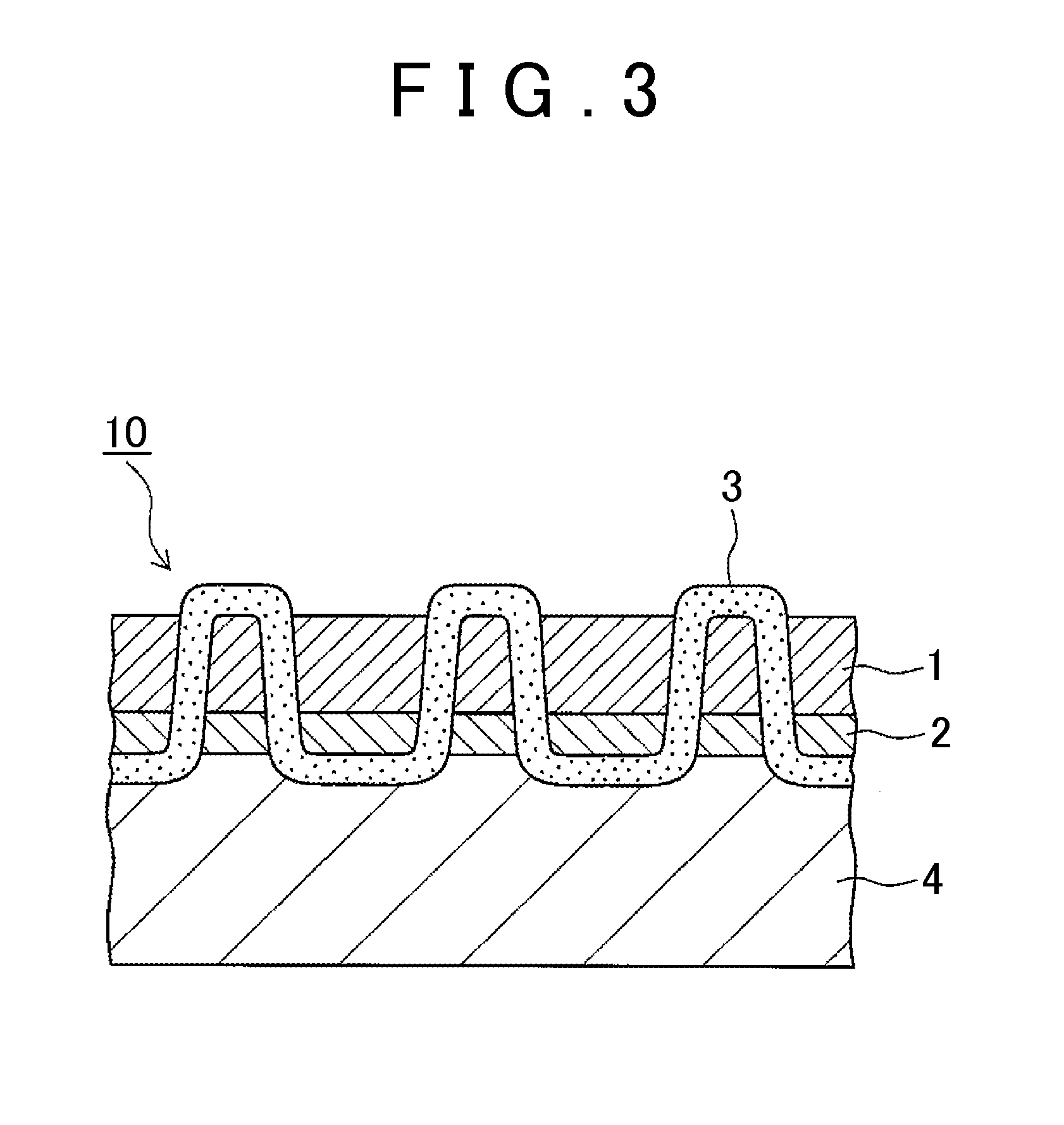

Split leather product and manufacturing method therefor

InactiveUS20110020590A1Increase physical strengthComposite leathersFurniture partsElastomerWrinkle skin

An aspect of the invention is a split leather product provided with a base material comprising split leather, and a skin layer laminated on a surface of the base material. The skin layer comprises a composite body of an entangled nonwoven fabric formed from microfine fibers, and a polymeric elastomer that impregnates the gaps in the entangled nonwoven fabric. The entangled nonwoven fabric in such a split leather product has the effect of increasing physical strength without detracting from a leather-like texture, in the same way as the longitudinally and transversally crisscrossing collagen fibers in the reticular layer. It is thus possible to obtain a split leather product that resembles leather not only in outward appearance but also in the feel derived from wrinkles and the like resulting when the leather is bent.

Owner:KURARAY CO LTD

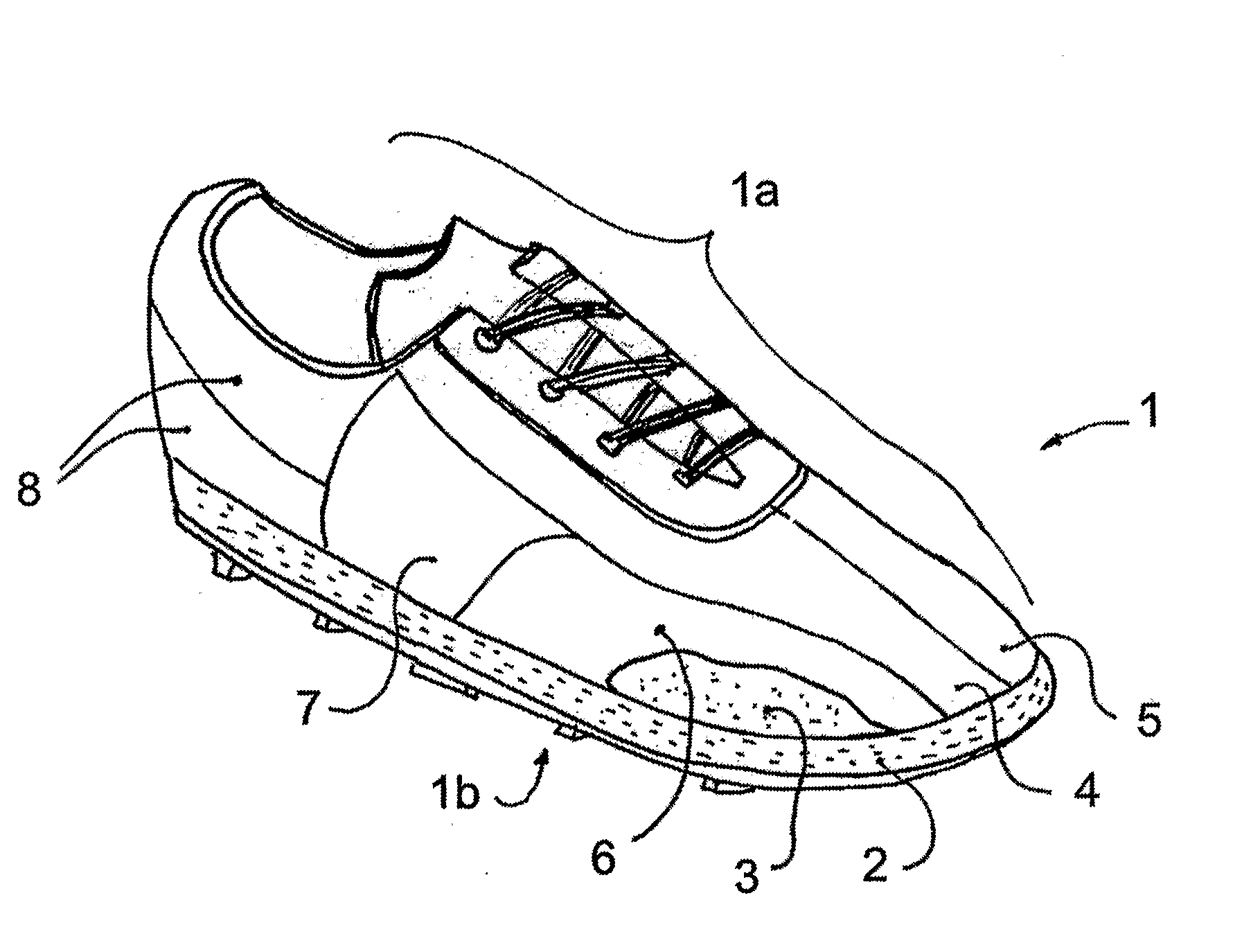

Goat Skin for Shoe and Apparel Manufacture

InactiveUS20080271344A1Improve adhesionImprove fiber structureEngine sealsComposite leathersEngineeringWear resistance

The present invention relates to the modification of goat and caprine leathers to render them suitable for use in the manufacture of sports shoes, and certain other items of footwear and apparel. Goatskin, while possessing some desirable properties, has poor wear and tear resistance. The present invention discusses the attachment of specific types of bonding layers to the non-grain face side to alter the overall performance of caprine leathers so that they may be used in durable footwear. Treatments to, and coatings on, the caprine leather are also discussed.

Owner:SKIRROW SIMON JEREMY

Leather laminated decorative panel

A heat and pressure consolidated laminate, and method for producing the same, is provided that includes in superimposed relationship a decorative layer consisting essentially of a leather material, an underlay layer, a substrate, and an optional backer layer. The substrate has a first surface and a second surface opposite one another. The underlay layer includes one or more cellulosic sheets impregnated with a thermosetting resin, and is disposed between the decorative layer and the first layer of the substrate. The backer layer includes one or more cellulosic sheets impregnated with a thermosetting resin, and is disposed contiguous with the second surface of the substrate.

Owner:DEUT BANK TRUST COMPANY AMERICAS

Split leather product and manufacturing method therefor

Disclosed is a split leather product provided with: a base material comprising split leather; and a skin layer laminated on the surface of the base material. The split leather product is characterized in that the skin layer comprises a composite body of an intertwined nonwoven fabric formed from microfibers, and an elastic polymeric substance with which the gaps of the intertwined nonwoven fabric are impregnated. In such a split leather product, the intertwined nonwoven fabric, like the horizontally and vertically crisscrossing collagen fibers in the reticular dermis, has the effect of increasing physical strength without detracting from the leather-like texture. Thus it is possible to obtain a split leather product that resembles leather not only in outward appearance, but also in the feel based on the wrinkles and the like caused by folding.

Owner:KURARAY CO LTD

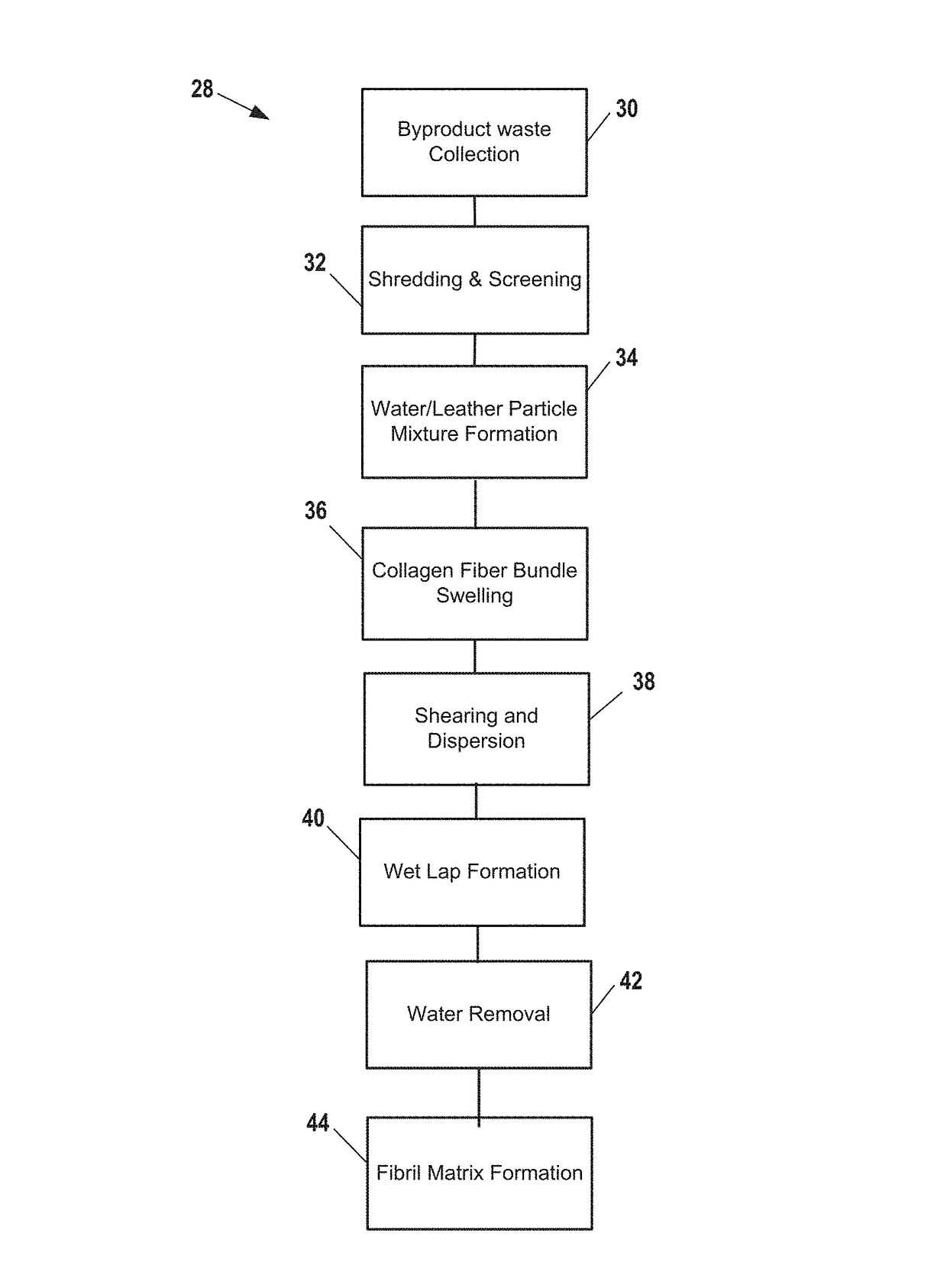

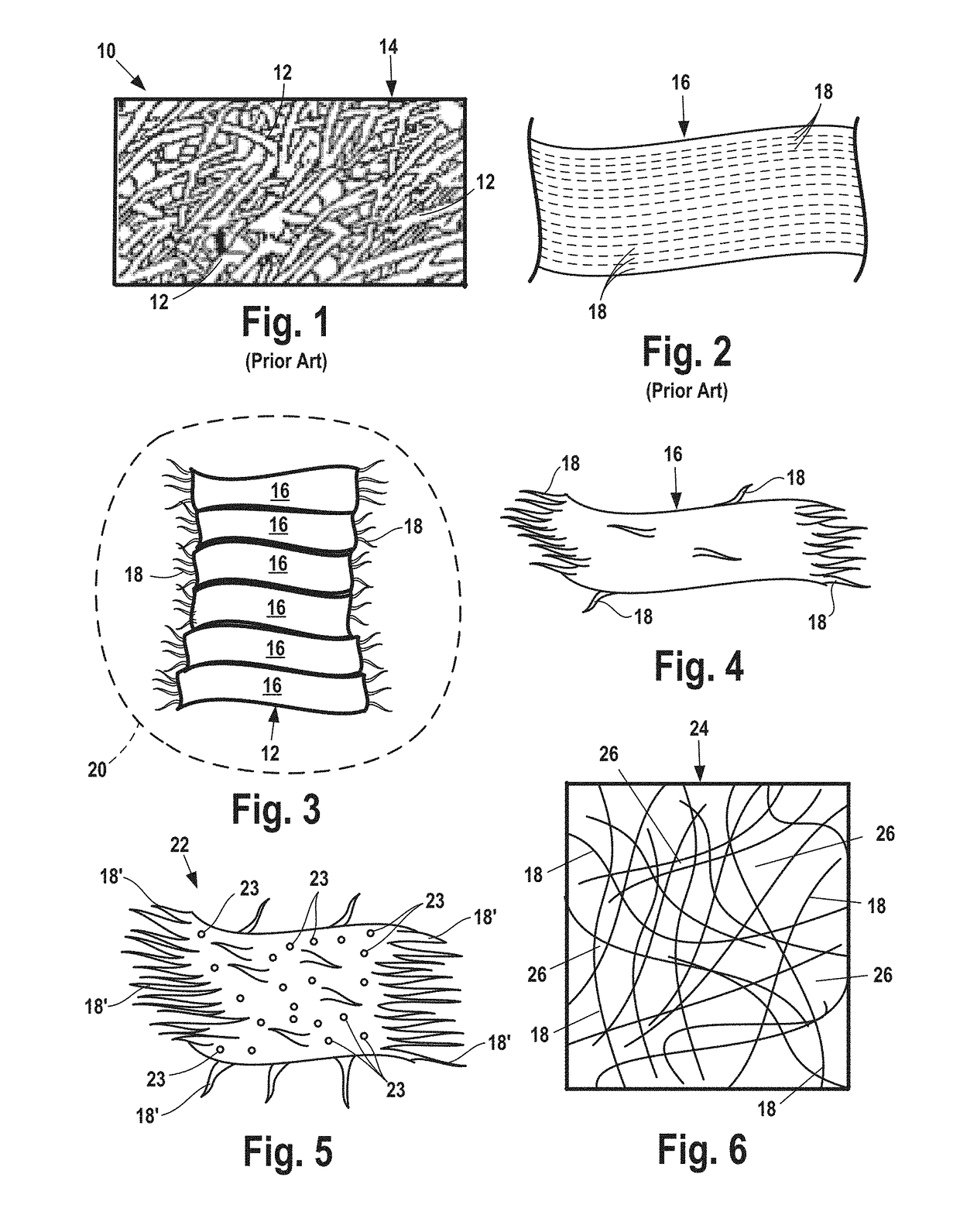

High strength leather material

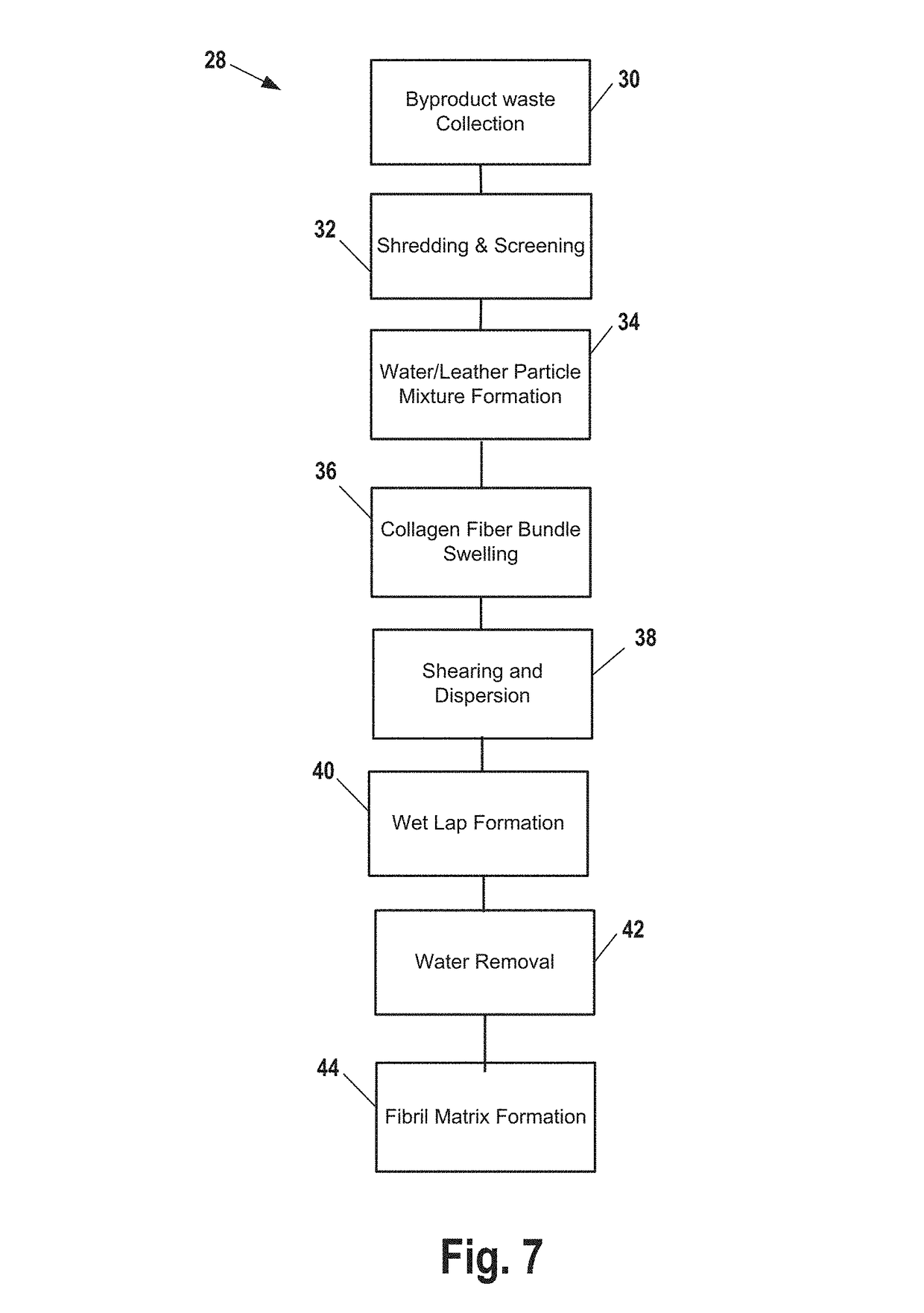

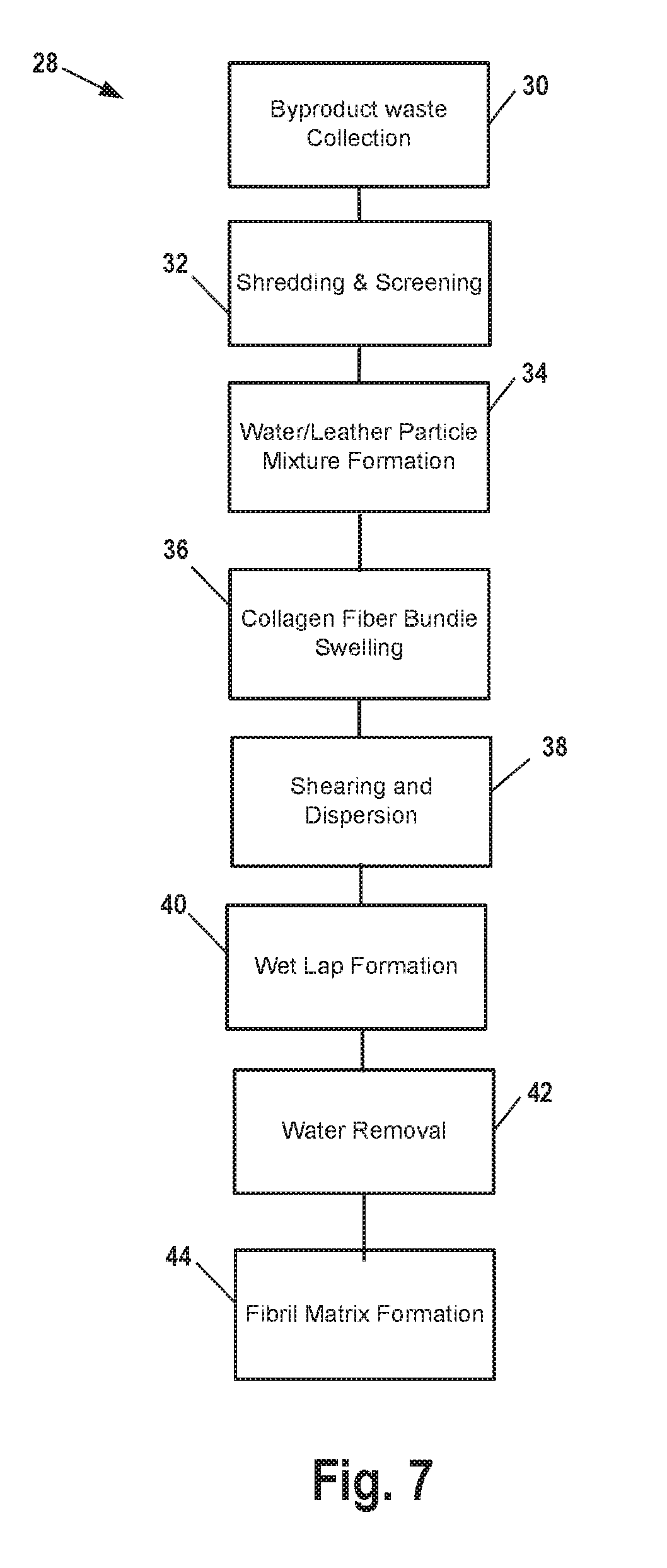

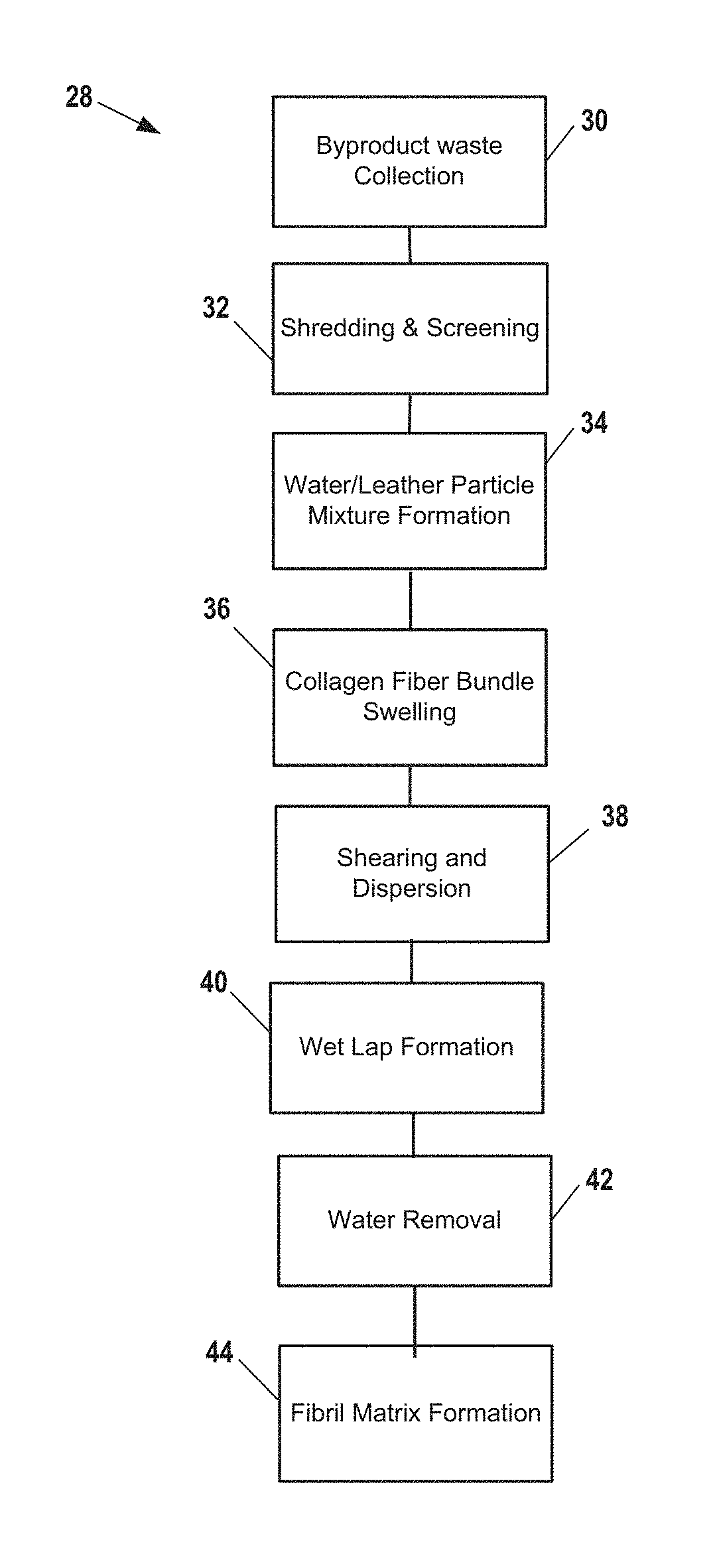

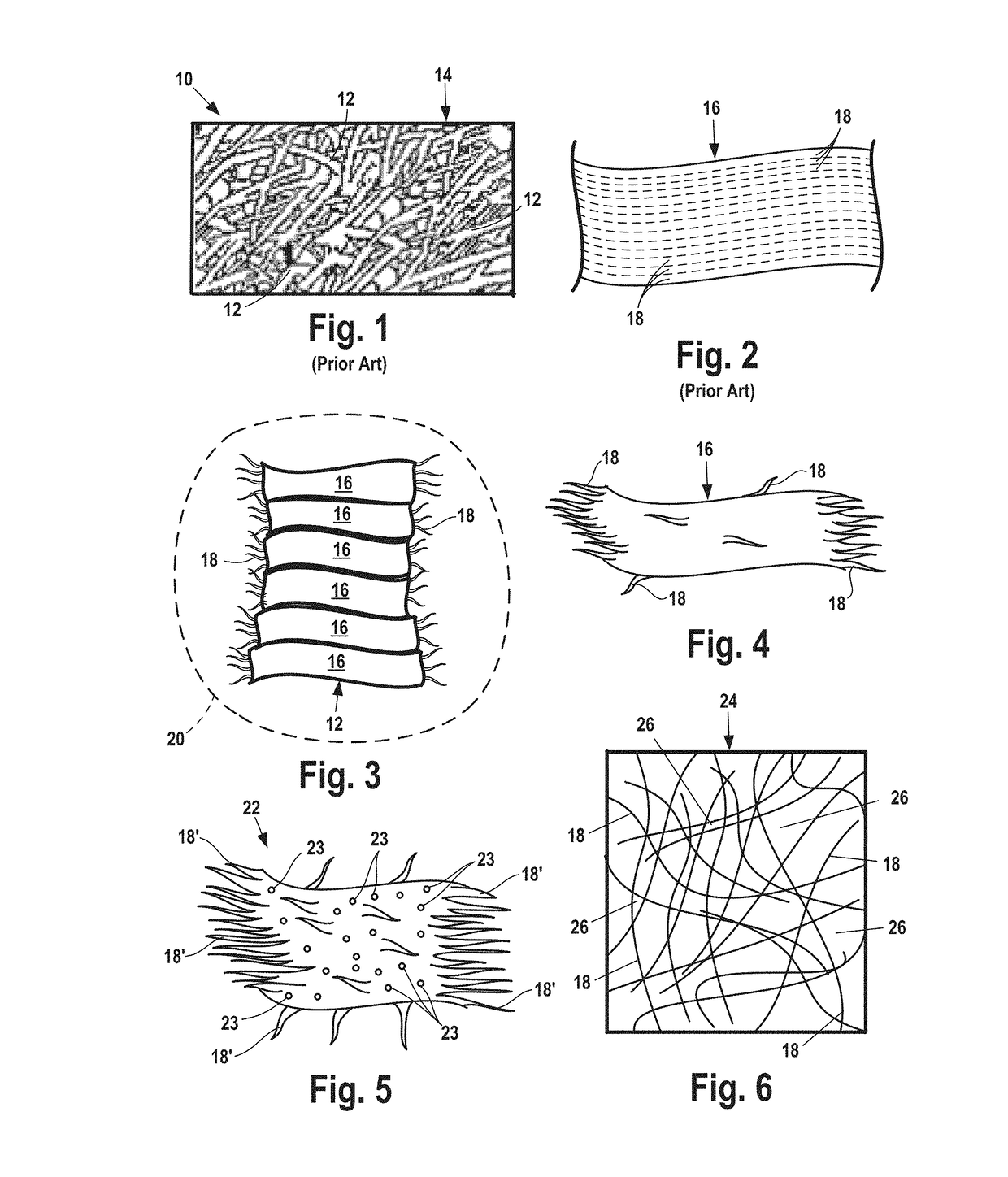

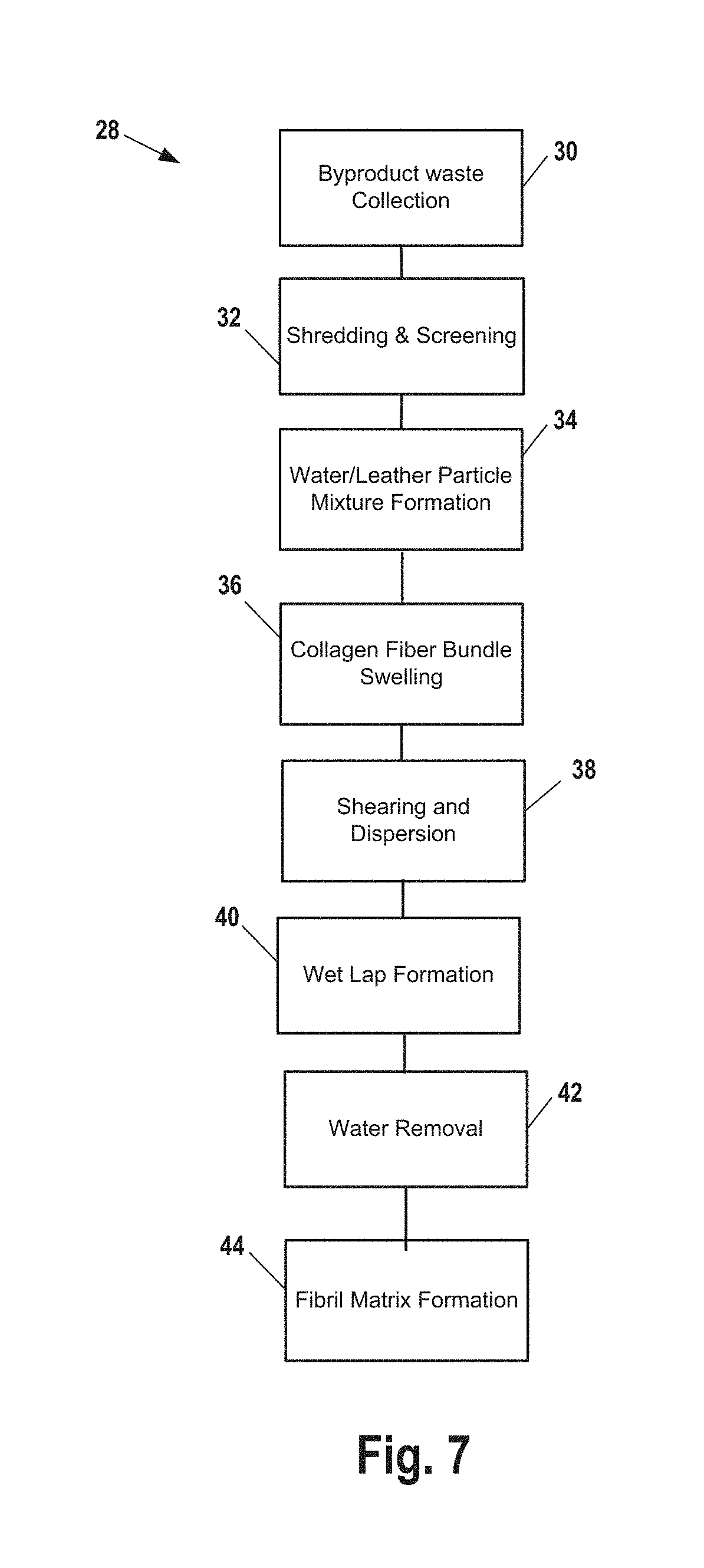

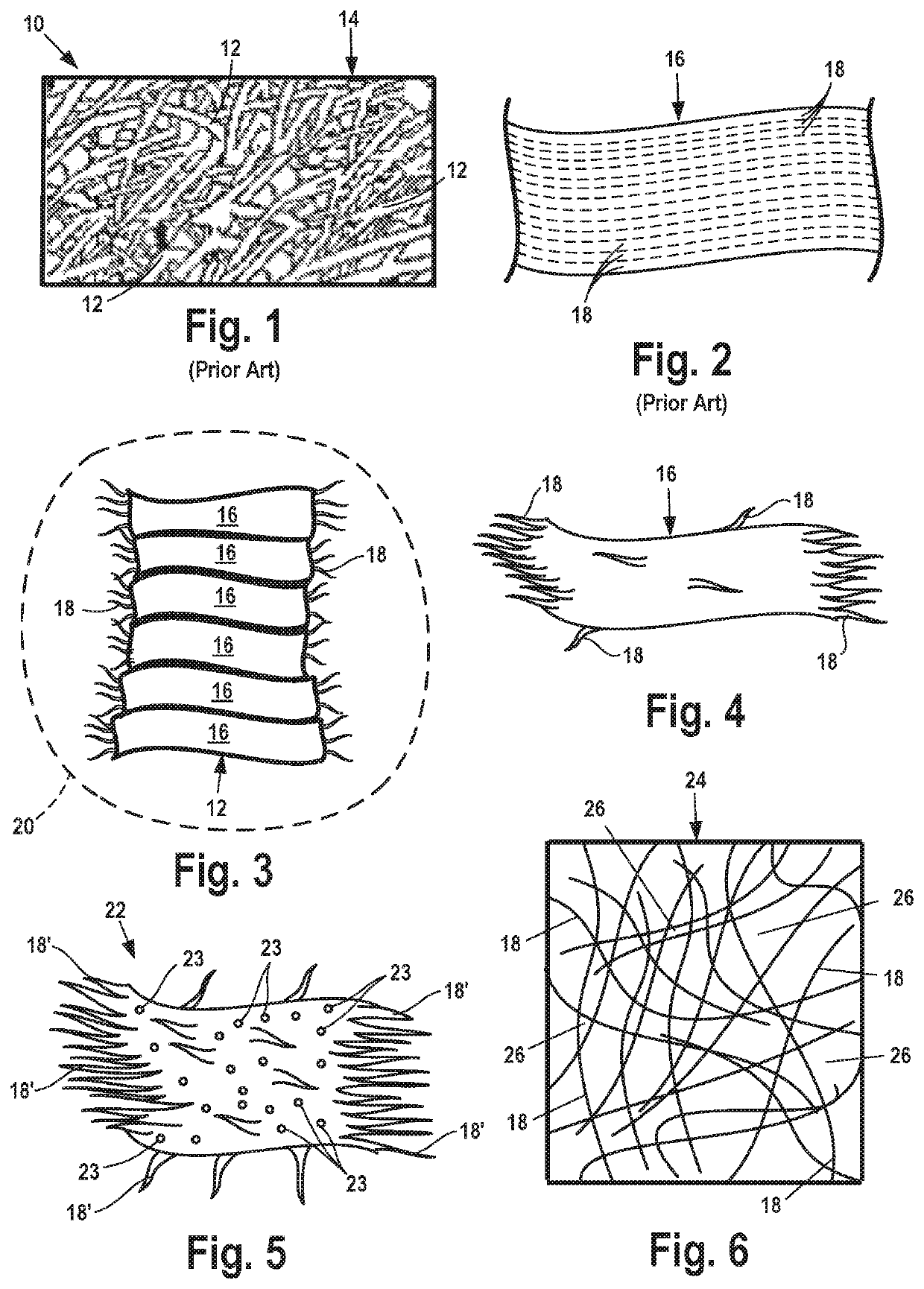

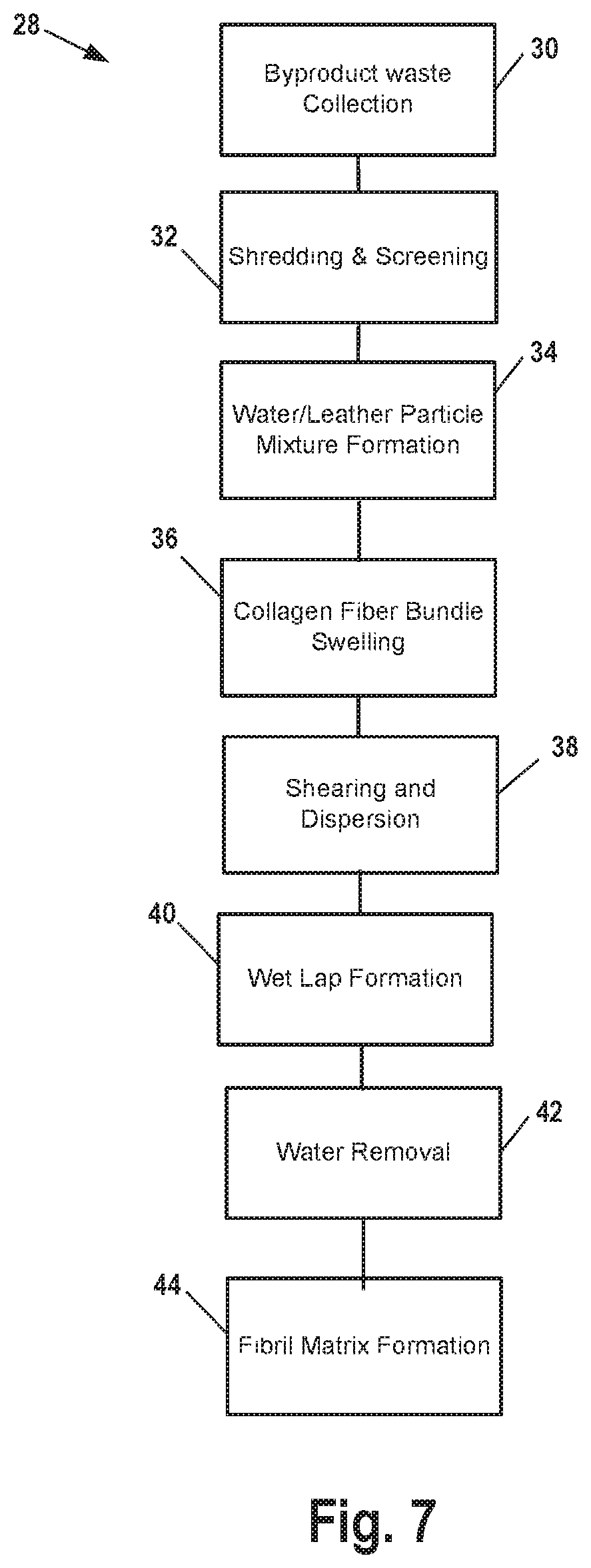

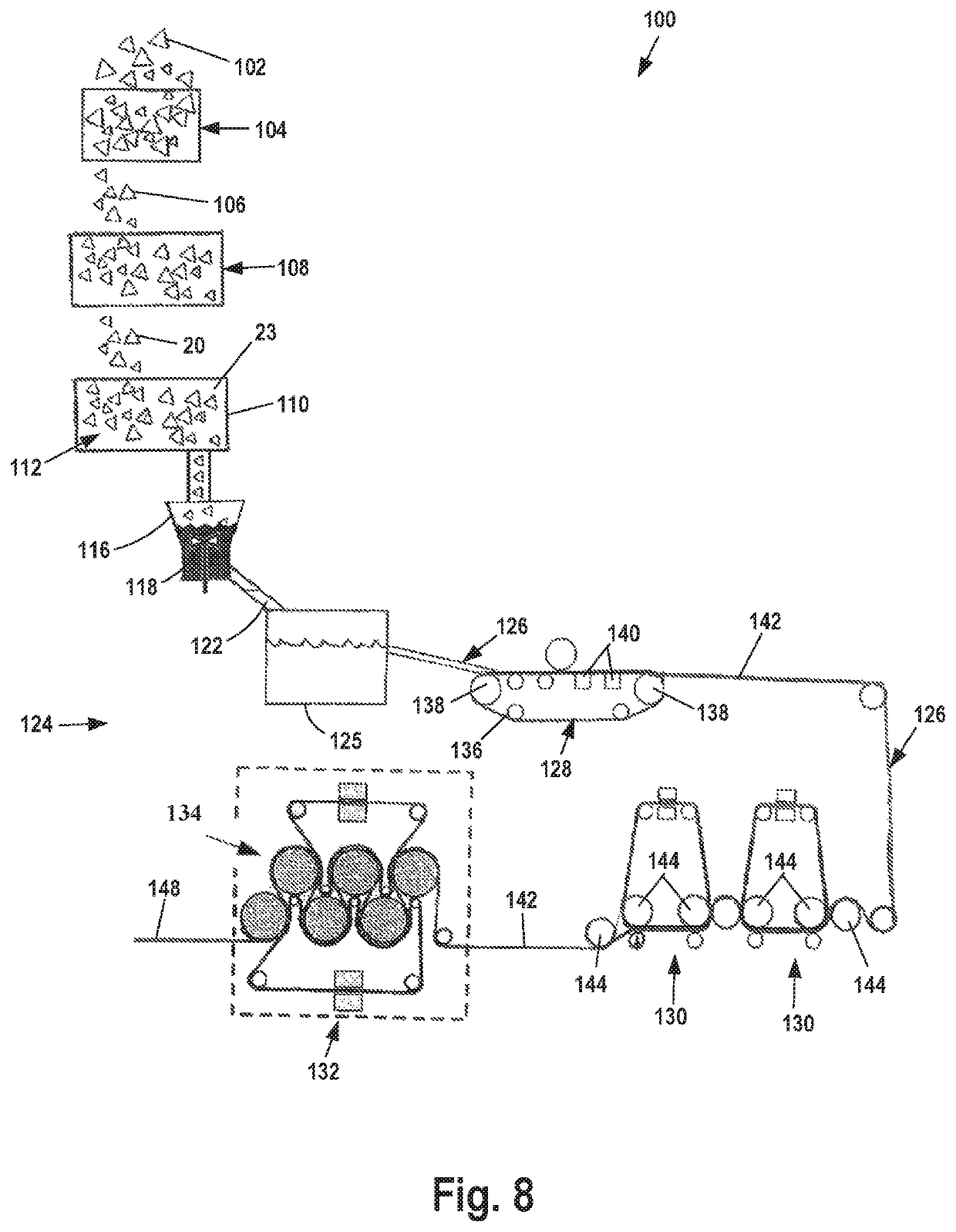

ActiveUS10124543B1Improve tear resistanceLower-strength end-productComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

Dispersion processing aids for the formation of a leather material

ActiveUS10138595B1Accelerates the dehydration processFacilitate physically manipulatingOrganic non-cellulose fibresComposite leathersFiberEngineering

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

High strength leather material

ActiveUS10131096B1High tensile strengthDesired elastic propertiesComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

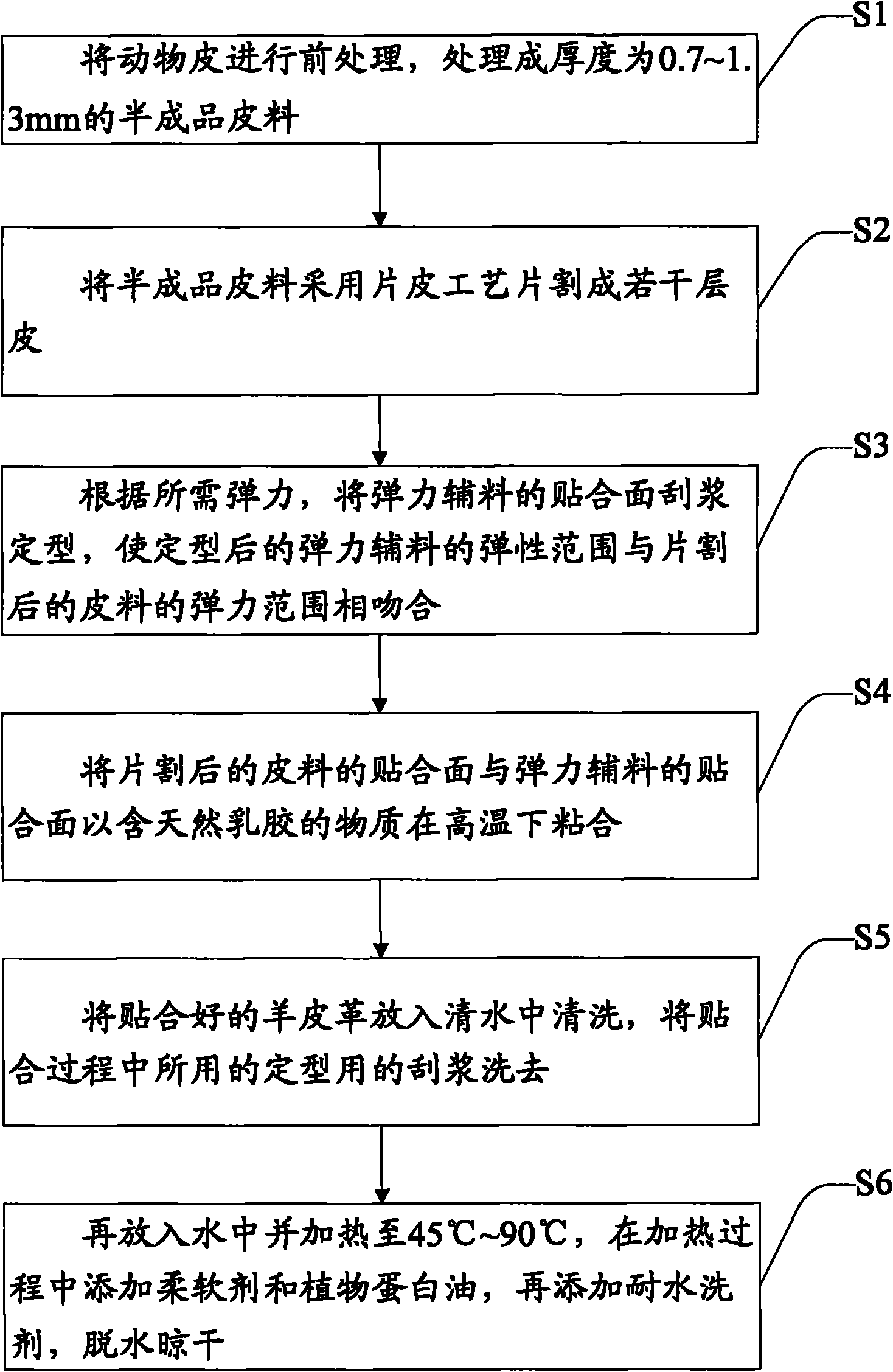

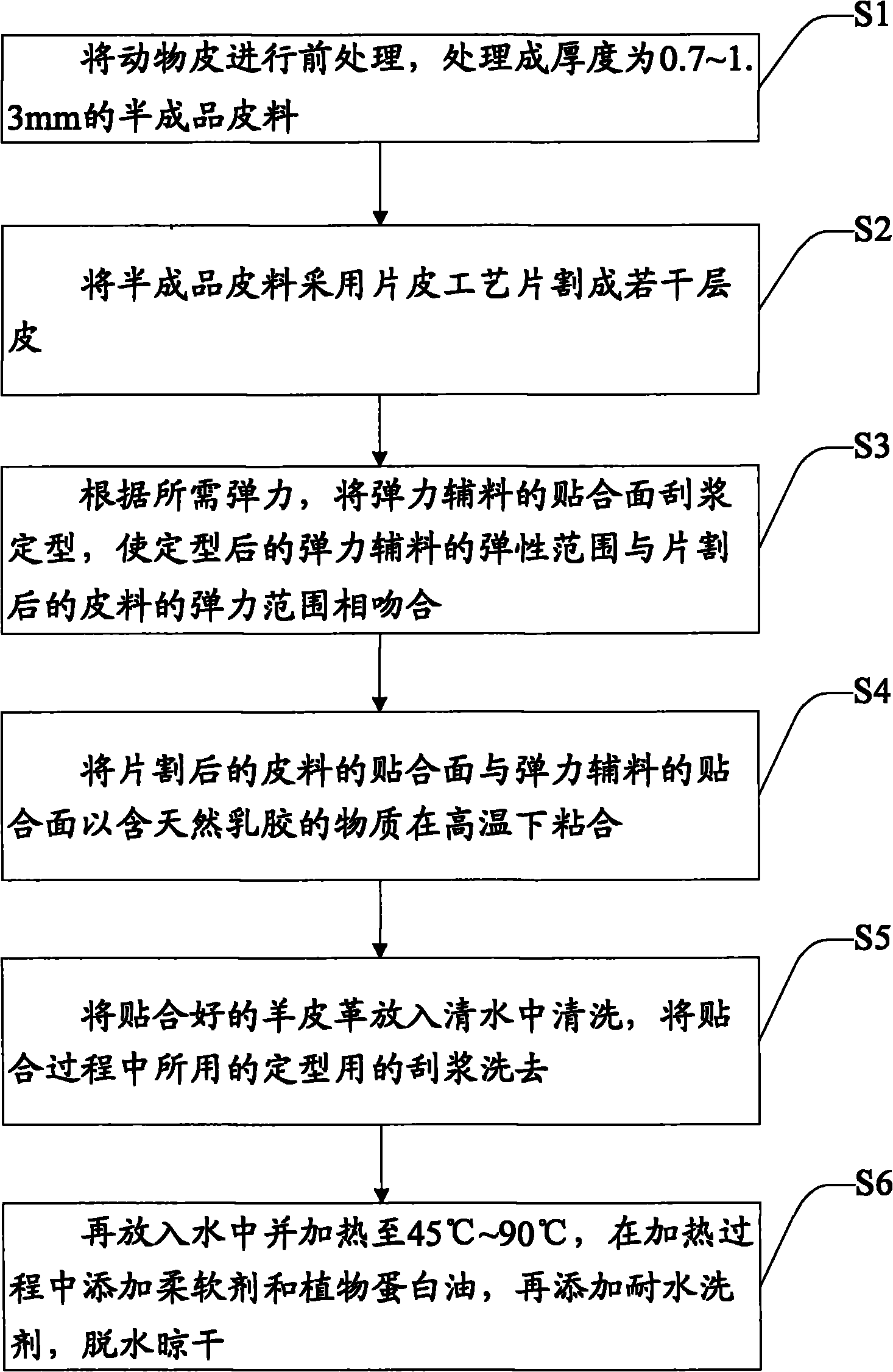

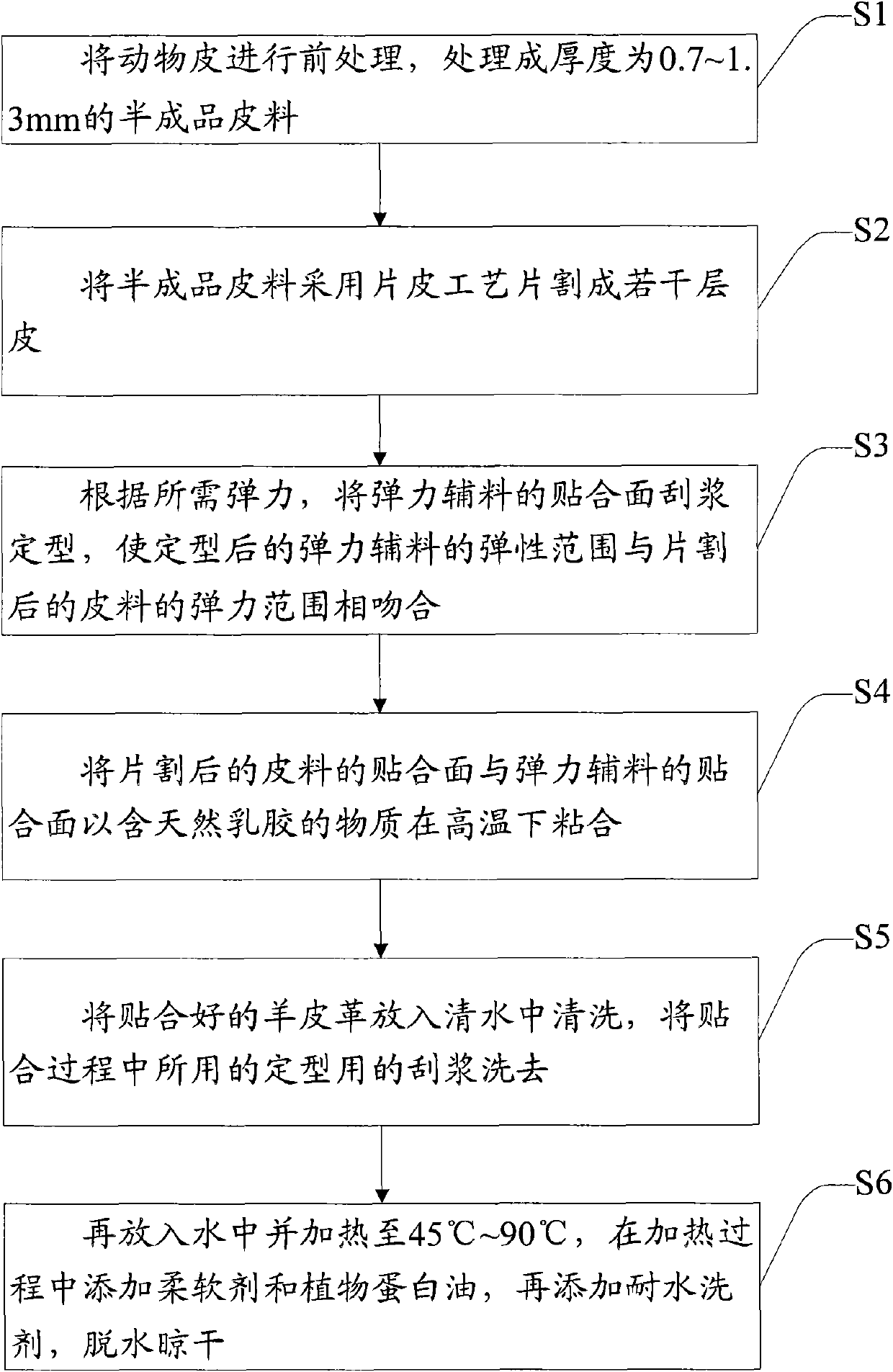

Leather material and processing method thereof

InactiveCN101956026AGive full play to the elastic propertiesIncrease elasticityLeather manufacturingComposite leathersEmulsionWork in process

The invention discloses a processing method of a leather material, comprising the following steps of: (1) pre-processing an animal skin into a semi-finished product of the leather material with the thickness of 0.7-1.3mm; (2) cutting the semi-finished product of the leather material into a plurality of layers of skins by utilizing a leather-splitting process; (3) forming scraping pulp for a binding surface of an elastic auxiliary material according to required elasticity so that the elastic range of the formed elastic auxiliary material is identical with that of the split leather material; (4) adhering the binding surface of the split leather material and the binding surface of the elastic auxiliary material at high temperature with a substance containing natural emulsion; (5) placing theadhered leather material into water for cleaning, and washing the scraping pulp for forming in the adhering process; and (6) placing into water again and heating to 45-90 DEG C, adding a softening agent and plant protein oil in the heating process, then adding a water-washing resistant agent, and dewatering and airing. The processing method of the leather material has the advantages of favorable elasticity of the obtained leather material, water-washing resistance and simple and convenient processing procedure. The invention also discloses the leather material.

Owner:谈国忠

Composite leather material

Engineered leather substrates, methods of making the substrates, engineered leather composites including the substrates, and articles of manufacture which include the engineered leather substrates or composites are disclosed. The substrate includes leather, non-leather fibers, a binding agent and one or more additional components such as cushioning agents, softeners, processing aids, and colorants. A composite material can be formed including the substrate and one or more additional layers, such as top coat layers, reinforcing layers, and cushioning layers. The substrate and or the composite can be chemically or mechanically embossed. The leather used to form the engineered leather substrate can be derived from post- industrial and / or post-consumer materials. The non-leather fibers can be organic or inorganic, and the composition can also include inorganic fillers, such as calcium carbonate, and clays. The cushioning agents can include polymeric microbubbles, foam, rubber particles, and other low density cushioning agents. The binding agents can be synthetic or natural, such as synthetic latex, natural latex, PVA, and starch.

Owner:MALLARD CREEK POLYMERS +1

Interior member and method of manufacturing the same

InactiveUS20150202839A1High urethane leakage prevention performanceReduce material costsVehicle seatsLeather sewingBiomedical engineeringPolyurethane

Owner:TOYOTA JIDOSHA KK

Superficial treatment process of high abrasion resistance metallic film synthetic leather

ActiveCN101445840AImprove surface wear resistanceStrong adhesionComposite leathersPretreated surfacesPolymer scienceMetal

The invention relates to a superficial treatment process of a high abrasion resistance metallic film synthetic leather, which is characterized that the superficial treatment process comprises the following steps: coating a colorless film on the metallic film surface of the metallic film of the metallic film synthetic leather; thermally sealing a colorless film release paper and the metallic film synthetic leather by using the colorless film and the metallic film; stripping the separated paper after being cooled; and then completing the preparation of the high abrasion resistance metallic film synthetic leather. The invention can not only effectively avoid stripping and surface decoloring, but also improve the product quality.

Owner:ANHUI ANLI MATERIAL TECH

Seamless binding technology for leather product

This invention relates to a seamless adhering technology characterizing in chopping the edges of the meat sides of two sheets of leather being combined as one to a 10mm wide slant one and chopping them steadily to thickless finally, removing the coat with stubbles on the surface of the pressed leather with a pneumatic grinding wheel, ahearing them with a high cycle seamless adhering technology to be heated for 6 minutes in a vacuum sulfurizing machine under 60 deg.C and adhering a layer of thermal reinforcing material at the joint place of the meat sides.

Owner:QINGDAO HENGDA CO LTD +2

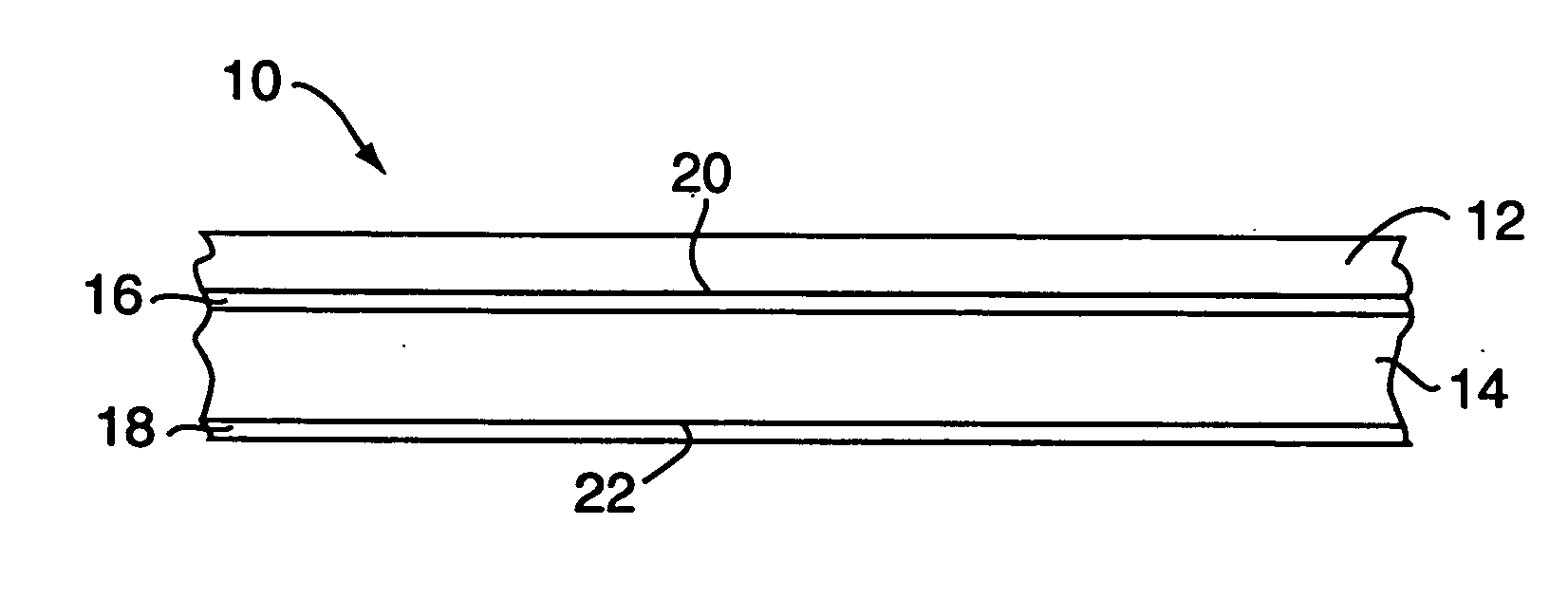

Leather decorative laminate

InactiveUS20060115663A1Easily incorporated into furnitureEasily cabinetryLamination ancillary operationsLayered product treatmentCelluloseEngineering

Owner:CORTLAND CAPITAL MARKET SERVICES

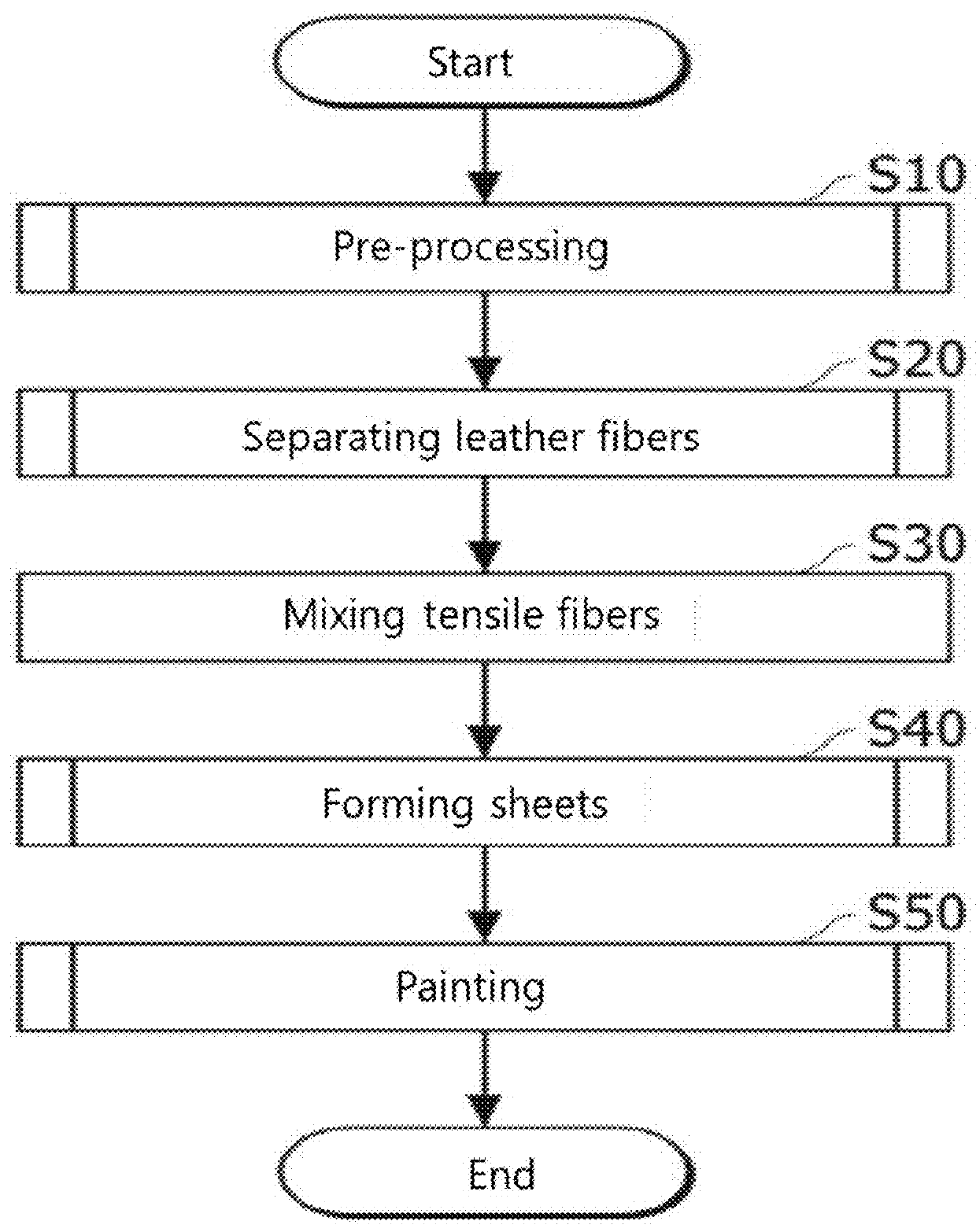

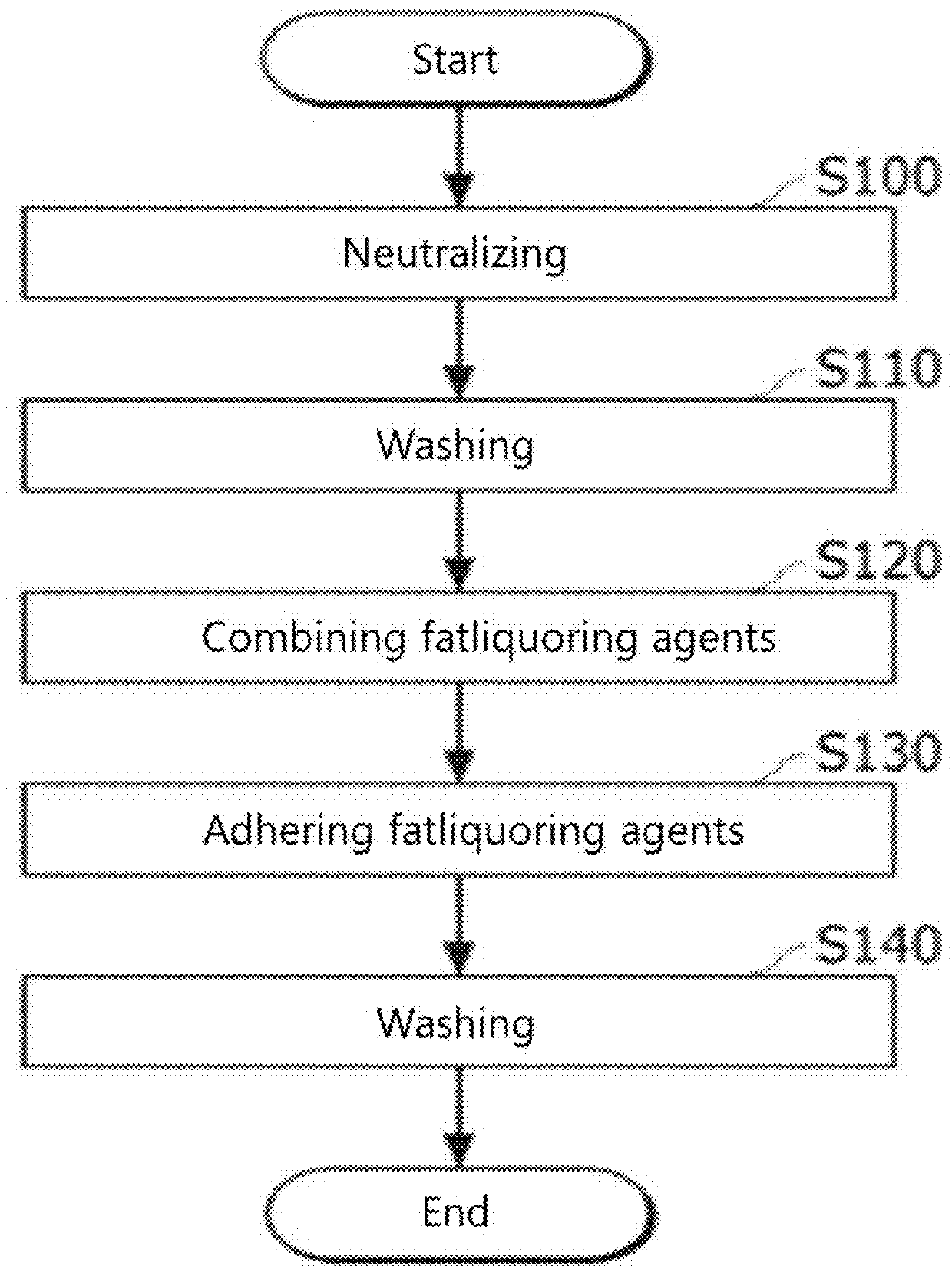

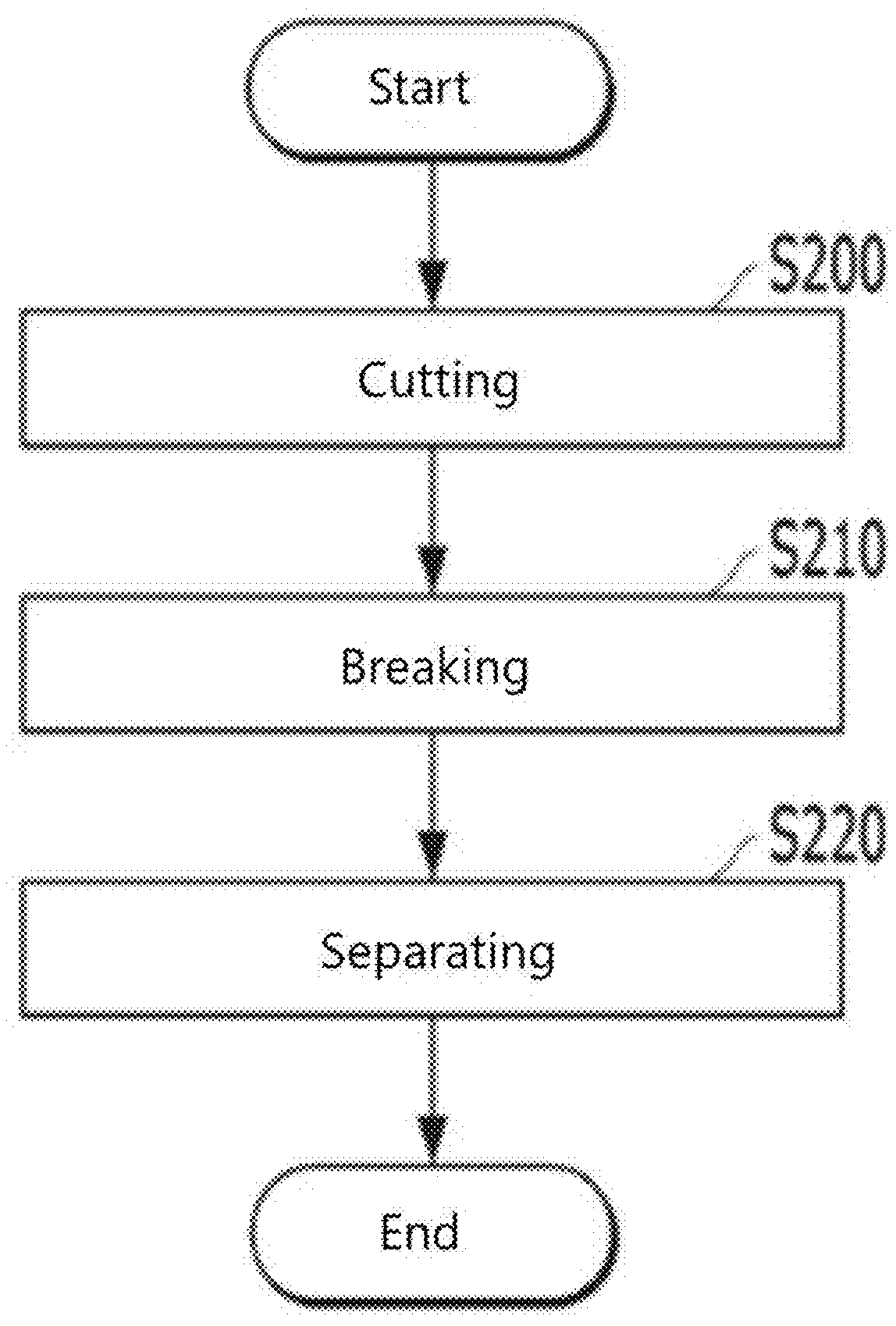

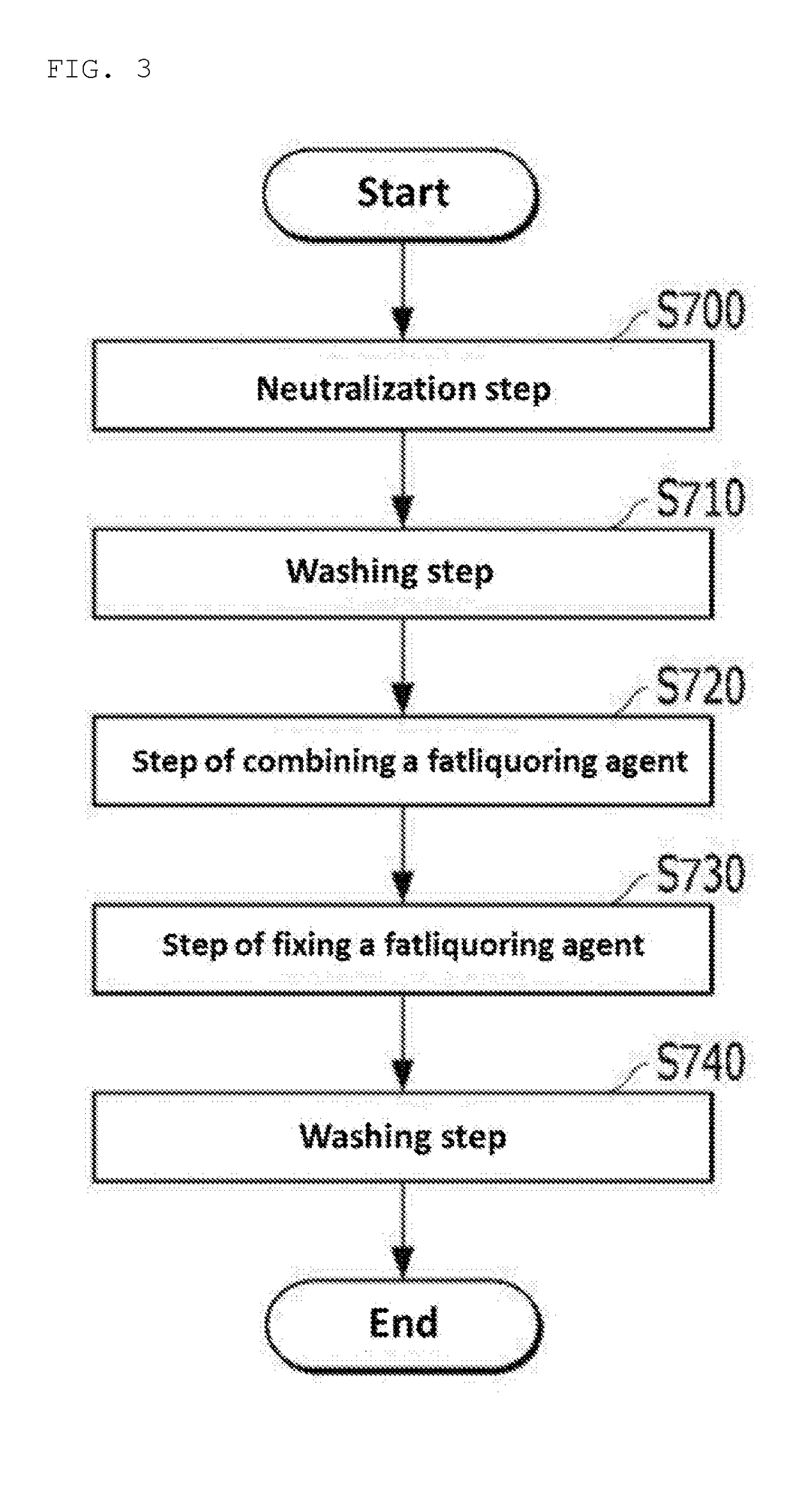

Manufacturing method of recycling leather sheet using fiber of leather

A method of preparing recycling leather sheets comprise: pre-processing where leather wastes are neutralized and fatliquoring agents are adhered; separating leather fibers from the leather wastes that has undergone the pre-processing; mixing the separated leather fibers with fibers for improving a tensile strength of the separated leather fibers; and forming sheets by combining the mixed leather fibers and raw fabrics for floor. The method of preparing recycling leather sheets in the present invention may reduce environmental pollution by preparing recycling leather sheets through physical combination without using adhesives.

Owner:ATKOPLANNING

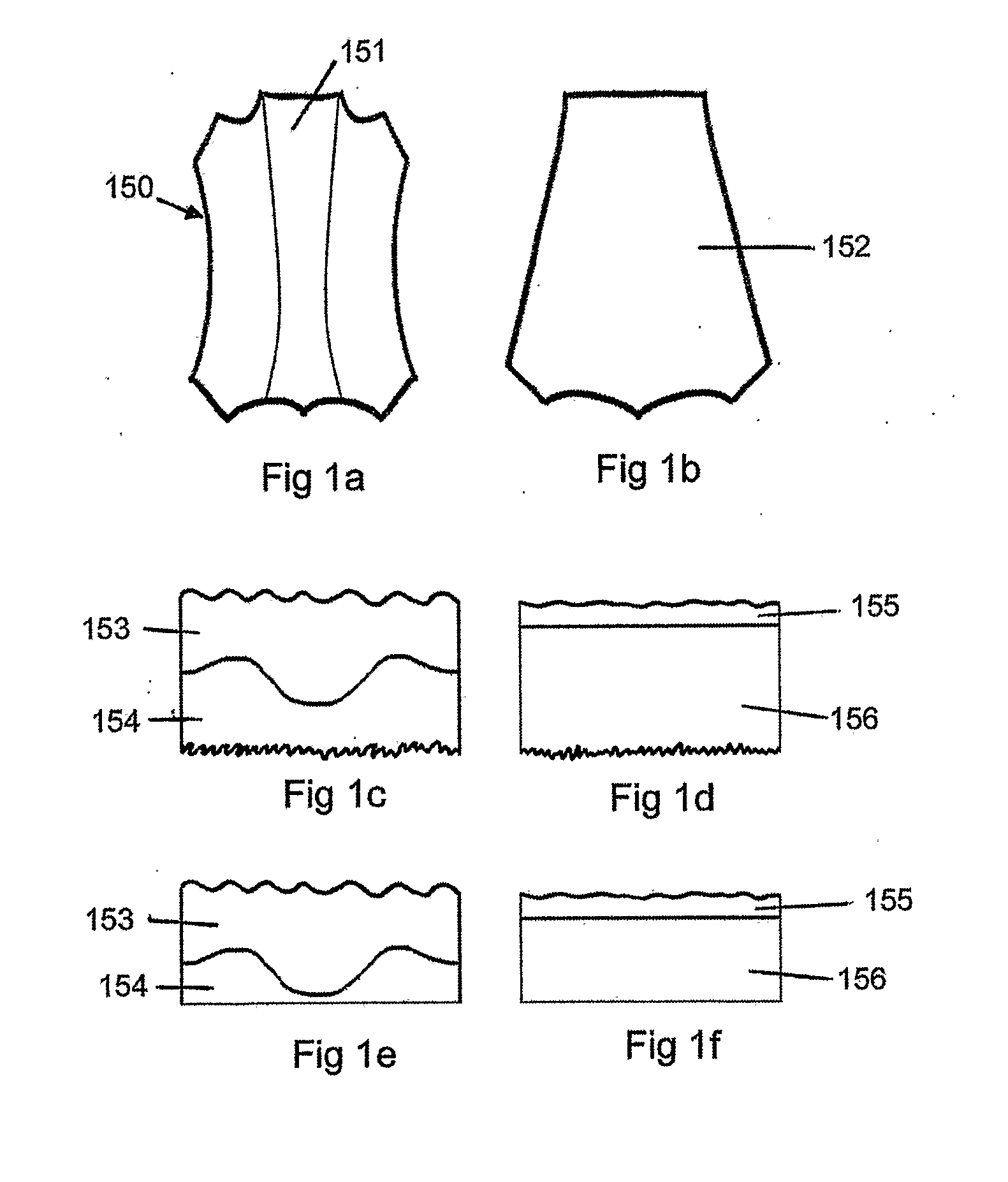

Two-layer pile elastic skin and processing process thereof

InactiveCN105463138AReduce processing costsHigh tear strengthComposite leathersSurface layerAfter treatment

The invention relates to a two-layer pile elastic skin which comprises a two-layer structure, the surface layer is a pile skin, the inner layer is elastic cloth, and a two-layer skin and the elastic cloth are compounded through glue to form the pile elastic skin. The processing process includes the steps that a template is separated; a white blank tanned; the skin is delaminated; waste, namely the two-layer skin 0.35 mm to 0.45 mm thick, generated in the traditional tanning process is delaminated mechanically, and the two-layer skin even in thickness and free of damage is selected; compounding is performed, wherein the pile skin part of the two-layer skin and the elastic cloth are compounded through the glue to form the two-layer pile elastic skin; leather buffing is performed; and dyeing is performed, wherein the two-layer pile elastic skin is obtained through after treatment. The waste generated in the traditional tanning process is delaminated through mechanical equipment and then compounded with the elastic cloth, the thickness of obtained leather reaches the thickness of existing large leather, the tearing strength is higher, the waste is used, the waste disposal cost of a tanning enterprise is reduced, the use rate of the two-layer skin is increased, and the obtained product is high in elasticity and wide in application range.

Owner:ZHEJIANG HENGYUAN LEATHER CO LTD

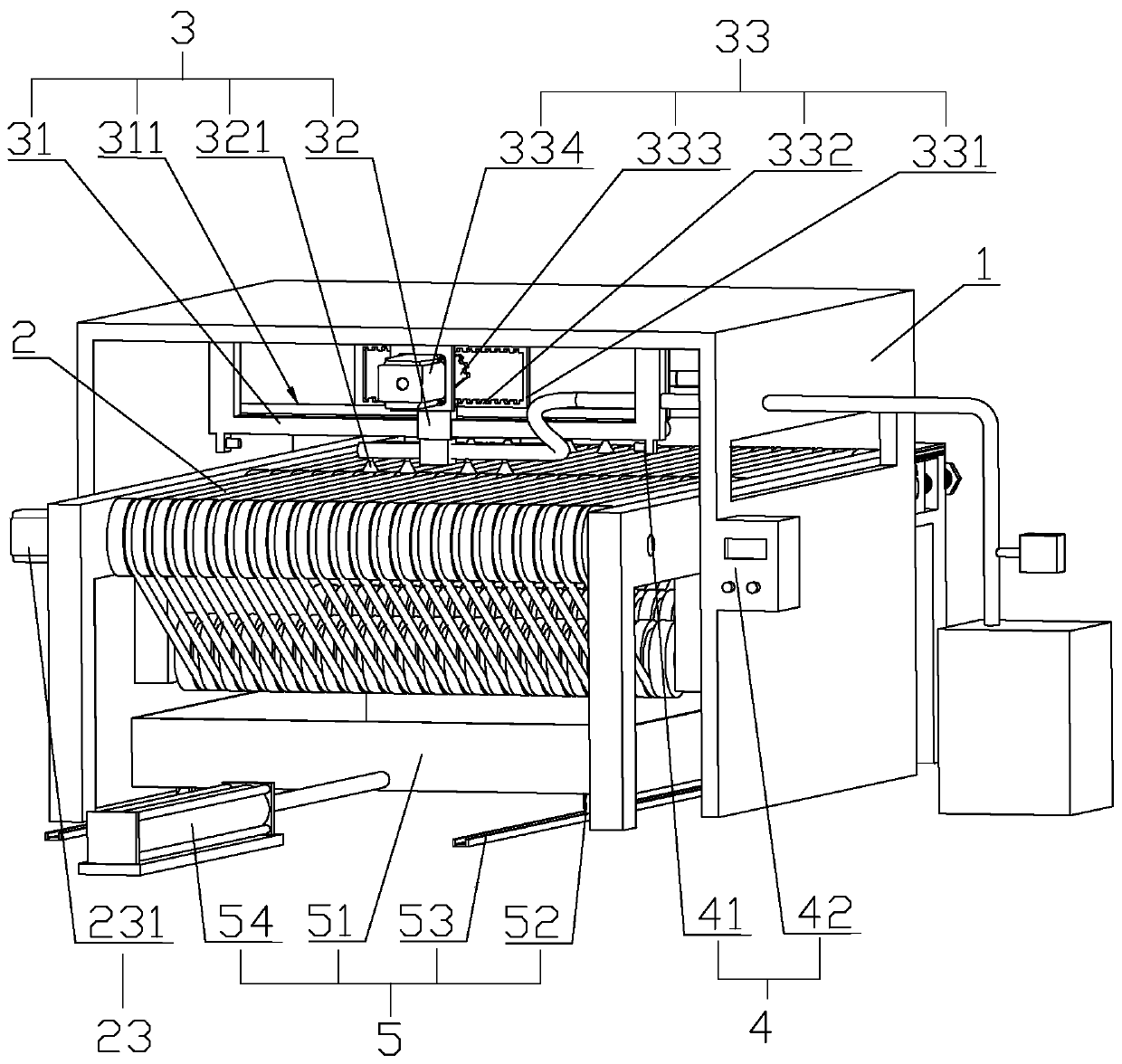

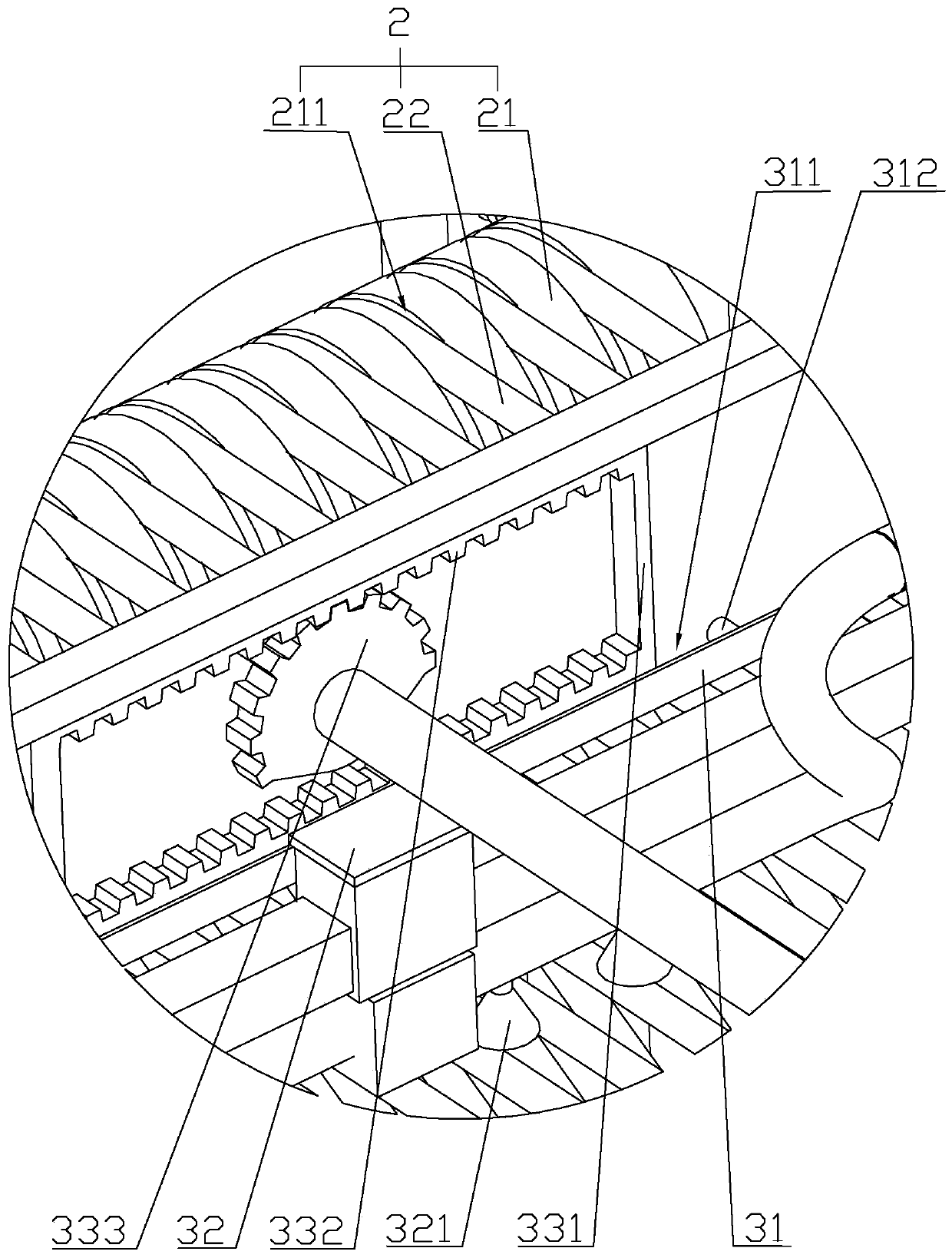

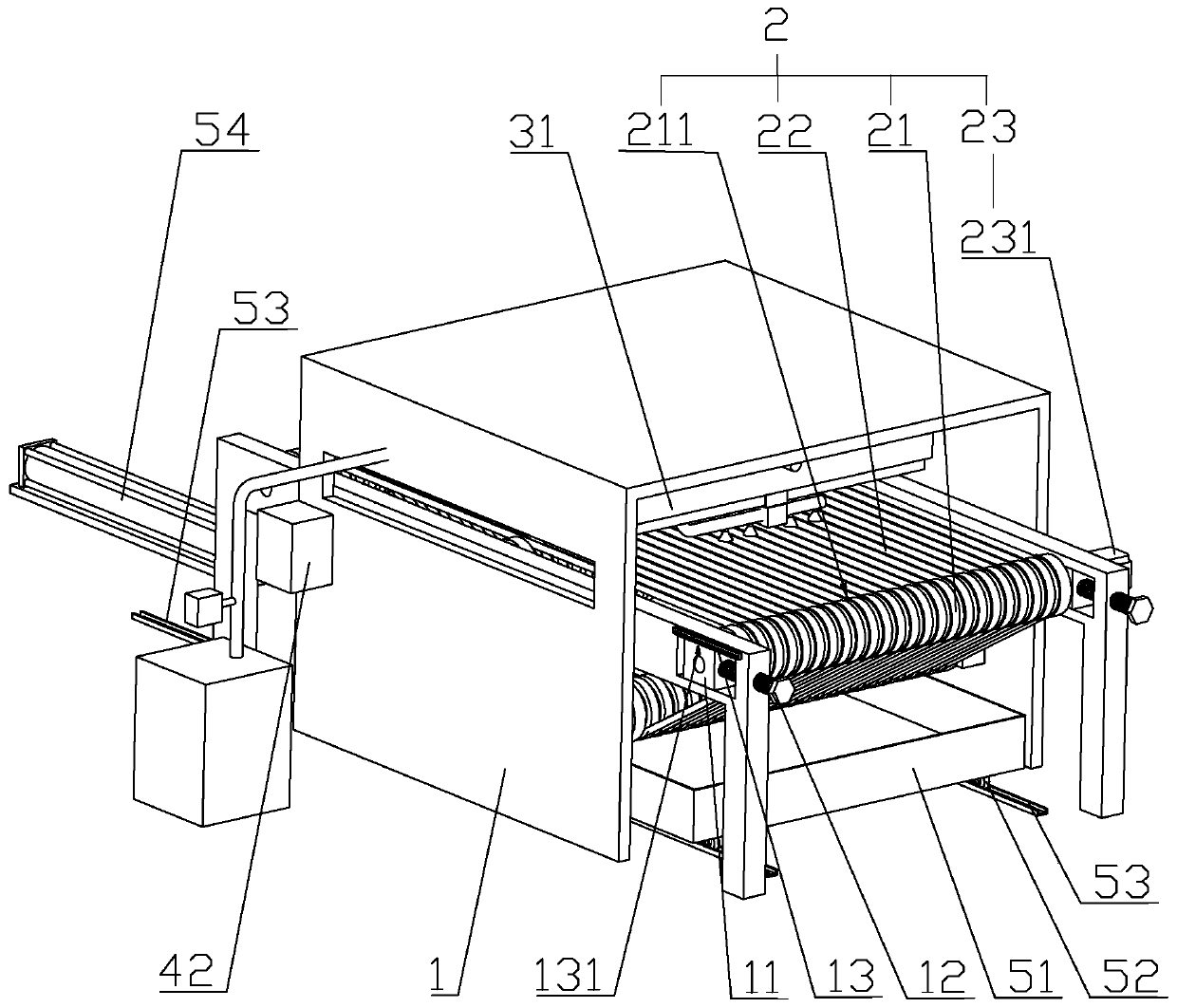

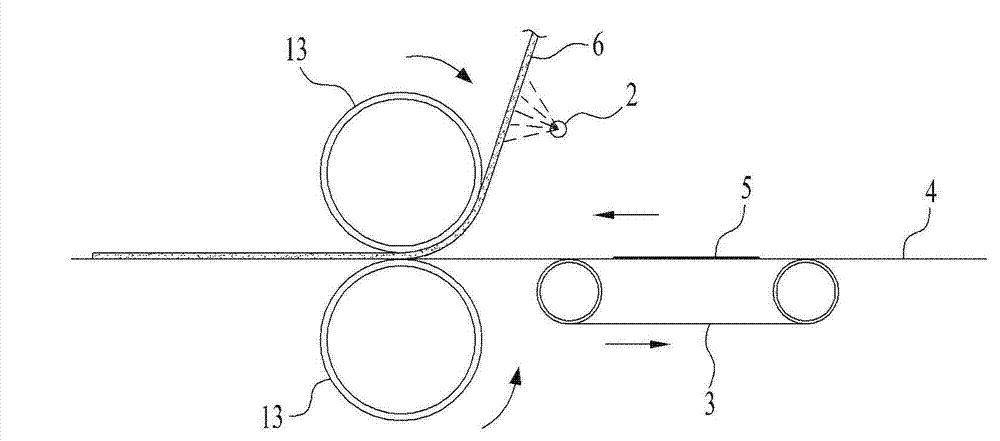

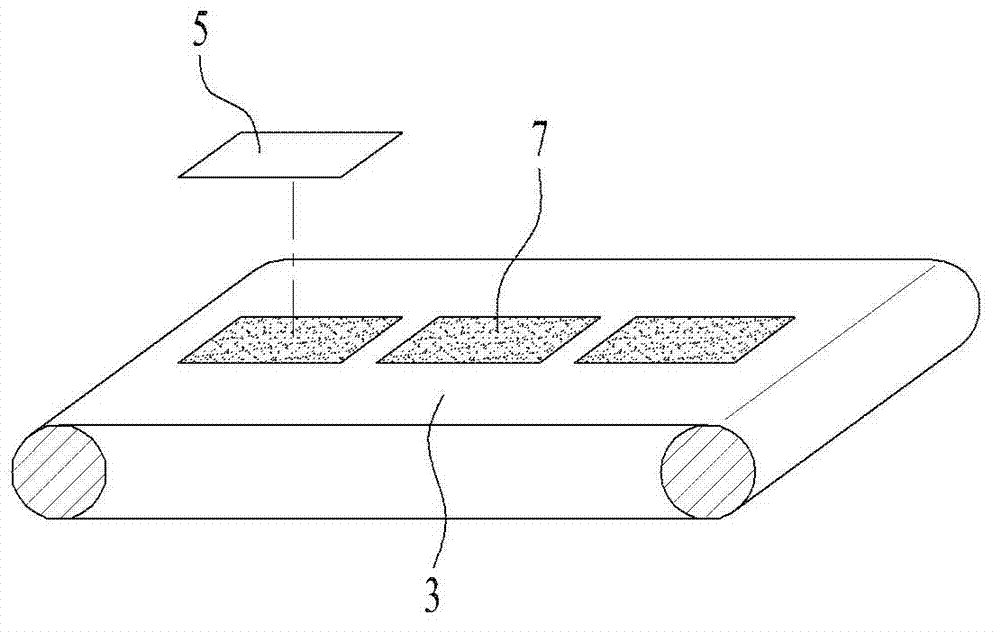

Embossed leather manufacturing technology and coating machine

ActiveCN109777900AEvenly paintedImprove spray qualityComposite leathersLeather/skins/hides/pelt chemical treatment apparatusManufacturing technologyX-machine

The invention relates to an embossed leather manufacturing technology and a coating machine, and relates to the technical field of leather production devices. The coating machine comprises a machine body, a guide belt arranged on the machine body and used for conveying a leather material, and a spraying mechanism arranged on the guide belt, the spraying mechanism comprises a crossbeam connected tothe top of the machine body, a support slidably connected with the crossbeam, nozzles arranged on the support, a driving part used for driving the support to slide back and forth in a direction perpendicular to the conveying direction of the guide belt and a material supply source communicated with the nozzles, and the crossbeam is parallel to the surface of the guiding belt. The invention has the effect of improving the uniformity of spraying to improve the spraying quality of the leather. The coating machine improves the spraying uniformity to improve the spraying quality of leather.

Owner:东莞意能达新材料科技有限公司

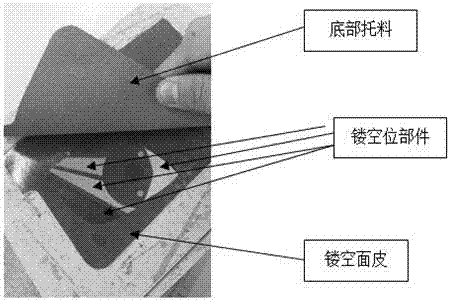

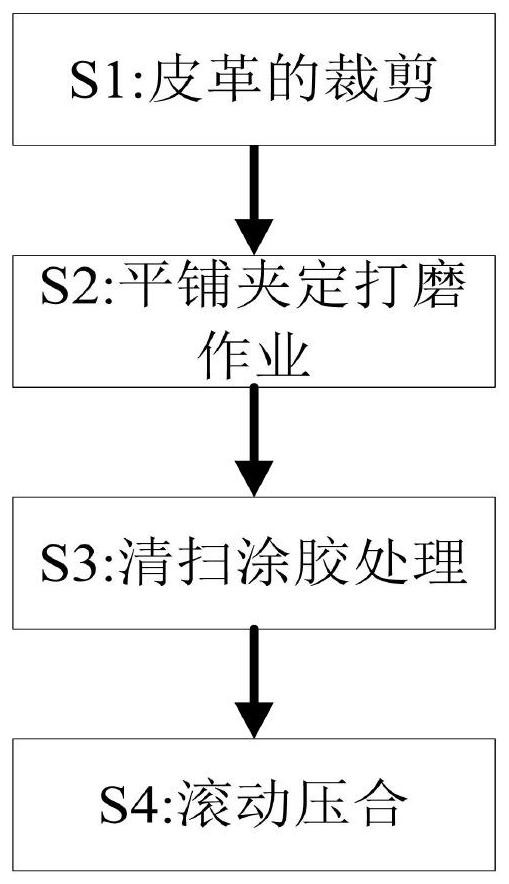

Seamless splicing production technology of leather

ActiveCN107164581AGuaranteed machining accuracyFit tightlyComposite leathersEngineeringOperation time

The invention discloses a seamless splicing production technology of leather. The leather is processed to be with a certain thickness in advance; then a shape mould is used for cutting, and the hollow-face leather with hollow patterns and hollow parts corresponding to the hollowing positions are obtained; and pressurizing and forming are conducted under a certain temperature, pressure and time by combining a hot press. The defect that according to an original leather splicing production technology, a splicing layer is liable to peel off and crack, is not attractive, not durable and the like is relieved. Tight and seamless attaching of splicing pieces can be achieved, obtained splicing patterns are high in stereoscopic impression and attractive in appearance, portions of the splicing patterns are more attractive and durable, a product is high in stereoscopic impression, and the decoration effect is good. The whole production technology process is simple in step, short in operation time, high in efficiency, safe and environmentally friendly.

Owner:深圳市德艺科技实业有限公司

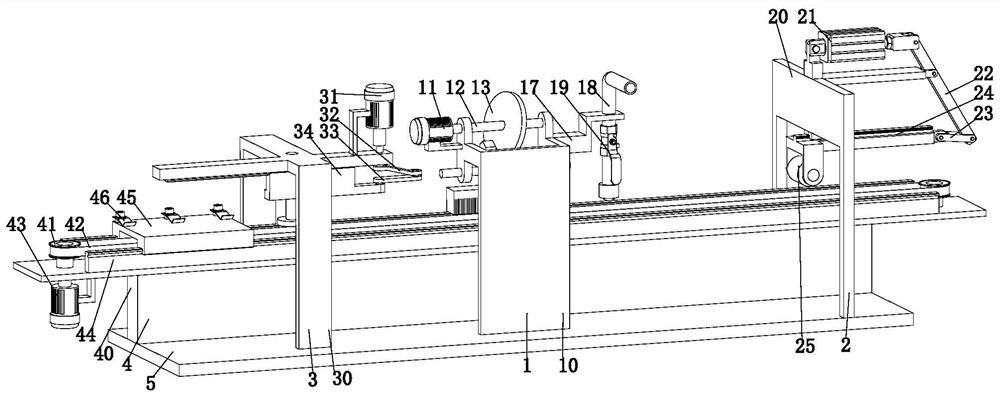

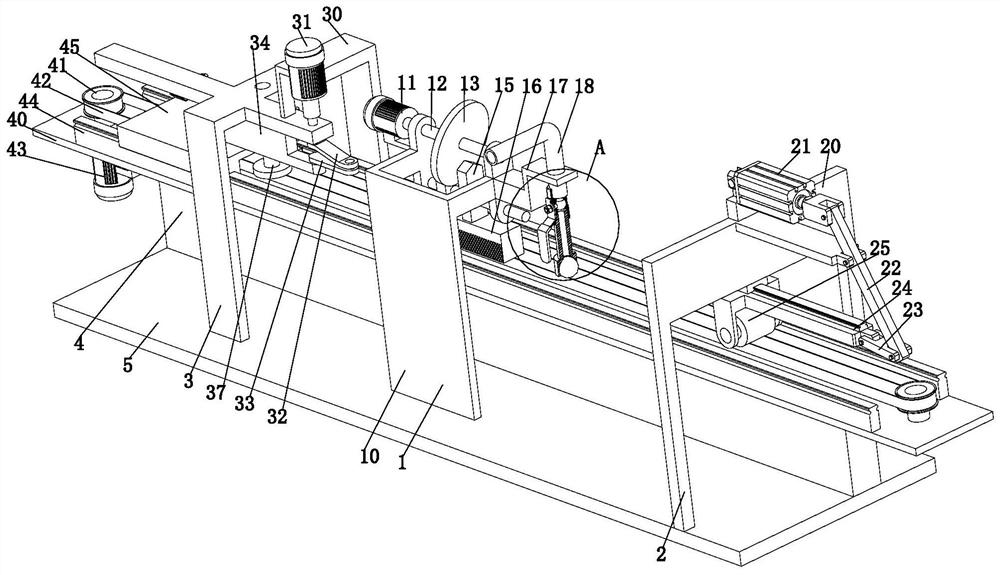

Bonding connection treatment method for automotive trim leather

ActiveCN113106173AEasy to excludeAdequate fitMechanical cleaningPressure cleaningPolishingAdhesive glue

The invention provides a bonding connection treatment method for automotive trim leather. The method involves a sweeping and coating mechanism, a rolling mechanism, a polishing mechanism, a translation mechanism and a bottom plate. The translation mechanism is mounted on the bottom plate, and the polishing mechanism, the sweeping and coating mechanism and the rolling mechanism are respectively arranged above the translation mechanism. The polishing mechanism and the rolling mechanism are installed on the left side end face and the right side end face of the bottom plate correspondingly, and the sweeping and coating mechanism is arranged between the grinding mechanism and the rolling mechanism and further located on the bottom plate. By means of the bonding connection treatment method for the automotive trim leather, the problems that the manual operation increases the labor cost and is low in working efficiency due to the fact that leather bonding connection treatment of leather interiors is mostly completed in a manual mode at present; and in addition, the surface roughness of leather bonding positions cannot be effectively improved through manual polishing operation, the bonding strength is affected, the coating amount of glue cannot be controlled, the bonding process is affected, the surface is prone to wrinkling and bubbling, and the bonding quality of the leather bonding surface cannot be guaranteed are solved.

Owner:江苏延立汽车零部件有限公司

Kind of production process for a fully covered leather sheath product

InactiveUS20170050413A1Save human effortPromotes appearanceLamination ancillary operationsLayered product treatmentAdhesiveManufacturing engineering

The present invention discloses a kind of production process for a fully covered leather sheath product, which comprises the following steps of: determining peripheral dimensions of leather such as the length and width according to the size of the product, and coating the leather with an adhesive; putting the shell of a product to be covered into the upper die of a mold, placing the trimmed leather into the lower die of the mold, and positioning it by a positioning post; heating the above-mentioned leather placed in the lower die of the mold; closing the upper die and the lower die immediately after the heating treatment is complete; opening the mold until the lamination is complete, taking out the product from the mold and fitting it with a fixture for the stretching folding treatment; heating the product along with the fixture to bond the leather with the interior of the product shell; and pressing it along with the fixture after heating; taking the pressed product out of the fixture and cutting excessive leather, attaching an inner lining material of the same dimensions after the excessive leather is cut, and pressing the inner lining material for bonding. The objective of the present invention is to provide a production process for the fully covered leather sheath product, which has high production efficiency and can improve the overall product design effect.

Owner:SENG TONG GRP INT BROS INVESTMENT LTD

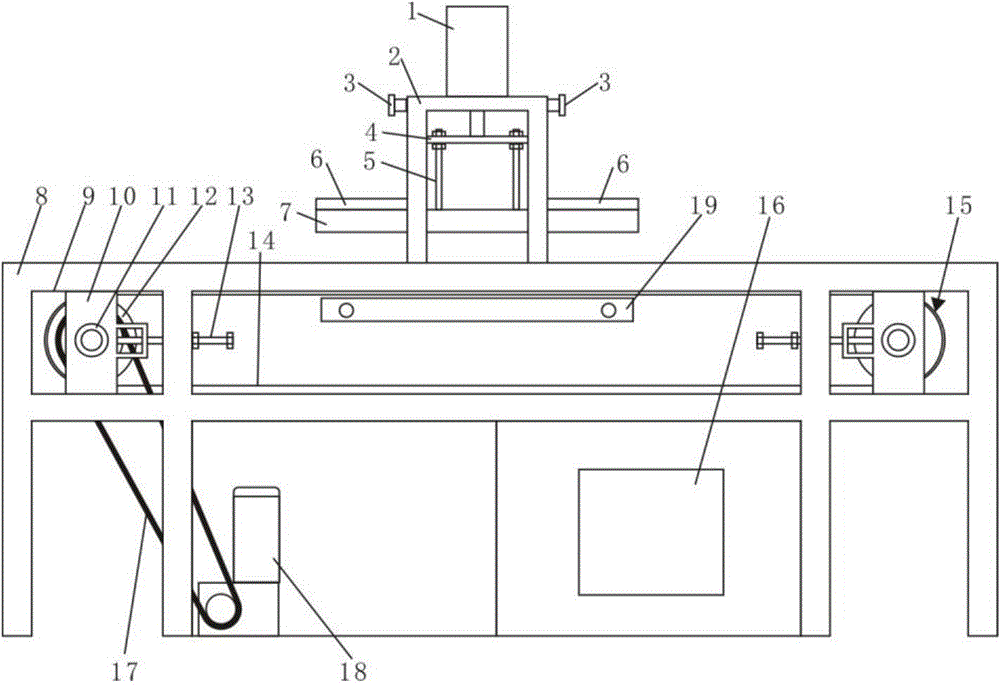

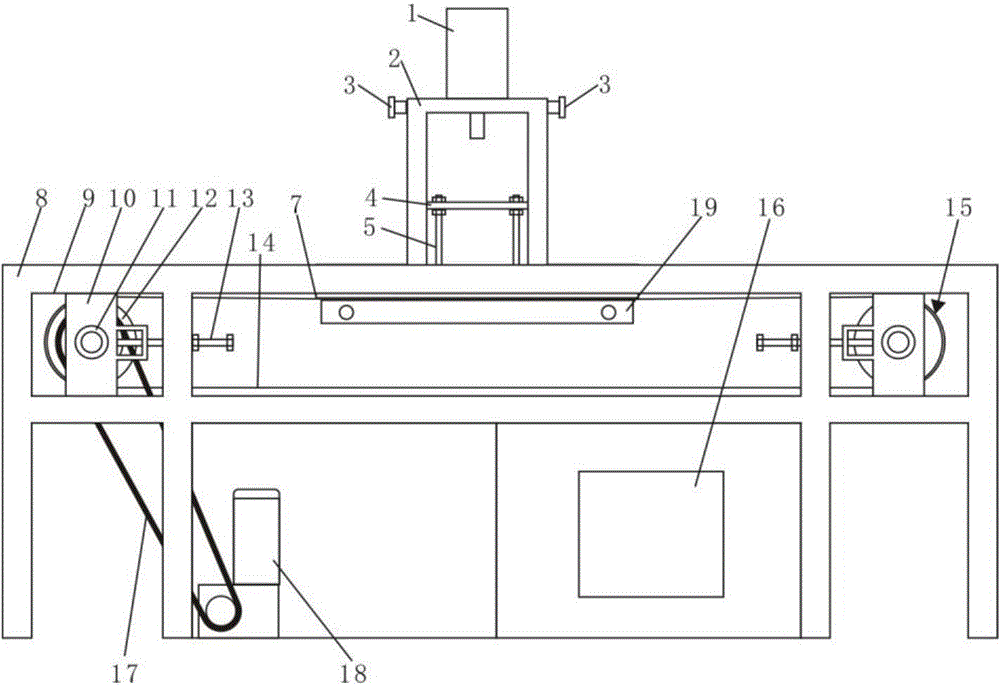

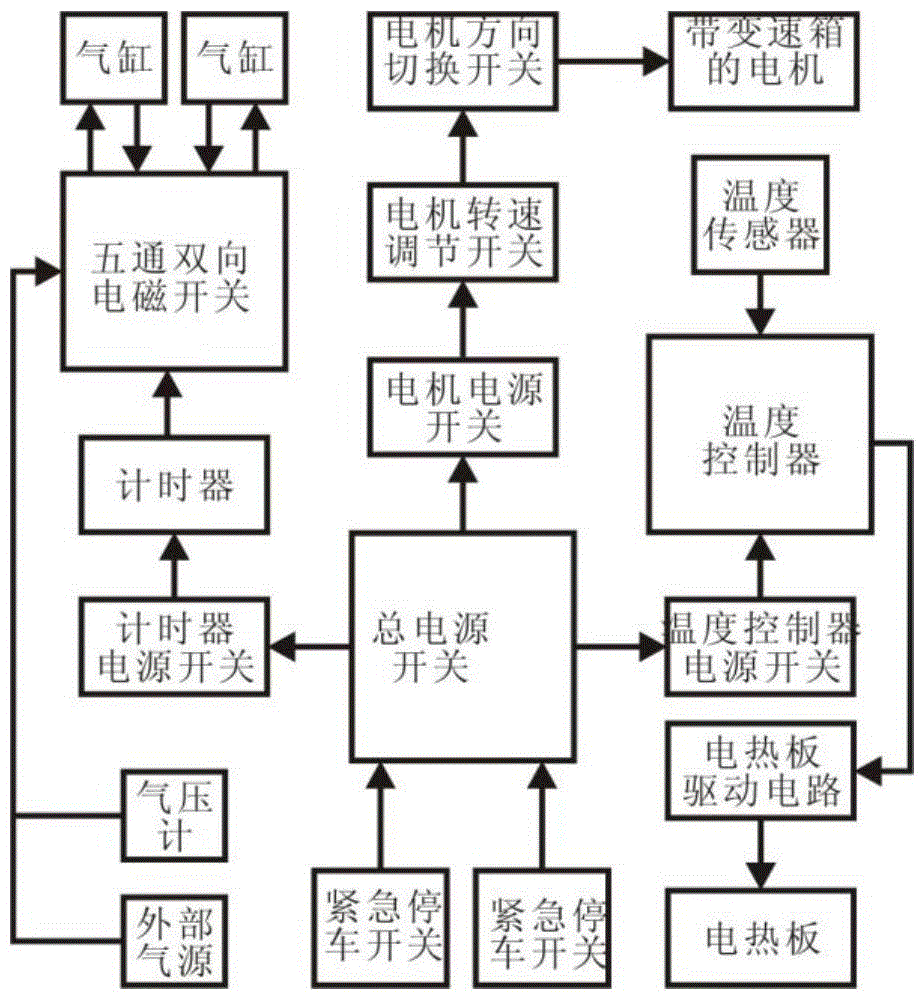

Flow-line pneumatic leather hot-pressing bonder and production technique thereof

The invention discloses a flow-line pneumatic leather hot-pressing bonder which comprises an electromechanical part and a control part, wherein the electromechanical part comprises an upper frame and a lower frame; in the upper frame, the tail ends of two cylinder piston rods are fixedly provided with a pressure plate, and a heating unit is installed on the pressure plate; the lower frame is provided with a conveyer belt; and the conveyer belt is connected with a transmission-containing motor installed on the lower frame through a chain. The invention also discloses a production technique of the bonder, which comprises an operating method, heating temperature, press-fit pressure, press-fit heating time and the like. When the bonder and production technique thereof are used for producing the press-fit leather and lapping cloth, the leather and lapping cloth can be bonded very firmly, and can not be separated easily; and the leather and the heat-shrinkable material can not generate buckling deformation; and the qualification rate of the product is enhanced to 90-100%.

Owner:四川非意欧国际皮革制品有限公司

Multifunctional leather preparation method and leather used for automobile

The invention relates to a multifunctional leather preparation method. The multifunctional leather preparation method comprises the following steps that 101, blind holes are dilled on a first layer of leather, the density of the holes is 2 / cm<2>, and the diameter of the holes is 0.1 cm; 102, the blind holes are filled with deodorants; 103, the two sides of the first layer of leather are pasted with a second layer of leather and a third layer of leather; 104, the three layers of leather are put into a paclitaxel solution to be immersed for 30 min and are dried; 105, the surface of the leather is coated with real stone paint; and 106, the leather is immersed in a supersaturated potassium chloride water solution for 15 min at the temperature of 4 DEG C, is taken out and is put into an autoclave to be processed for 15 min at the temperature of 105 DEG C, drying is conducted, a leather color brightening agent is added, and the leather is processed for 15 min and immersed in an interferon solution for 20 min. According to the multifunctional leather preparation method, the preparation process is simple, and the prepared leather has a good healthcare function.

Owner:浙江富邦汽车内饰科技有限公司

Recombinant yeast strains

ActiveUS20190093116A1Increase productionMonocomponent protein artificial filamentComposite leathersBiotechnologyYeast

This invention relates to genetically engineered strains of yeast and methods, for producing recombinant protein (e.g., collagen). Recombinant protein of the present invention is used to produce biofabricated leather or a material having leather-like properties containing recombinant or engineered collagen. The yeast strains are engineered to produce ascorbate and / or increased production of α ketoglutarate.

Owner:MODERN MEADOW INC

Water-resistant low-temperature-resistant water-based adhesive and application thereof and method for bonding two-layer cowhide product

InactiveCN108342180AImprove adhesion fastnessImprove water resistance and low temperature resistanceNon-macromolecular adhesive additivesComposite leathersWater basedAdhesive

The invention provides a water-resistant low-temperature-resistant water-based adhesive and application thereof and a method for bonding a two-layer cowhide product, wherein the water-resistant low-temperature-resistant water-based adhesive comprises 90% to 95% by weight of carboxylated styrene-butadiene latex, 2%-4% of an aqueous curing agent, 0.5%-1.5% of a thickener, 0.3%-0.5% of a leveling agent, 0.2% of a defoamer and balance of water, wherein the carboxylated styrene-butadiene latex is carboxylated styrene-butadiene latex compounded with aqueous polyurethane. The water-based adhesive hasthe advantages of low temperature resistance of-10 DEG C, bending resistance, water resistance and the like. The water-based adhesive is applied to the bonding of two-layer cowhide, enhances the strength, durability and storage resistance of the two-layer cowhide, and broadens the use environment of the two-layer cowhide. The produced two-layer cowhide is suitable for most of two-layer cowhide clothing, bags and other products on the market.

Owner:运研材料科技(上海)有限公司

Leather material and processing method thereof

InactiveCN101956026BGive full play to the elastic propertiesIncrease elasticityLeather manufacturingComposite leathersEmulsionWork in process

The invention discloses a processing method of a leather material, comprising the following steps of: (1) pre-processing an animal skin into a semi-finished product of the leather material with the thickness of 0.7-1.3mm; (2) cutting the semi-finished product of the leather material into a plurality of layers of skins by utilizing a leather-splitting process; (3) forming scraping pulp for a binding surface of an elastic auxiliary material according to required elasticity so that the elastic range of the formed elastic auxiliary material is identical with that of the split leather material; (4) adhering the binding surface of the split leather material and the binding surface of the elastic auxiliary material at high temperature with a substance containing natural emulsion; (5) placing theadhered leather material into water for cleaning, and washing the scraping pulp for forming in the adhering process; and (6) placing into water again and heating to 45-90 DEG C, adding a softening agent and plant protein oil in the heating process, then adding a water-washing resistant agent, and dewatering and airing. The processing method of the leather material has the advantages of favorable elasticity of the obtained leather material, water-washing resistance and simple and convenient processing procedure. The invention also discloses the leather material.

Owner:谈国忠

Goose feather fur with leather surface and mfg. method thereof

InactiveCN1597990ANot easy to fall offNo pollution in the processComposite leathersLayered productsEngineeringCold weather

The invention relates to goose down fur and its making method. It relates to deep-processing production of goose down fur and its technique. A layer of leather or man-made leather is compounded on one side of worn-out fur. Suture: select goose down fur after taning and forming and cut the boundary of direcly; fix it up on the flat with the down facing the ground. Pressing: spray the glue onto the worn-out fur, press the leather or man-made leather with the same size onto it and make it into a unit. The features rare high shock resistance, can be bare to the light, is benefit for making the fur clothes and the products to prevent the cold weather.

Owner:马树祥

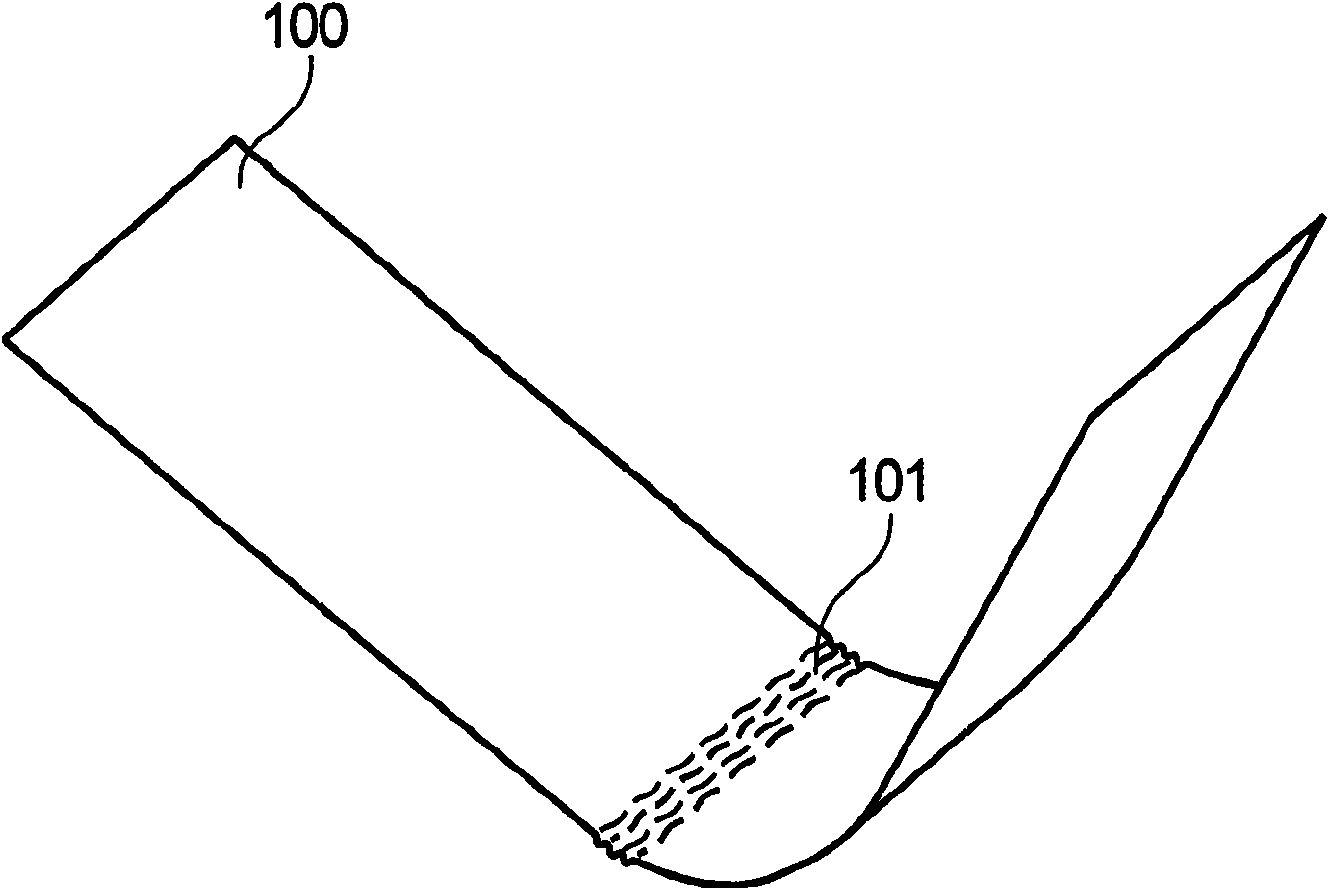

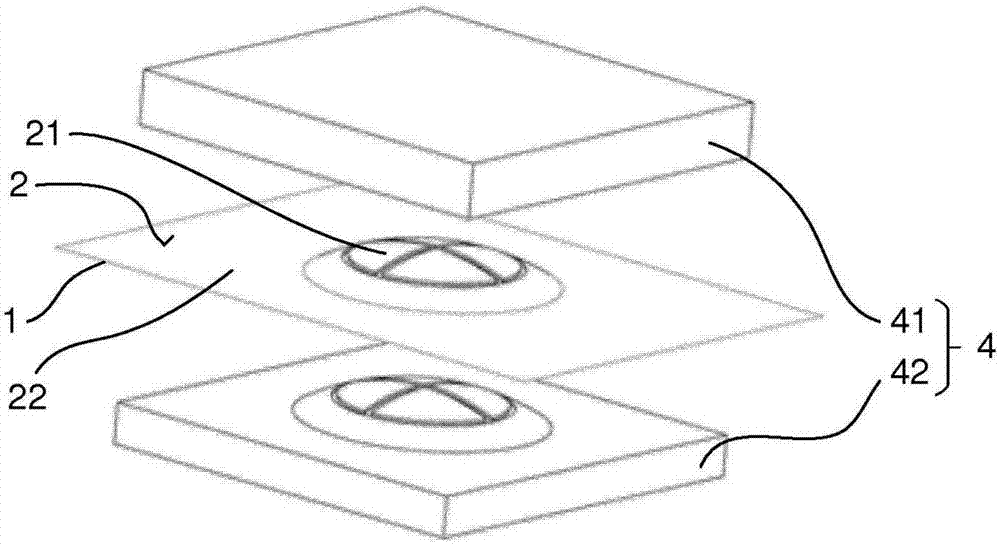

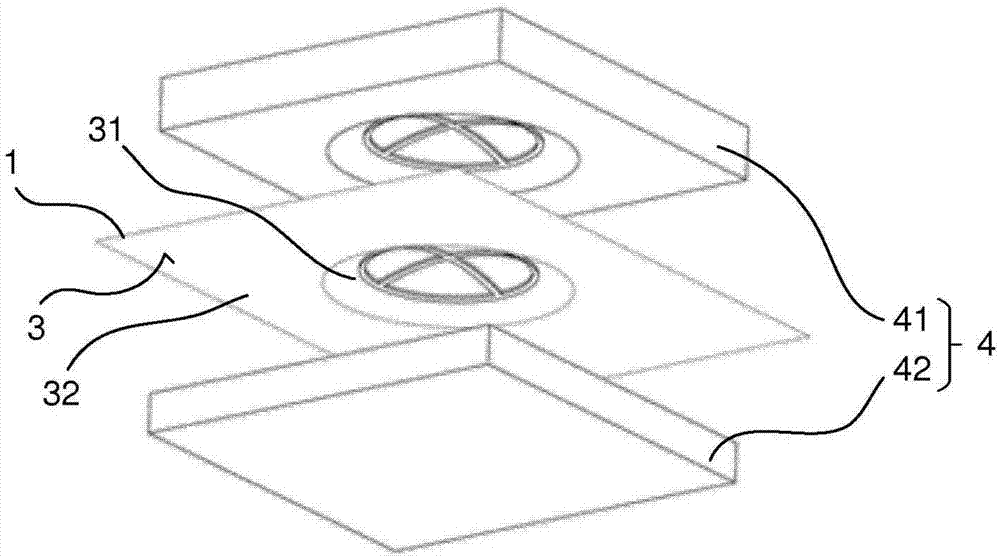

Method for manufacturing a decorative element having a raised embossed visible surface, and decorative element manufactured by said method

The invention relates to a method for manufacturing a decorative element (100) having a raised embossed visible surface (2). According to said method, an embossing device (4) having a female embossingdie (41) and a male embossing die (42) and at least one decorative material layer (1) are provided. Said decorative material layer (1) is disposed between the female embossing die (41) and the male embossing die (42) such that a visible surface of the decorative material layer (1) faces the female embossing die (41), and a backing surface (3) of the decorative material layer (1), opposite the visible surface (2), faces the male embossing die (42). The embossing is then carried out using the embossing device (4) such that the decorative material layer (1), after embossing, has a raised region(21) on the visible surface (2) and an opposite recessed region (31) on the backing surface (3). In order to stabilize the raised region (21), an insert element (5) is inserted in the recessed region(31). The invention further relates to a decorative element (100) manufactured according to the said method.

Owner:BAYERISCHE MOTOREN WERKE AG

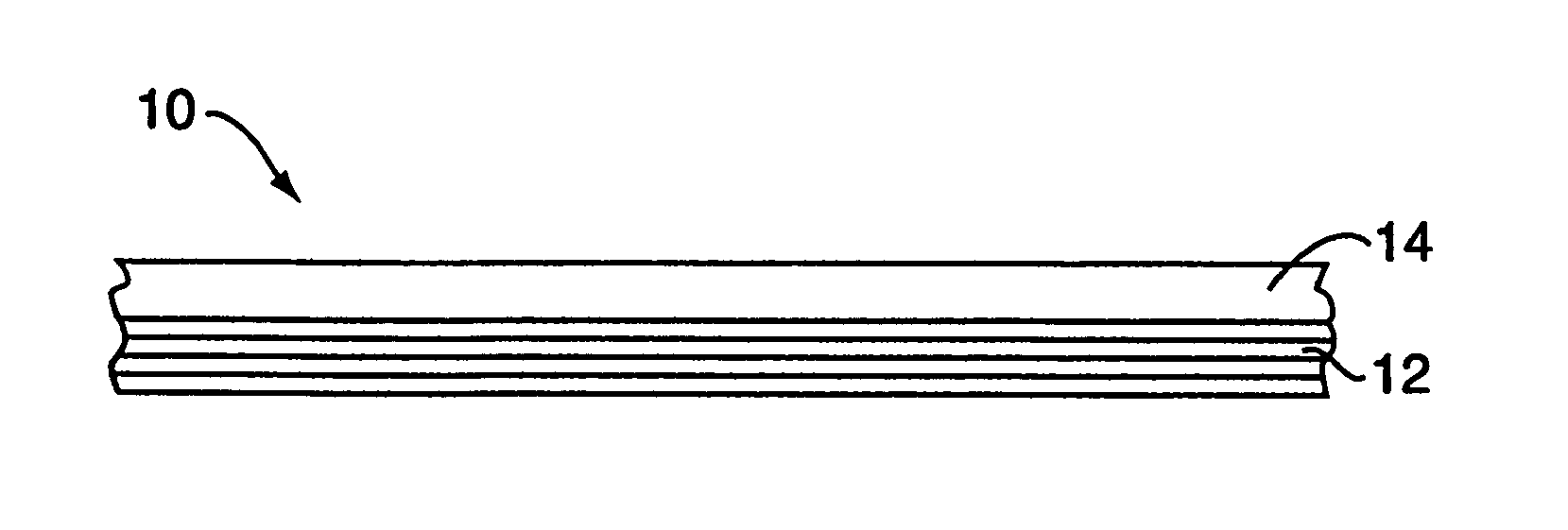

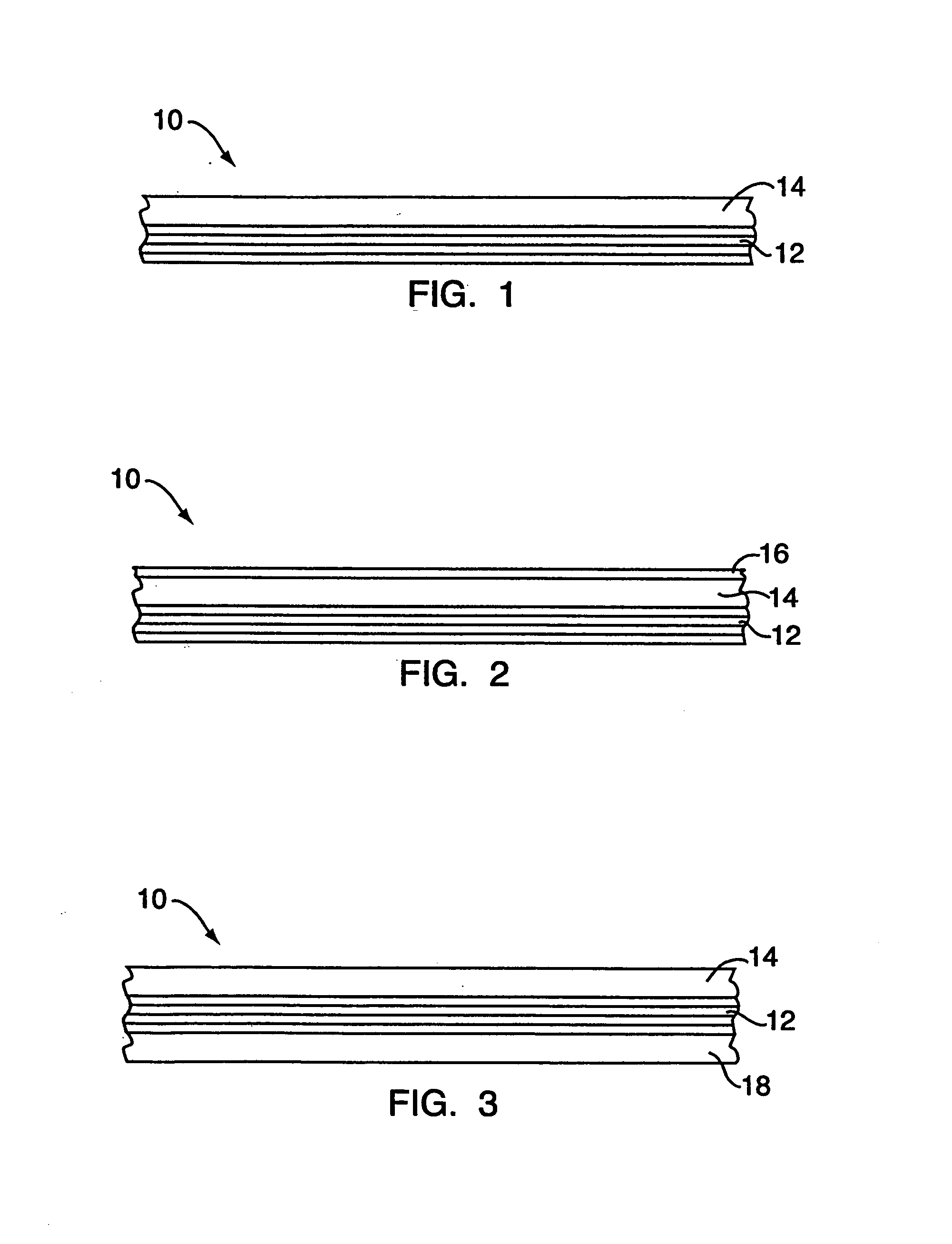

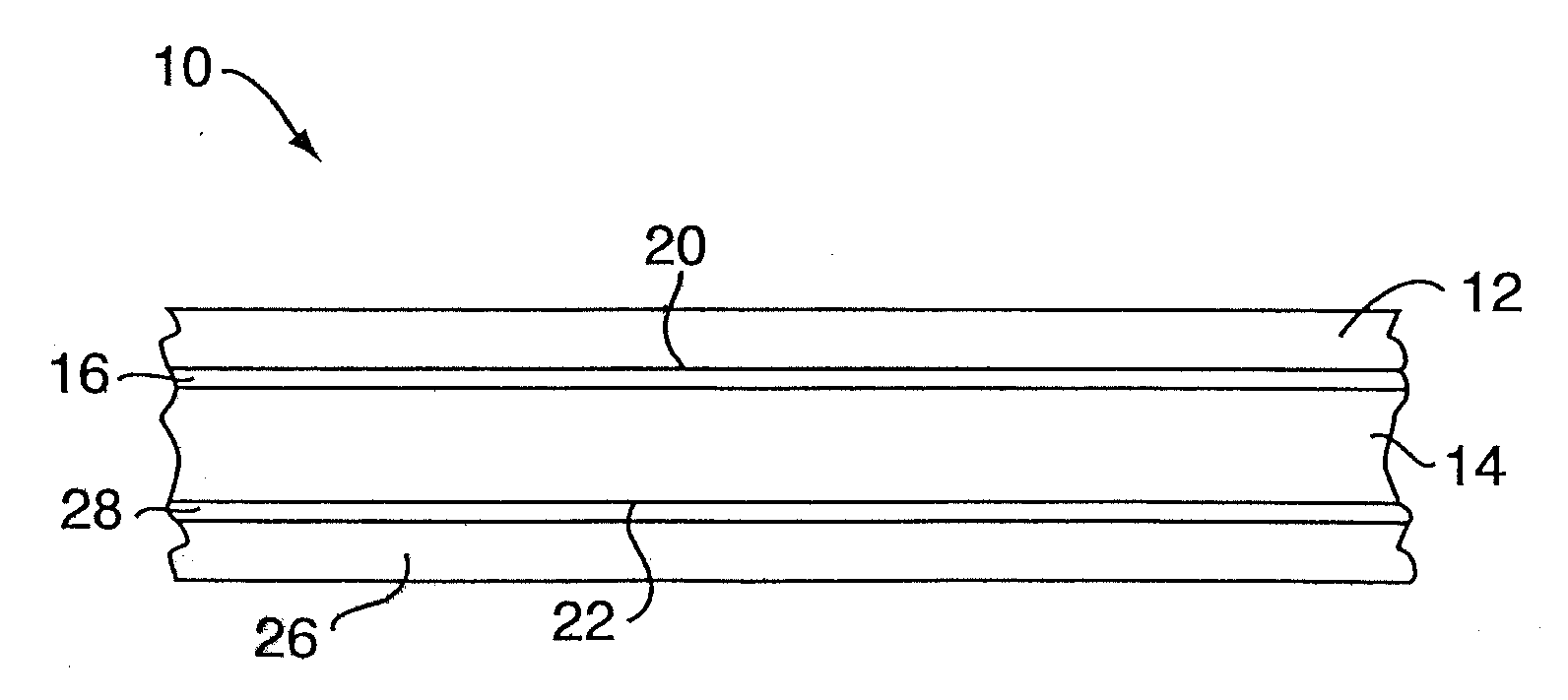

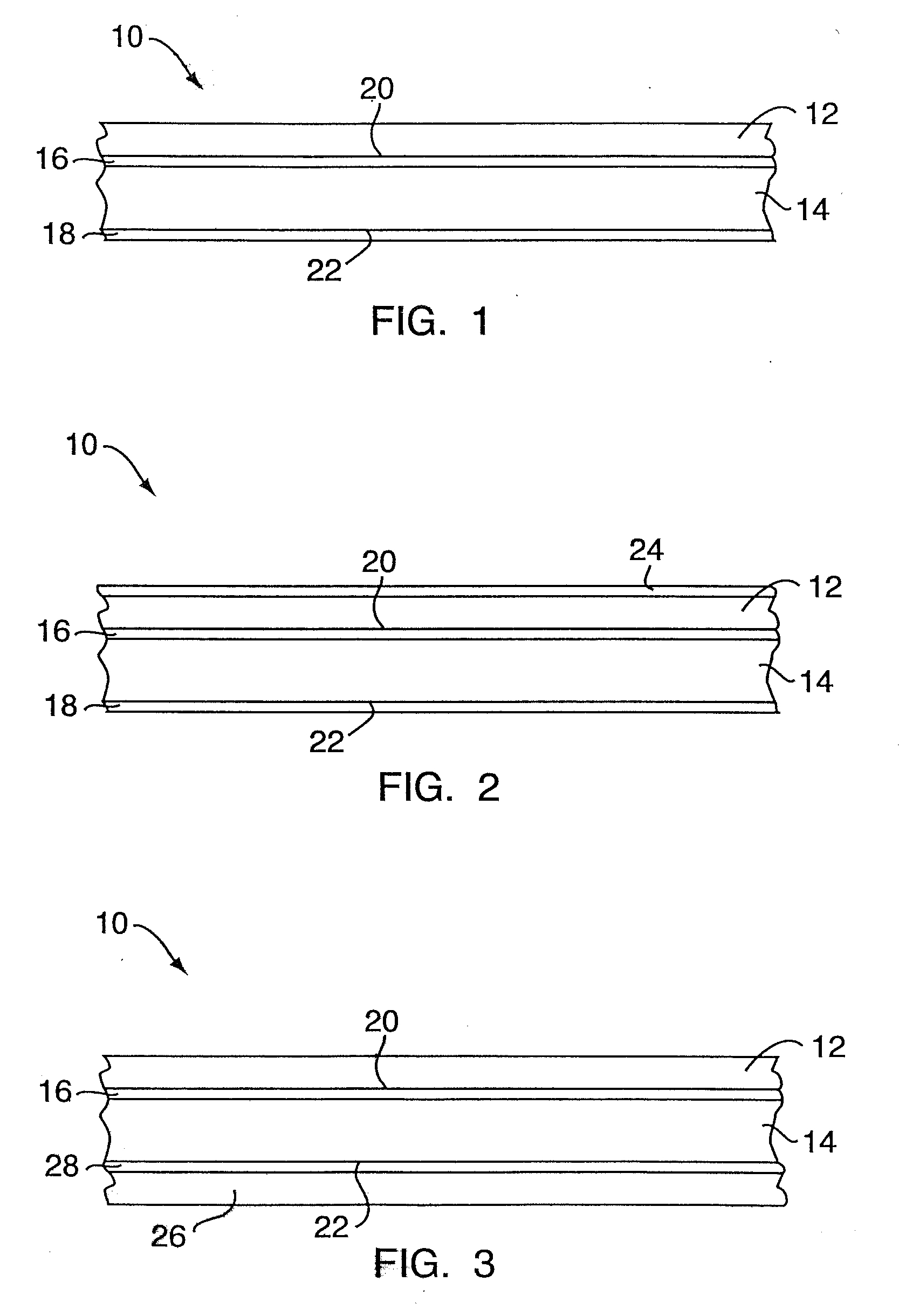

Leather laminated decorative panel

A heat and pressure consolidated laminate, and method for producing the same, is provided that includes in superimposed relationship a decorative layer consisting essentially of a leather material, an underlay layer, a substrate, and an optional backer layer. The substrate has a first surface and a second surface opposite one another. The underlay layer includes one or more cellulosic sheets impregnated with a thermosetting resin, and is disposed between the decorative layer and the first layer of the substrate. The backer layer includes one or more cellulosic sheets impregnated with a thermosetting resin, and is disposed contiguous with the second surface of the substrate.

Owner:CORTLAND CAPITAL MARKET SERVICES

High strength leather material

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

Manufacturing method of breathable hybrid-leather

ActiveUS20180371558A1Satisfies physicalSatisfies chemical performanceLamination ancillary operationsComposite leathersHot-melt adhesiveRaw material

A method for manufacturing a breathable hybrid leather includes: a raw material supply step of supplying the natural leather of recycled leather; a step of applying a hot-melt adhesive to the upper surface of the leather raw material; a bonding step of supplying a fabric to the upper surface of the adhesive layer and applying heat and pressure to the leather raw material, the adhesive layer, and the fabric to obtain a bonded fabric; and a step of ironing and coating the bonded fabric a plurality of times.

Owner:ATKOPLANNING

Method for laminating leather, and leather seat using same

InactiveCN103029402AAvoid stickingImprove productivityLamination ancillary operationsComposite leathersWorkbenchPaper sheet

The present invention relates to a method for laminating leather, comprising the steps as follows: separated papers are distributed on a horizontal workbench along a longitudinal direction; a plurality of leather sheets spaced to each other are fed to a position between two first rollers which are rotatable and matched with each other in order, wherein back sides of the leather sheets are upwards; a sponge is fed to the position between the two first rollers, a surface of the sponge is heated and fused by a heating device; while the fed sponge and leather sheets are pressed through the first rollers, the fused surface of the sponge is adhered to the back side of the leather sheet, so as to form a sponge-leather-separating paper composition; the sponge-leather-separating paper composition is cut into a predetermined size; the separating papers are removed, then the completed product is prepared for use.

Owner:DK LEAR KOREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com