Production technology for bearing steel wire rod

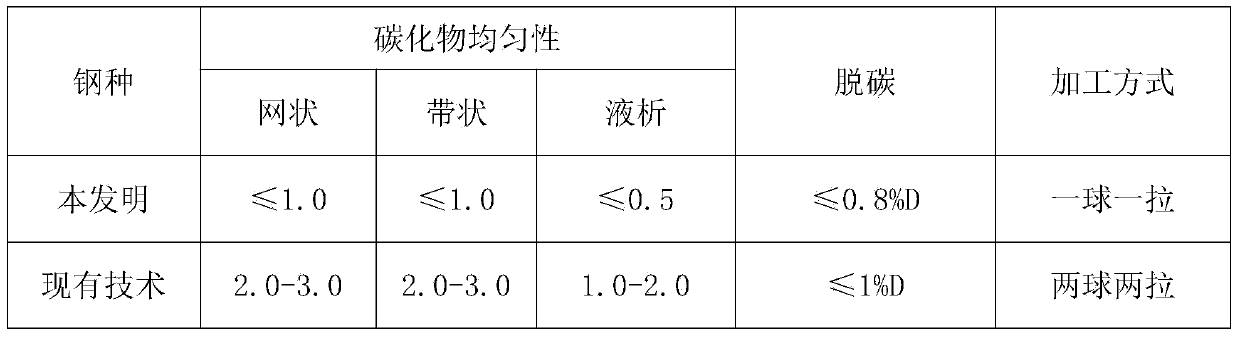

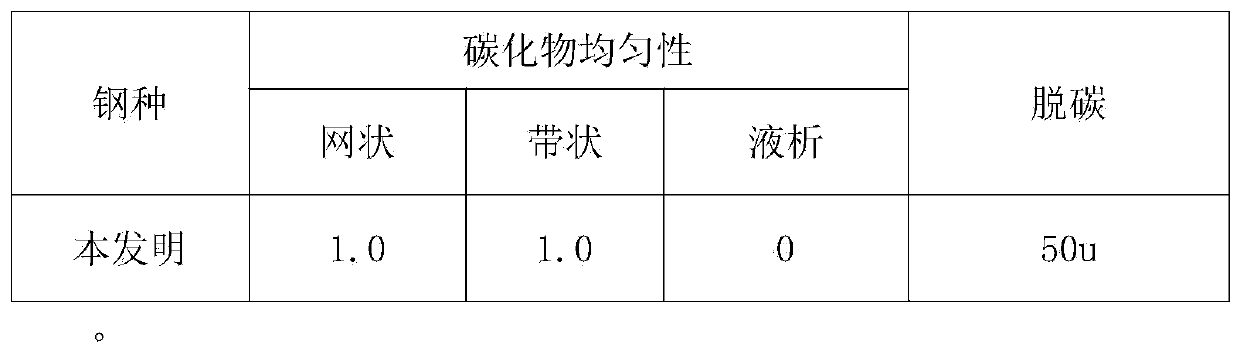

A production process and technology of bearing steel, applied in the direction of metal rolling, etc., can solve the problems of carbide uniformity and surface decarburization difficult to control, poor plasticity index of bearing steel wire rod, affecting bearing service life, etc., to achieve good carbide Uniformity, slight surface decarburization, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A production process of bearing steel wire rod. The bearing steel is composed of the following components by weight percentage: C: 1.003%, Mn: 0.315%, Si: 0.231%, P≤0.008%, S: 0.002%, Cr: 1.554%, Ni : 0.047%, Cu: 0.052%, Ti: 0.0015%, Al: 0.011%, Mo: 0.004%, Ca: 0.0002%, and the balance is Fe.

[0022] The production process of 8mm bearing steel wire rod in this embodiment includes the following steps: billet pretreatment→steel billet heating→high-pressure water descaling→rough and intermediate rolling, pre-finishing rolling→water cooling zone 1→finishing rolling unit→water cooling zone 2→ Reduction and sizing rolling→hot eye online inspection→finished product online diameter measurement→water cooling zone 3→spinning→air cooling→surface inspection→finishing→baling→weighing→warehousing→physical and chemical inspection→final judgment→delivery;

[0023] The billet is pretreated, and the billet is inspected by magnetic particle flaw detection. The defects where the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com