Flow-line pneumatic leather hot-pressing bonder and production technique thereof

A hot-pressing bonding, pipeline technology, applied in the direction of composite leather, etc., can solve the problems of poor pressing effect, warping deformation of leather, different coefficients of thermal expansion and cold contraction, etc., to improve product qualification rate and avoid warping deformation. , The effect of large pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

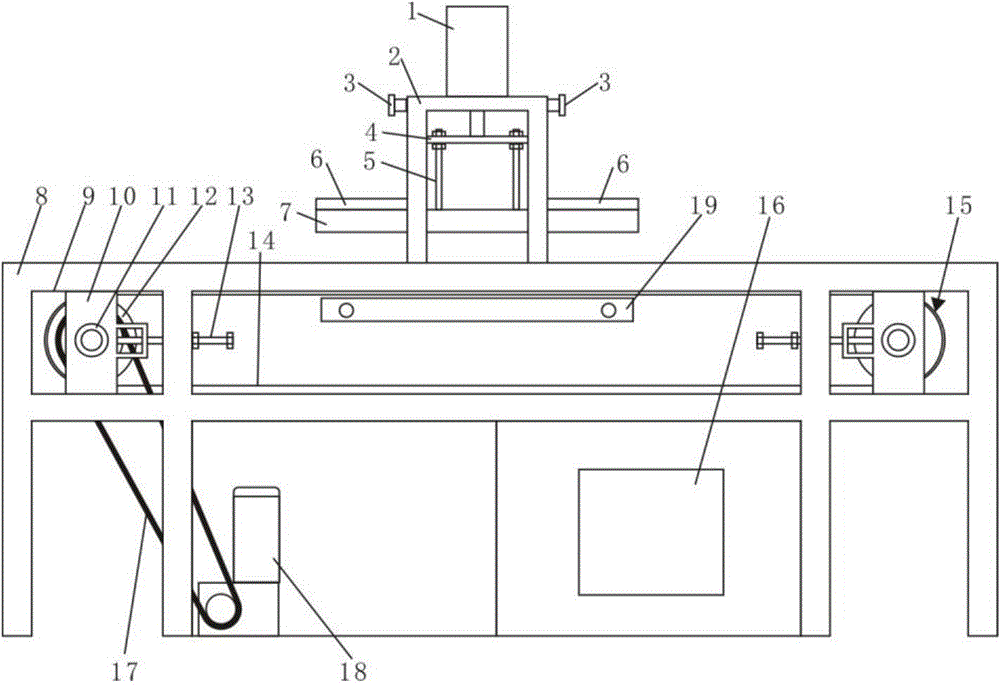

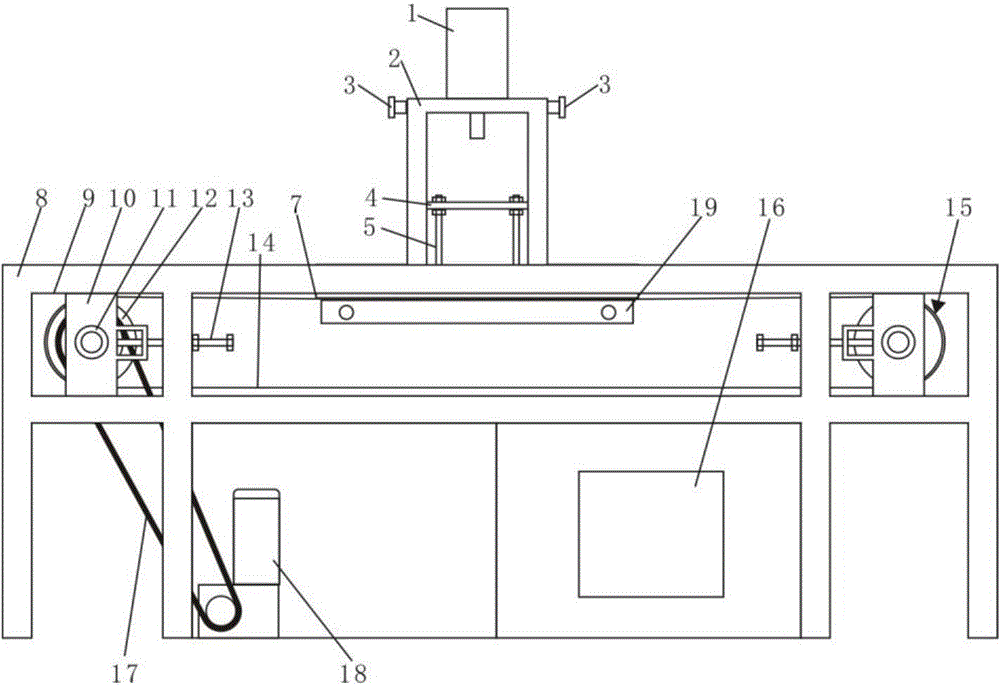

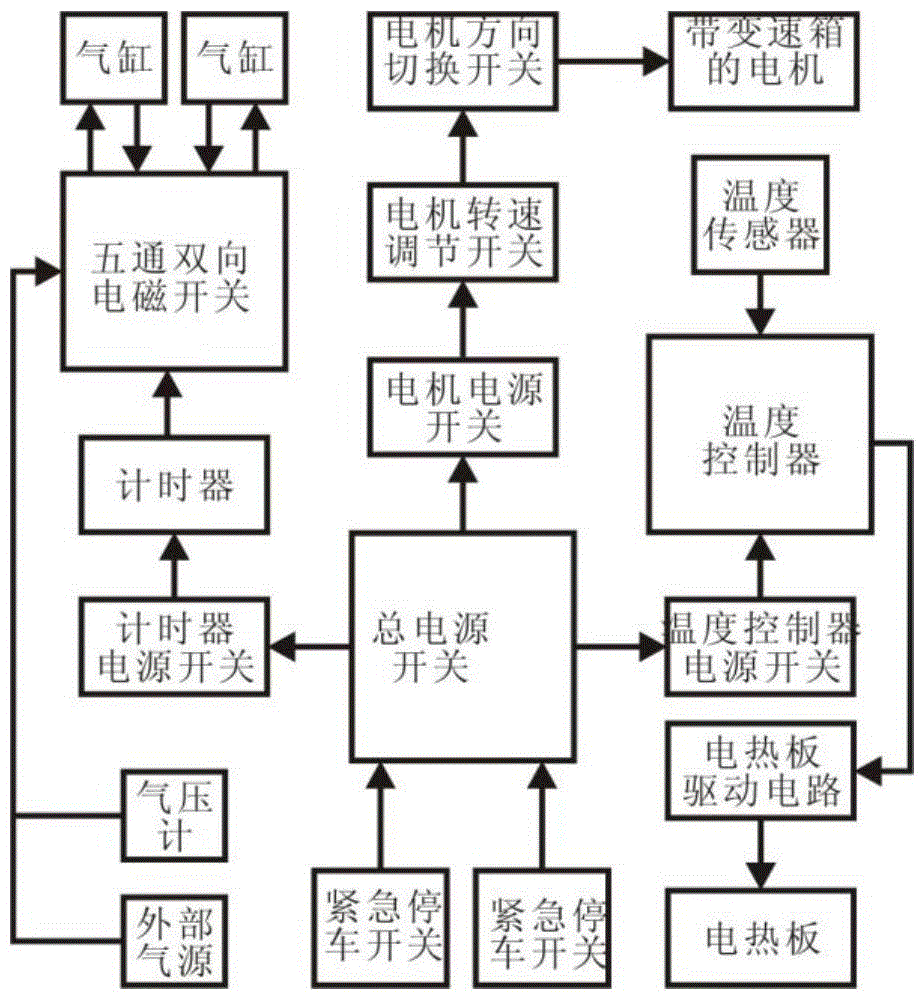

[0031] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0032] Such as figure 1 and 2 As shown, the line-type pneumatic leather hot-press bonding machine includes an electromechanical part and a control part. The electromechanical part includes an upper frame 2 and a lower frame 8. The upper frame 2 is set upside down with two cylinders 1 and two cylinders. 1 A pressing plate 7 is fixedly installed at the end of the piston rod, and a heating device 6 is installed on the pressing plate 7; a conveyor belt 15 is installed on the lower frame 8, and the conveyor belt 15 is connected to the motor with a gearbox installed on the lower frame 8 through a chain. 18 power connections.

[0033] In order to achieve stronger cooling of the leather, a cooling device 19 is provided below the belt on the side facing the pressing plate 7 in the conveyor belt 15 . The cooling device 19 is a cooling plate provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com