Container plate with good strength and toughness and production method thereof

A production method and container technology, applied in manufacturing tools, manufacturing computing systems, metal rolling, etc., can solve the problems of many alloy components, internal and external cracks and bending cracks in steel plates, and achieve the effect of fine and uniform structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

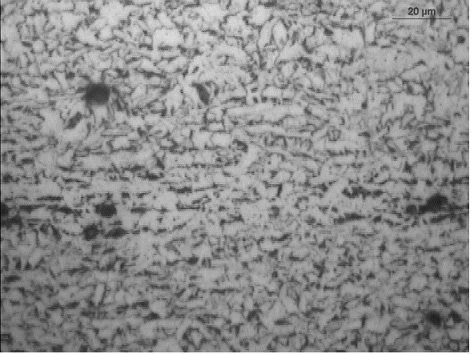

Image

Examples

Embodiment 1-9

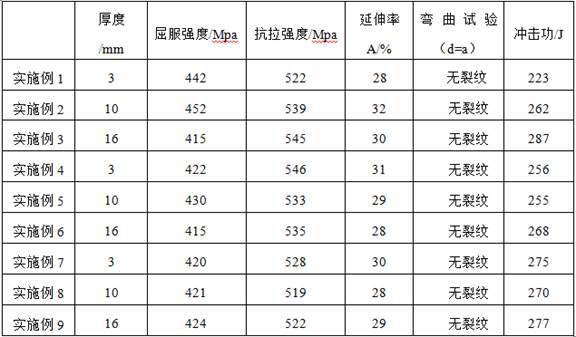

[0019] Examples 1-9 The chemical composition and weight percentage of a container board with good strength and toughness are shown in Table 1. The production method includes slab heating, rolling process, slab heating process, and the heating furnace heating temperature is shown in Table 2. In the slab rolling process, the F5 stand is used in the finish rolling process, and only the front 4 stands and the rear 2 stands are used, and the pressing and rolling forces of the F5 stand are evenly distributed to the other 6 stands.

[0020] Table 1

[0021]

[0022] Table 2

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com