Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Containerboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Containerboard (CCM or corrugated case material) is a type of paperboard specially manufactured for the production of corrugated board. It includes both linerboard and corrugating medium (or fluting), the two types of paper that make up corrugated board. Since containerboard is made mainly out of natural unbleached wood fibers, it is generally brown, although its shade may vary depending on the type of wood, pulping process, recycling rate and impurities content. For certain boxes that demand good presentation, white bleached pulp or coating is used on the top ply of the linerboard that goes outside the box.

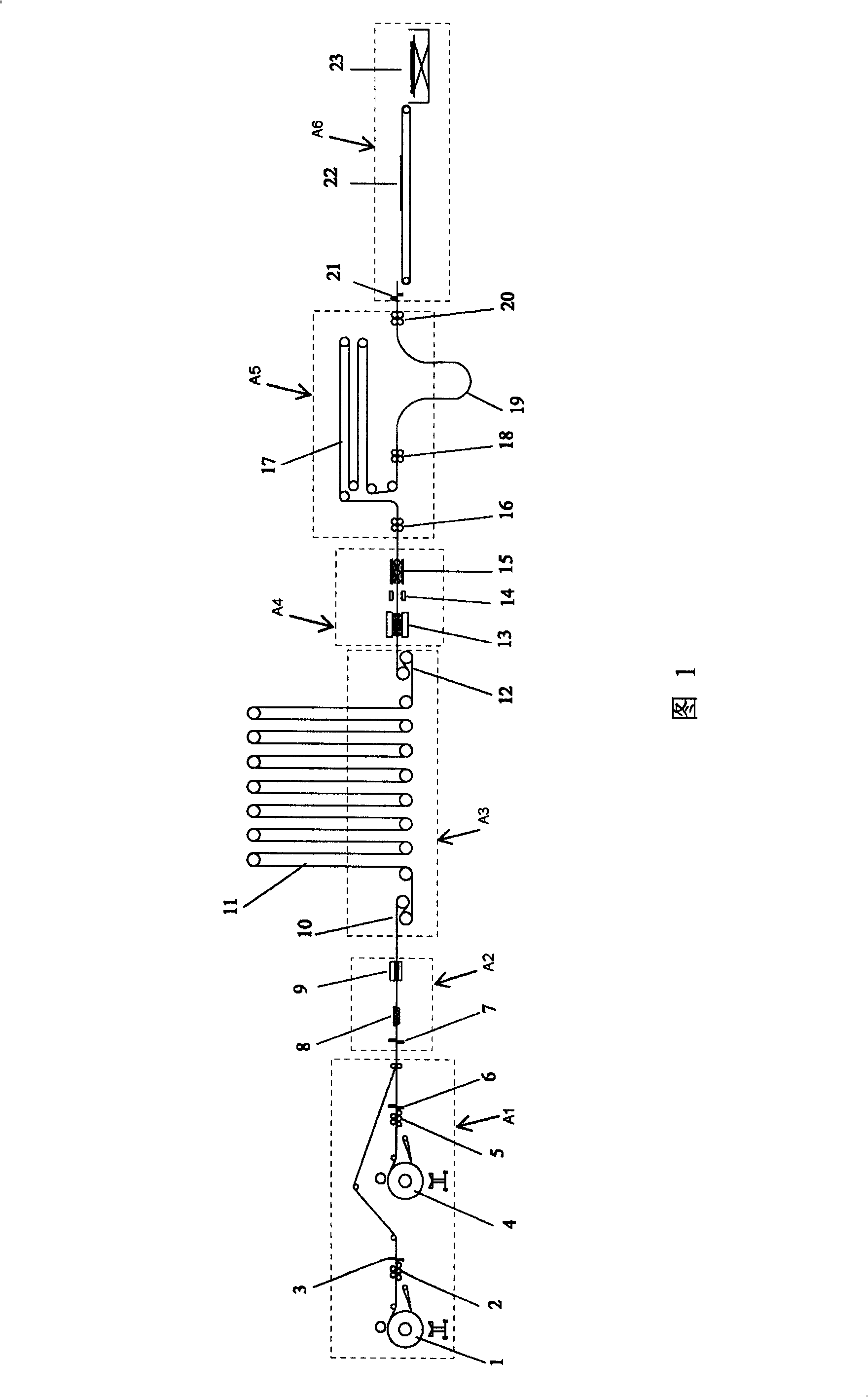

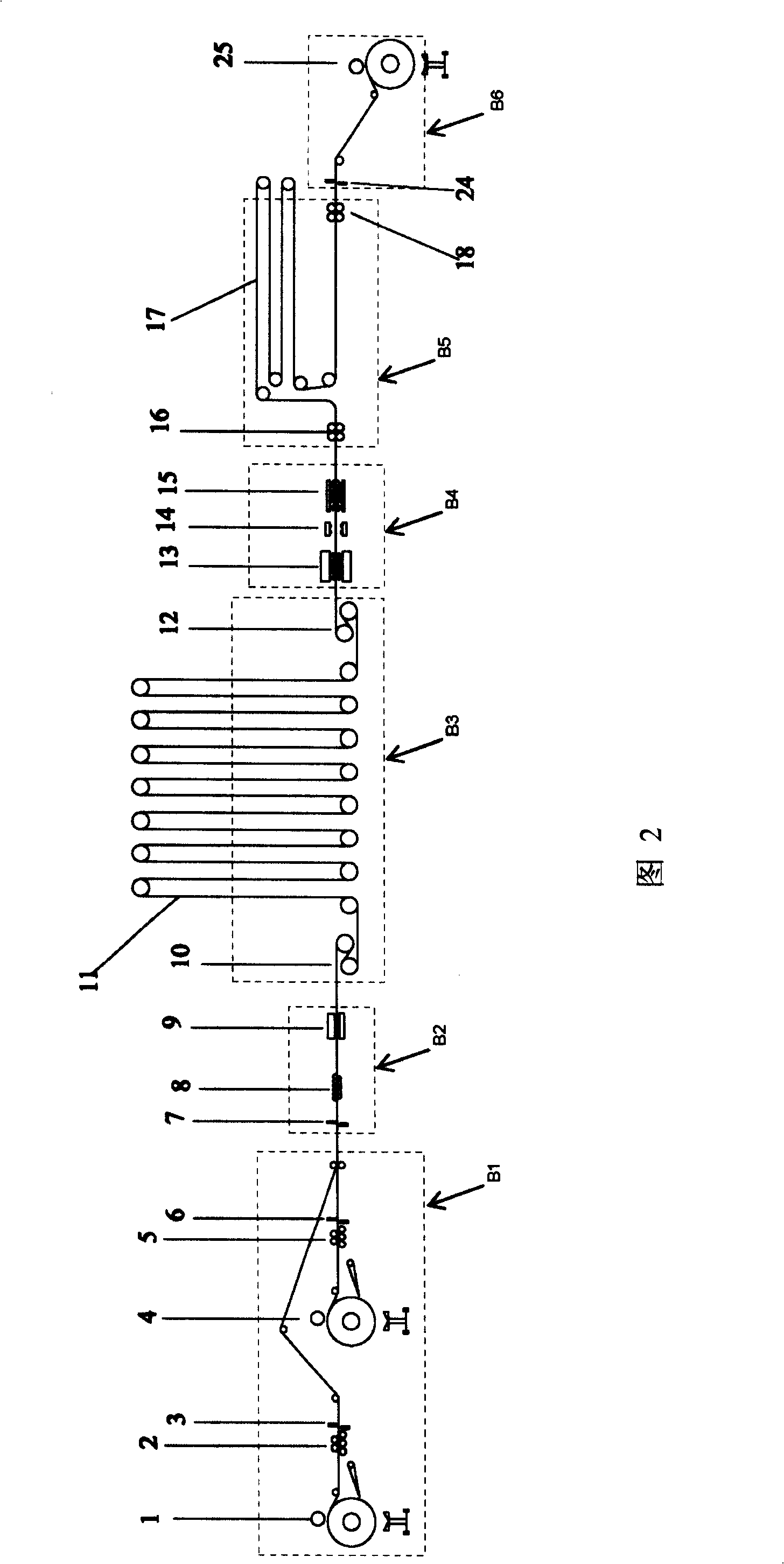

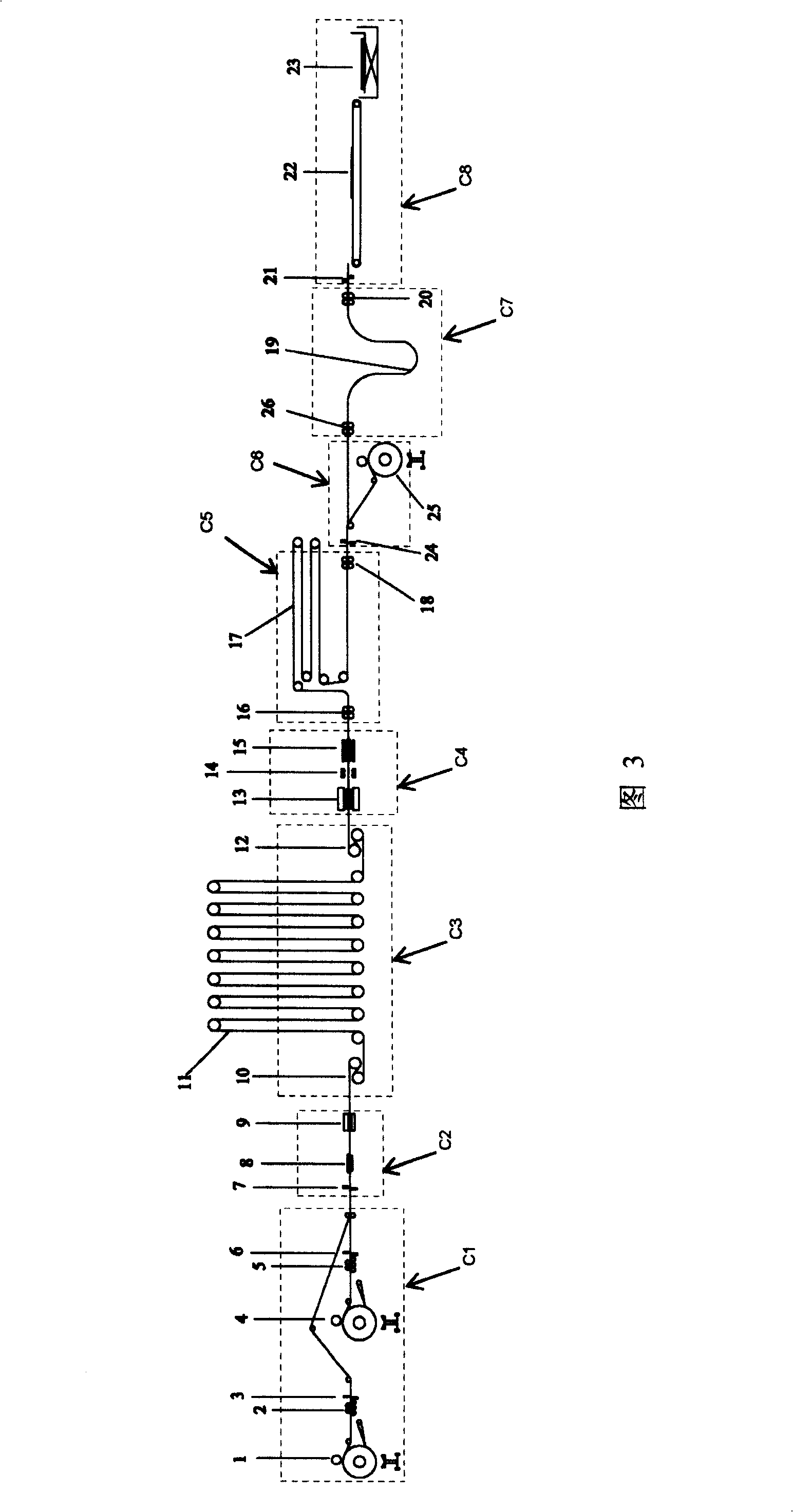

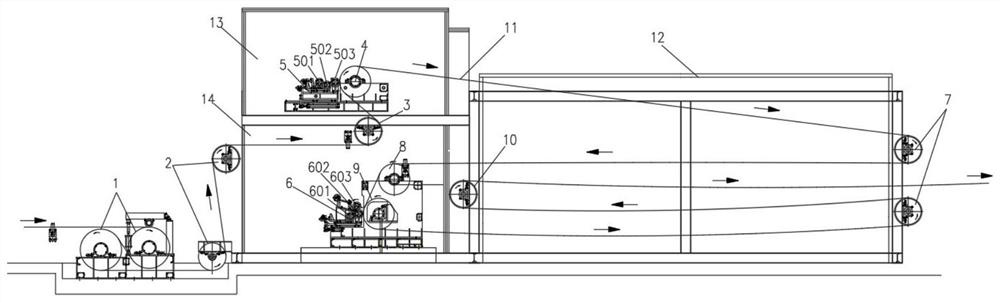

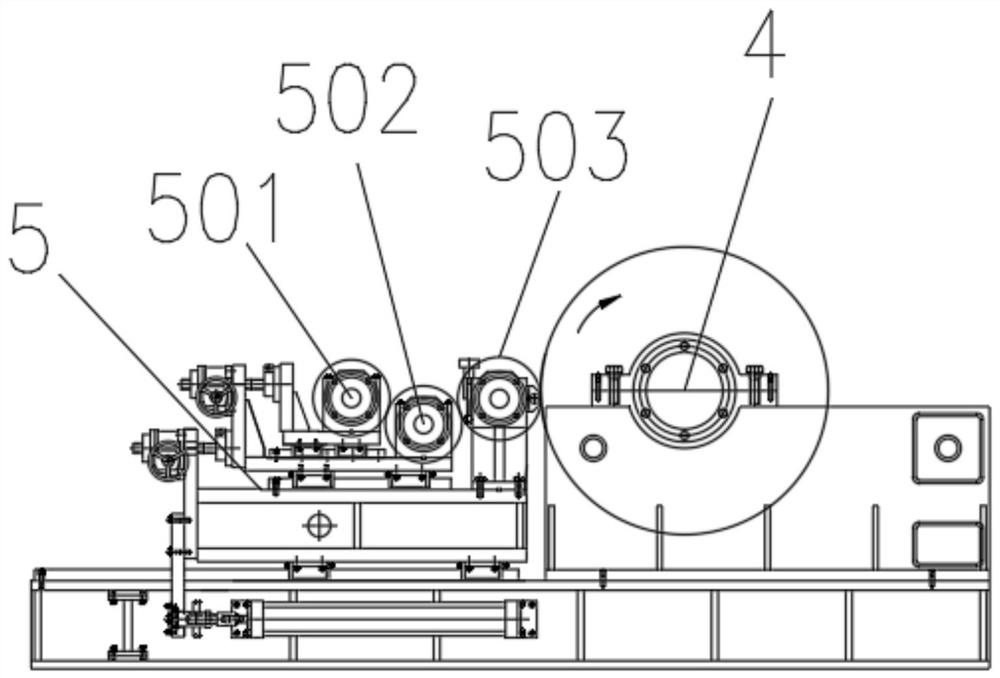

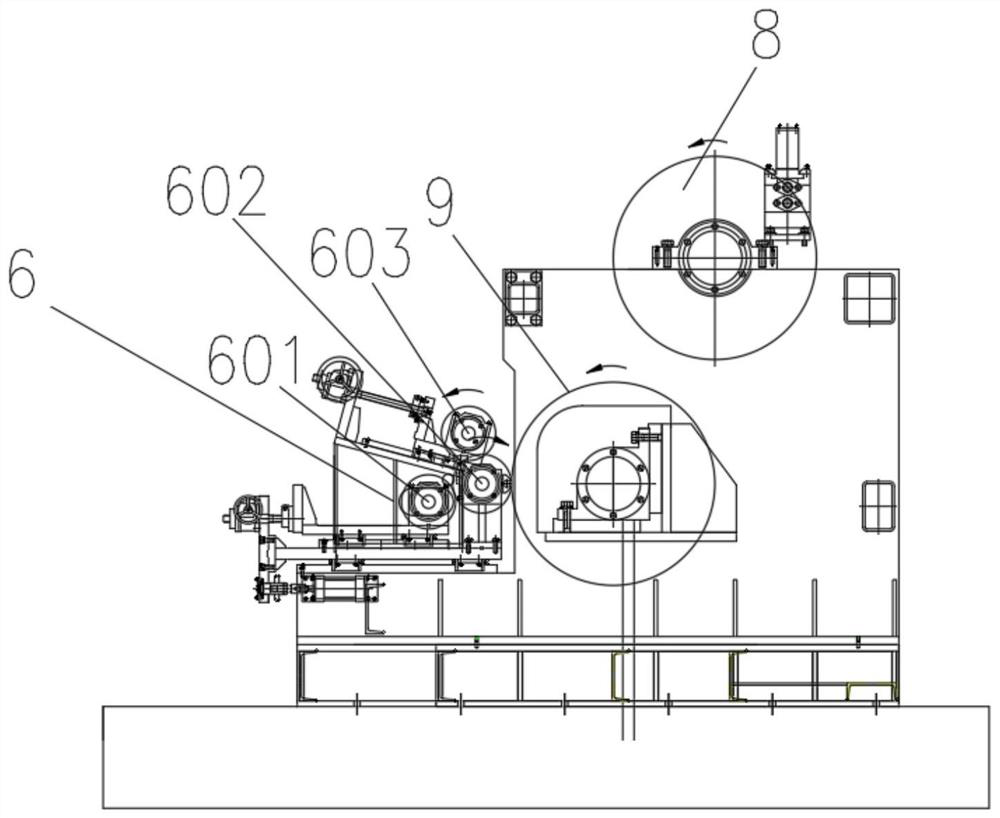

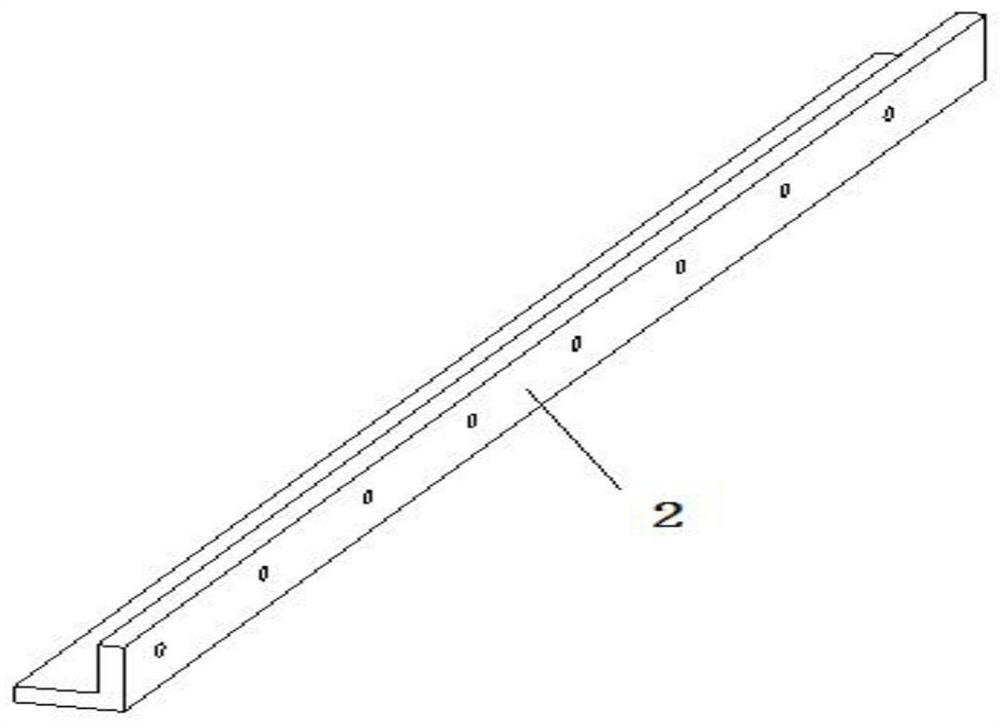

Pre-process production method and product line for container sheet material

ActiveCN101244512AReduce installed powerSmall footprintLiquid surface applicatorsOther manufacturing equipments/toolsProduction lineEngineering

The invention relates to a pretreatment production method of container sheet, comprising the steps as below: S1. The roll material is unreeled, and the continuous strip material is led out; S2. The continuous strip material is fed into a first storing and feeding mechanism; S3. The continuous strip material discharged by the first storing and feeding mechanism is pretreated on the surface; S4. The pretreated continuous strip material is fed into the second storing and feeding mechanism; S5. The continuous strip material discharged from the second storing and feeding mechanism is cut and stacked, or rolled up. The method also comprises a step of S6 between S1 and S2, that is, when two rolls of roll material need to be connected, the two rolls of roll materials are overlapped. The invention also relates to a pretreatment production line of container sheet. By adopting the full production line technology of container sheet pretreatment, compared with the prior art, the pretreatment production line has the advantages that the installed power of production equipment can be reduced by 50%; the occupied area can be decreased by 60%; the labor force can be reduced by 90%, and the productivity can be increased nearly 3 times.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

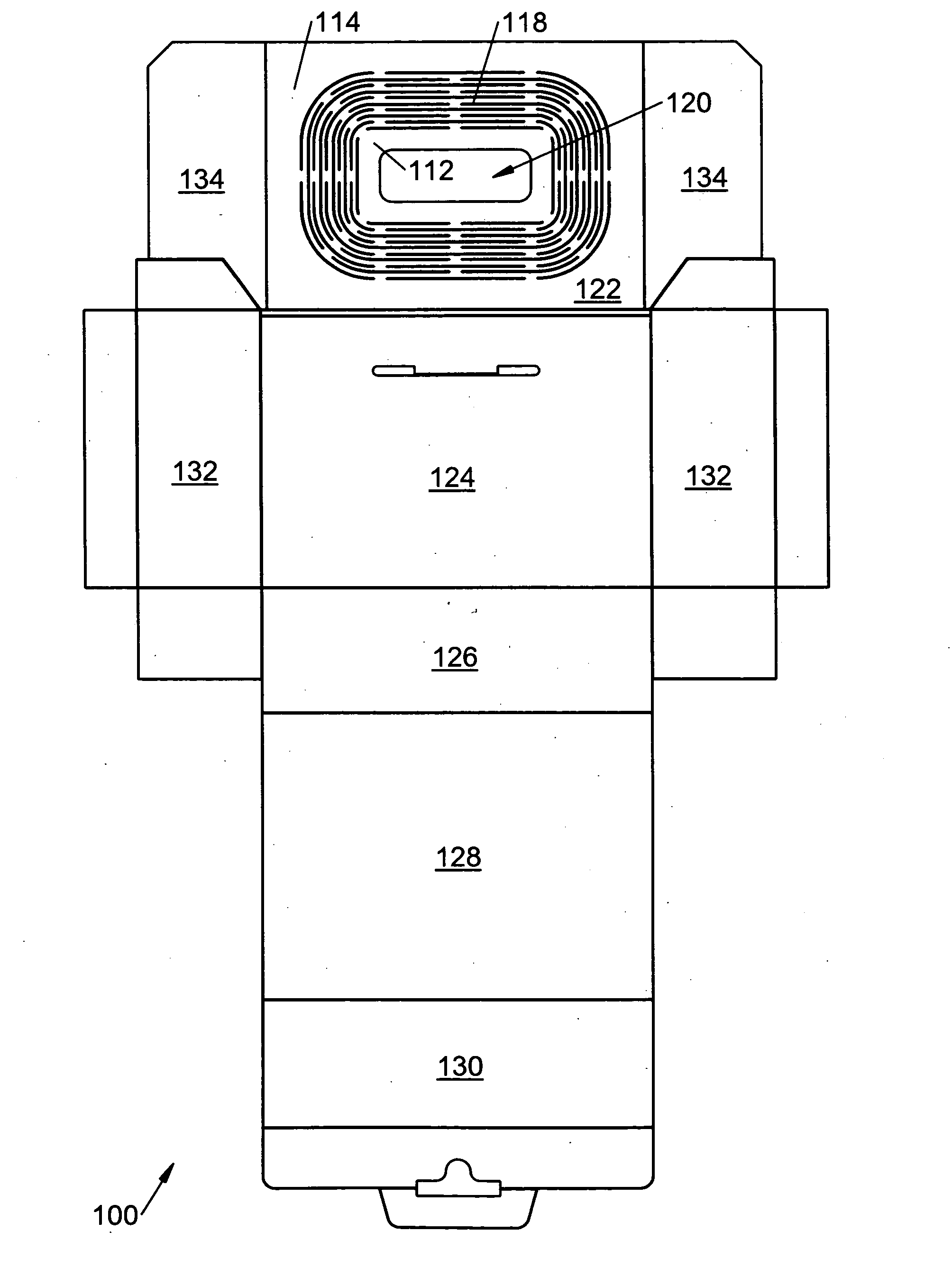

Suspension / retention packaging

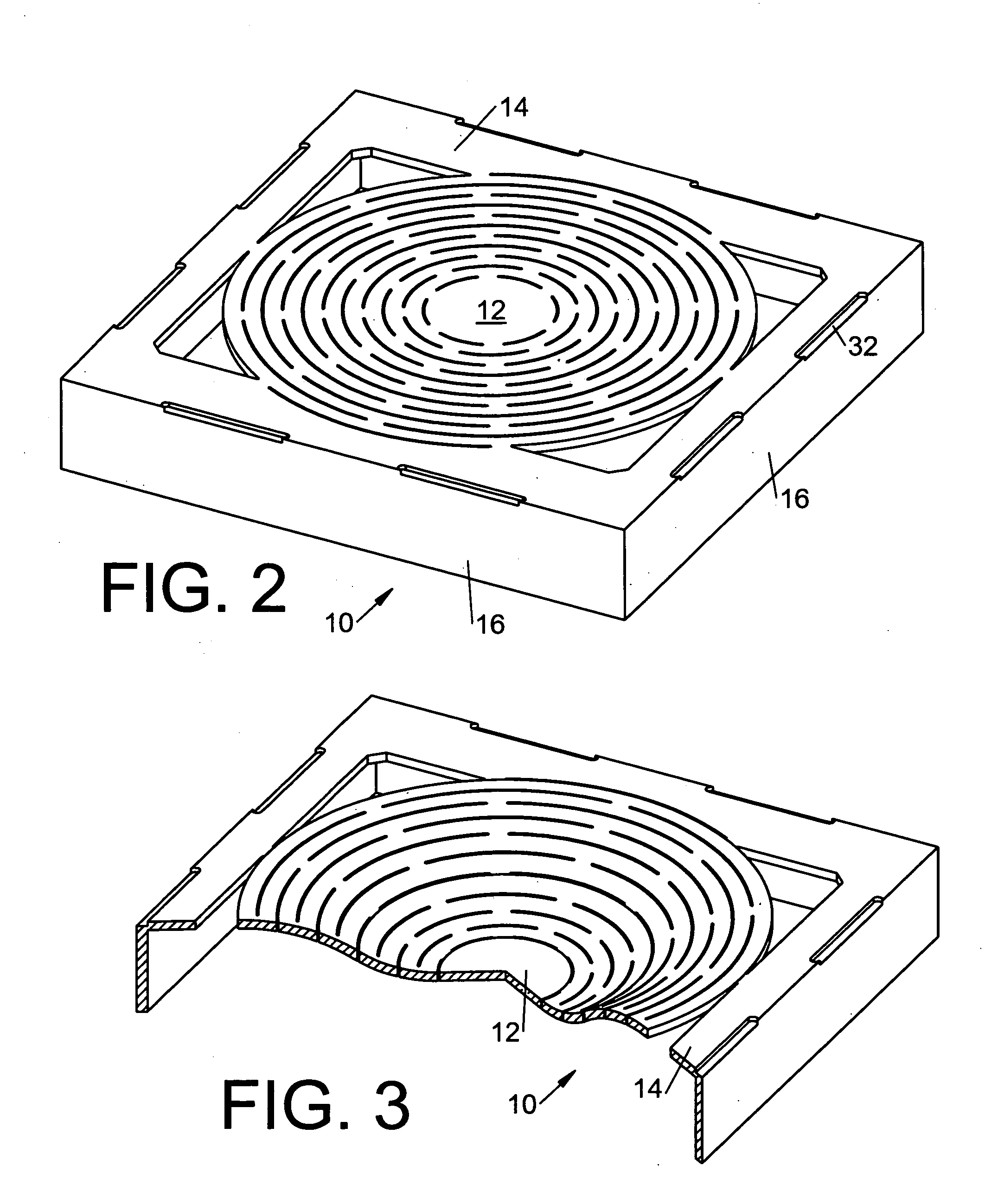

InactiveUS20110024324A1Package recyclingContainers to prevent mechanical damageContainerboardBiomedical engineering

An improved suspension package system in which one or more suspension frames are used to suspend an article within a shipping container, wherein the suspension frame includes a suspension mechanism formed by a plurality of generally concentric cuts forming a plurality of suspension channel members, each cut being interrupted by one or more nicks. The nicks conjoin adjacent channel members, and conjoin an innermost channel member to an optional article platform, and conjoin an outermost channel member to an optional perimeter portion. Sidewalls give the suspension frame a 3-D shape and provide suspension clearance. The article can be sandwiched between two opposing suspension frames. The suspension frame can be formed as a monolithic piece of corrugated containerboard. Forming the suspension of corrugated containerboard improves the recyclability of the product, and reduces its manufacturing cost by eliminating the need for purchasing and assembling a plastic suspension sheet. The frame can also be configured as a retention frame.

Owner:COLUMBIA CORRUGATED BOX AN OREGON HAVING AN AGENTS ADDRESS AT COLUMBIA CORRUGATED BOX

Preparation method of plywood for full-bamboo or bamboo wood composite container

InactiveCN101508124AImprove radial bending strengthNo crackingOther plywood/veneer working apparatusPlywood pressesThermal energyWear resistant

The invention provides a method for preparing a plywood for a full-bamboo or bamboo-wood composite container, which belongs to the field of containers. By adopting automatic glue penetration on a bamboo mat rigid rolling laminator and bamboo shades elastic needle rolling laminator, instead of directly soaking materials such as veneers, bamboo mats and bamboo shades for manufacturing plates of the containers in a phenolic resin solution, the method not only makes glue solution penetrated to the inside of the materials and improves the meandering strength of the materials, but also has small damage to the environmental protection and the human body. As the method has simple process, the temperature is always maintained within a certain range, the energy loss is greatly reduced, and the production cost is greatly reduced. The method and the equipment can manufacture a plurality of pieces of plywoods once and greatly improve the working efficiency. The full-bamboo products have smooth and wear resistant surface of the outer layer, and can be widely applied to manufacturing case plates of the containers.

Owner:杨湘云

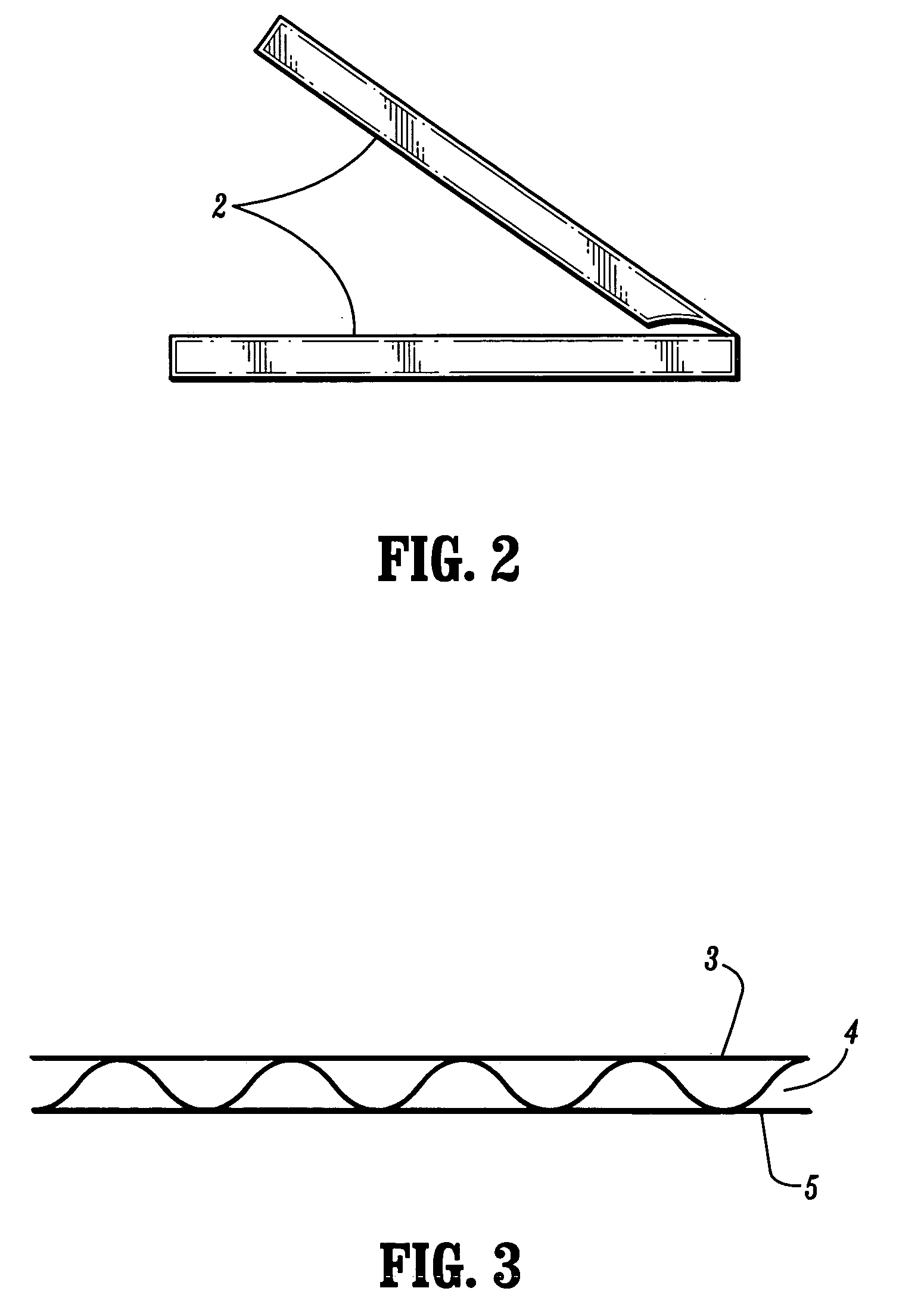

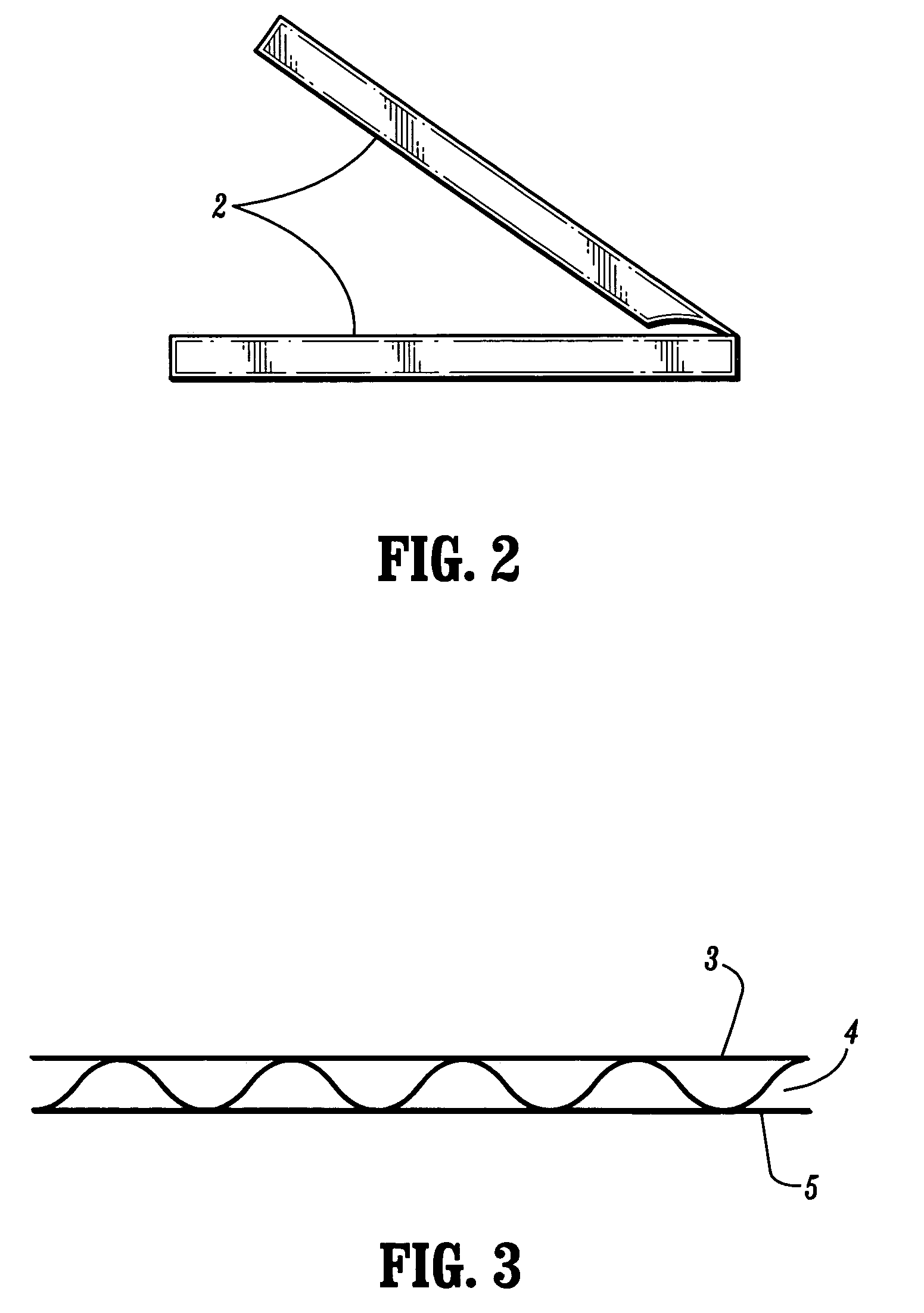

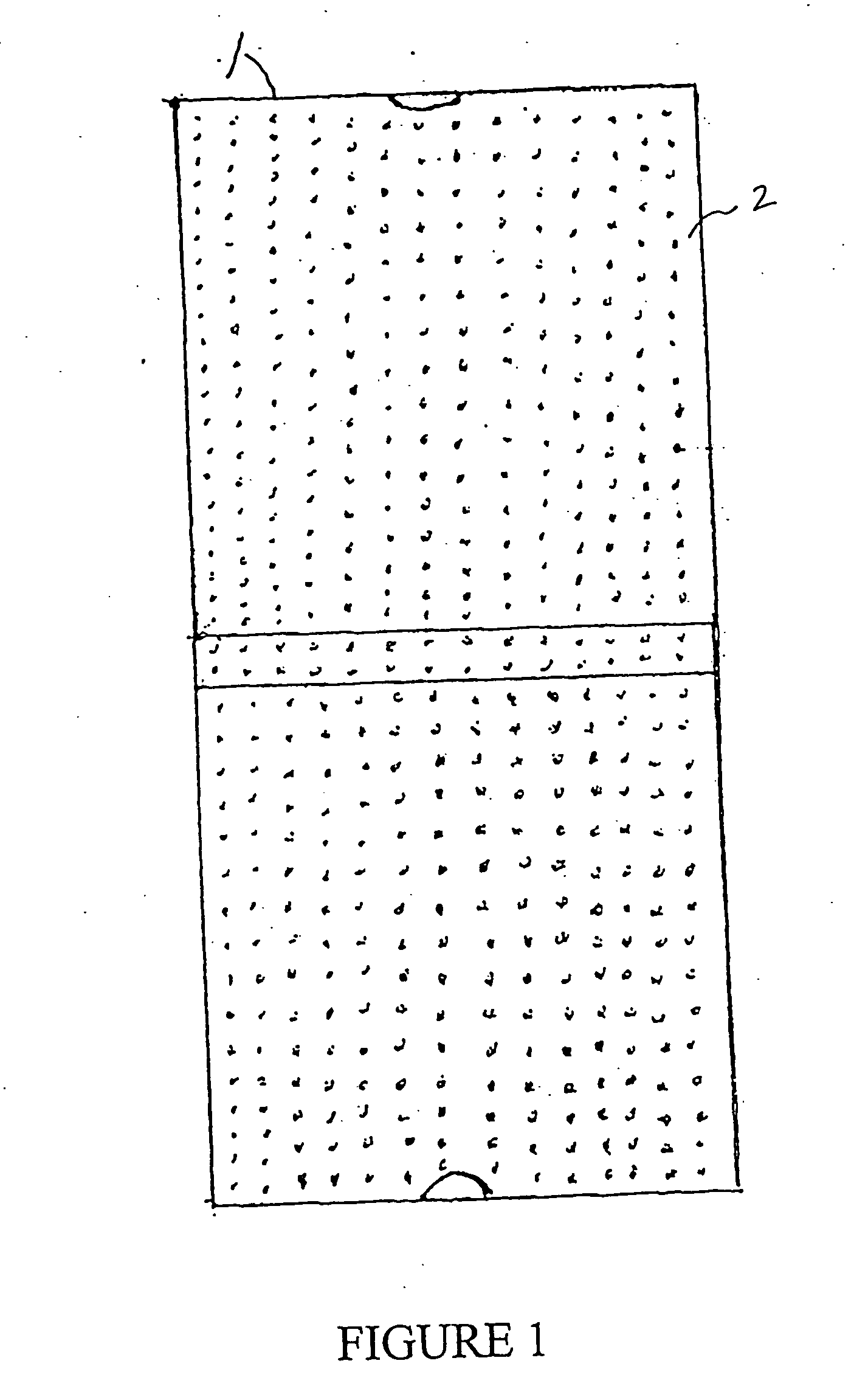

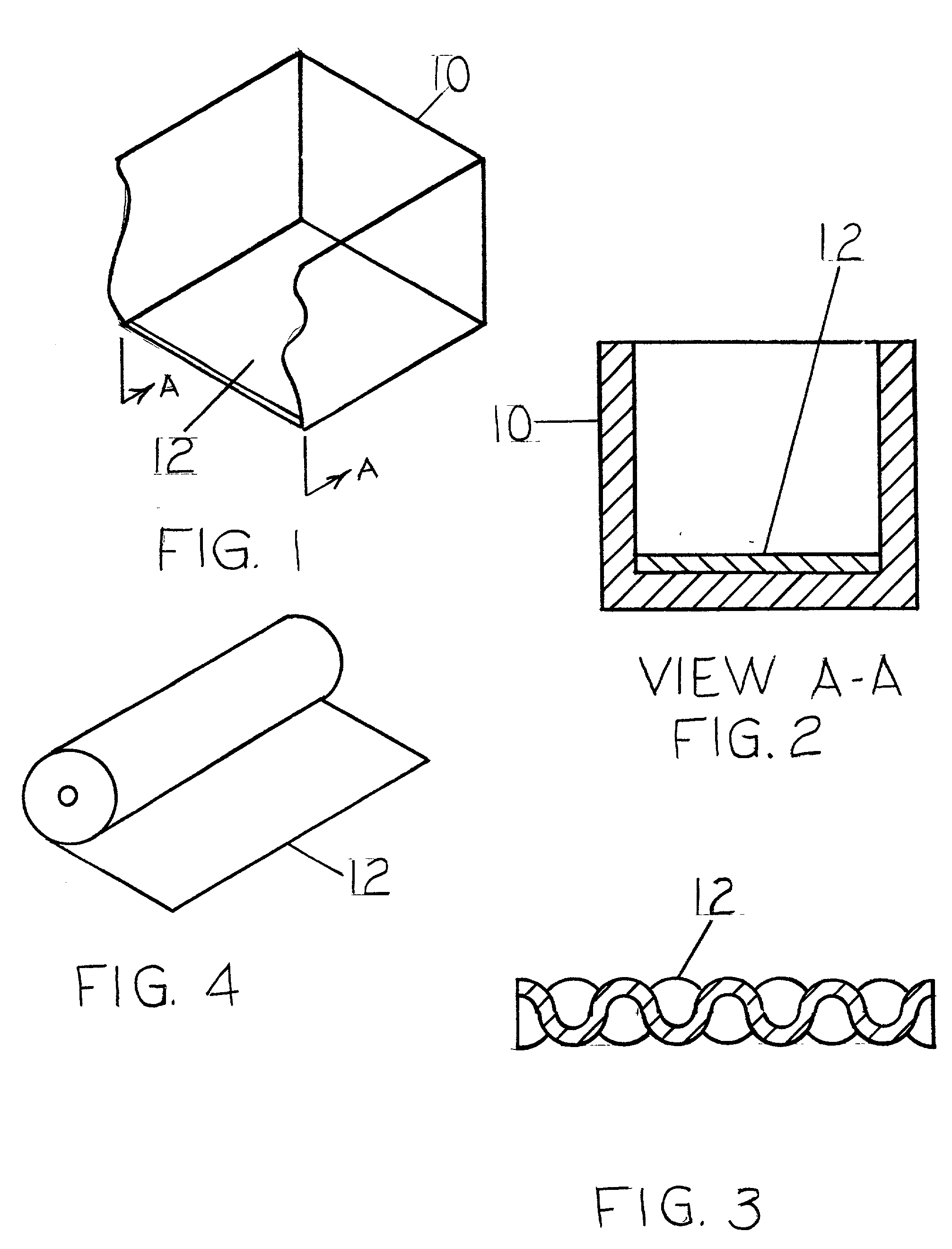

Packaging device and method for absorbing moisture

InactiveUS20060029771A1Non-fibrous pulp additionNatural cellulose pulp/paperCardboardActivated carbon

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations may be added in the boards to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:ONEILL KEVIN J +1

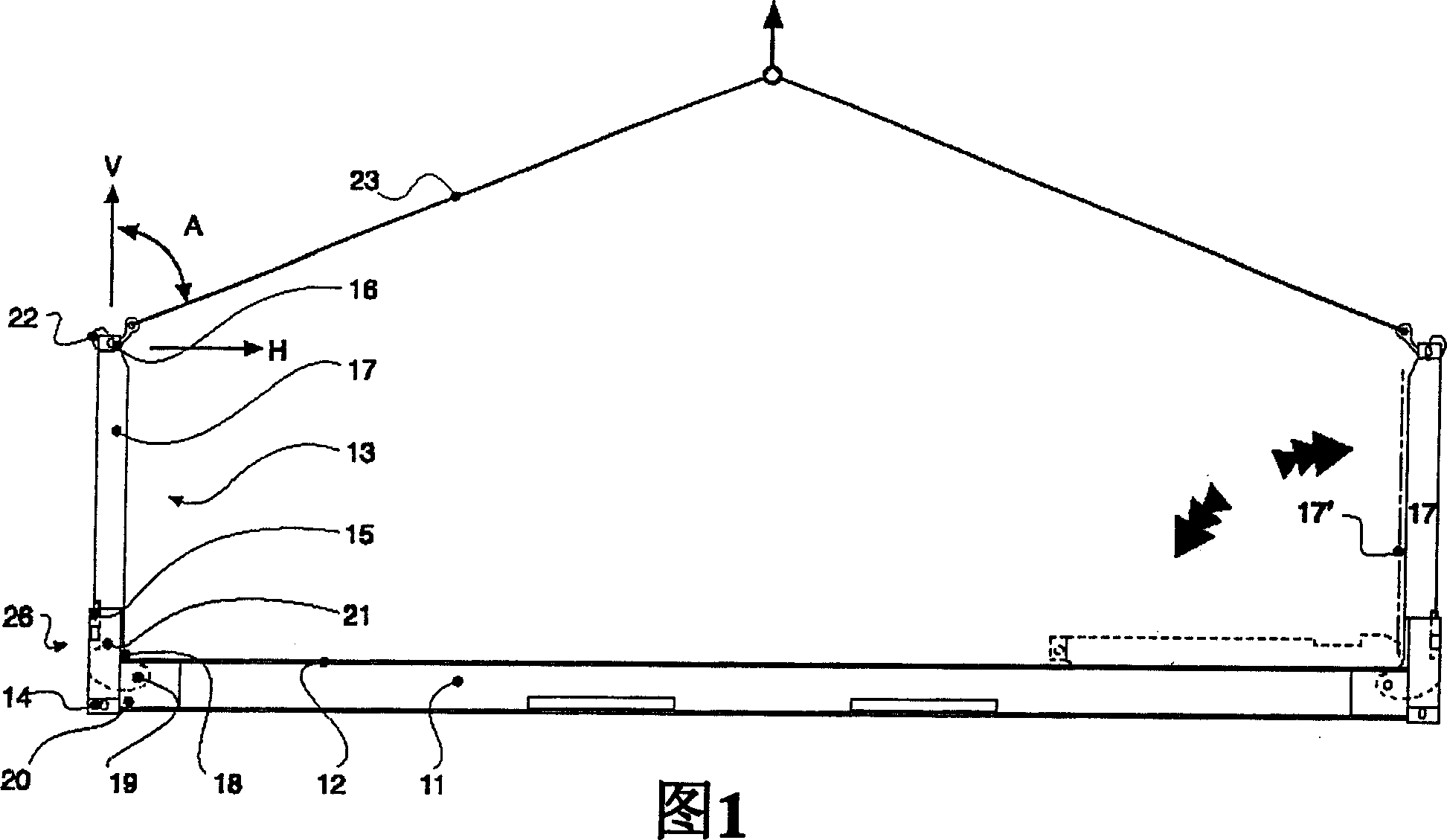

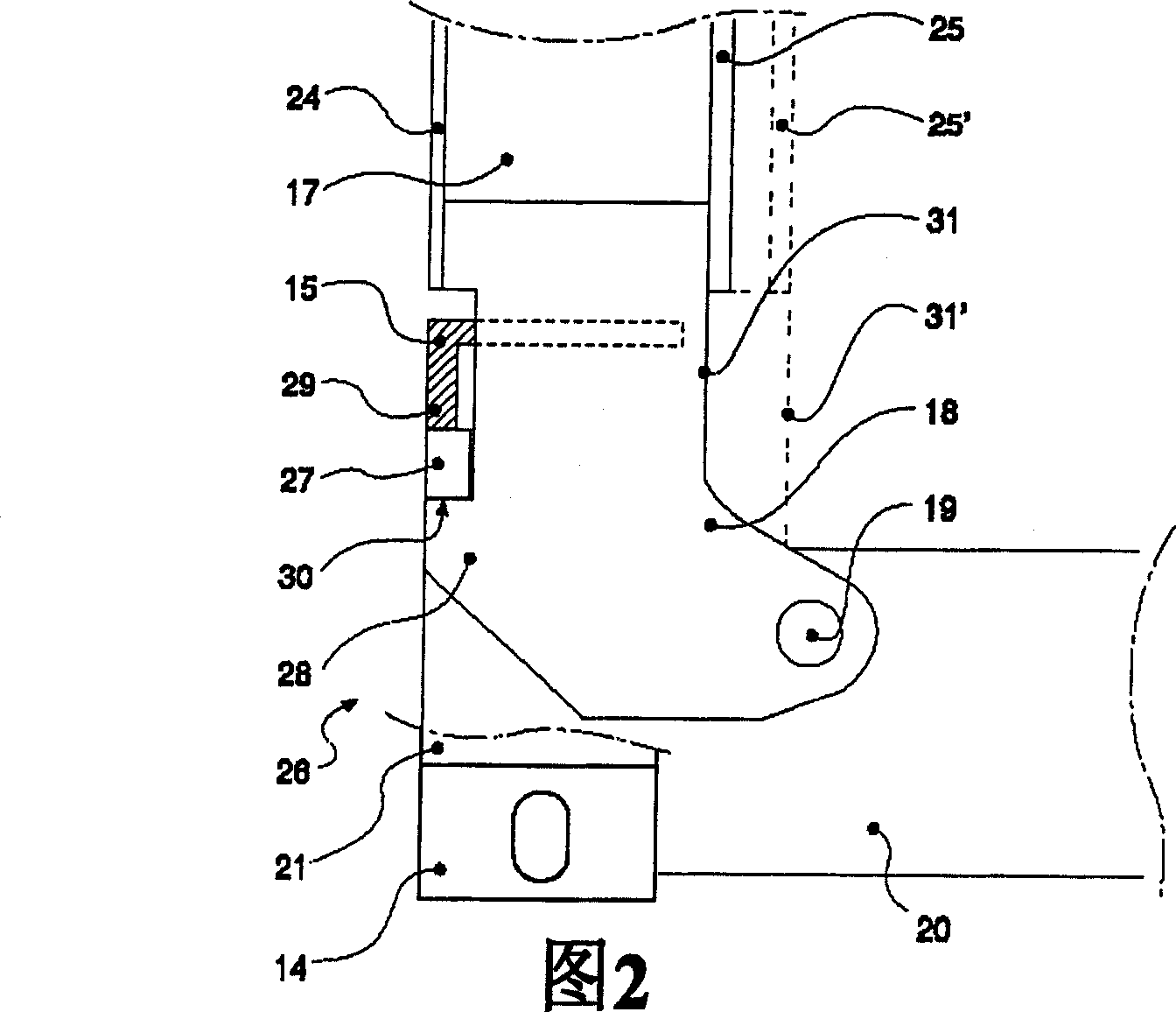

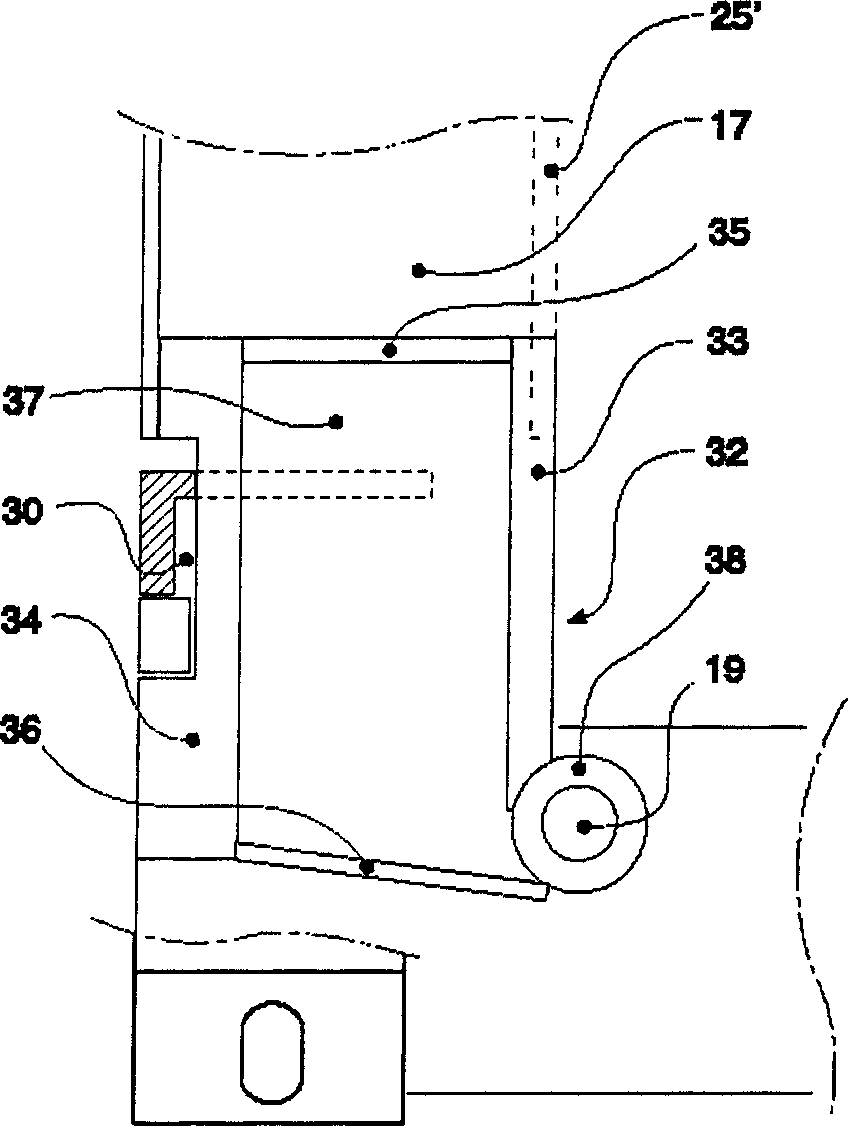

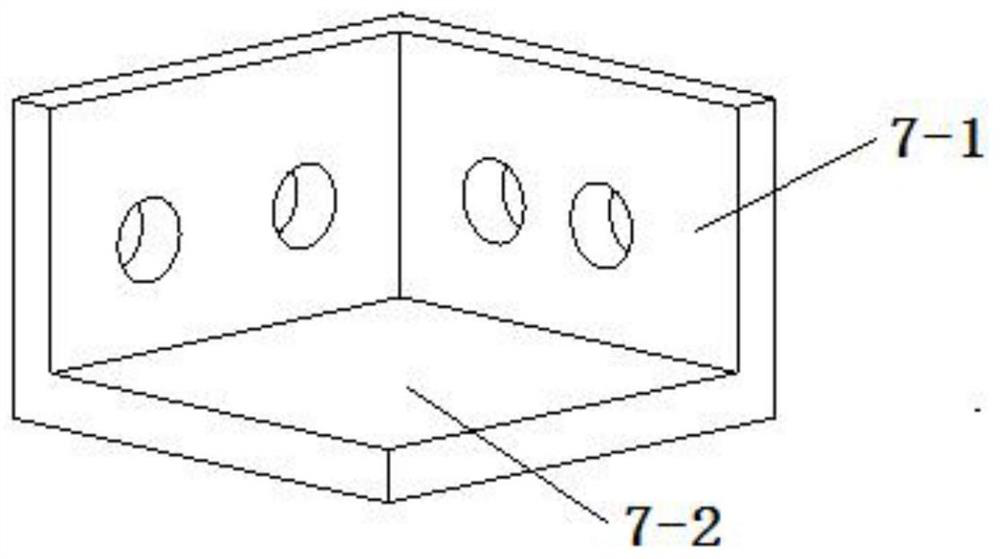

Hinge for collapsible flatrack

A hinge, for a collapsible flatrack container, is fabricated of multiple elements, including a hinge inner portion, with discrete opposed flanges, and an intervening web, such that relative flange and web, depth and disposition, can be configured to optimize any of, weight, strength or cost considerations.

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS

Packaging device and method for absorbing moisture

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations may be added in the boards to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:ONEILL KEVIN J +1

Packaging device and method for absorbing moisture

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations and corrugated mediums in the boards may be added to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:ONEILL KEVIN J +1

Packaging device and method for absorbing moisture

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations may be added in the boards to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:ONEILL KEVIN J +1

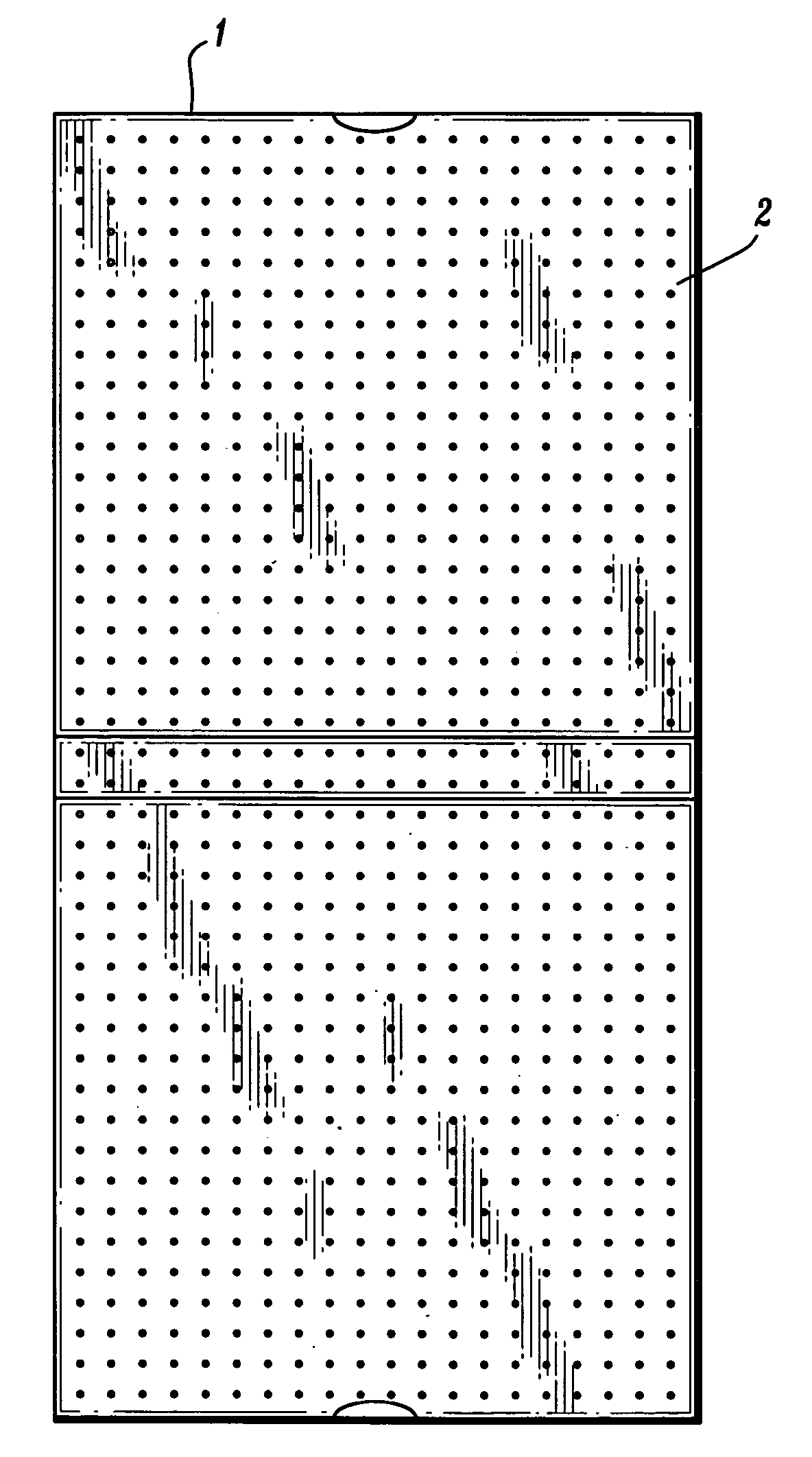

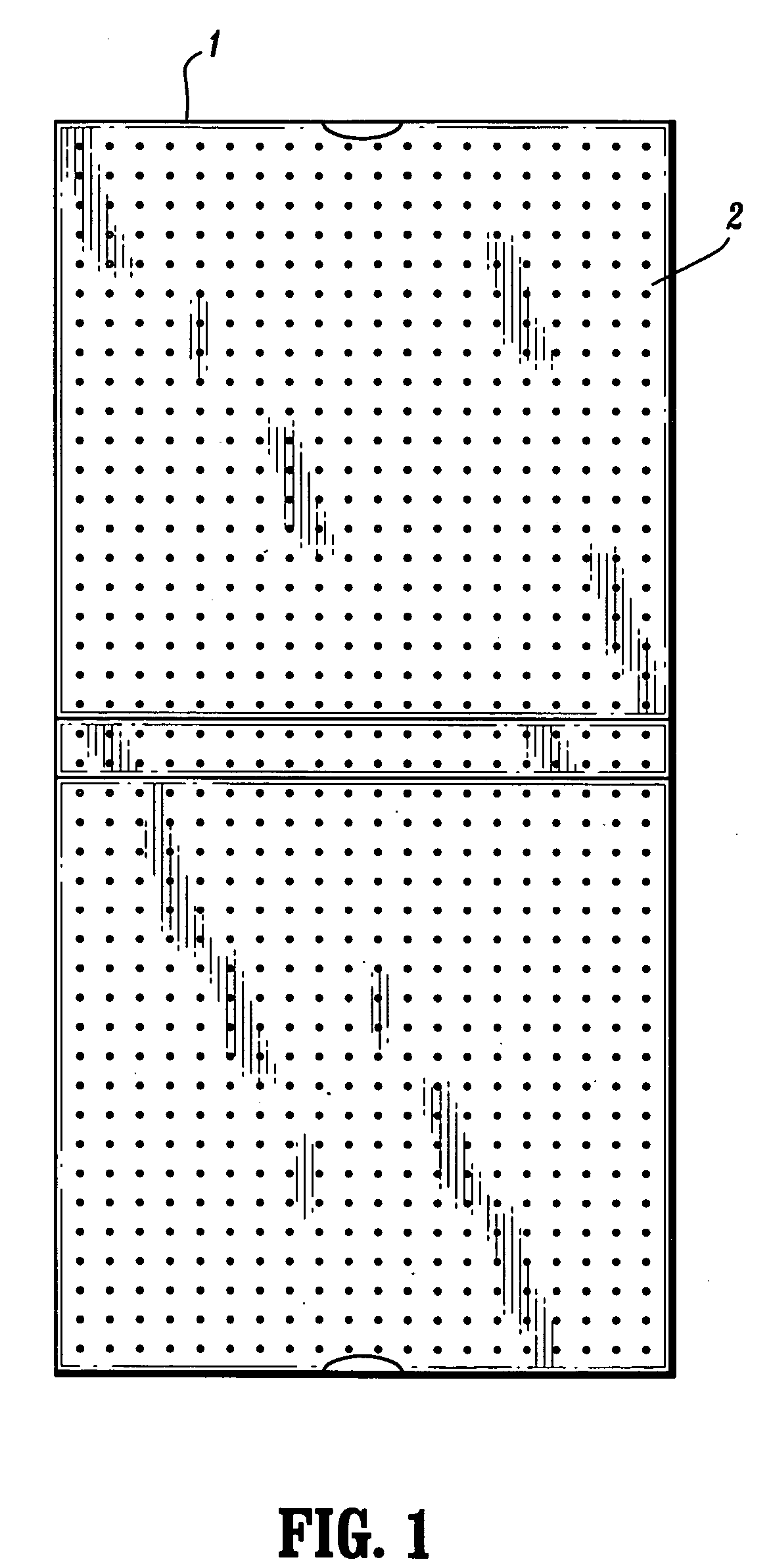

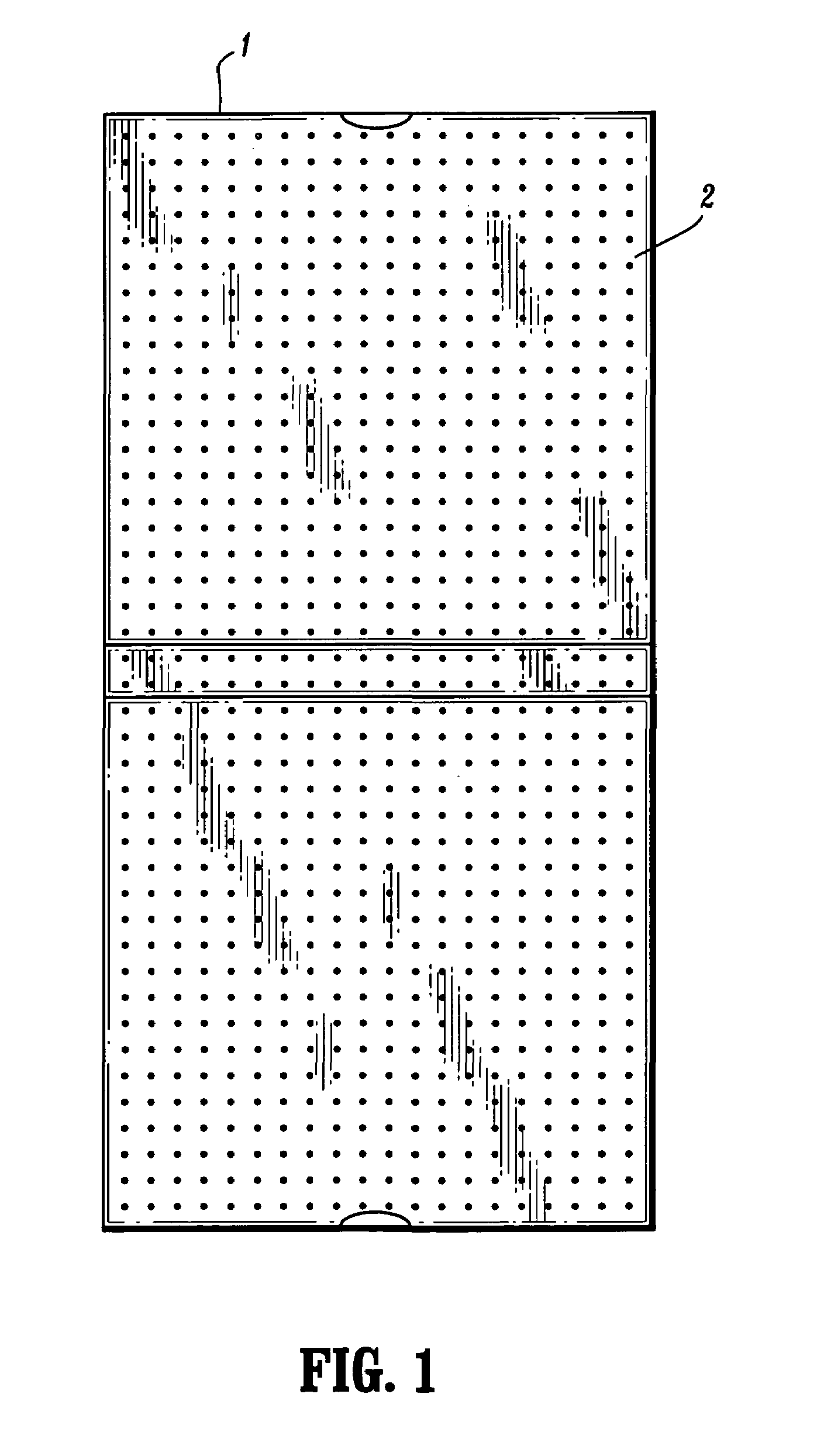

Method for digital die cutter for containerboard packaging

InactiveUS20070000365A1Eliminate needReduce downtimeMetal working apparatusEngineeringContainerboard

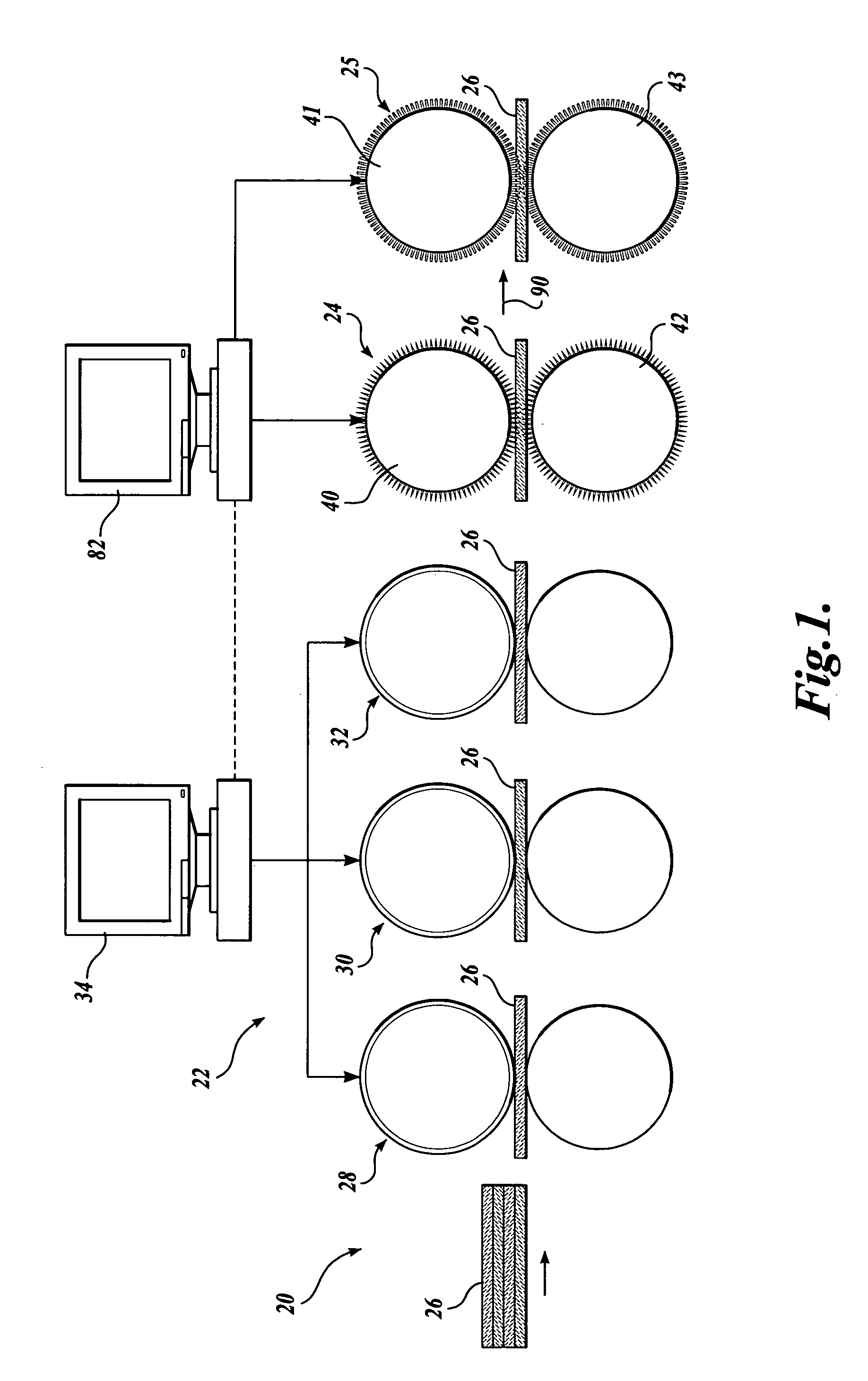

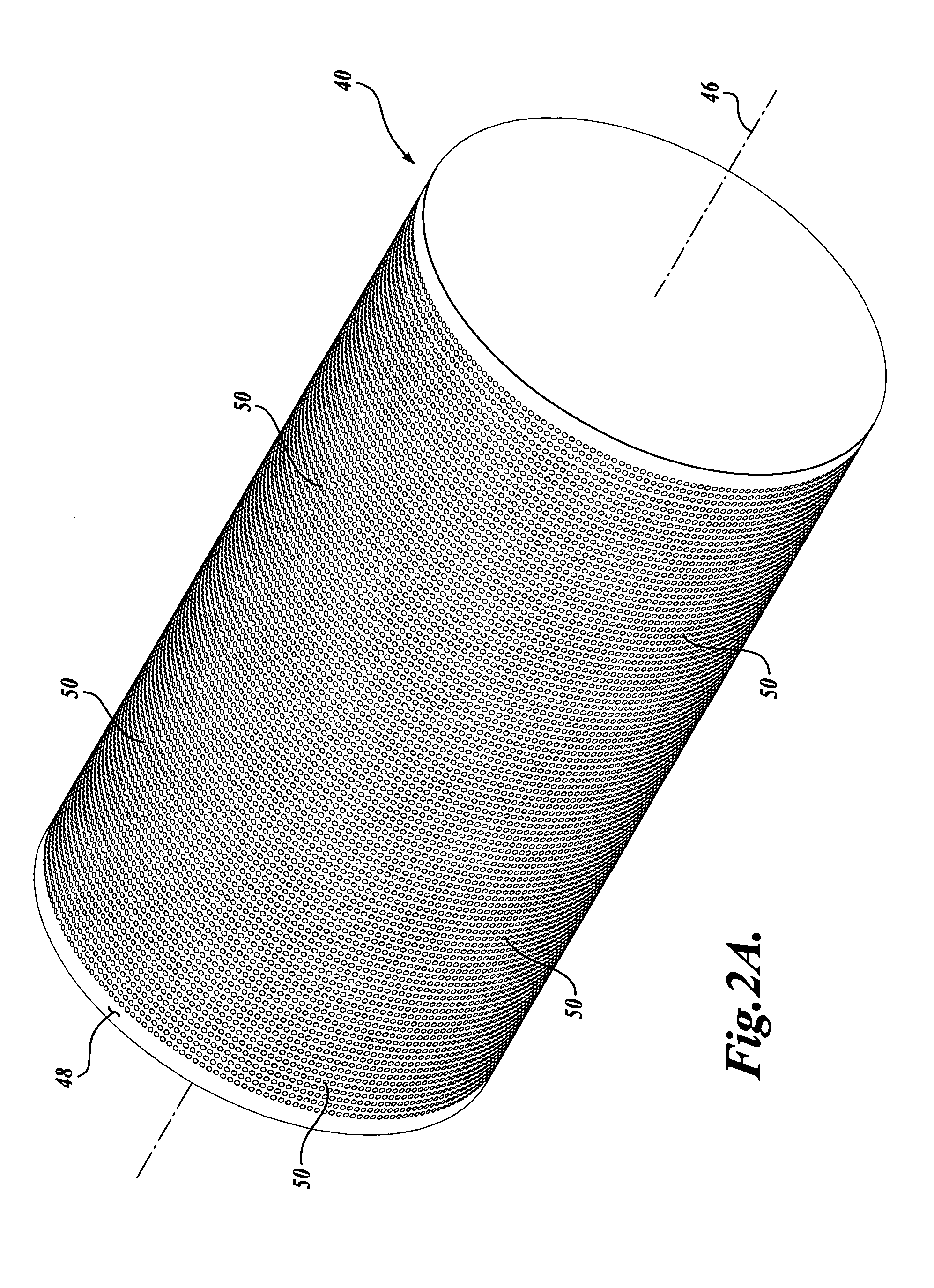

A digital die cutting system including at least a first addressable die cutter having a surface carrying a plurality of knives in an array, each of the knives extendable and retractable above and below the surface is presented / provided. A controller is provided for individually addressing, and extending, and retracting the knives above and below the surface. A central processing unit receives an image of a pattern to be cut by selected ones of the knives, processes that image for a controller, which then extends selected ones of the knives to correspond to the shape of the pattern. The die cutter is then presented by conventional apparatus to the surface of a panel to be die cut when at least some of the knives are extended.

Owner:INT PAPER CO

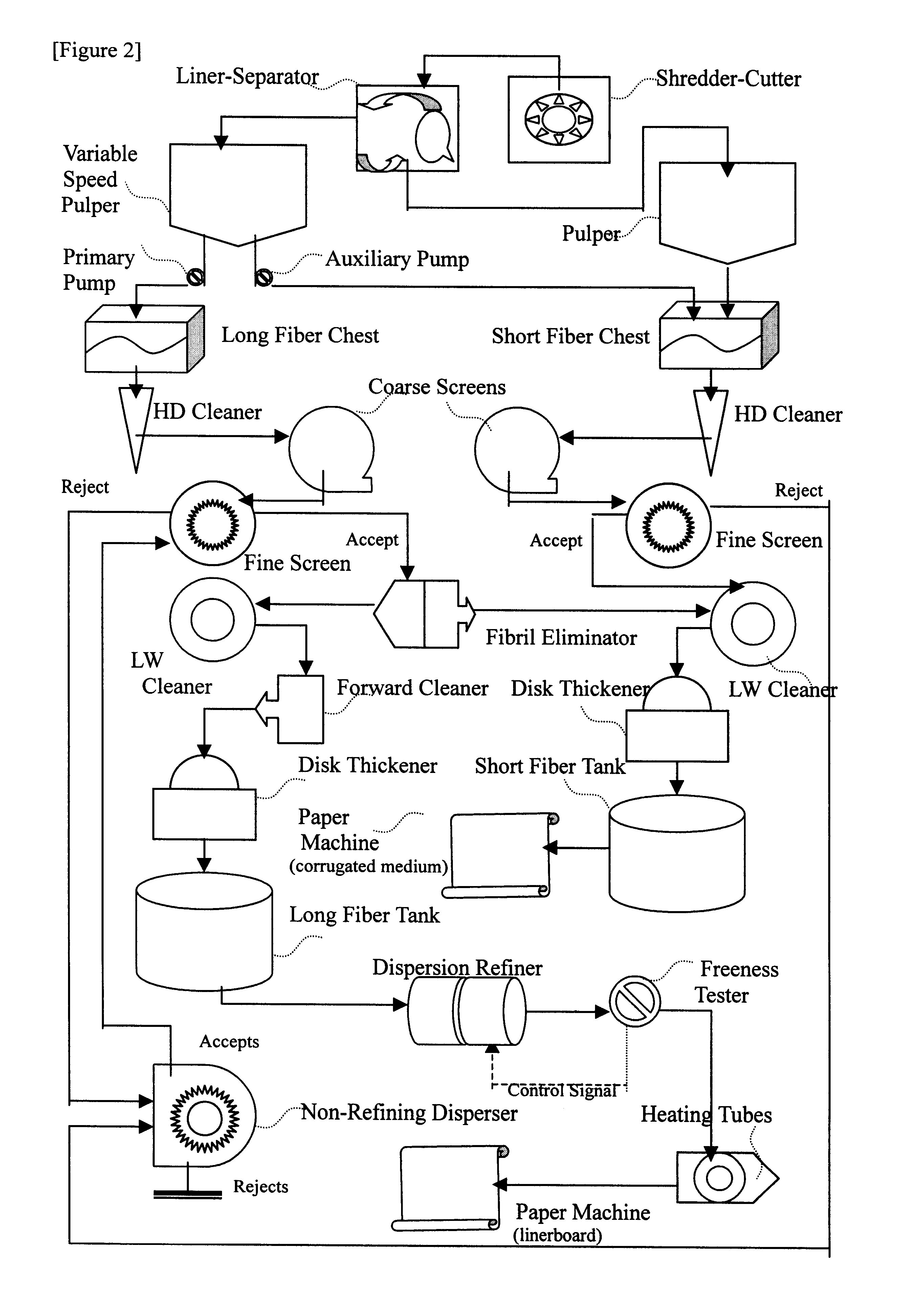

Process of making recycled linerboard or Kraft paper from old corrugated container

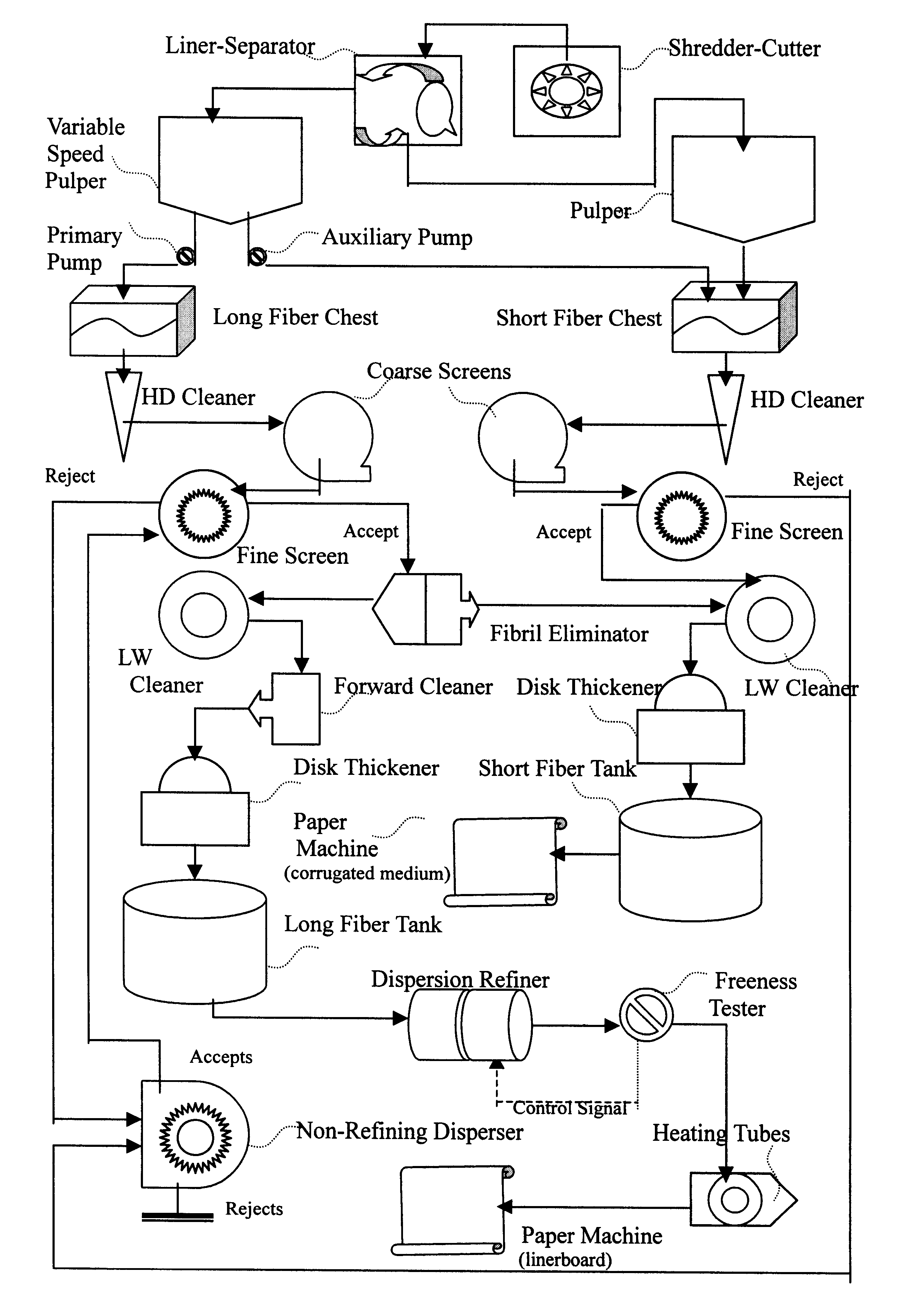

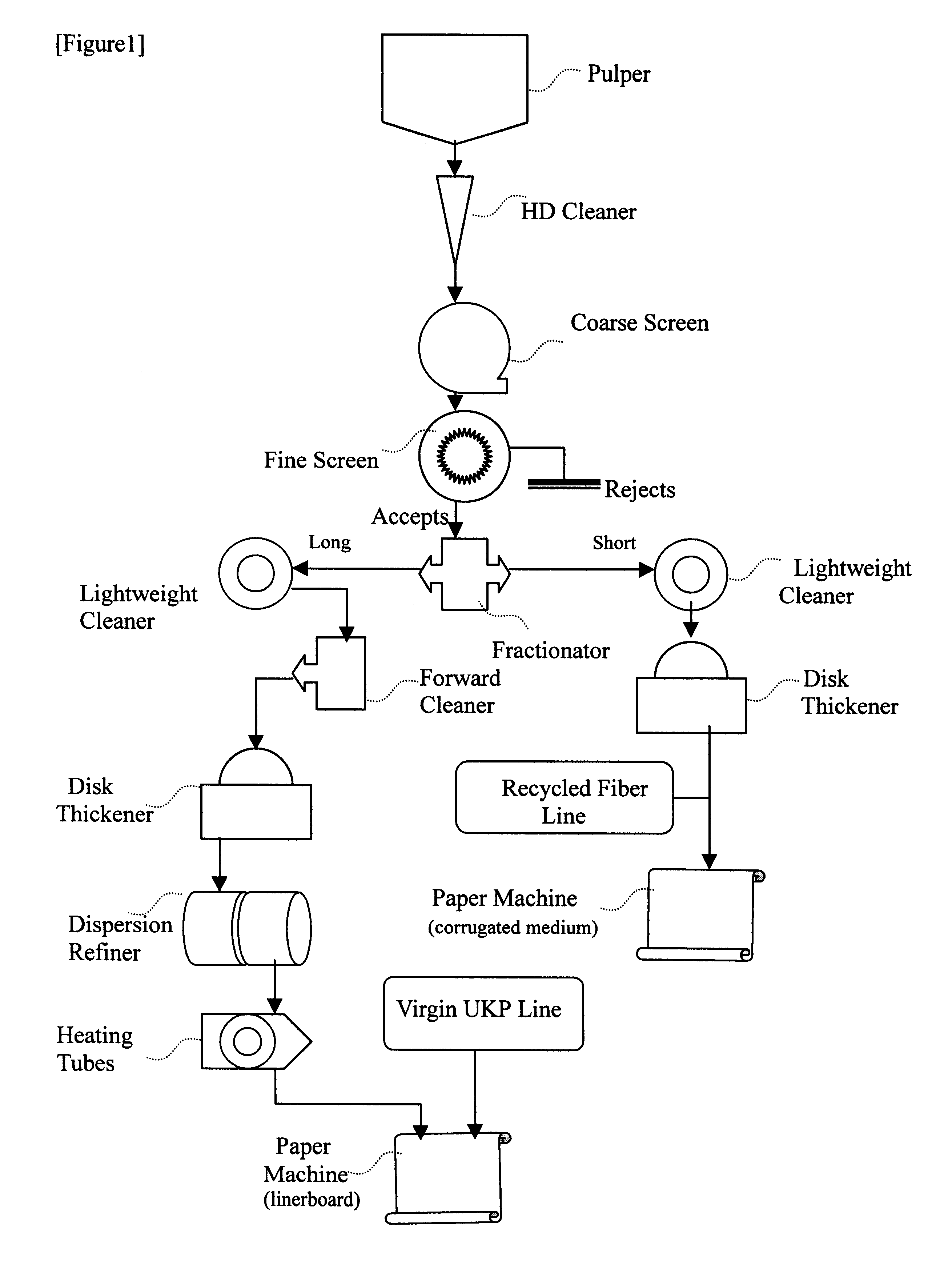

A process for producing new corrugated containerboard from old corrugated container (OCC) without using expensive virgin UKP includes three new steps. These steps are separating corrugated medium from OCC before pulping linerboard, removing micro-fibrils from defibered linerboard furnish, and minimizing the loss of long fibers through reject streams of fine screens.

Owner:GKP TECH

Packaging device and method for absorbing moisture

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations may be added in the boards to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:ONEILL KEVIN J +1

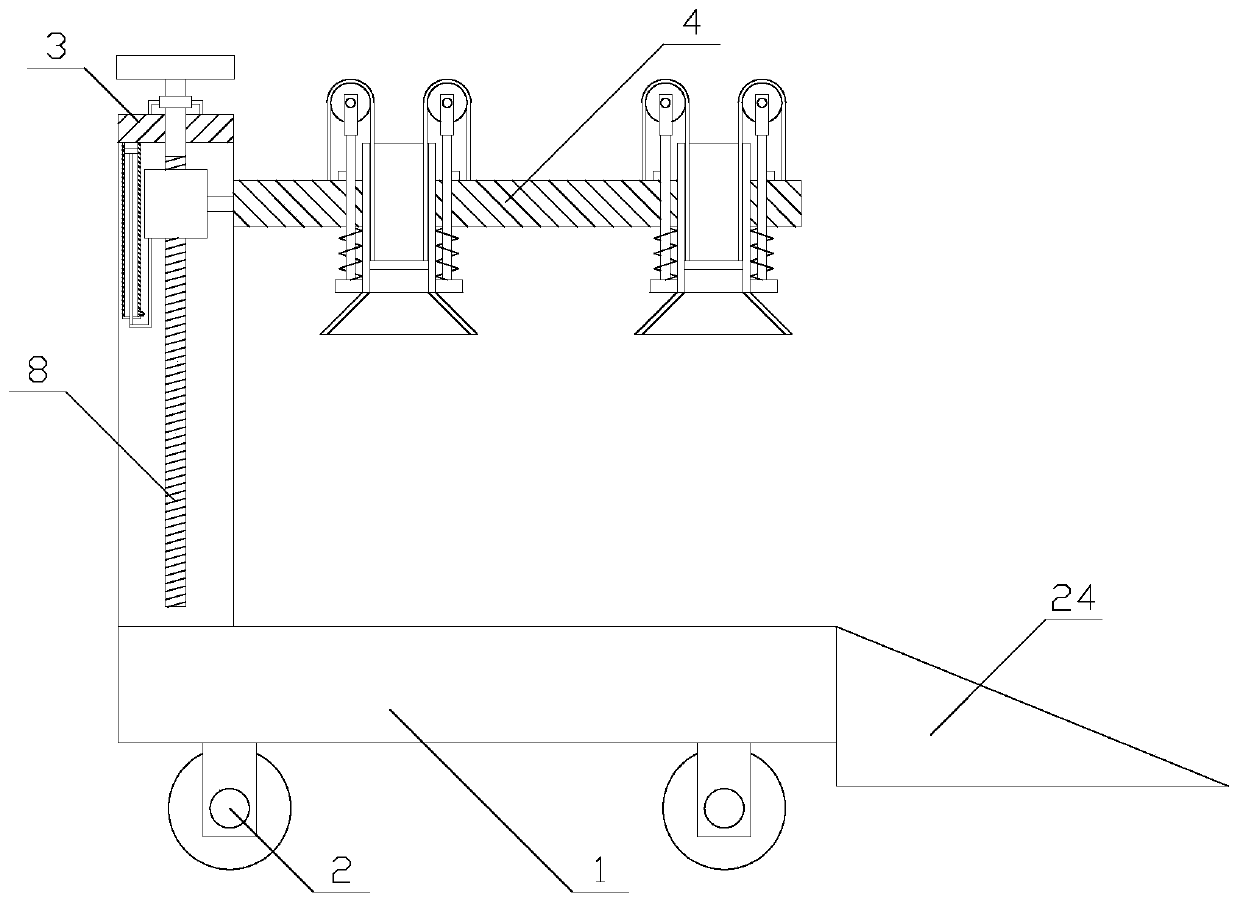

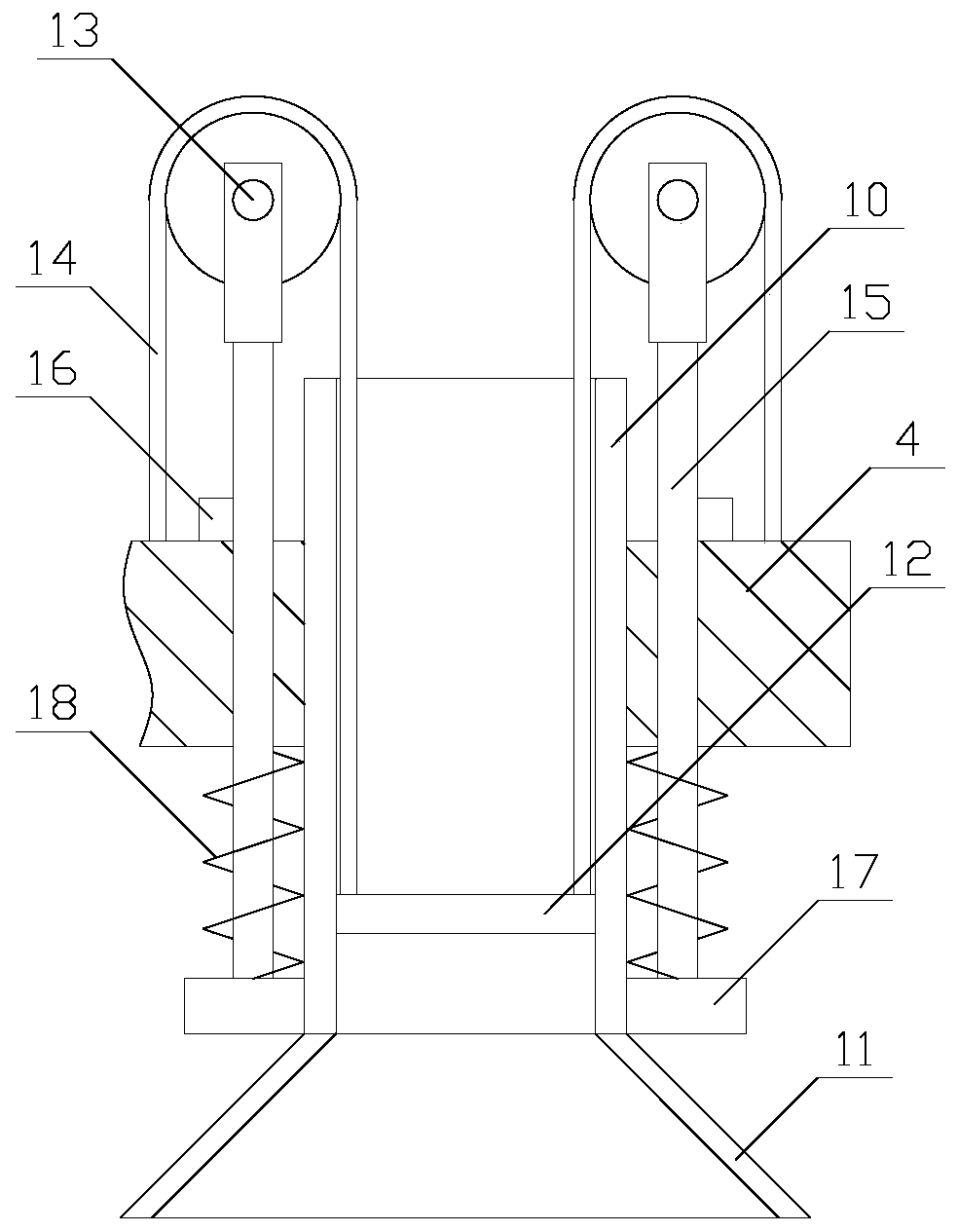

Energy-saving type moving device for container producing and machining

InactiveCN111115255APracticalImprove stabilityConveyorsConveyor partsStructural engineeringContainerboard

The invention relates to an energy-saving type moving device for container producing and machining. The energy-saving type moving device comprises a supporting plate and four rolling wheels; the supporting plate is arranged horizontally and is in a cuboid shape; the rolling wheels are uniformly arranged at the four corners of the bottom of the supporting plate; an auxiliary mechanism and a stabilizing mechanism are disposed at the top of the supporting plate; the auxiliary mechanism comprises a fixed plate, a movable plate and a moving assembly, and the moving assembly comprises a rotary disc, a rotary shaft, a bearing, a screw rod, a sliding block and an installing hole; and the stabilizing mechanism comprises two stabilizing assemblies which are arranged on the movable plate uniformly,and each stabilizing assembly comprises a moving pipe, a suction cup, a moving disc, a through hole and two connecting units. According to the energy-saving type moving device for container producingand machining, the function of handling container plates is achieved through the auxiliary mechanism, and moreover, the handling stability is improved through the stabilizing mechanism.

Owner:广州市索德士皮具皮革贸易有限公司

Method for producing odor and moisture absorbing pad for animals using protective containerboard

InactiveUS20030015145A1High speedEncouraging disposabilityAnimal housingOther apparatusBiotechnologyAnimal use

Owner:DEG DENNIS

Packaging device and method for absorbing moisture

A packaging device and method for absorbing and reducing moisture as well as a manufacturing process for such device. The packaging device is a container made from paperboard such as containerboards or linerboards with a corrugated medium. The paperboard is insulated with moisture absorbing additives comprising charcoal, activated charcoal, activated carbon, or substances mostly comprised of carbon. Perforations may be added in the boards to further permit moisture to reach the corrugated medium, permitting further absorption by the additives embedded within the corrugated medium in between the boards. This packaging device and method is favorable for storing or transporting objects which are sensitive to or would benefit from low moisture / humidity conditions.

Owner:凯文·J·奥尼尔 +1

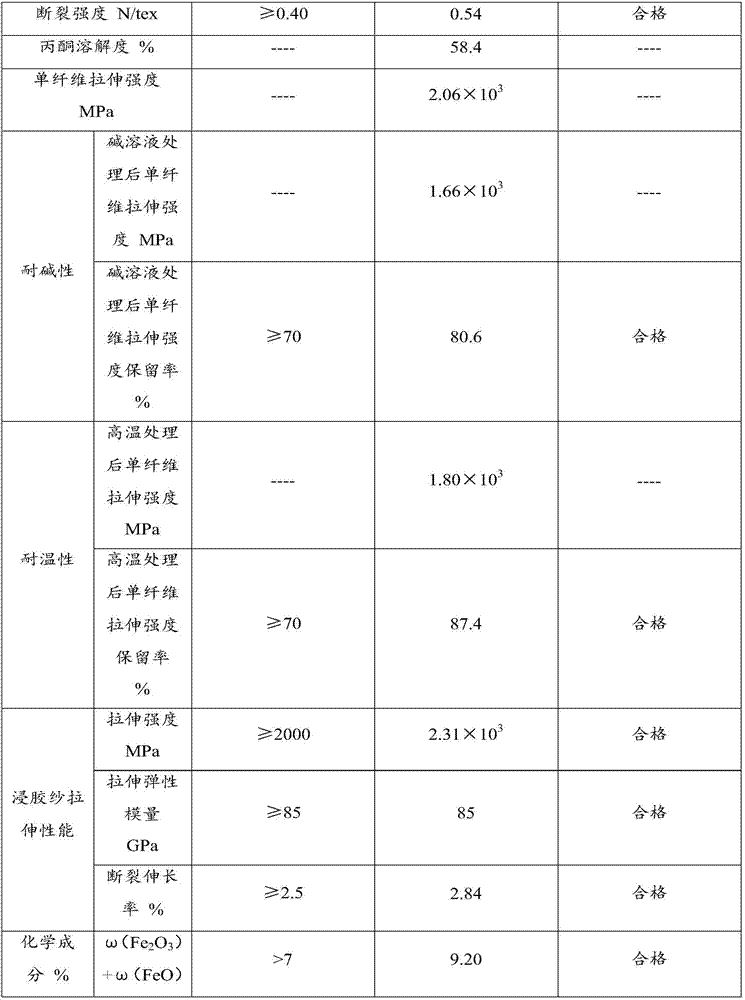

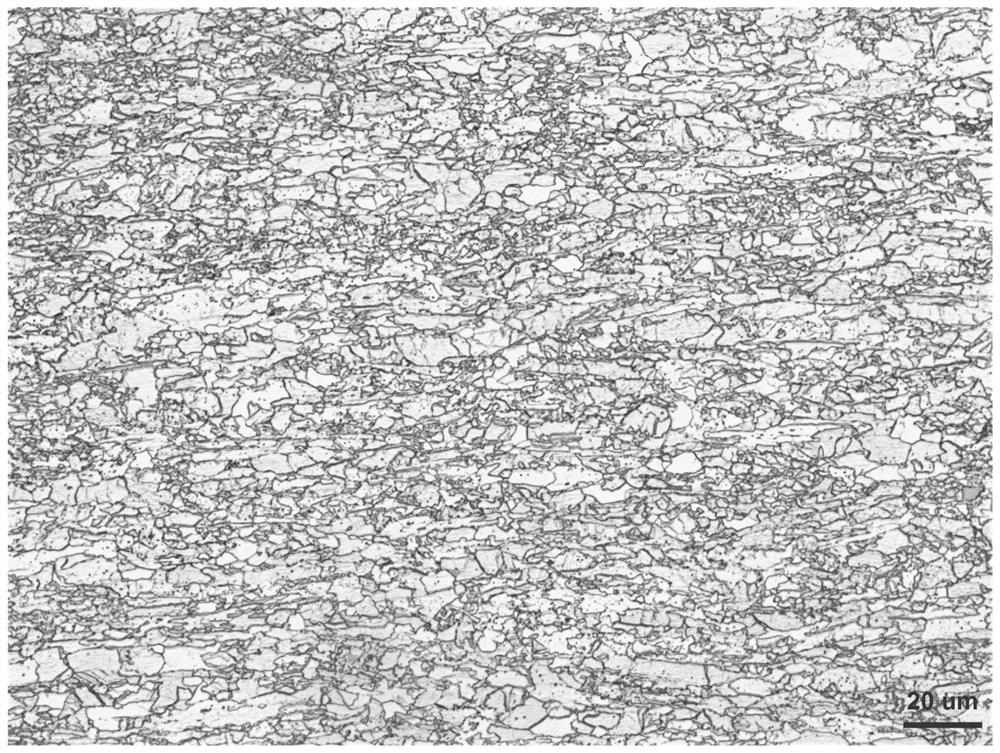

Novel glass mat-reinforced thermoplastic (GMT) board and production process thereof

InactiveCN103287028AHigh strengthLose weightSynthetic resin layered productsGlass/slag layered productsThermoplasticGlass fiber

The invention discloses a novel glass mat-reinforced thermoplastic (GMT) board and a production process thereof, relating to the field of office partition plates, vehicle and boat boxboards, container boards and building decoration products. Polypropylene fibers, alkali-free coarse glass fibers and alkali-free fine glass fibers are primarily mixed in a proportion of 5:4:1, and are fully mixed through a large bin, a cotton box and carding equipment to prepare a semi-finished product. The semi-finished product with a certain size is subjected to hot-pressing compounding through a pressing machine at the temperature of 230+ / -5 DEG C, within 130+ / -10 seconds and under the pressure of 7+ / 2MPa to form a board. The novel GMT board is simple in structure and reasonable in design; the proportion of high-strength alkali-free coarse glass fibers to high-strength alkali-free fine glass fibers to modified polypropylene fibers is optimized; a machining process is improved; high-strength and low-weight GMT products are successfully tested and produced in batch; under the conditions of the same weight and the same density, the strength of the board is improved, the novel GMT board is applied to a vehicle, the weight of the vehicle can be reduced, and a great environmental benefit is brought.

Owner:合肥杰迈特汽车新材料有限公司

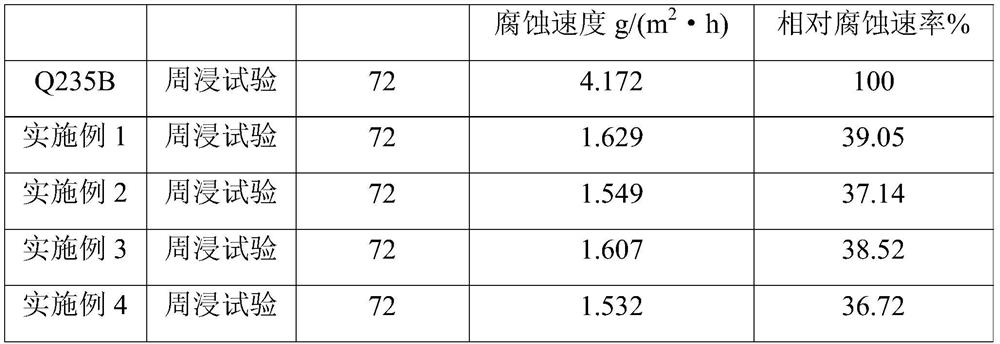

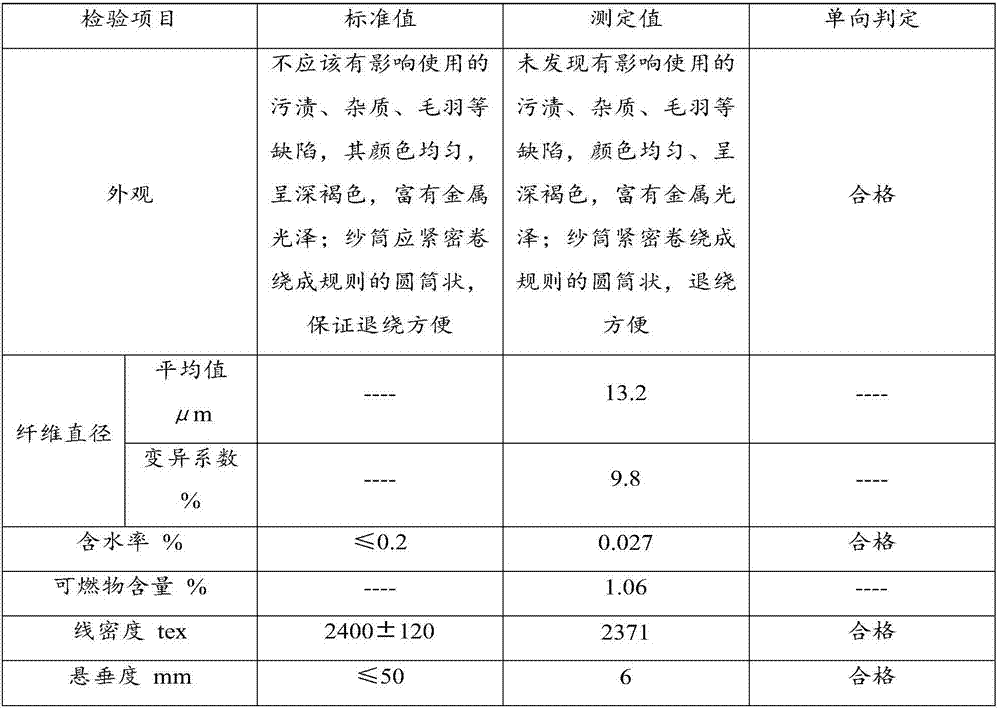

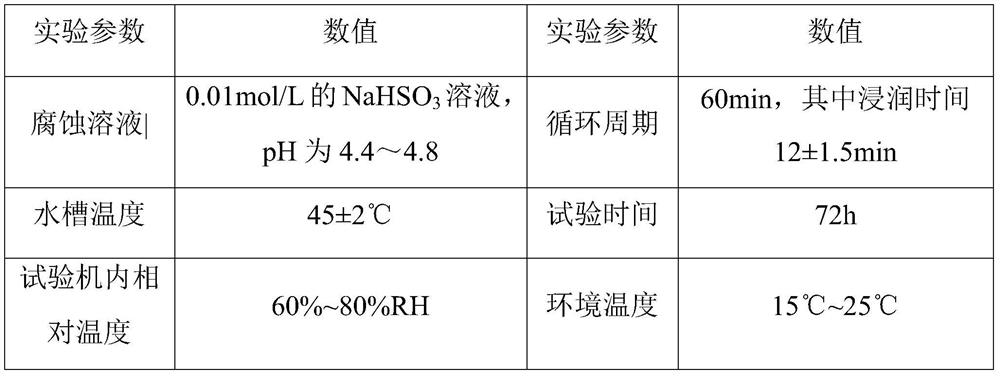

Thin-specification container board and manufacturing method thereof

ActiveCN112063920AMake up strengthMake up for the loss of weather resistanceWeather resistanceCopper

The embodiment of the invention provides a thin-specification container board. Thin-specification container board steel consists of the following components in percentage by mass: 0.05%-0.065% of C, 0.20%-0.4% of Si, 0.30%-0.45% of Mn, 0.07%-0.12% of P, 0.3-0.5% of Cr, 0.03-0.05% of Ti, less than or equal to 0.006% of S, 0.20%-0.35% of Cu, and the balance of Fe and other inevitable impurities. Thethin-specification container board is reasonable in constituent elements, which are matched with one another, and corresponding content. The constituent elements do not comprise an element Ni, and content of P and Cu is controlled to compensate loss of strength and weather resistance of the Ni-reduced thin-specification container board, and restrain occurrence of the copper brittleness defect. The thin-specification container board is lower in cost without higher-cost element Ni, and has better mechanical property and weather resistance.

Owner:湖南华菱涟钢特种新材料有限公司 +2

Preparation method of plywood for full-bamboo or bamboo wood composite container

InactiveCN101508124BAvoid damageDamage will not occurOther plywood/veneer working apparatusPlywood pressesThermal energyEngineering

Owner:杨湘云

Folding type storage box

The invention discloses a foldable storage box, which comprises a box body and Velcro, the Velcro is sewn on the box body, and the box body includes a first box board, a second box board, and a third box board , the fourth box board, the fifth box board and the sixth box board, the Velcro includes the first Velcro round hair, the second Velcro round hair, the third Velcro round hair, the fourth Velcro round hair, Five Velcro round hairs, first Velcro bristles, second Velcro bristles, third Velcro bristles, fourth Velcro bristles, and fifth Velcro bristles. The beneficial effect is that the storage box is made of box boards and magic stickers. When there is no item in the storage box and it needs to be carried away, it can be disassembled and folded into a square, which is easy to carry and carry. It only needs to be assembled, and the disassembly and assembly are simple, convenient, quick and has good practicability.

Owner:朱石明

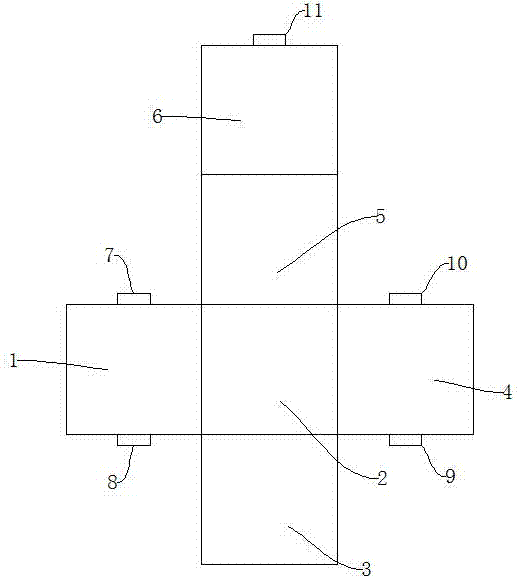

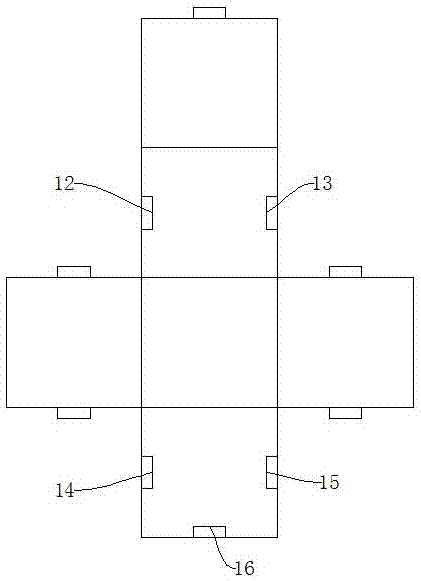

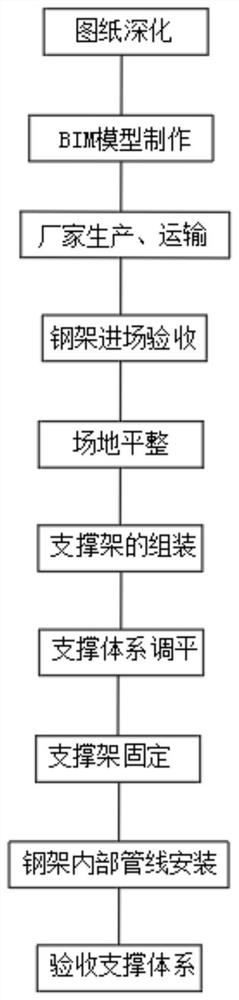

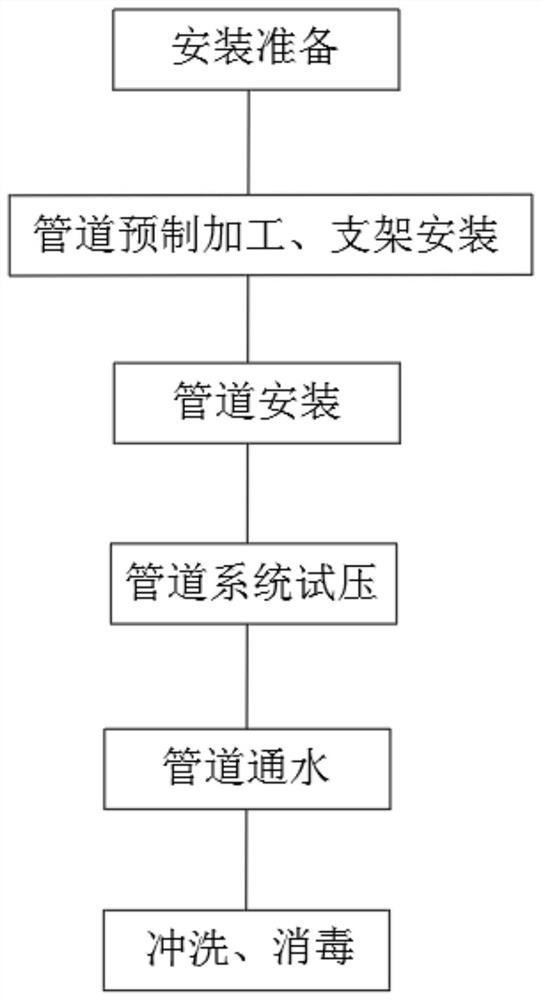

House modular division type building method for quickly building container

PendingCN113027172AGuaranteed connection fitMeet the requirements of better airtightnessSpecial buildingService pipe systemsSupporting systemBuilding design

The invention discloses a house modular division type building method for quickly building a container, and relates to the technical field of container board houses. The method aims to solve the problem of modular building of houses. The method specifically comprises the steps of drawing deepening, namely, the position, the appearance and the like of a building supporting system are preliminarily designed on the basis of a building design drawing, after drawing design is completed, site arrangement and pipeline erection are optimized through a BIM model, reworking caused by dislocation collision after a main body is installed is reduced, then the main body is delivered to a manufacturer for production and transportation, and a supporting frame entering the site is checked and accepted. According to the method, the elevation is adjusted from the bottom of the supporting frame through the methods of pouring concrete foundation cushion blocks, additionally arranging iron part foot pads and the like, so that the whole engineering supporting frame foundation is integrally leveled, the connection integrating degree of the container house is guaranteed, and therefore the requirement for good air tightness after the house is connected is met; and meanwhile, the concrete foundation cushion blocks play a role in isolating the supporting frame from accumulated water under the condition that a small amount of accumulated water exists in the site.

Owner:广西建工第五建筑工程集团有限公司

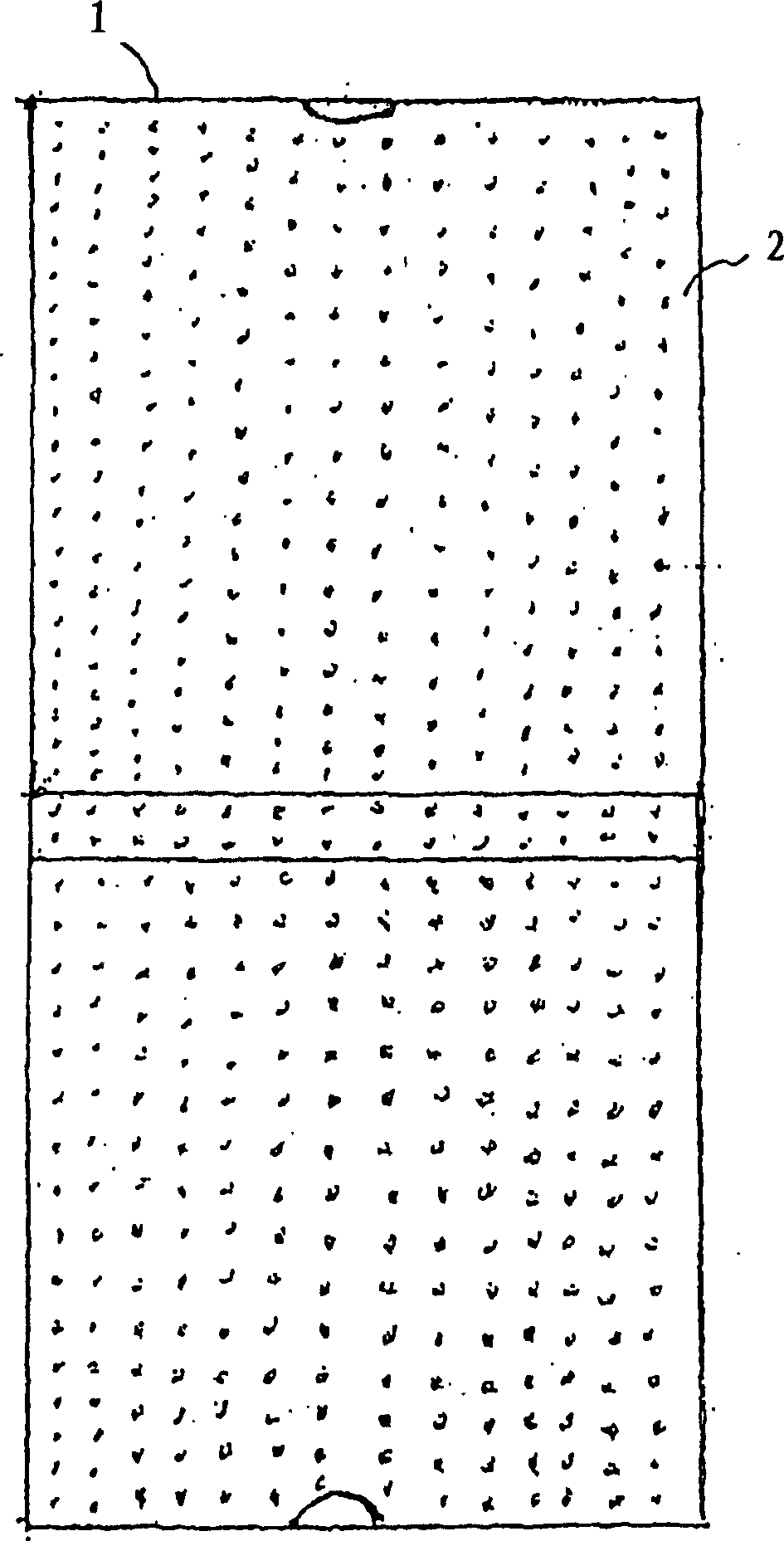

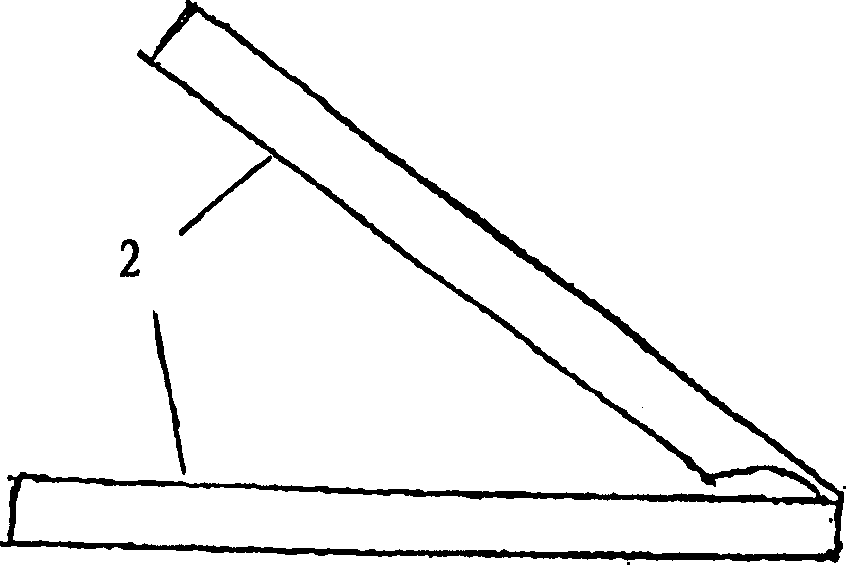

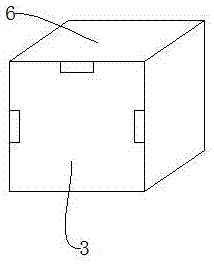

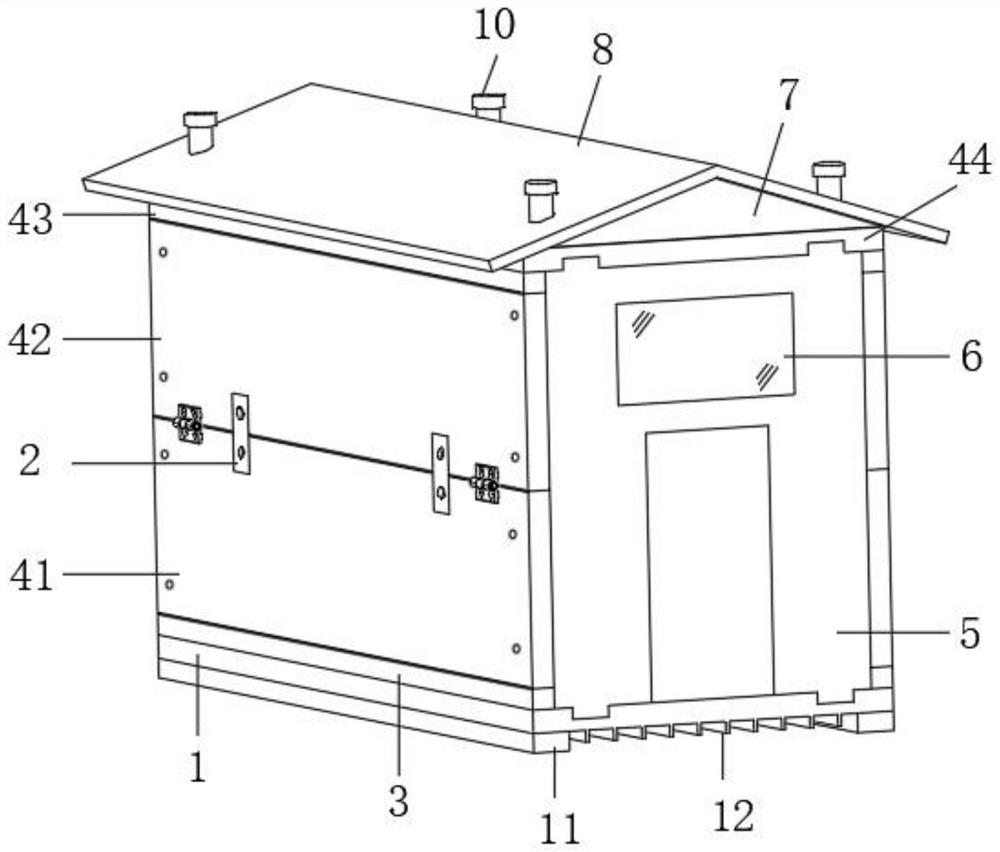

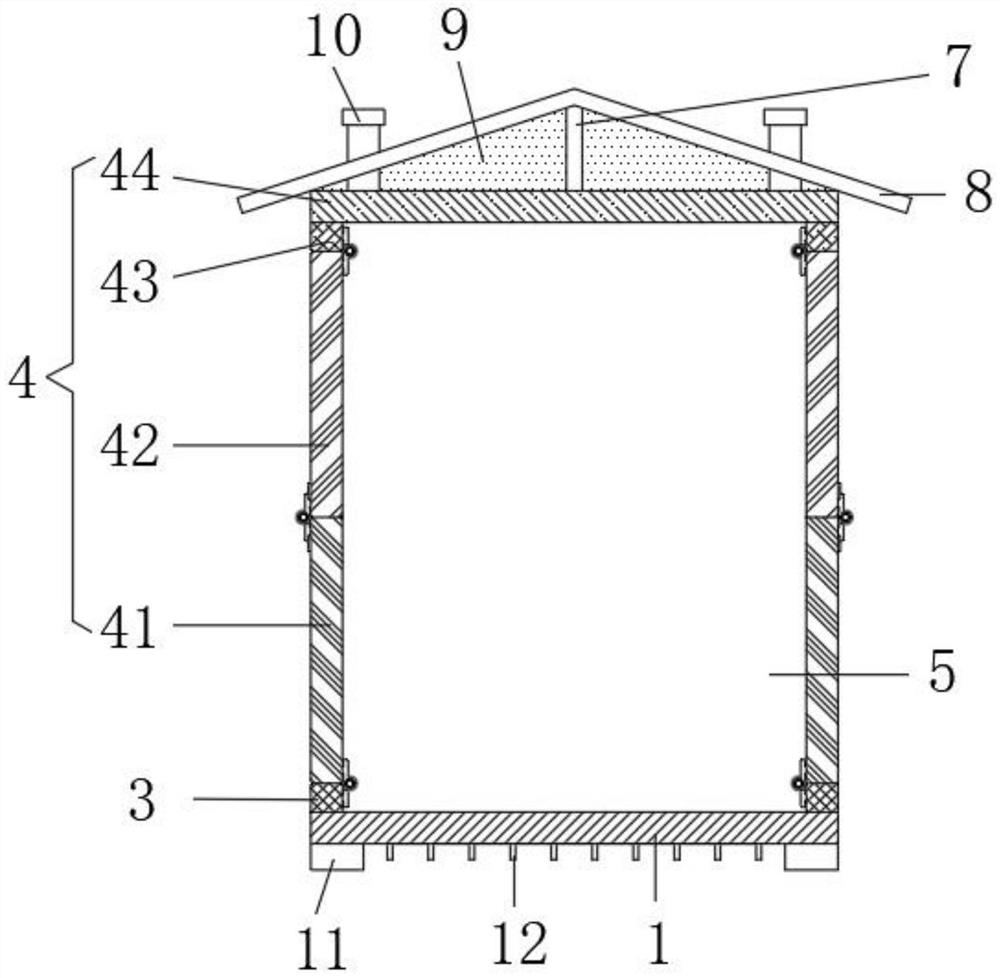

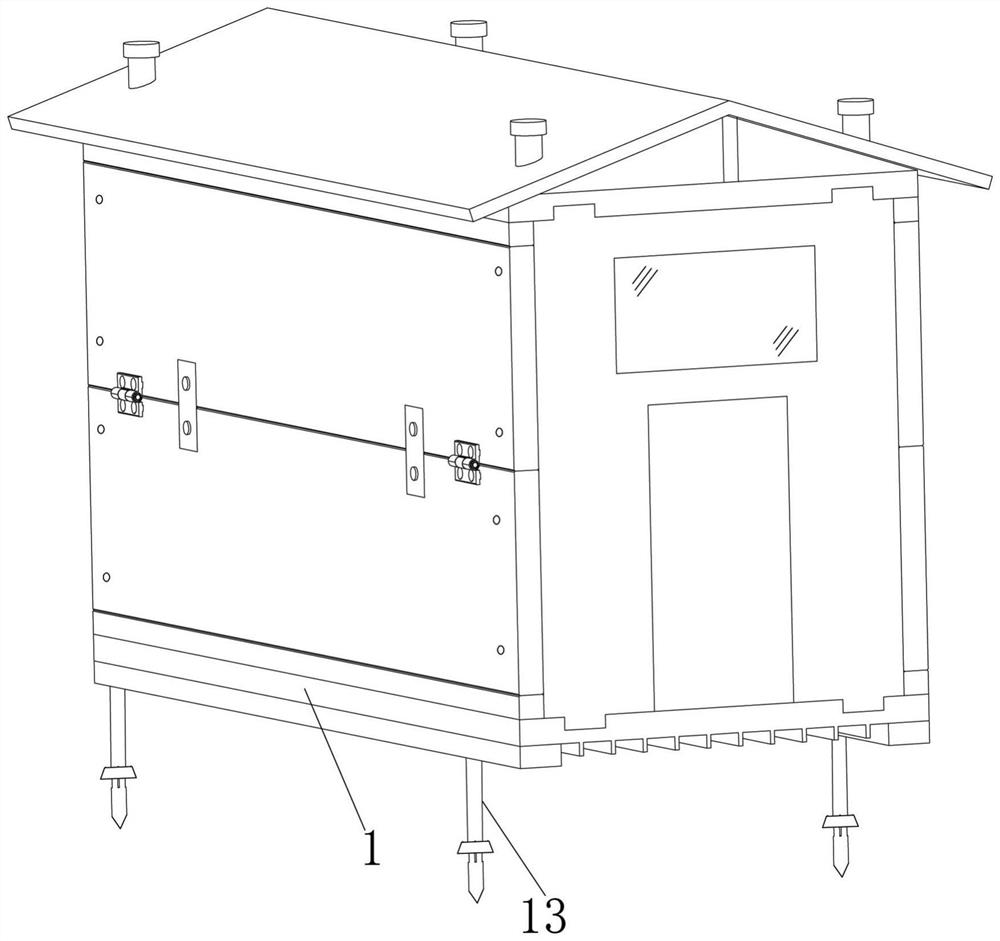

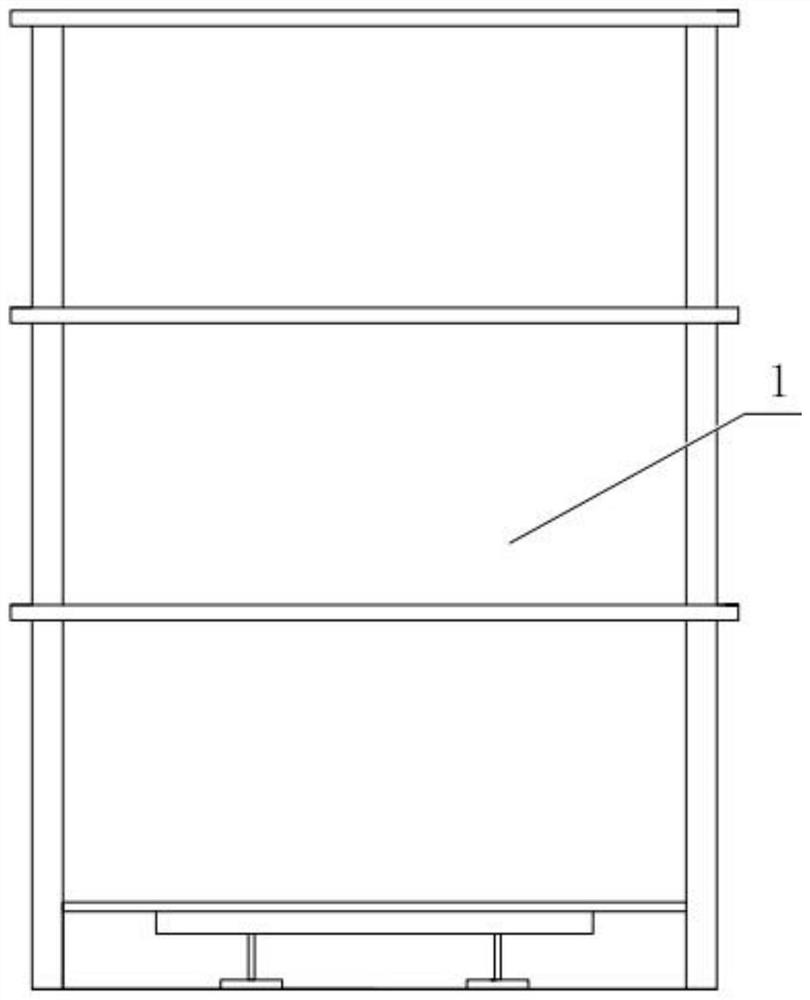

Assembly type intelligent container board house and construction method thereof

InactiveCN113502911AEasy to transportImprove assembly efficiencyHeat proofingBuilding material handlingContainerboardWall plate

The invention discloses an assembly type intelligent container board house and a construction method thereof. The intelligent container board house comprises a base (1), wall boards (4) and door and window boards (5); two symmetrically-distributed fixing bases (3) are arranged on the upper surface of the base (1); the two wall boards (4) are symmetrically arranged and hinged to the upper ends of the fixing bases (3) through hinges correspondingly; the two door and window boards (5) are symmetrically arranged and fixedly connected with the wall boards (4) through bolts correspondingly; and glass windows (6) and doors are arranged in the door and window boards (5). According to the assembly type intelligent container board house and the construction method thereof, folding and stretching of the container board house can be achieved, the number of needed assembly components is decreased while the container board house is convenient to transport, and the assembly efficiency of the container board house is improved.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

Bottom plate material for container

The present invention relates to a container board material, the mixture in the board material is made up by adopting the following method. The synthetic resin whose diameter is 0.1-0.3 mm and rice husk and wood dust whose grain size is 20-50 meshes / sq.inch are mixed together according to the ratio of 55%-75% and 45%-25% in mixer, dehydrated, dried and extruded by means of main extruder to obtain the invented first mixture, 70%-90% of synthetic resin and 30%-10% of additive are mixed, dehydrated, dried and extruded by means of secondary extruder to obtain second mixture as surface adhesive. Said two mixtures are bound together in mould. Besides, the filler consisting of resin and natural fibre material can be pressed into the interior of the board material.

Owner:TOYO KAGAKU SANGYO

A kind of all-bamboo container board with bamboo curtain or bamboo mat as the surface layer and its one-time molding manufacturing process

InactiveCN102285170AGood paving effectGuaranteed thicknessBio-packagingLarge containersSurface layerEngineering

The invention relates to an artificial plate, in particular to a full-bamboo container plate, which takes a bamboo curtain or a bamboo mat as the surface layer and a bamboo directional structure base plate as the core layer. The full-bamboo container plate with the bamboo curtain or mat surface layer comprises the core layer and the surface layer, and is characterized in that the core layer is a large bamboo sheet direction structure plate, and the surface layer is the bamboo curtain or the bamboo mat. In the container plate disclosed by the invention, the core layer and the surface layer are respectively prepared by a bamboo material, so that the property meets the requirement of the container plate, the wood of the container plate is completely replaced, thus, the implementation of the ecological protection measures and the development of the manufacturing of the container plate can be promoted.

Owner:云南永利发林业有限公司

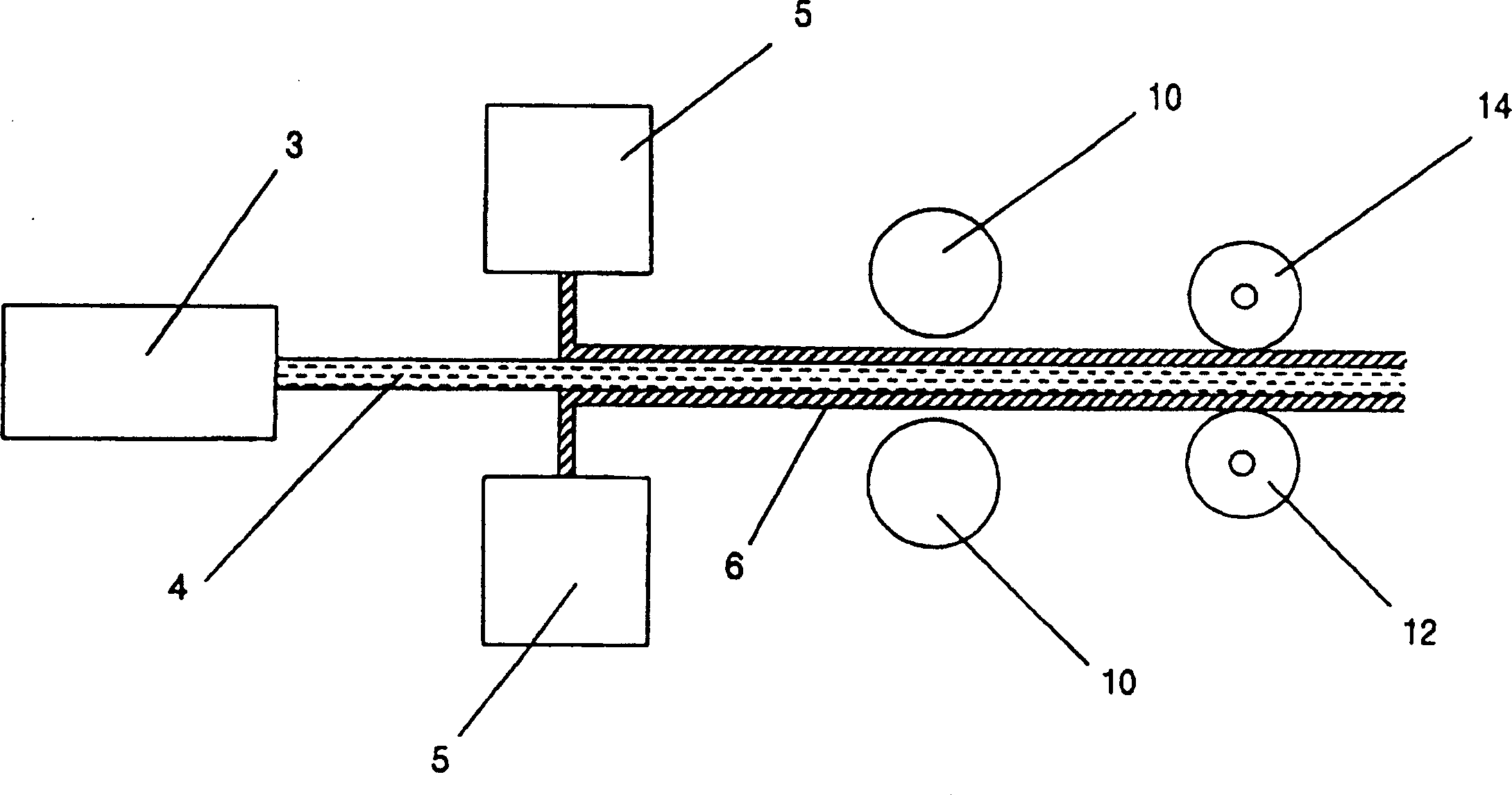

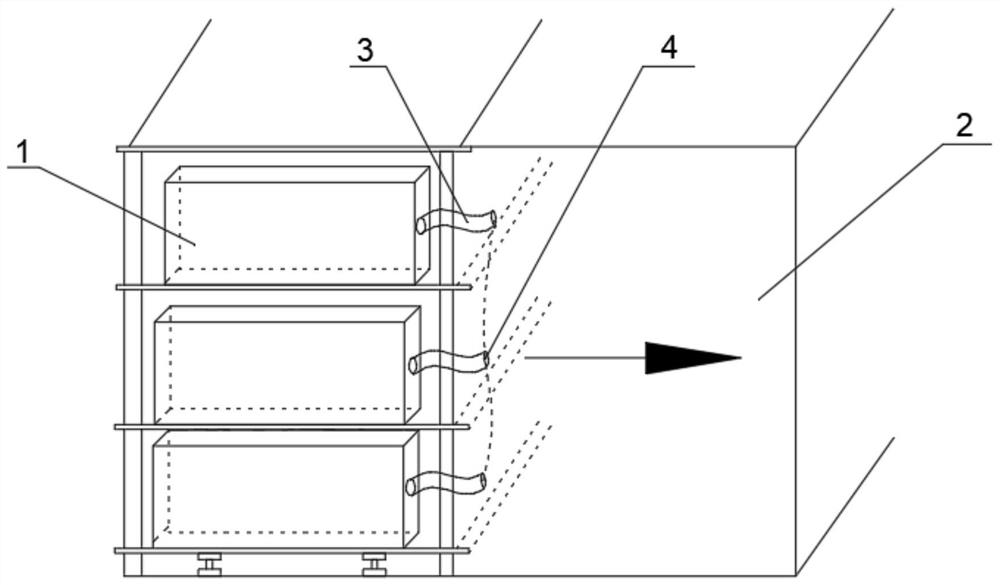

Refrigerated container plate pretreatment roller coating device and processing technology thereof

PendingCN114798304AGuaranteed craftsmanshipGuaranteed workmanshipPretreated surfacesCoatingsEngineeringMachining process

The invention provides a refrigerated container plate pretreatment roller coating device and a processing technology thereof.The device comprises a roller coating device, a drying device and a guiding assembly, an upper-layer roller coating chamber provided with an upper-layer roller coating machine and a lower-layer roller coating chamber provided with a lower-layer roller coating machine which are communicated with each other are arranged in the roller coating device, and conveying of a steel belt is achieved through the guiding assembly; and the conveying line comprises an upper-layer roller coating chamber, a drying device, a lower-layer roller coating chamber and a drying device. By arranging the upper-layer roller coating chamber and the lower-layer roller coating chamber, double-sided local area roller coating of the steel belt is achieved; and in the roller coating process, the single face is pre-dried through the drying room, and the processing performance in the double-face roller coating construction process is guaranteed. After the refrigerated container plate pretreated by the device is subjected to final assembly, only the welding bead area needs to be subjected to sanding and primer treatment, and overall secondary sanding is not needed, so that the workload is saved, the use of auxiliary materials is reduced, and the energy consumption is reduced.

Prefabricated frame steel group isolation type container house structure

PendingCN112392296ARealize fully assembled constructionAvoid quality problemsSpecial buildingBuilding constructionsThermal insulationEngineering

The invention discloses a prefabricated frame steel group isolation type container house structure, and particularly relates to the field of prefabricated container board house buildings. According tothe prefabricated frame steel group isolation type container house structure, angle steel columns and angle steel beams are connected to an upper-layer container house frame plate and a lower-layer container house frame plate through connecting corner fittings, an interlayer frame is arranged at the position, along the edges of the angle steel columns, of the lower-layer container house frame plate, a walking plate is laid on the upper side of the interlayer frame, corrugated steel plates are arranged on three sides of a container house wall part, outer web parts of the corrugated steel plates are connected to the angle steel beams through bolts, a steel fence is arranged on one side of a container house wall and is connected to the angle steel beams through bolts, wall connecting parts are arranged at the left end and the right end of a light thermal insulation wallboard, and inner web parts of the corrugated steel plates are connected to the wall connecting parts. The prefabricatedframe steel group isolation type container house structure has the advantages that complete prefabricated construction is realized, all on-site connection is realized through the bolts, welding spotsare avoided, the quality problem possibly caused by on-site welding can be solved, the machining speed is high, in addition, the precision is high, the installation efficiency can be greatly improved,transportation is convenient, repeated disassembly and assembly are facilitated, environmental protection and energy conservation are better realized, and the labor productivity is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Enzymatic Hydrolysis of Old Corrugated Cardboard (OCC) Fines from Recycled Linerboard Mill Waste Rejects

InactiveUS20150259719A1Negative is costEliminate inhibitors from hydrolyzateBioreactor/fermenter combinationsBiological substance pretreatmentsCardboardFiber

A significant fraction of short fibers (fines) is produced while recycling Old Corrugated Containerboards (OCC), which are usually rejected as solid waste stream, requiring landfilling and posing environmental problems. The major component of these fines rejects are primarily cellulose that can be hydrolyzed into sugars for possible fermentation into biofuels, bioplastics or other sugar based products. Use of fines also offers benefits such as negative costs and production of fermentable sugars without requiring complex pretreatment processes, now required to hydrolyze and eliminate inhibitors from hydrolyzate. Enzymatic hydrolysis of reject fines from a recycled OCC mill, employing different strains of cellulases, were investigated. Fillers (up to 30 mass %) in the fines increases the required dosage of enzymes and costs. Enzyme loading can be lowered by addition of surfactants to reduce their inhibitory activity. The nonionic surfactant Triton X-80 improved hydrolysis yields by up to 10 percent points.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Container sheet material and preparation method thereof

InactiveCN107128030AAchieve preparationSimple methodLayered productsDomestic containersBasalt fiberUltimate tensile strength

The invention provides a container plate and a preparation method thereof, and relates to the field of basalt fiber. The preparation method of the container plate comprises: mixing the first resin and a curing agent to obtain a resin pool, laying cloth in the resin pool, scattering basalt fibers in the resin pool and distributing them on the cloth, spraying the second resin on the basalt fibers, and The second resin covers the film, roll extrusion and thermoforming. The container board uses basalt fiber as the skeleton material, which has the characteristics of good flame retardancy, strong corrosion resistance and light weight of basalt fiber, and at the same time, has high mechanical strength.

Owner:贵州石鑫玄武岩科技有限公司

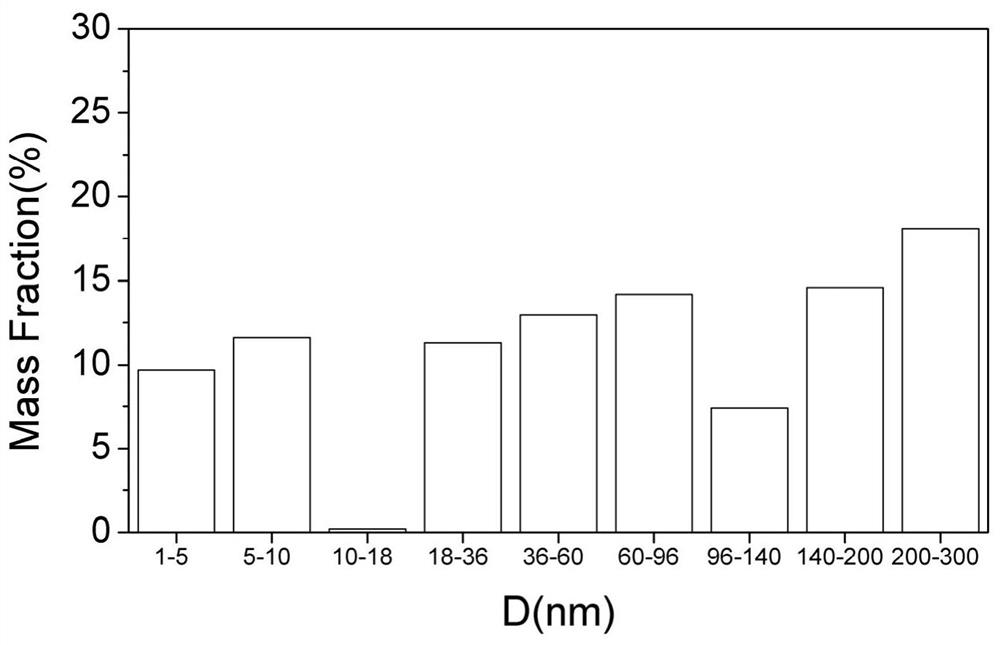

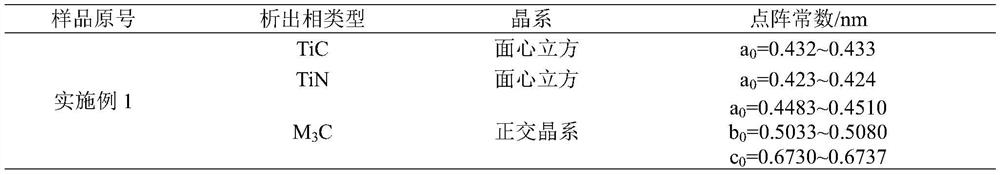

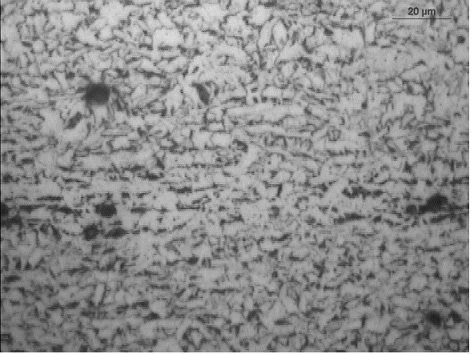

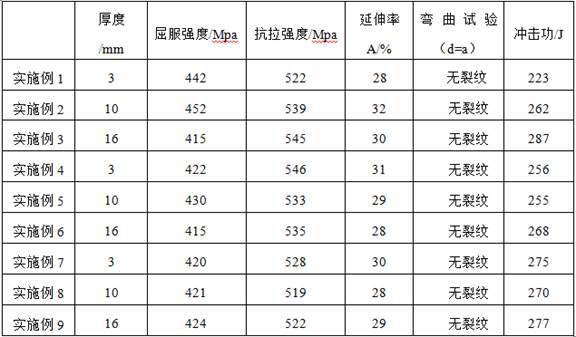

Thin-specification high-strength container plate and preparation method thereof

ActiveCN112111690AReduce manufacturing costReasonable contentTemperature control deviceWork treatment devicesUltimate tensile strengthContainerboard

An embodiment of the invention provides a thin-specification high-strength container plate, which comprises the following components in percentage by mass: 0.050-0.065% of C, 0.30-0.40% of Si, 0.90-1.0% of Mn, 0.11-0.13% of Ti, 0.40-0.60% of Cr, 0.030-0.050% of V, less than or equal to 0.004% of S, less than or equal to 0.018% of P and the balance of Fe and other inevitable impurities. According to the thin-specification high-strength container plate, the composition elements do not contain precious Nb, Mo, Cu and other alloy elements, and the V element replaces the Nb element, so that the manufacturing cost of steel can be greatly reduced. The trace V can act together with Ti and Cr elements to form a fine (TiCrV) (CN) M (CN) precipitate with the particle size of 10 nm or less, so that the strength increment is greatly increased.

Owner:湖南华菱涟钢特种新材料有限公司 +2

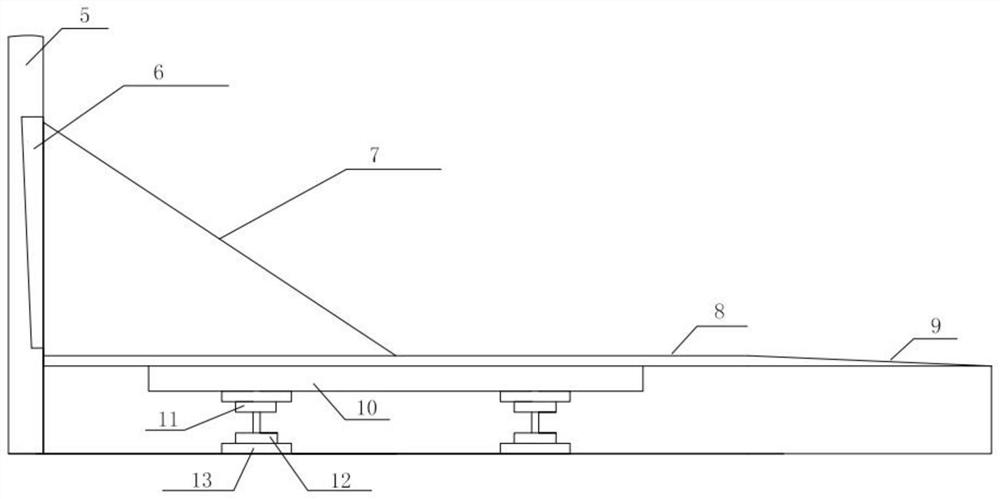

Fuel supplementing system based on container three-dimensional lifting system and leaked fuel

PendingCN113002708ASolve the status quo that cannot change the positionAvoid dangerContainer filling methodsContainer discharging methodsNatural gas fuelContainerboard

The invention discloses a leaked fuel supplementing system based on a container three-dimensional lifting system, and the system comprises a plurality of containers and a cabin; hoses are connected to output ports of the containers, pressure sensors are arranged on the cabin wall of the cabin, and the containers are connected with the pressure sensors on the cabin wall of the cabin through the hoses; the container comprises stand columns, guide plates, diagonal draw bars, an upper container plate and a slope guide section, the slope guide section is arranged on the outer side of the upper container plate and integrally formed with the upper container plate, and a lower container plate, rollers, a transverse moving guide rail and a guide rail roadbed are arranged at the bottom of the upper container plate. According to the invention, the pressure sensor and the container are combined, so that on-time monitoring by manpower is avoided, and the accident occurrence possibility is reduced. And whether the pressure in the second cabin is too high is monitored through the sensor. The natural gas leaked accidentally is firstly recycled to the natural gas fuel tank, and the redundant natural gas is discharged when necessary, so that the danger to the ship body is avoided.

Owner:薛云涛

Thin-gauge container board and preparation method thereof

ActiveCN112063920BMake up strengthMake up for the loss of weather resistanceWeather resistanceEngineering

Owner:湖南华菱涟钢特种新材料有限公司 +2

Container plate with good strength and toughness and production method thereof

ActiveCN112375966AImprove toughnessGood Performance Test TensileMetal rolling stand detailsMetal rolling arrangementsChemical compositionContainerboard

The invention discloses a container plate with good strength. The container plate comprises the following chemical components of, in percentage by weight, 0.04%-0.06% of C, 0.20%-0.25% of Si, 0.50%-0.60% of Mn, 0.070%-0.080% of P, less than or equal to 0.005% of S, 0.015%-0.050% of Als, 0.010%-0.020% of Nb, 0.36%-0.40% of Cu, 0.38%-0.48% of Cr, 0.21%-0.25% of Ni and the balance Fe and inevitable impurities, wherein Cu / Ni is larger than or equal to 1.44 and less than or equal to 1.90. Due to the reasonable design of chemical components in the steel, the produced container plate has good strength and toughness, and in performance inspection, the tensile, bending and impact properties are good.

Owner:HANDAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com