Integrated polymer and metal case ammunition manufacturing system and method

a technology of integrated system and manufacturing method, which is applied in the direction of cart ammunition, weapons, transportation and packaging, etc., can solve the problem of not disclosing the operation of the feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

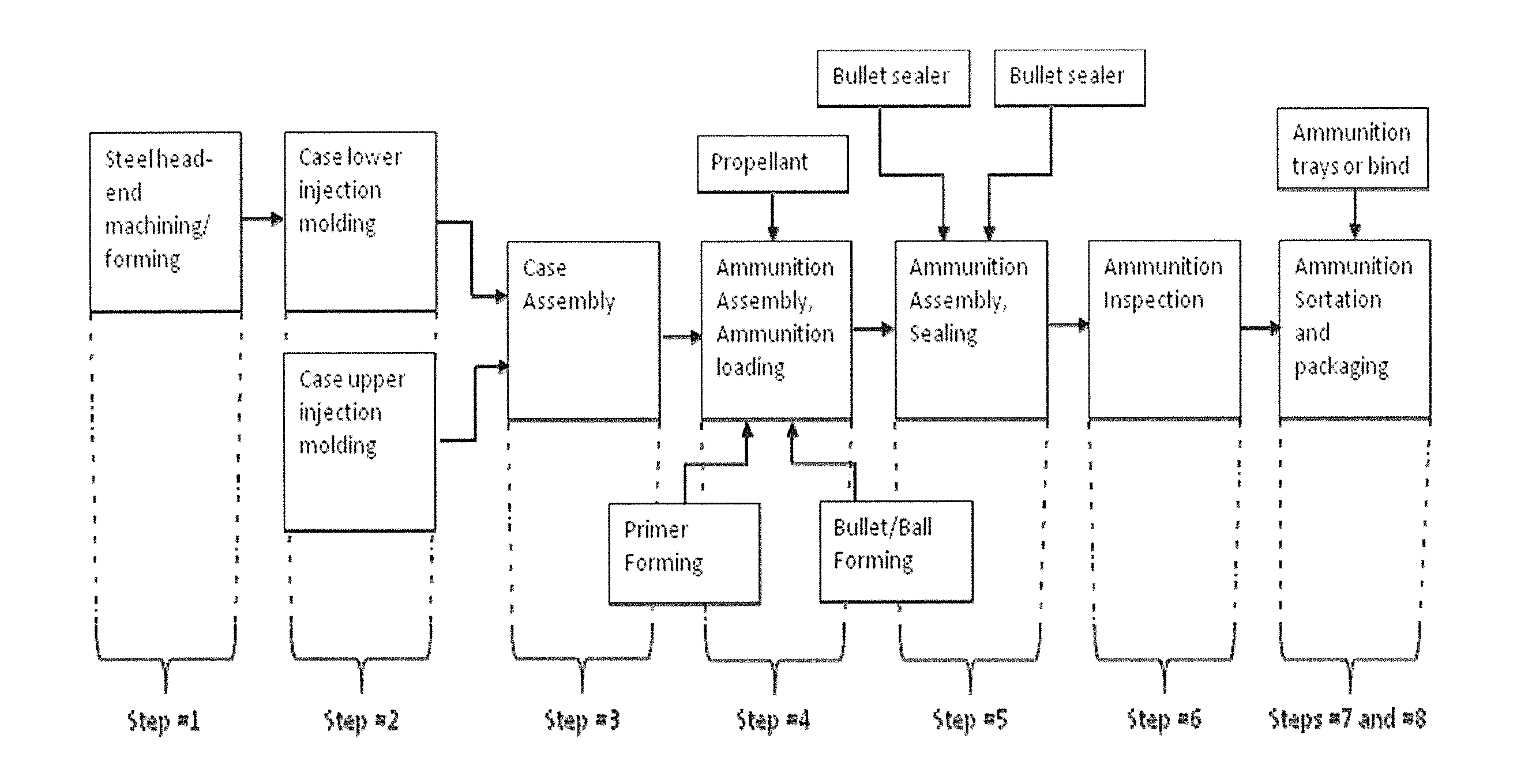

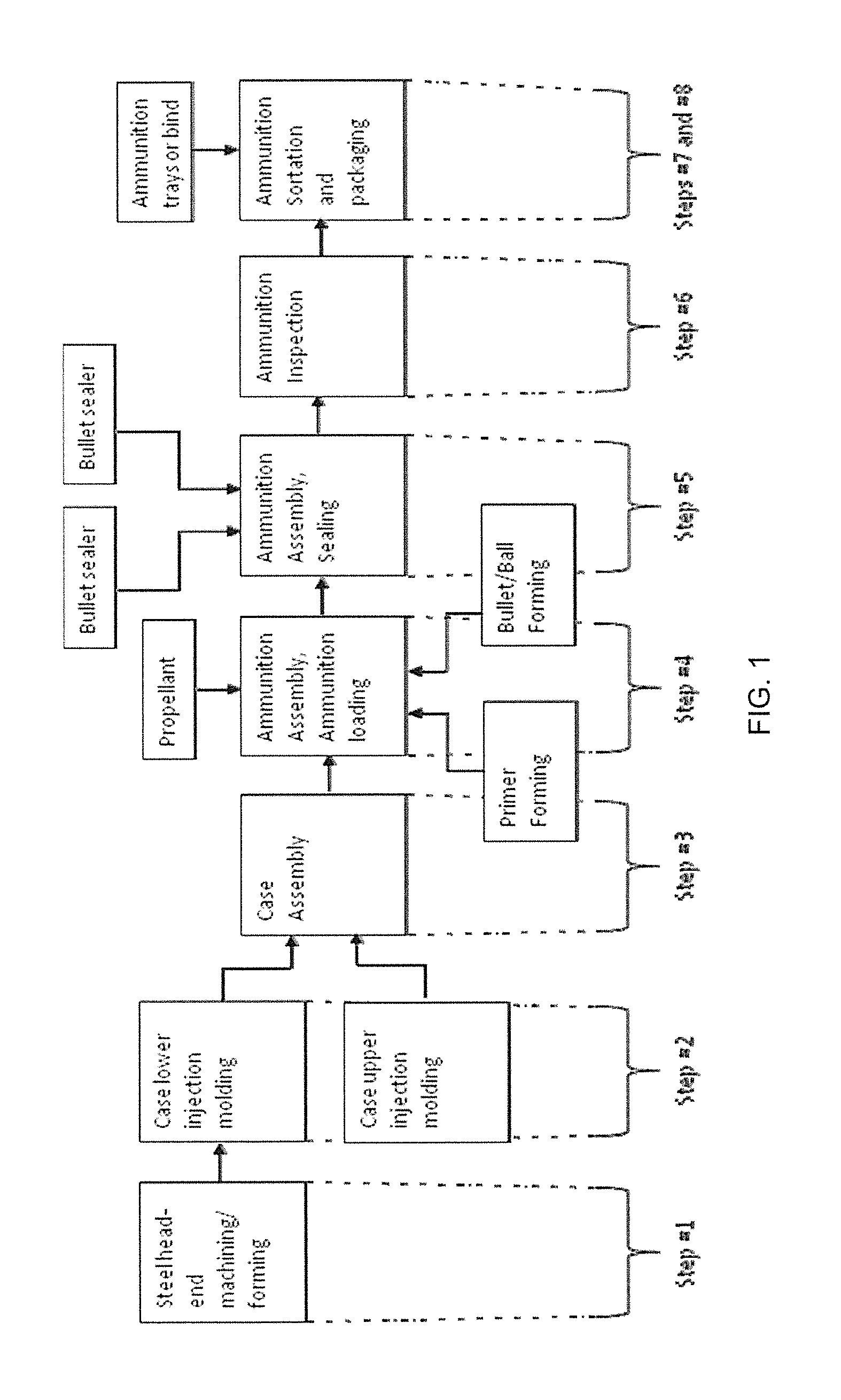

[0044]Compared to conventional rounds that use brass, nickel or steel (metal) cases, polymer ammunition is a potentially lower cost, lighter weight, and more accurate alternative. However, supporting this emerging technology requires a new set of manufacturing stations, methods and techniques. This disclosure describes a fully automatic manufacturing system and method for polymer-cased ammunition, including injection molding re-purposed for polymer case manufacturing; at least four new manufacturing process machines that support case assembly, sealing, and full in-process, final product inspection and cartridge packaging or binning; and a more conventional ammunition loading machine that is modified to support a fully automated manufacturing line. The disclosed fully automatic manufacturing system also supports conventional metal case ammunition or ammunition that is a combination of metal and polymer cased. FIG. 1 diagrams a fully automated and integrated compact manufacturing line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com