Assembly type intelligent container board house and construction method thereof

A container and assembly technology, applied in building components, thermal insulation, construction, etc., can solve the problems of low strength, low assembly efficiency of container house, long assembly time, etc., to achieve convenient transportation, fast folding operation, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

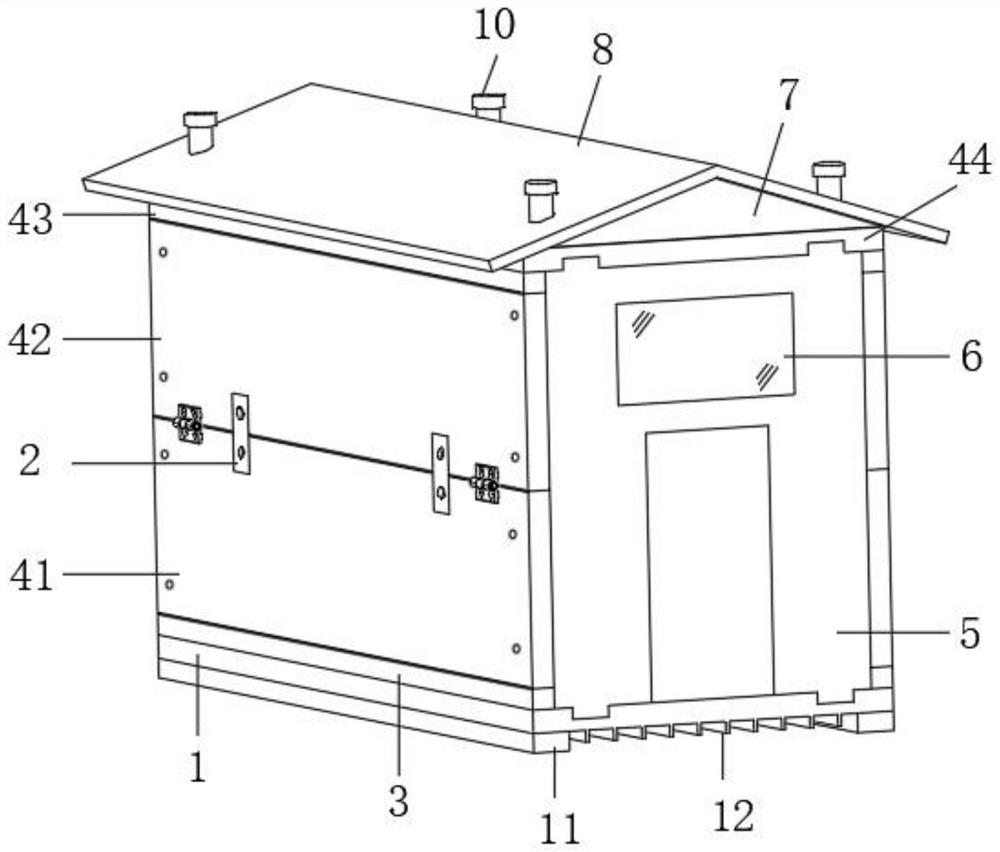

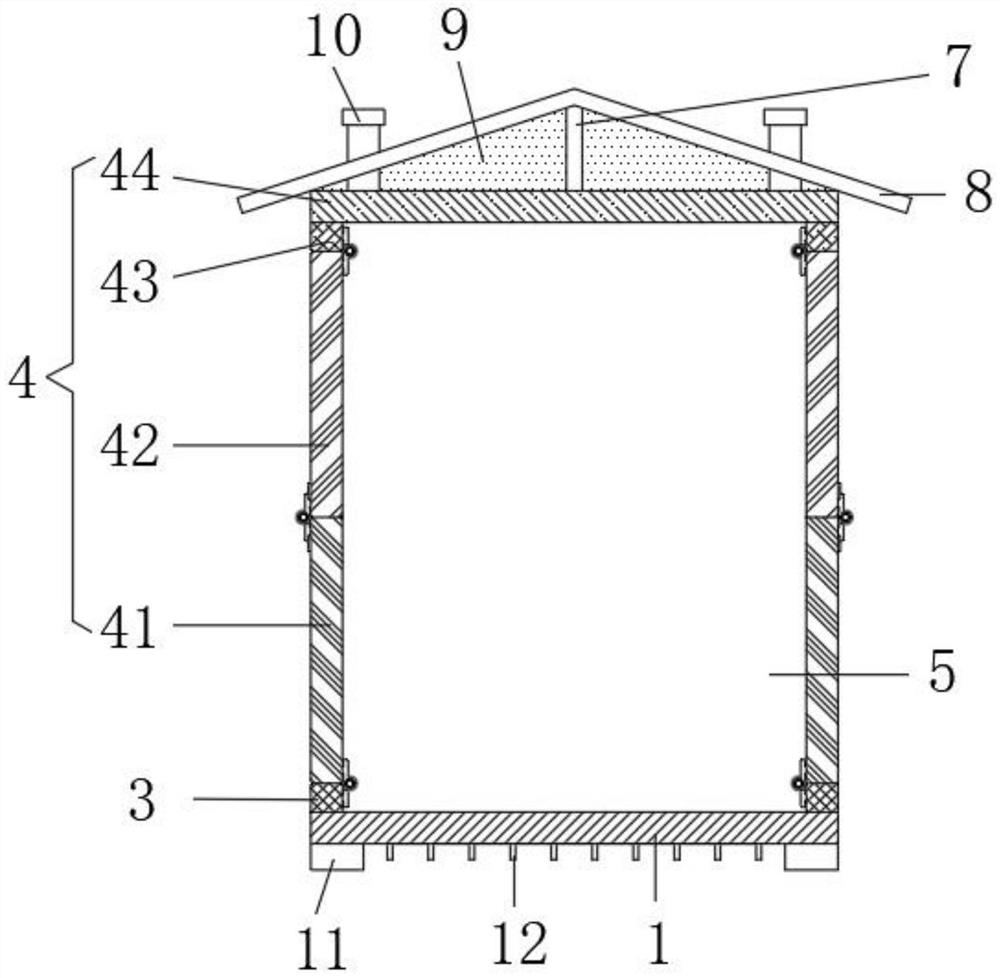

[0032] see figure 1 and 2 , this embodiment provides a technical solution: a prefabricated intelligent container board house, including a base 1, wall panels 4 and door and window panels 5;

[0033] The base 1 provides an installation place for other components, and its upper surface is provided with two symmetrically distributed fixing seats 3, and also includes a backing plate 11 and a reinforcing rib 12, and the backing plate 11 is symmetrically arranged on the left and right ends of the lower surface of the base 1 , The reinforcing ribs 12 are evenly distributed in the middle of the lower surface of the base 1 . The backing plate 11 can protect the upper parts and reduce the wear of the upper parts, and the reinforcing ribs 12 can strengthen the strength of the base 1;

[0034] The wall panel 4 can realize the folding and stretching of the container board room, and is hinged to the upper end of the fixing seat 3 through a hinge. Plates 41 are respectively hinged to the ...

Embodiment 2

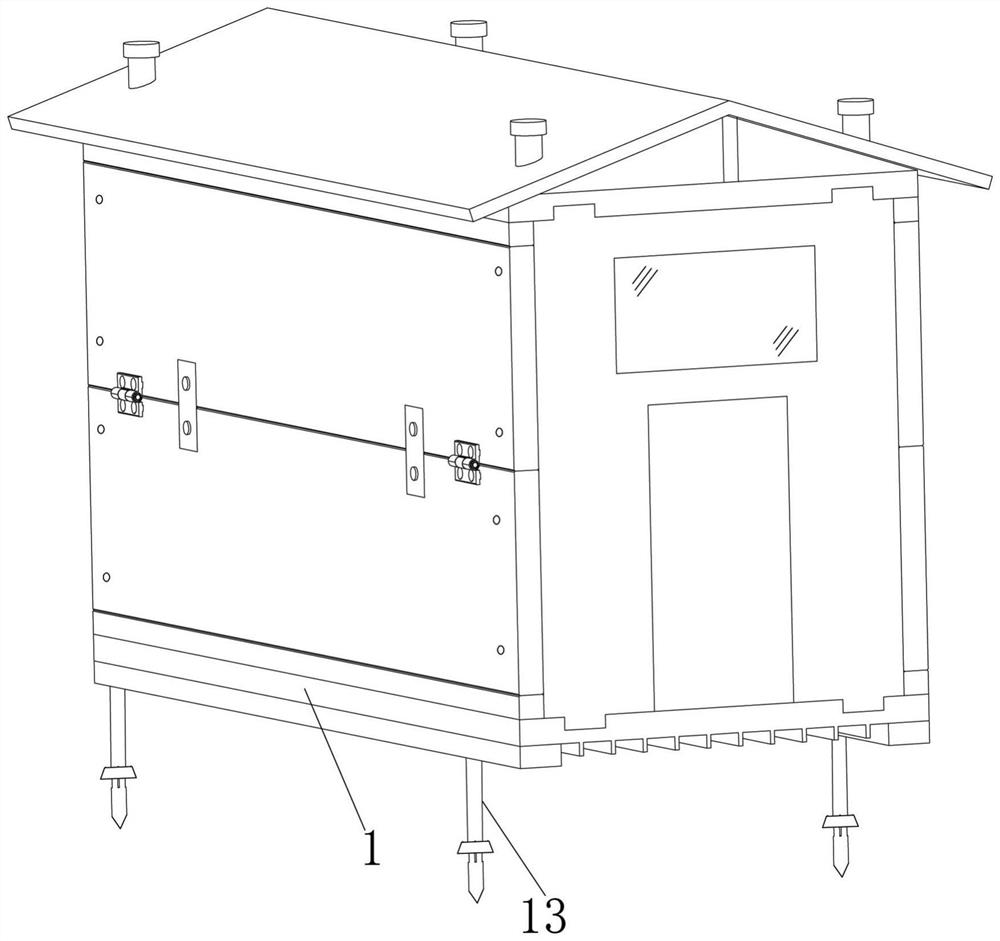

[0044] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: please refer to Figure 3-5 An anchor assembly is arranged on the base 1, and the anchor assembly 13 is used to fasten the base 1 to the ground, including an anchor rod 131 and a driving screw 132, and a lifting plate 133 is arranged inside the anchor rod 131, and the peripheral sides of the lifting plate 133 are uniformly hinged A plurality of barbs 134, the lower end surface of the barbs 134 is provided with engaging teeth 135, a plurality of elongated through holes 136 corresponding to the barbs 134 are arranged on the anchor rod 131, and the long sides of the elongated through holes 136 extend vertically The shed 137 set on the outside of the anchor rod 131 is a hollow structure with a triangular or trapezoidal cross section. Line 138, the upper end of the anchor rod 131 is fixedly connected with the threaded plate 139, and the lower end of the driving screw rod 132 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com