Rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold

A seamless thin-walled, rare-earth magnesium technology, used in metal extrusion dies, metal extrusion, metal extrusion control equipment, etc., can solve the problems of large extrusion deformation force, narrow processing range, and high blank requirements. The effect of small extrusion force, good surface quality and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 - In this example, a Mg-4.0Y-2.0Nd-0.4Zr magnesium alloy seamless tube with an outer diameter of 8 mm and an inner diameter of 6 mm was hot-extruded.

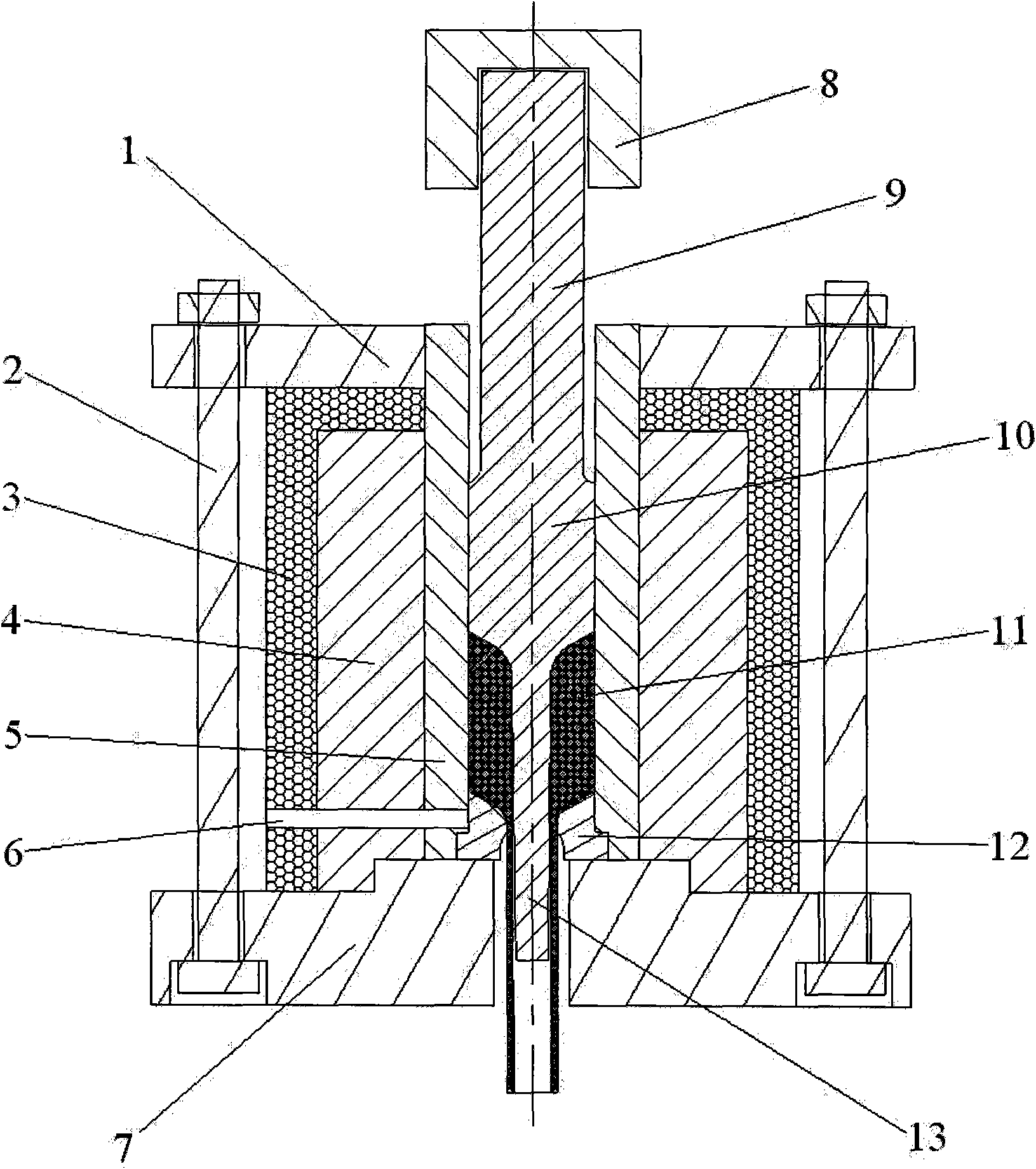

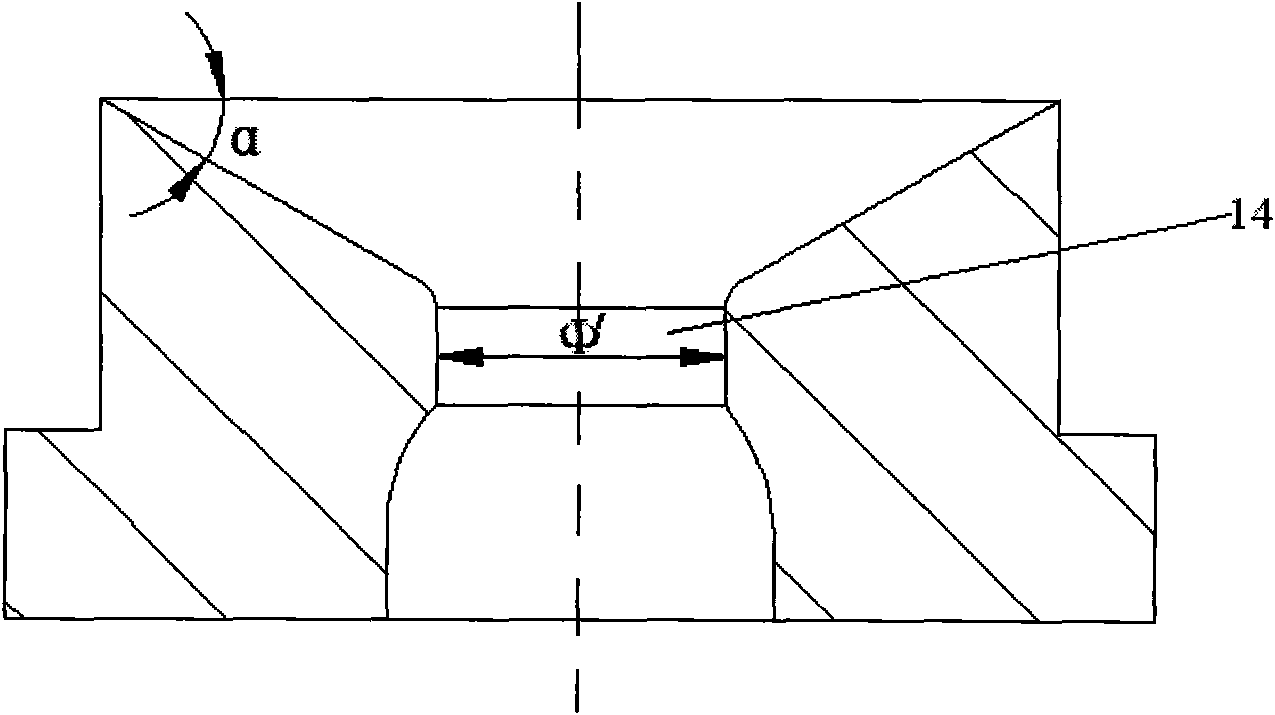

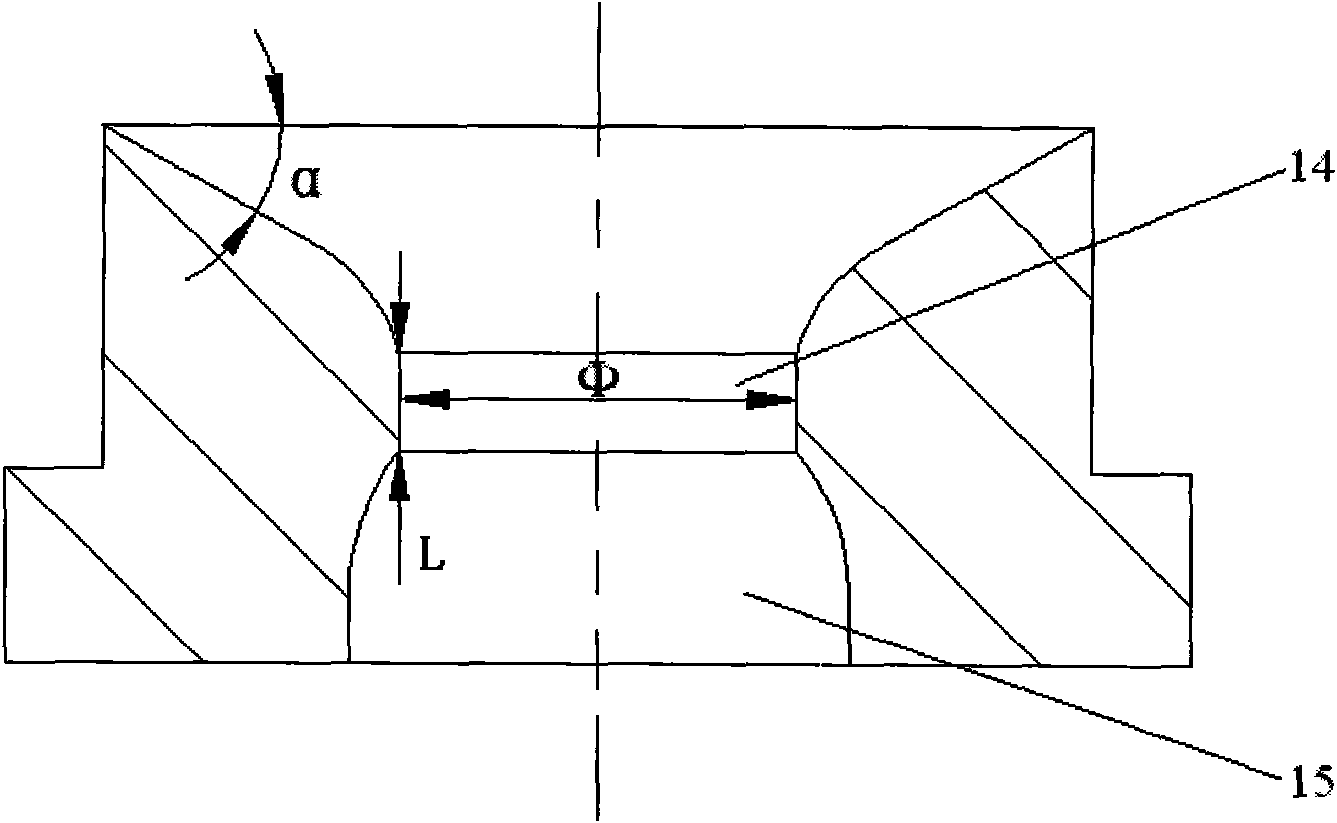

[0043] The special mold structure used in this embodiment is as follows: figure 1 shown. Extrusion cylinders 4 and 5 adopt a two-layer prestressed combined structure with temperature measuring holes 6, and the diameter of the working inner hole is 20mm; Diameter is 6mm; pre-extrusion die 12 (see figure 2 ) or forming die 12 (see image 3 ) is fixed on the lower mold base 7 through the extrusion cylinder, wherein the diameter of the pre-extrusion concave mold cavity is 6mm, and the diameter of the forming concave mold cavity is 8mm; the outside of the extrusion cylinder adopts a glass fiber insulation layer 3; The position pressure head 8 ensures that the punch is not directly pressed on the forming die;

[0044] The specific process steps of extruding the Mg-4.0Y-2.0Nd-0.4Zr rare earth magnesium alloy seam...

Embodiment 2

[0053] Example 2 - In this example, a Mg-4.0Y-2.0Nd-0.4Zr magnesium alloy seamless tube with an outer diameter of 7.2 mm and an inner diameter of 6 mm was extruded.

[0054] The mold used in this example is basically the same as that in Example 1, except that the cavity diameter of the forming die used is 7.2mm, and the extrusion temperature is 400°C.

[0055] The specific process steps adopted in this example are based on Example 1, adjusting the extrusion speed to 3mm / s, the extrusion ratio to 25, and the solution aging treatment parameters to 500°C×2h+180°C×16h.

[0056] The maximum extrusion force in the extrusion process of this embodiment is 161KN, and the cup-shaped remaining material is less than 1% of the billet. The obtained Mg-4.0Y-2.0Nd-0.4Zr magnesium alloy seamless thin-walled thin tube has a smooth surface, a wall thickness difference of less than 0.05 mm, a grain size of less than 5 μm, a tensile strength of 246 MPa, and an elongation of 28.2%. After solid sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com