Fuel supplementing system based on container three-dimensional lifting system and leaked fuel

A lifting system and fuel replenishment technology, applied in the directions of bulk cargo, transportation and packaging, load handling devices, etc., can solve the problems of inability to effectively monitor LNG leakage, inability to recycle LNG, and high risks for monitoring personnel, so as to reduce the occurrence of accidents. Possible, avoid on-time monitoring, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] In conjunction with the accompanying drawings, the present invention is described in detail.

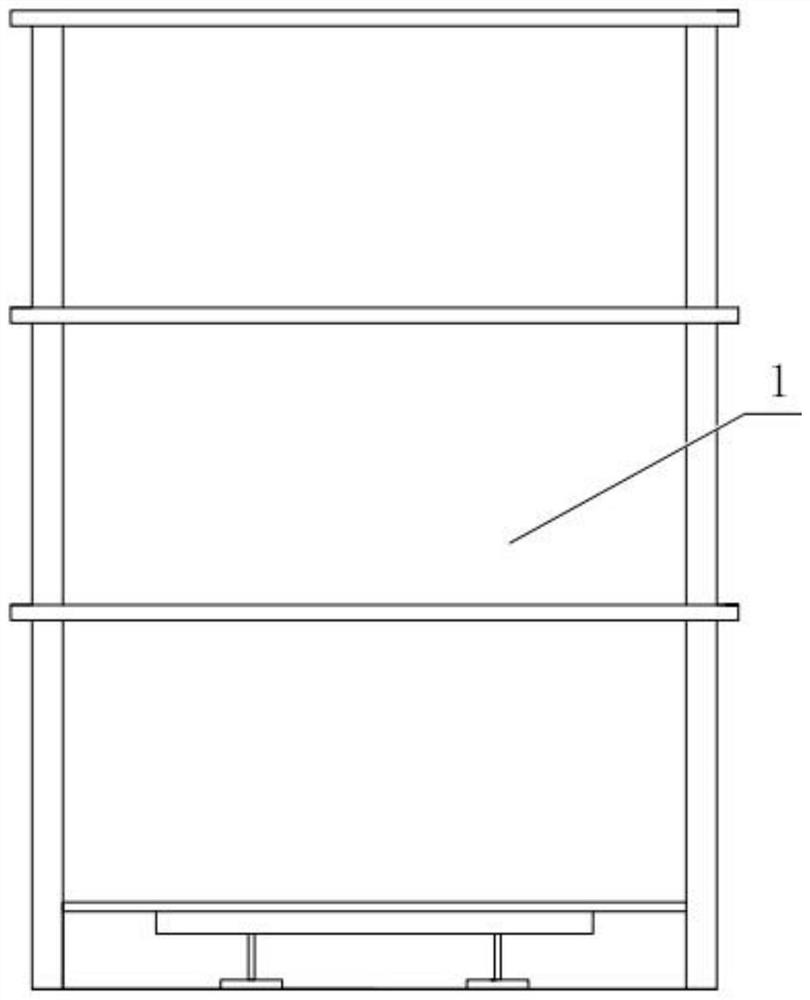

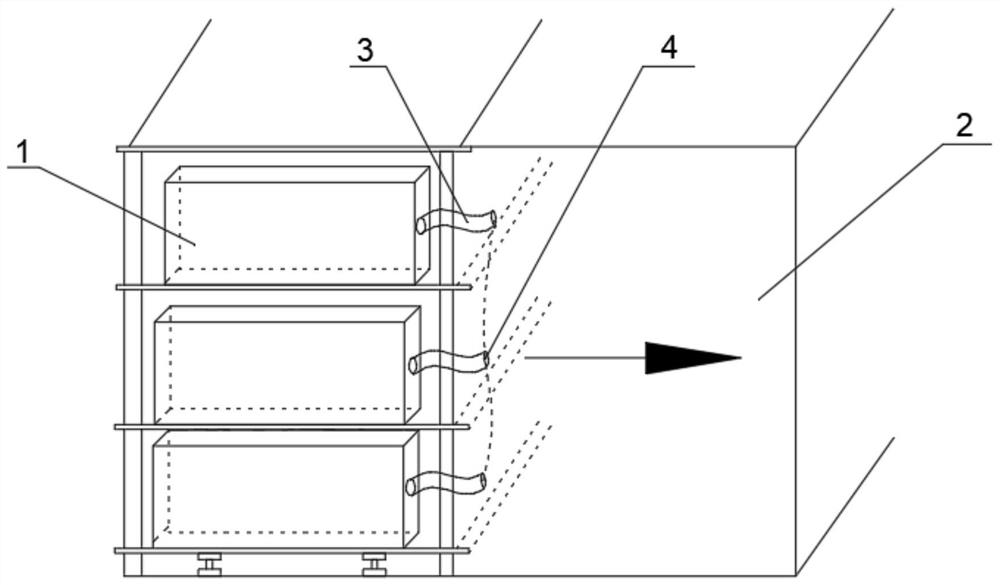

[0021] During specific implementation, the present invention provides a fuel replenishment system based on a three-dimensional container lifting system and leakage, including several containers 1 and cabins 2, the output ports of the containers 1 are connected with hoses 3, and the bulkheads of the cabins 2 A pressure sensor 4 is provided, and the container 1 is connected to the pressure sensor 4 on the bulkhead of the cabin 2 through a hose 3;

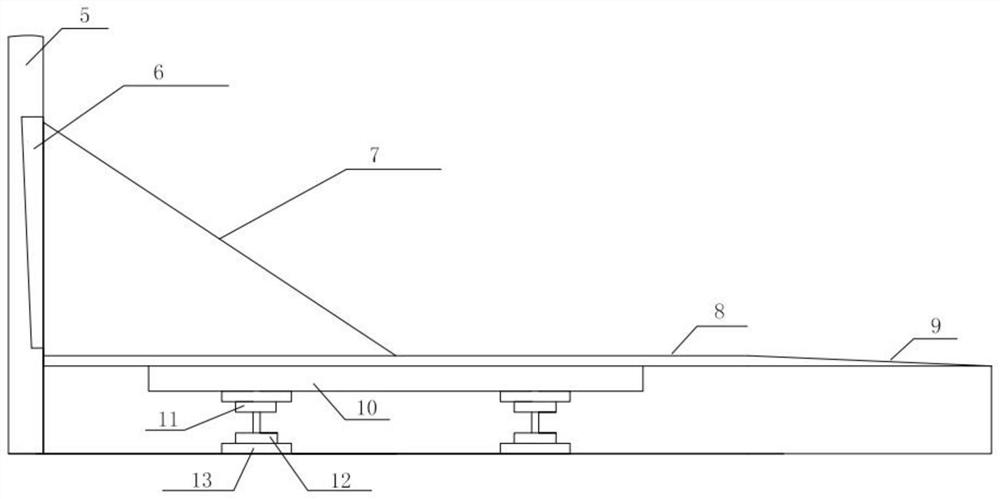

[0022] The container 1 includes a column 5, a guide plate 6, a diagonal tie rod 7, an upper container plate 8 and a leading slope section 9, and the said leading slope section 9 is arranged on the outer side of the upper container plate 8 and integrally formed with the upper container plate 8, so that The bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com