Refrigerated container plate pretreatment roller coating device and processing technology thereof

A refrigerated container and pretreatment technology, which is applied to the pretreatment surface, the device for coating liquid on the surface, coating, etc., can solve the problems of anti-corrosion performance, easy to occur flash rust, long cycle, etc., to ensure process performance and anti-corrosion performance, reduce the use of auxiliary materials, and save the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further clearly illustrate the purpose, technical solutions and advantages of the present invention, the present invention is further described below with reference to the accompanying drawings. The accompanying drawings of the present invention are simple and easy-to-read structural framework diagrams and cannot limit the real purpose of the present invention.

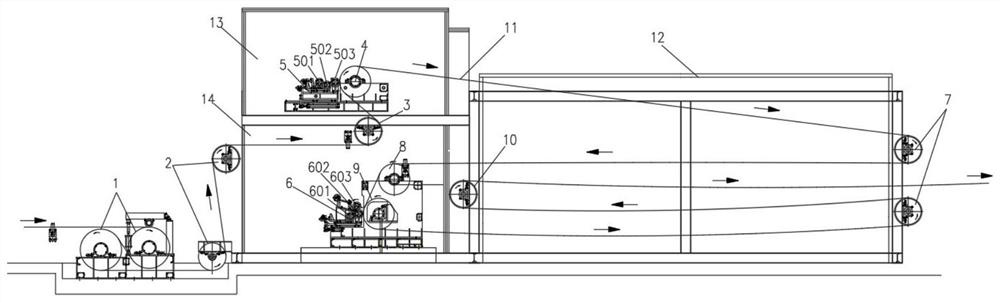

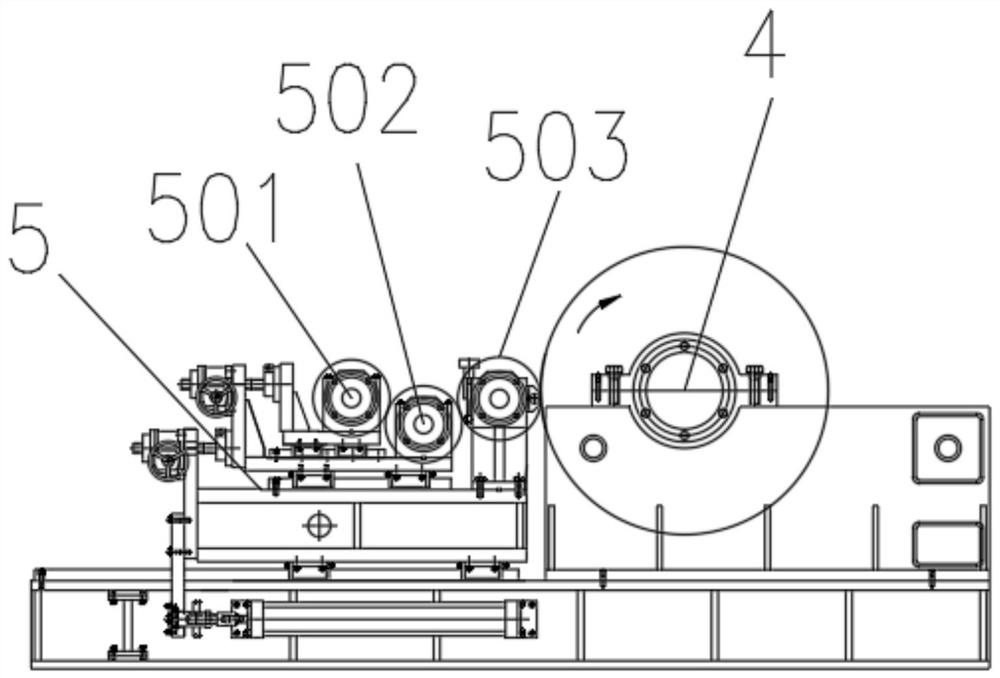

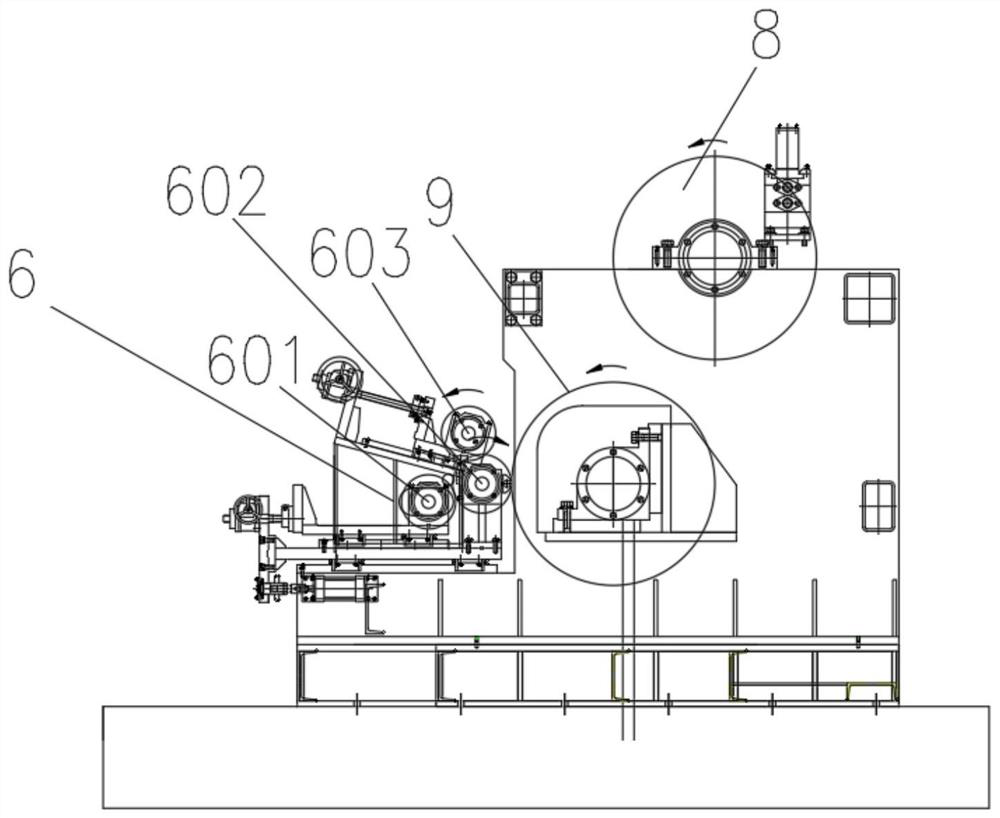

[0040] combine Figure 1 to Figure 9 The content shown, the present invention proposes to include a roller coating device, a drying device and a guide assembly, and the roller coating device is provided with an upper layer roller coating chamber 13 that communicates with each other and is provided with an upper layer roller coater 5 and is provided with a lower layer roller coater. 6 lower roll coating chamber 14,

[0041] The steel belt 11 is run through the guide assembly as follows:

[0042] The upper roller coating chamber 13-drying device-lower roller coating chamber 14-drying device.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com