Warm press forming method and automobile frame component

A molding method and warm pressing technology, applied in vehicle parts, manufacturing tools, furnace types, etc., can solve the problems of large shape change, limited parts, poor press formability, etc., and achieve the effect of improving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

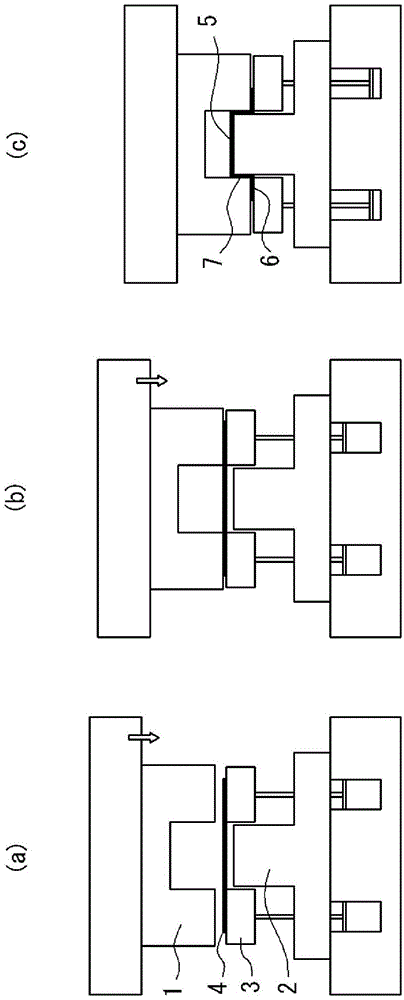

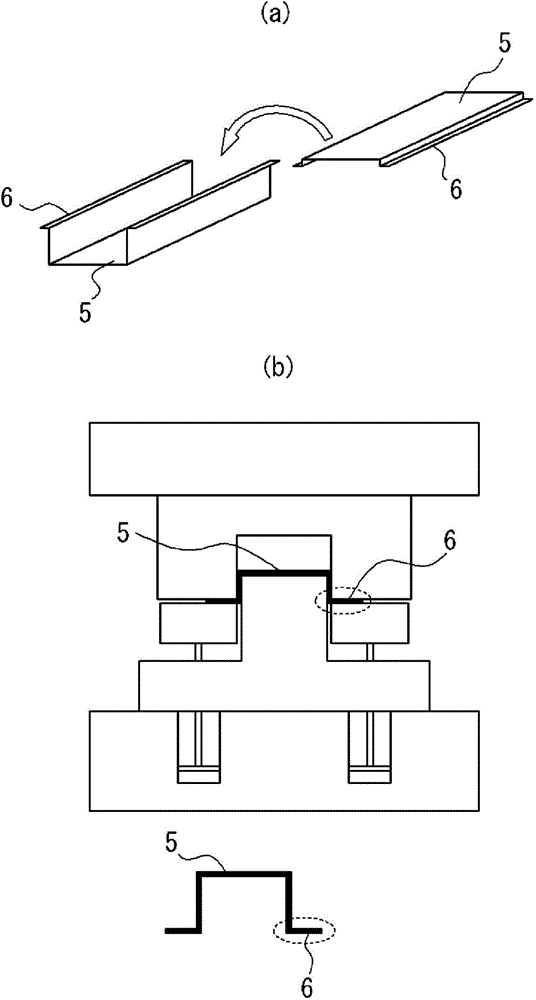

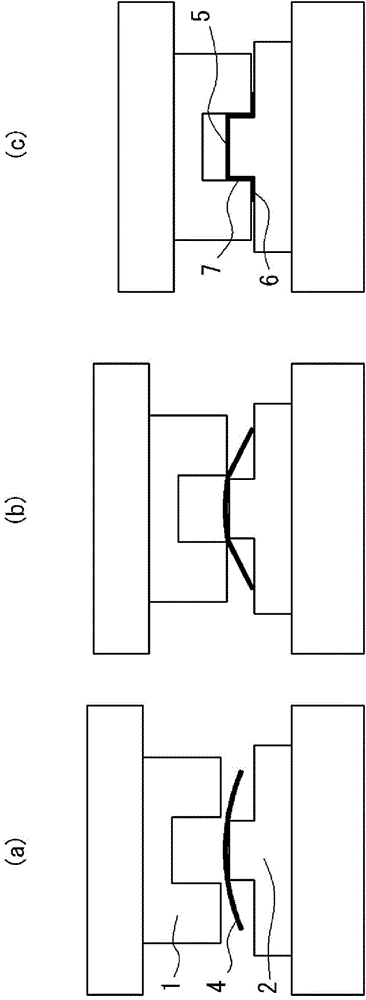

[0197] Steel plates with a thickness of 1.6mm and a tensile strength of 440MPa class to 1180MPa class were heated under the conditions shown in Table 1, and then formed into Figure 6 (a) The upper pressure plate of the center pillar, one of the car frame components shown. In addition, for comparison, under the conditions shown in Table 1, the forming of the center column upper plate was carried out by warm drawing forming and cold flangeless drawing forming at room temperature (the steel plate was not heated).

[0198] Here, an electric furnace is used for heating the steel plate. The time in the furnace was set to 300 seconds, so that the entire billet was heated with a uniform temperature distribution. The heated billets were taken out of the furnace, fed into a press after a transfer time of 10 seconds, and formed under the conditions shown in Table 1. Immediately thereafter, the temperature difference between the flange portion and the portion other than the flange port...

Embodiment 2

[0211] Molten steel having the composition shown in Table 2 was smelted in a converter and cast by a continuous casting method to produce a thick slab (steel raw material). These thick steel billets (steel raw materials) were heated to the heating temperature shown in Table 3, soaked and held, and after rough rolling, they were finished rolled and cooled under the hot rolling conditions shown in Table 3, and coiled into coils. Made into a hot-rolled steel plate (thickness: 1.6mm). It should be noted that the steel sheets a, i, k, and m are heated to 700°C in a continuous hot-dip galvanizing line, and then immersed in a hot-dip galvanizing bath with a liquid temperature of 460°C to form a hot-dip galvanized layer on the surface. , and then perform alloying treatment on the coating layer at 530° C. to form an alloyed hot-dip galvanized layer. It should be noted that the plating adhesion is 45g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com