Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

A non-Newtonian fluid and ultra-precision technology, which is applied in the direction of surface polishing machine tools, polishing compositions containing abrasives, grinding/polishing equipment, etc., can solve the problem of high-efficiency and high-quality processing requirements for various curved surfaces, and processing equipment Complicated problems such as high cost and poor processing consistency achieve the effect of wide application range of processing, high-efficiency high-quality polishing, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, scheme of the present invention is further described:

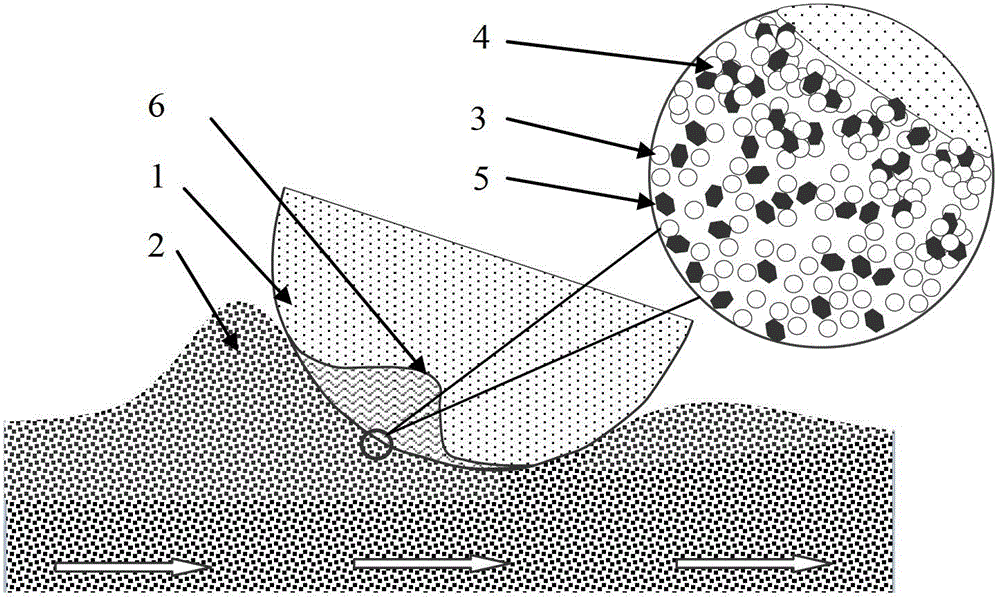

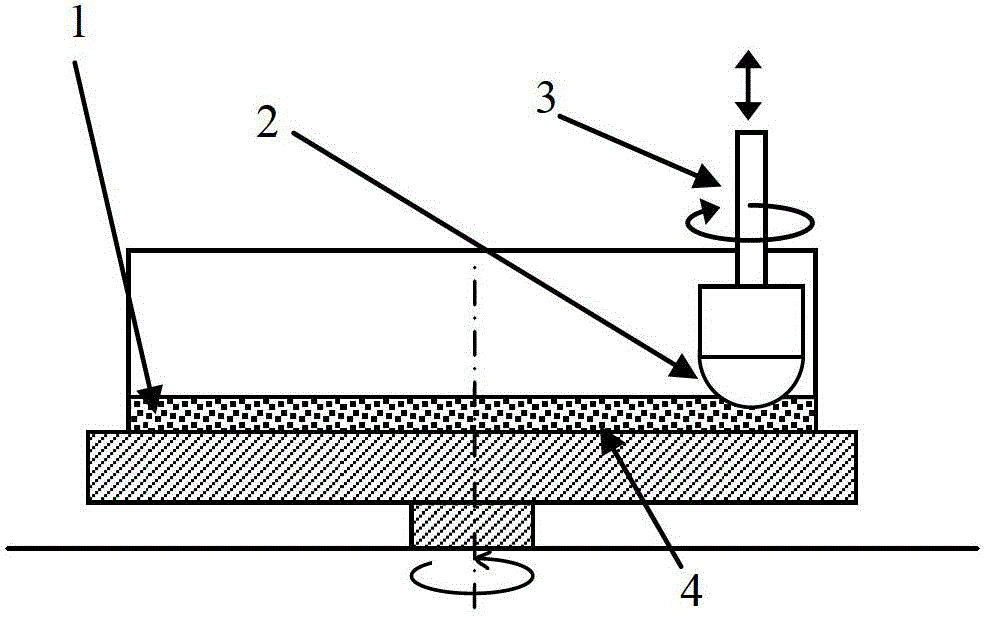

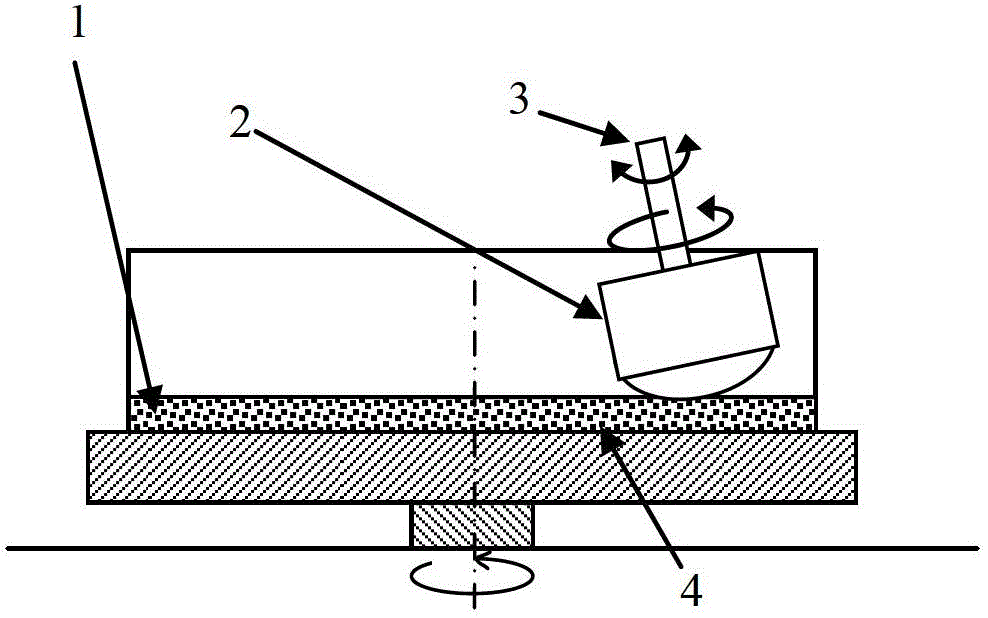

[0027] refer to Figure 1~Figure 3 , an ultra-precision curved surface polishing method based on the shear thickening effect of non-Newtonian fluids. The non-Newtonian fluid is used as the base liquid to prepare the polishing liquid, and the abrasive grains for polishing are dispersed in the non-Newtonian fluid. During the polishing process, due to the relative movement between the workpiece 1 and the polishing liquid 2, the contact part of the polishing liquid 2 and the workpiece 1 is sheared and thickened by shearing, and the dispersed colloidal solid particles 3 in the polishing liquid aggregate into a large number of particle clusters 4 , and wrap the abrasive grains 5 therein. The viscosity of the polishing fluid in the contact area increases sharply, showing solid characteristics instantly, which enhances the holding force on the abrasive grains, and forms a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com