Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Good self-leveling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic composition

ActiveUS20080196629A1Excellent self leveling capabilityShort setting timeCoatingsCellulose adhesivesWater solubleEther

Hydraulic compositions comprising a setting accelerator, a water-soluble cellulose ether having a degree of alkyl substitution of 1.6 to 2.5 which is a water-soluble alkyl cellulose or a water-soluble hydroxyalkyl alkyl cellulose, and water are useful as self-leveling compositions having an excellent self-leveling capability, a minimal change with time of fluidity, and a short setting time, or as cement mortar compositions having a long open time and a short setting time.

Owner:SHIN ETSU CHEM IND CO LTD

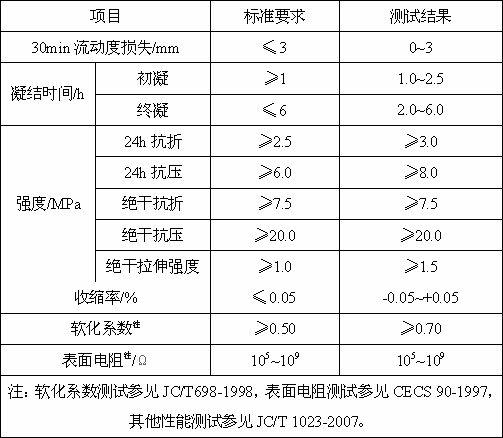

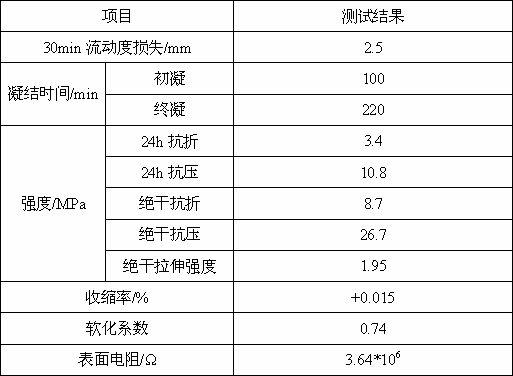

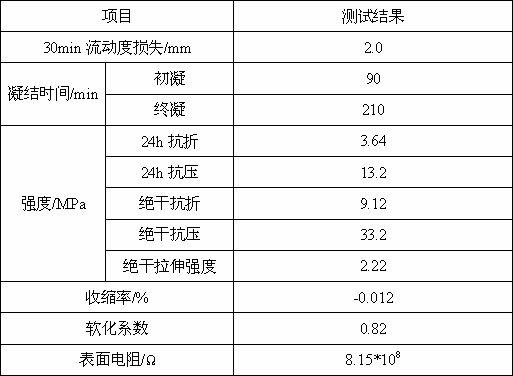

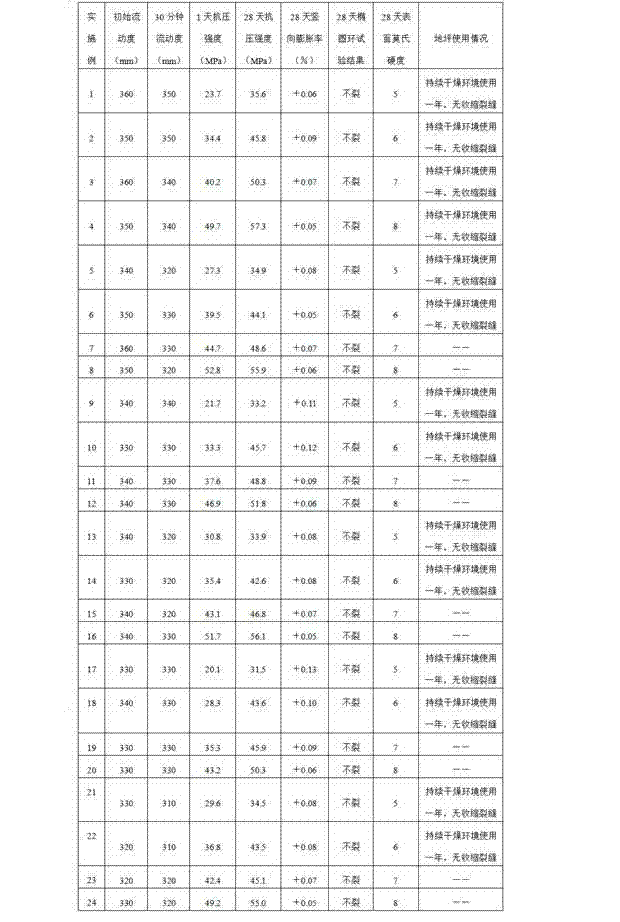

Desulfurized gypsum based antistatic self-leveling mortar and its preparation method

The invention relates to desulfurized gypsum based antistatic self-leveling mortar and its preparation method. Adopting calcined desulfurized gypsum as the main raw material, the desulfurized gypsum based antistatic self-leveling mortar comprises the following components by weight: 25-45 of desulfurized gypsum, 5-10 of slag powder, 3-10 of fly ash, 5-12 of portland cement, 15-25 of quartz sand, 15-25 of steel slag sand, 0.03-0.2 of modified carbon fiber, 0.5-2.0 of redispersible emulsion powder, 0.02-0.07 of cellulose ether, 0.10-0.25 of a water reducer, 0.1-0.4 of an antifoaming agent, 1.2-2.5 of an early strength agent, 0.02-0.06 of a retarder, and 0.002-0.005 of a carbon nanotube. The desulfurized gypsum based antistatic self-leveling mortar has good antistatic performance, bonding property, wear resistance, as well as high compressive strength, and overcomes the defect of poor water proofness of gypsum based materials. By utilizing a lot of industrial solid waste, the self-leveling mortar of the invention has the advantages of environmental protection, energy saving, and low cost, etc., and can be applied in various building ground projects with requirements for electrostatic protection and levelability.

Owner:TONGJI UNIV

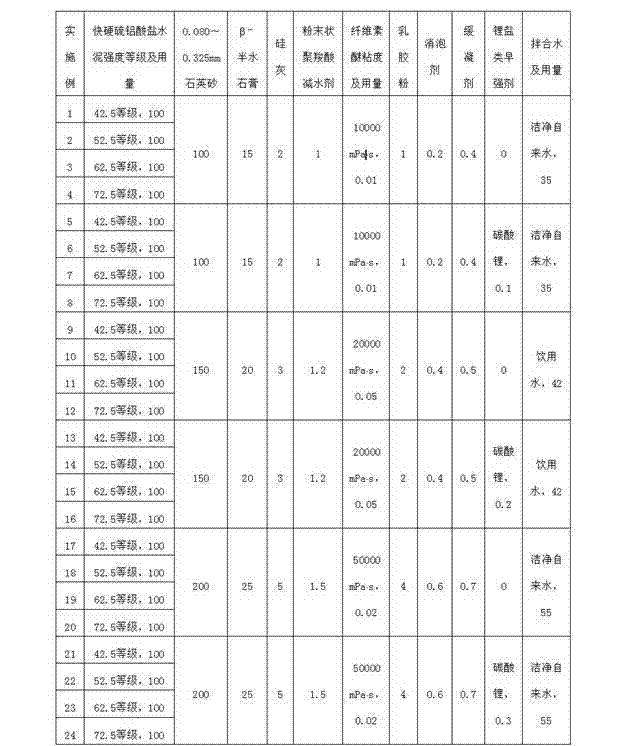

Cement-based self-leveling mortar

ActiveCN102826814AAchieve condensation hardeningAchieve self-leveling performanceCrack resistanceHigh surface

The invention relates to the field of building material, and in particular relates to cement-based self-leveling mortar, which takes sulphoaluminate cement as basic cementing material and quartz sand as aggregate, uses b-semi-hydrated gypsum to control the mortar not to contract and utilizes other additives to enable the prepared mortar to have the comprehensive performances required by the cement-based self-leveling mortar. The newly stirred mortar has the performances of high fluidity, self-leveling property, bleeding resistance and separation resistance; and the hardened mortar has the performances of shrink resistance, crack resistance, high surface hardness and good wear resistance. Compared with the existing self-leveling flooring mortar product with shrink resistance and crack resistance, the cement-based self-leveling mortar is low in production cost and wide in application scope.

Owner:湖南交泰建材有限公司

Ceramic slurry for photo-curing 3D printing

ActiveCN108083817AHigh solid contentLow viscosityAdditive manufacturing apparatusSlurryPhotoinitiator

The invention provides ceramic slurry for photo-curing 3D printing. The slurry is prepared from the following components: ceramic powder, a dispersant, an acrylate monomer combination, an organic aidand a photoinitiator, wherein the acrylate monomer combination comprises at least two acrylate monomers, and the weight ratio of the acrylate monomer combination to the ceramic powder is 0.14-0.175; the weight of the dispersing agent is 0.05%-5% of the weight of the ceramic powder; the weight ratio of the organic aid to the acrylate monomer combination is 0.1-0.5; the weight ratio of the photoinitiator to the acrylate monomer is 0.002-0.01. The ceramic slurry has the advantages of high solid content, extremely low viscosity, excellent sedimentation resistance and the like.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Modified cement-based self-leveling mortar and preparation method and application thereof

The invention relates to improved cement-based self-leveling mortar and a preparation method and application thereof. The improved cement-based self-leveling mortar comprises the following components in percentage by weight: 50%-70% of aggregate, 31%-40% of cement, 13%-15% of anhydrite, 5%-15% of ground calcium carbonate, 0.05%-0.3% of water-retaining agent, 0.05%-0.2% of carbonate, 0.4%-0.9% of retarder, 0.3%-0.9% of lignocellulose, 0.2%-0.3% of antifoaming agent, 0.6%-0.9% of water reducer and 1.5%-4.5% of pure acrylic emulsion powder. The invention has the advantages of simple preparation and application methods, good construction peaceability, good waterproofness, greatly reduced microcracks, high mechanical physics property, good self-leveling performance and impact resistance, and excellent flexibility; no cracking and shrinkage occur to constructed ground; and in addition, the invention can effectively solve the problems of complex site operation process, unstable mortar performance, environmental pollution and the like of the existing dual-component cement-based self-leveling mortar, thus the self-leveling mortar is a green building material because no toxic and harmful matter is contained.

Owner:北京天维宝辰化学产品有限公司

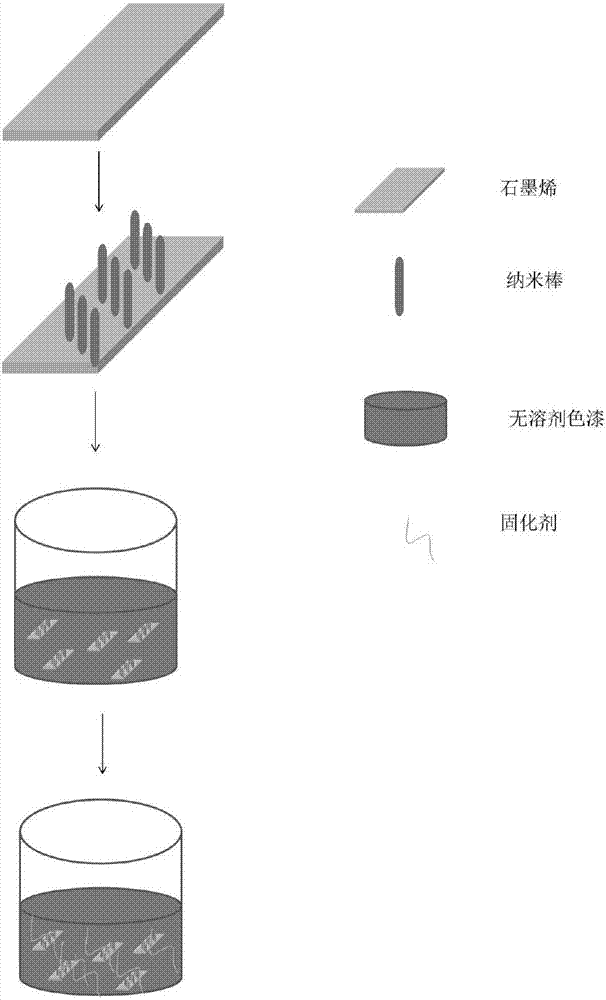

Humid rusted solvent-free graphene modified epoxy paint and preparation method thereof

ActiveCN106867363AGood self levelingUniform colorAnti-corrosive paintsEpoxy resin coatingsAdhesion forceSolvent free

The invention relates to humid rusted solvent-free graphene modified epoxy paint and a preparation method thereof. The paint is prepared from a material A and a material B, wherein the material A is colored paint; the material B is a curing agent; graphene-oxide nano-rods are added into the colored paint; in the aspect of selecting epoxy resin, two types of epoxy resin including solvent-free epoxy resin E-51 and organic zinc-enriched epoxy resin, which have complementary properties, are selected, so that the adhesion force and antirust effect of the paint and a substrate are enhanced; in the aspect of selecting the curing agent, two curing agents are adopted; a polyamide curing agent is added on the basis of a cashew nut shell oil modified phenolic aldehyde amine curing agent which is researched latest, so that the humid rusted solvent-free graphene modified epoxy paint is prepared.

Owner:邹亚静

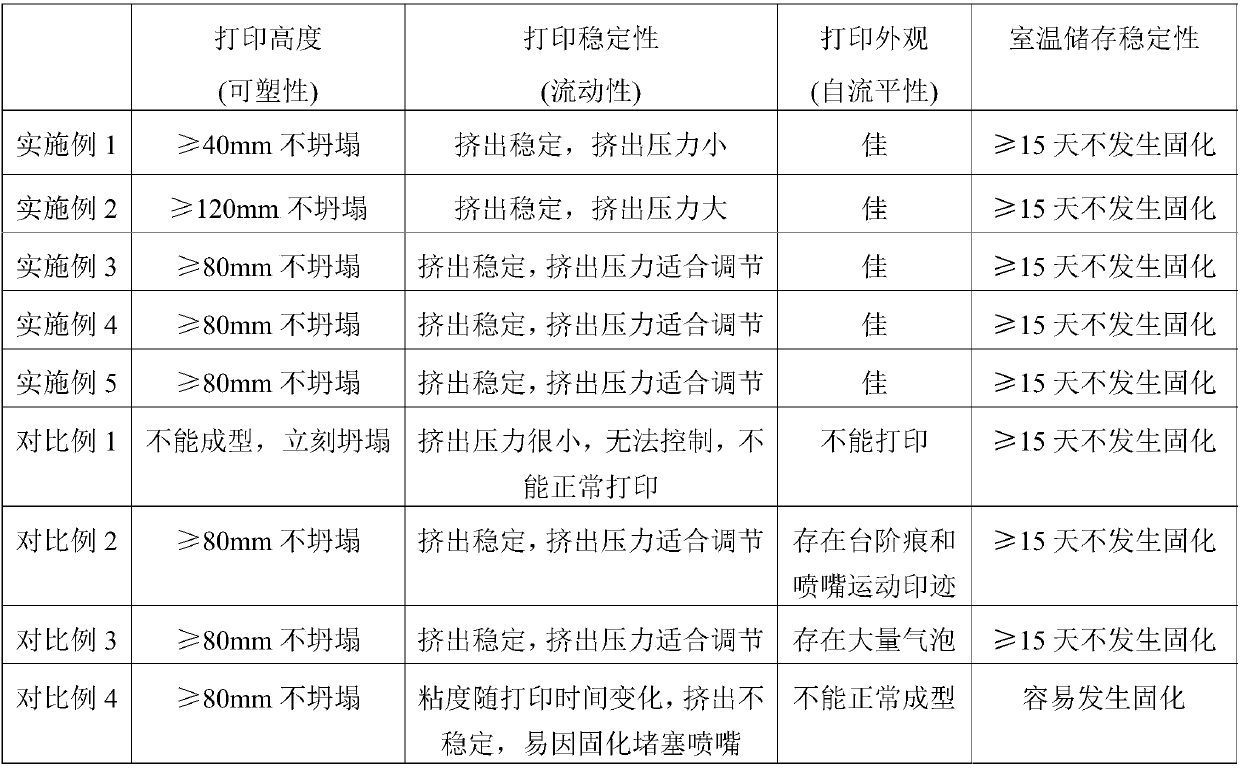

3D printing silica gel and printing method thereof

InactiveCN107674429ASolve problems that are difficult to 3D printIncrease elasticityAdditive manufacturing apparatusManufacturing material handlingHydrogenSpray nozzle

The invention discloses 3D printing silica gel and a printing method thereof. The 3D printing silica gel is prepared from, by weight, 100 parts of vinyl silicone oil, 2-100 parts of hydrogen-containing silicone oil, 1-50 parts of filler, 0.0001-0.1 part of catalyst, 0.00001-0.1 part of inhibitor and 0-1 part of toner. The plasticity, liquidity, self-levelling property, storage stability and curingcontrollability of the 3D printing silica gel are strictly controlled, and a silica gel product good in printing stability, controllable in fineness, good in elasticity after thermo-curing and high in strength is obtained. In addition, it is ensured that the viscosity of the silica gel does not change in the printing process, the spray nozzle blockage problem is not caused, and improvement of theprinting precision is also facilitated. The good self-levelling property is endowed for the 3D printing silica gel, step marks and prints left after spray nozzle movements are eliminated, and productappearance is improved. Photosensitive components and other components are not introduced, and the silica gel is friendly to the environment and can be applied to the fields, having higher requirements, such as foods and medical treatment after 3D printing.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Hydraulic composition

Hydraulic compositions comprising a setting accelerator, a water-soluble cellulose ether having a degree of alkyl substitution of 1.6 to 2.5 which is a water-soluble alkyl cellulose or a water-soluble hydroxyalkyl alkyl cellulose, and water are useful as self-leveling compositions having an excellent self-leveling capability, a minimal change with time of fluidity, and a short setting time, or as cement mortar compositions having a long open time and a short setting time.

Owner:SHIN ETSU CHEM IND CO LTD

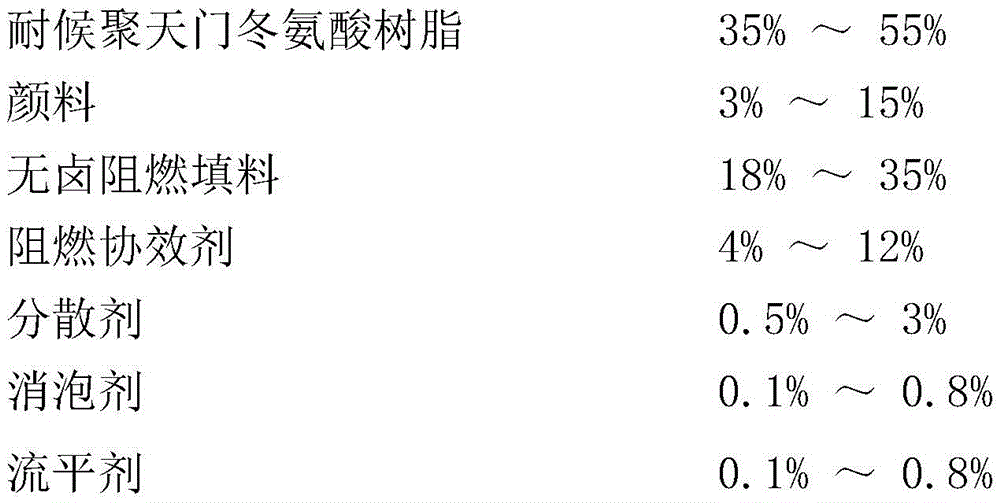

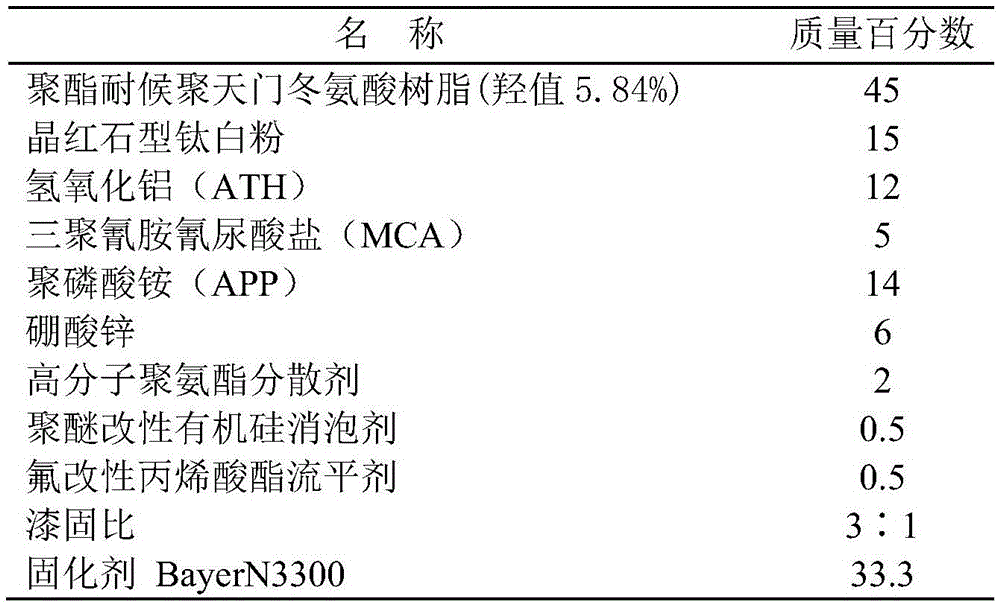

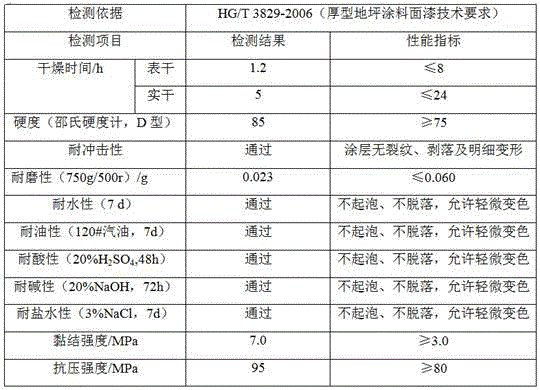

Weather-proof halogen-free flame retardant insulation polyurea coating

InactiveCN105602424AEfficient flame retardantDoes not produce irritating hydrogen halide toxic substancesFireproof paintsPolyurea/polyurethane coatingsSolvent freeSolvent

The invention relates to a double-component weather-proof halogen-free flame retardant insulation polyurea coating. A halogen-free flame retardant compounded form weather-proof polyaspartic acid resin is adopted as a component A, and a solvent-free polyisocyanate curing agent is adopted as a component B, wherein a ratio of the component A to the component B is (2.5 to 4): 1. The weather-proof halogen-free flame retardant insulation polyurea coating is green and environment-friendly, free of discharge of solvent, high in insulation strength, good in flexibility and resistant to wear and impact, and has the breakthrough voltage being larger than 15kV / mm; the flame retardant is environment-friendly and halogen-free, and has the inflammable level of S2 upon flame retardance according to a DIN5510 standard; meanwhile, the weather-proof halogen-free flame retardant insulation polyurea coating is simple in construction and good in self leveling property, has a smooth surface and wide practical applicability, and is especially suitable for flame retardance and insulation in an pantograph mounting region of an urban rail vehicle.

Owner:广东四方威凯新材料有限公司

Low-cost self-leveling mortar

The invention discloses a low-cost self-leveling mortar. The low-cost self-leveling mortar comprises the following components in proportions: 22-35% of quartz sand, 20-40% of modified fluorine gypsum, 18-25% of silicate cement, 4-18% of aluminate cement, 3-8% of zeolite powder, 4-8% of wollastonite powder, 8-18% of rapid hardening cement, 0.05-1.5% of de-foaming agent, 0.05-1% of water reducing agent, 0.05-0.3% of retarder, 0.01-2% of leveling agent, 0.1-2% of lignocelluloses, 0.1-2% of hydroxyethylcellulose, 0.1-2% of methylcellulose, 1-6% of casein and 0.02-0.06% of lithium carbonate. The low-cost self-leveling mortar has the advantages of high leveling property, wear resistance, stability, breaking strength and the like, good quality, high efficiency, low cost and helpfulness for energy saving, consumption reduction and environment improvement.

Owner:徐敏

Anti-static epoxy self-leveling coating material

InactiveCN104673051AImprove anti-static effectImprove anti-static performanceEpoxy resin coatingsElectrically-conductive paintsSlurryReactive diluent

The invention relates to an anti-static epoxy self-leveling coating material which comprises the following components in percentage by weight: 30-50 percent of bisphenol A epoxy resin, 1-5 percent of a reactive diluent, 5-20 percent of a conductive filler, 0.1-0.2 percent of a dispersing agent, 1-3 percent of a leveling agent, 0.1-0.5 percent of a defoaming agent, 5-10 percent of a curing agent and 20-50 percent of water. A preparation method of the anti-static epoxy self-leveling coating material comprises the following steps: (1) adding the reactive diluent into the bisphenol A epoxy resin, and stirring for 20min at a constant speed; (2) adding the conductive filler, the dispersing agent, the leveling agent and the defoaming agent into a mixture prepared in step (1), dispersing for 30min at a high speed, and grinding to obtain slurry; (3) mixing the curing agent and water, and stirring for 20 min at a constant speed to form a water solution; and (4) adding the slurry prepared by grinding into the curing agent water solution prepared in step (3), and mixing uniformly.

Owner:TIANJIN YUJIN COATING ENG

Antiskid polyurethane paint and its prepn

InactiveCN1453319ASolve self-leveling problemsShorten drying timePolyurea/polyurethane coatingsSolventTolylene Diisocyanate

The antiskid polyurethane paint is prepared with tolylene diisocyanate, polyether N210, trihydroxymethyl propane, butyl acetate, acetone, dibutyltin dilaurate, benzoyl chloride, antioxidant, 1,2-propylene glycol and water absorbent, and through dewatering butyl acetate, acetone and polyether N210 in reactor at 90-100 deg.c; adding trihydroxymethyl propane into the reactor before heating and stirring to dewater; adding benzoyl chloride, antioxidant and tolylene diisocyanate, heating and adding dibutyltin dilauratel; reflux evaporating solvent butyl acetate or acetone; packing the prepolymer into paint tank; and mixing prepolymer, xylene or butyl acetate or acetone, 1,2-propylene glycol and water absorbent in certain proportion to obtain the paint. The paint has simple preparation process,strong adhesive force, high wear resistance, high weather resistance and other advantages.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Super early strong cement base underwater non-dispersible repairing material and preparation method

The invention provides a super early strong cement base underwater non-dispersible repairing material. The material is prepared from the following components in percentage by weight: 25.0%-35.0% of portland cement, 50.0%-60.0% of sulphoaluminate cement, 3.0%-6.0% of lithium slag powder, 1.0%-3.0% of ganister sand, 3.0%-6.0% of hollow microbeads, 0.20%-0.50% of a compound flocculant, 0.5%-1.5% of an early strong agent, 0.20%-0.50% of a retarding agent, 4.0%-8.0% of a volume stabilizing agent, 0.30%-0.80% of a polycarboxylate based superplasticizer and 0.01%-0.03% of a deformer. The super earlystrong cement base underwater non-dispersible repairing material provided by the invention has the characteristics of rapid hardening, early strong performance, high underwater anti-dispersing performance, good bonding, super large flowability, stable volume, simple construction methods, and no toxicity, and is especially suitable for urgent underwater projects such as damp and poor-quality sections, large flow areas and areas waiting to be urgent operation.

Owner:安徽瑞和新材料有限公司 +1

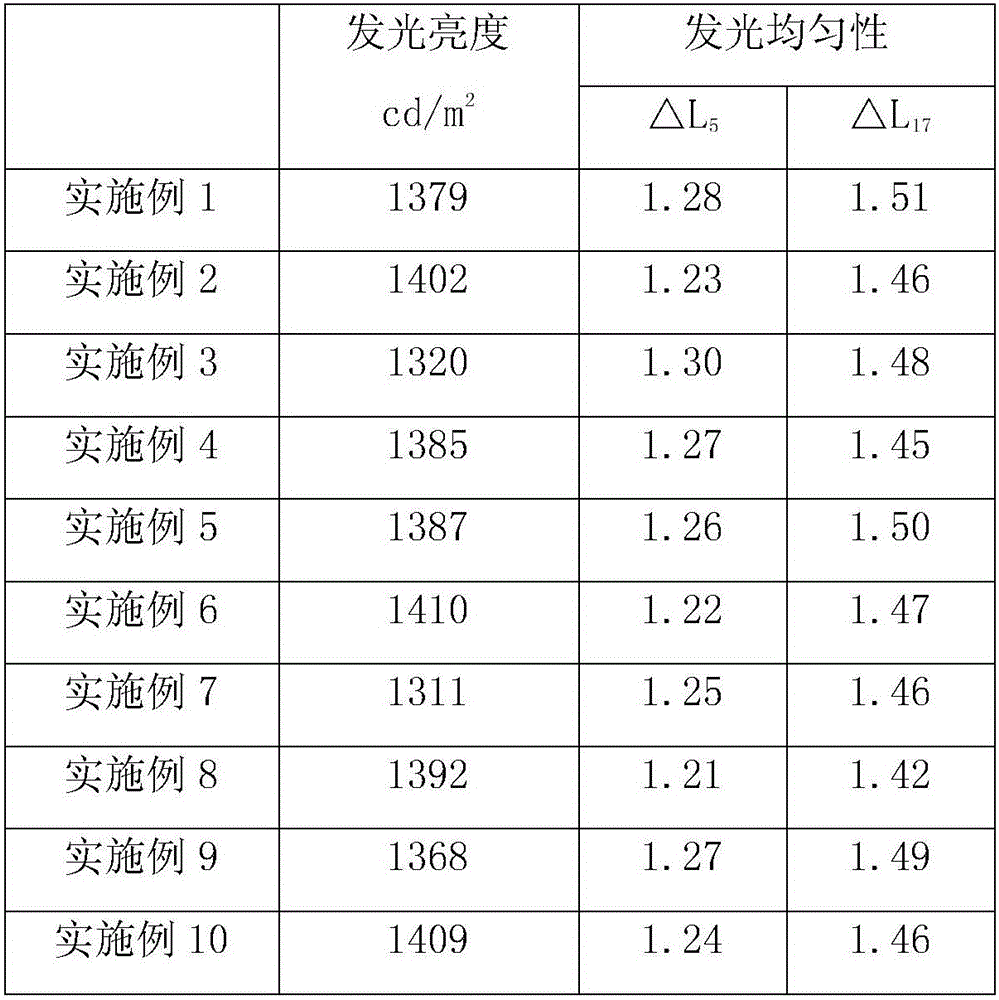

Dual-curing light guide glue for display screen backlight modules and preparation method of dual-curing light guide glue

InactiveCN106497498AHigh peel strengthImprove dispersion uniformityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyMethacrylate

The invention discloses dual-curing light guide glue for display screen backlight modules. The dual-curing light guide glue comprises a component A and a component B, wherein the component A is prepared from a light-curing monomer, polybutadiene dimethacrylate, aliphatic polyurethane acrylate, epoxy resin, a activated diluent, a crosslinker, a leveling agent, a dispersant, a coupling agent and light guide powder by means of mixing and reacting; the component B is prepared from a light initiator, epoxy resin-modified aliphatic amine, a defoaming agent, light guide powder and a rheological agent by means of reaction. The invention further relates to a preparation method of the dual-curing light guide glue for the display screen backlight modules. The preparation method has the advantages of short process flow and low cost. The dual-curing light guide glue prepared by the method has the advantages of excellent peel strength, storage stability, impact resistance, high luminance and uniformity and the like.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

Macromolecular multifunctional binder

The invention discloses a macromolecular multifunctional binder, which is prepared by mixing a binding component A and a curing agent B; wherein the binding component A is prepared by mixing and evenly stirring resin, organic silicon, a thickener, glycerin, flyash A1 grade, and talc powder through excitation technology; the binding component A is added with the curing agent B, the mixture is fullystirred evenly, and then the binder can be used; and in the binding process, the horizon adopts self-levelling matching technology. The macromolecular multifunctional binder has convenient use, goodperformance, high strength, high construction speed, no toxicity or harm to human bodies, low manufacturing cost and long service life, can increase a utilization area when binding interior walls, andonly has the thickness of 1mm to meet and surpass a specified standard requirement. Compared with cement mortar, the macromolecular multifunctional binder used increases a space, namely increases theutilization area. The macromolecular multifunctional binder has environmental protection, high quality and low cost, and the self-levelling matching technology is adopted to open up a new way for horizontal decoration.

Owner:安徽邦宁节能建材有限公司 +1

Modified methyl cellulose flocculant for underwater grouting and its manufacturing method

The present invention relates to one kind of modified methyl cellulose flocculant for underwater grouting mortar, cement slurry and concrete. The modified methyl cellulose flocculant is methyl cellulose-acrylamide copolymer prepared through polymerizing methyl cellulose and acrylamide while introducing nitrogen and adding potassium persulfate, ferrous chloride or ammonium persulfate. The modified methyl cellulose flocculant may have amido sulfate-formaldehyde condensate, polycarboxyl acid sulfidizer and melamine-formaldehyde condensate added. The modified methyl cellulose flocculant makes the underwater grouted mixture possess excellent antidispersivity and result in less water pollution and less strength loss.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Two-component high-thermal-conductivity self-leveling pouring sealant as well as preparation method and application thereof

ActiveCN112812740AImprove thermal conductivityLow thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPtru catalystProcess engineering

The invention discloses a two-component high-thermal-conductivity self-leveling pouring sealant as well as a preparation method and application thereof. The pouring sealant comprises a component A and a component B; the component A is prepared from the following components in parts by weight: 6 to 7 parts of vinyl-terminated silicone oil, 0.1 to 0.3 part of surface treating agent, 90 to 95 parts of heat-conducting filler, 0.05 to 0.15 part of pigment and 0.1 to 0.3 part of platinum catalyst; and the component B is prepared from 3 to 4 parts of vinyl-terminated silicone oil, 0.1 to 0.3 part of surface treating agent, 90 to 95 parts of heat-conducting filler, 2 to 3 parts of terminal hydrogen silicone oil, 0.5 to 1 part of side hydrogen silicone oil and 0.05 to 0.15 part of inhibitor. The heat conductivity coefficient of the pouring sealant reaches up to 4 W / m.K, and the pouring sealant is low in viscosity, good in self-leveling property, excellent in flame retardant property and good in electrical insulation property, shows very good comprehensive performance and is very suitable for being used for pouring electronic modules with efficient heat dissipation requirements; and the raw materials are easily available, and the preparation method is simple and easy to implement and facilitates industrialization.

Owner:广东皓明有机硅材料有限公司

Solvent-free epoxy polyurethane resin floor coating

InactiveCN106366883AGood self-levelingImprove wear resistanceAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The invention belongs to the field of preparation of epoxy coatings and particularly relates to a solvent-free epoxy polyurethane resin floor coating. The coating is prepared from a component A and a component B. The component A comprises, by weight, 40-60 parts of dicyclohexylmethylmethane-4, 20-30 parts of glycerin, 1-5 parts of fumaric acid diethyl ester diisocyanate, 1-10 parts of p-tert-butyl phenyl glycidyl ether and 0.8-1.5 parts of p-toluenesulfonyl isocyanate. The component B is prepared from, by weight, 10-15 parts of epoxy resin, 0.5-1.0 part of stannous octoate, 0.1-0.8 part of cellulose acetate butyrate and 40-45 parts of quartz sand. The mass ratio of the component A to the component B is 4:1. The coating has the advantages that the coating is good in self-leveling performance, environmentally friendly, good in abrasion resistance, resistant to heavy load, excellent in chemical resistance, high in adhesive force, resistant to mould, easy and convenient to construct, easy to maintain and good in impact resistance, and elasticity can be adjusted according to site application.

Owner:FUZHOU ROYAL FLOOR

Self-leveling dry powder mortar and preparation method thereof, terrace manufactured from dry powder mortar, and construction method of terrace

The invention discloses self-leveling dry powder mortar and a preparation method thereof, a terrace manufactured from the dry powder mortar, and a construction method of the terrace. The dry powder mortar is prepared from common portland cement, 4-8-mesh mineral substance aggregates, 10-30-mesh quartz sand, 60-140-mesh quartz sand, methycellulose, dispersible emulsion powder, a high-efficiency water reducing agent, an antifoaming agent, rutile type titanium dioxide and high-strength high-mold polyvinylalcohol fibers. The preparation method comprises the following steps of after the three kinds of the mineral substance aggregates are blended, adding the common portland cement, the methycellulose, the dispersible emulsion powder, the high-efficiency water reducing agent, the antifoaming agent, the rutile type titanium dioxide and the high-strength high-mold polyvinylalcohol fibers, and performing blending. The self-leveling dry powder mortar and the preparation method thereof disclosed by the invention have the advantages that the dry powder mortar is high in surface compressive strength, high in density, high in tenacity and high in crack resistance; besides, the self-leveling dry powder mortar is full and bright in color, and has definite decoration properties; and in addition, the preparation technology is simple, complicated synthesis equipment is not needed, the production cost is reduced, and the self-leveling dry powder mortar is environmentally-friendly and pollution-free.

Owner:南京徽腾环保科技有限公司

Loadable solvent-free epoxy resin floor coating

ActiveCN106336773AGood self-levelingHigh hardnessAnti-corrosive paintsEpoxy resin coatingsPolyamideSolvent free

The invention belongs to the field of epoxy coating, and particularly relates to a loadable solvent-free epoxy resin floor coating. The coating is prepared from a component A and a component B; the component A is prepared from, by weight, 90-100 parts of bisphenol A epoxy resin, 40-45 parts of quartz sand and 10-15 parts of tea stem powder; the component B is prepared from, by weight, 10-15 parts of modified polyamide and 0.2-2.0 parts of trimethyl hexamethylene diamine; the mass ratio of the component A to the component B is 5:1. The coating is environmentally friendly, high in hardness, good in wear resistance, applicable heavy-load places, good in chemical resistance, high in adhesive force, excellent in durability and corrosion resistance, resistant to scratches, short in drying time and easy and convenient to construct.

Owner:胜利油田德利实业有限责任公司

Pouring sealant and preparation method thereof, solar inverter and electronic component

PendingCN111139008AImprove water resistanceWaterproofNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceFirming agent

The invention relates to the field of chemical engineering, and particularly discloses a pouring sealant and a preparation method thereof, a solar inverter and an electronic component. The pouring sealant comprises a component A and a component B. The component A comprises the following raw materials: epoxy resin, a diluent, an auxiliary agent, a flame retardant, a heat conduction filler, a hydrophobic filler and a waterproof silane coupling agent. The component B at least comprises an anhydride curing agent and an accelerant. The pouring sealant prepared in an embodiment of the invention hasexcellent performances of water resistance, moisture resistance, heat conduction, flame retardance and the like, and also has high bonding force, high strength and high hardness unique to epoxy glue;the provided preparation method is simple; the water resistance of the pouring sealant is improved by adding the hydrophobic filler and the water-resistant silane coupling agent, and the original heat-conducting and flame-retardant properties of the pouring sealant are not influenced; the problem that conventional epoxy-anhydride system pouring sealants have water resistance defects is solved; andthe application of the epoxy-anhydride system pouring sealant in the solar inverter is realized.

Owner:上海汉司实业有限公司

Special high-performance additive for underwater masonry mortar

The invention discloses a special high-performance additive for underwater masonry mortar. The special high-performance additive is composed of, by weight, 2-5 parts of a thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special cement, 12-15 parts of a set controlling agent and 5-8 parts of an early strength agent. In the special high-performance additive for the underwater masonry mortar, the thickening agent can improve the adhesiveness of a mixed product, and therefore the underwater non-disperse mortar is endowed with the properties of dispersing and separating resistance. The super plasticizer can improve the fluidity and workability of the mixed product, and therefore the material is endowed with good self-leveling and self-compacting properties. The frequently-used super plasticizer mainly includes sulfonated resin or sulfonate, and therefore the material has the properties of underwater dispersing and separating resistance. Through the combined action of the doped special cement and the set controlling agent, the material is endowed with early strength and rapid hardening.

Owner:北京建工新型建材有限责任公司

Freeze-thaw resisting cement and its production process

The present invention discloses one kind of freeze-thaw resisting cement and its production process. The material consists of clinker 90-92 wt%, limestone 4.5-6 wt%, and gypsum 4.2-5.0 wt%, and the clinker has KHú¢0.90+ / -0.02, nú¢1.80+ / -0.10 and pú¢0.90+ / -0.10. It has the mineral composition of: C3Sú“54.0 wt%, C2Sú¥20.0 wt%, C3Aú“6.0 wt%, C4AFú¥14.0 wt%, and f-CaO less than 1.5 wt%. The freeze-thaw resisting cement has specific surface area over 350 sq m / Kg and fineness below 2.5 %, and after 250 times of freeze-thaw, it has 3-day breaking strength over 5.0 Mpa and compression strength over 25.0 Mpa, and 28-day breaking strength over 7.0 Mpa and compression strength over 50.0 Mpa. It has low C3A content, good freeze-thaw resisting performance, fast curing, high wear resistance and high permeation resistance.

Owner:CAOYUAN CEMENT XIZHUOZISHAN NEI MONGOL AUTONOMOUS REGION

Fluorine-containing imine cationic surfactant preparation method and application thereof

InactiveCN102351755ARaw materials are easy to getEasy to prepareOrganic compound preparationTransportation and packagingAcyl groupSulfonyl fluoride

A fluorine-containing imine cationic surfactant preparation method and an application thereof. The preparation method provided by the invention comprises the following steps of: performing an amidation reaction between perfluoroalkyl sulfonyl fluoride and N,N'-dimethyl(ethyl)-1,3-propane diamine to obtain an intermediate 1, refining, performing an amidation reaction between the intermediate and alkyl sulfonic acid fluoride (chlorine) or alkyl acyl fluoride (chlorine) to obtain an intermediate 2, refining, reacting with substances such as iodomethane to obtain the fluorine-containing imine cationic surfactant. The surfactant can be used as an emulsifier, a metal surface conditioning agent, a leveling agent, an extinguishing chemical additive, a foam flotation agent and a crude oil evaporating inhibitor. The invention has the following advantages: the surfactant production cost is low; the preparation method is simple; the requirement on production equipment is low; the production technology is concise; the product is environment friendly; the yield is high and the conversion rate of the fluorine containing monomer reaches 100%; the surface performance is excellent, and the lowest water surface tension of some compounds is below 18mN / m.

Owner:HUAZHONG NORMAL UNIV

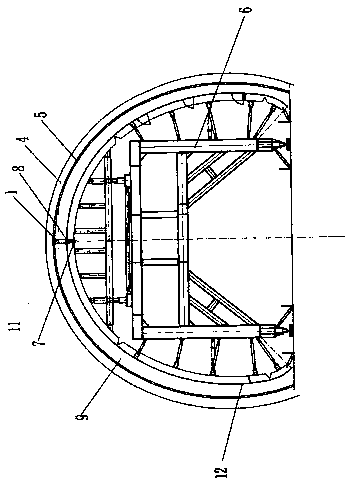

Concrete with-mold backfill grouting system and grouting method for vault of tunnel

PendingCN108316950AGood fluidity and pumpabilityHigh strengthUnderground chambersTunnel liningClerestoryPolytetrafluoroethylene

The invention discloses concrete with-mold backfill grouting system and grouting method for a vault of a tunnel. The problems which exist in an existing backfill grouting way and that a device is manyin investment, the construction period is long and the backfill grouting of a disengagement area is incompact are solved. A vault of a secondary lining trolley (6) is provided with a backfill grouting opening (7); the end of a backfill grouting pipe (1) passages through a ring flange (8) and then is inserted into the backfill grouting opening; a port of the backfill grouting pipe is top-stuck ona primarily lined waterproof layer (5); a polytetrafluoroethylene tape is wound on the outer side of a crisscross grouting groove (3); a polytetrafluoroethylene tape is stuck on a pipe orifice of thebackfill grouting pipe; a pressure sensor (13) is arranged in a pipe orifice of the lower end of the backfill grouting pipe; the pipe orifice of the lower end of the backfill grouting pipe is connected with a connecting sleeve; (16); the lower end of the connecting sleeve is connected with a grout delivery pipe (18) and a grouting pump; backfill grouting grout is arranged in the grouting pump. thedefect of a cavity in a secondarily lined vault is eliminated to the maximum extent.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD

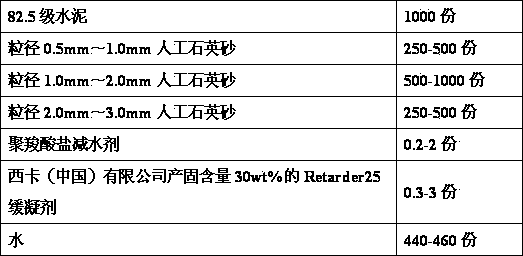

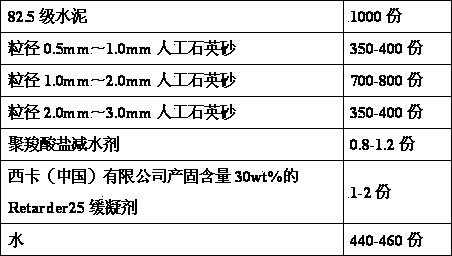

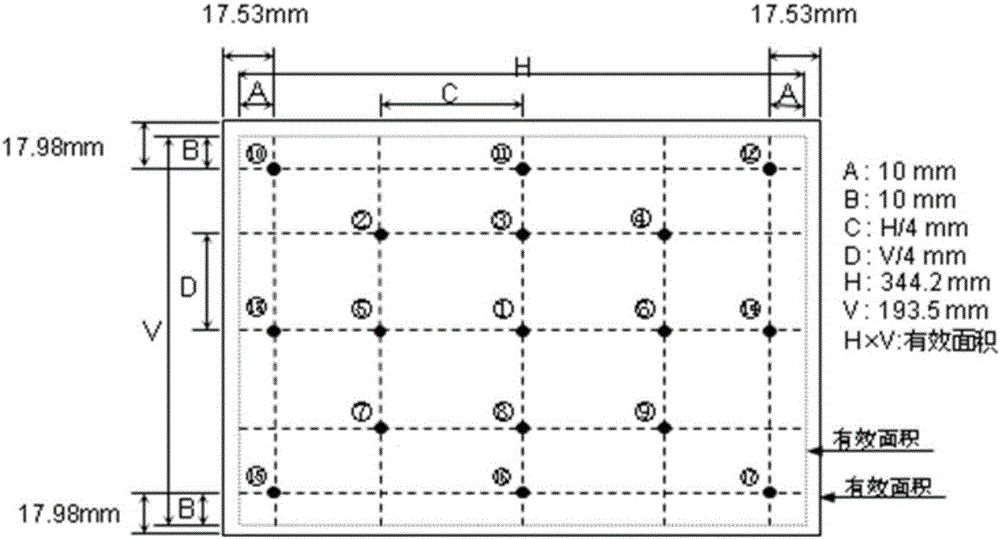

Formula for fixing solid radioactive wastes by using cement mortar

ActiveCN103588433ALow condensation hardening temperature riseGood self-levelingSuperplasticizerEngineering

The invention belongs to the field of radioactive waste processing and provides a formula for fixing solid radioactive wastes by using cement mortar in order to solve the problems that existing formulas for fixing low and intermediate level solid radioactive wastes by using cement mortar has lower fixer compressive strength, the temperature rise in a setting and hardening process is higher, and the like. The formula comprises components of 82.5-grade cement, mixed artificial quartz sand with different granularity, a polycarboxylate superplasticizer, a retarder 25 which is produced by the Sika limited company in China and water. A fixer prepared with the formula for fixing the solid radioactive wastes by using the cement mortar is high in compressive strength and good in anti-permeability; the cement mortar has lower setting and hardening temperature rise and very good self-leveling performance; and according to the formula, the components are simple, the cost is low, and the curing operation is easy to master.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

UV-curing light guide adhesive and preparation method thereof

ActiveCN106634540AGood yellowing resistanceReduce production processPolyurea/polyurethane coatingsMethacrylateAdhesive

The invention discloses UV-curing light guide adhesive and a preparation method thereof; the UV-curing light guide adhesive comprises a photoinitiator, a monomer, polybutadiene dimethacrylate, aliphatic polyurethane acrylate, a rheological agent, a leveling agent, a dispersant, a coupling agent, a defoaming agent, and light guide powder; the preparation method comprises the steps of first, mixing well a photo-curing monomer, polybutadiene dimethacrylate and a coupling agent; second, adding aliphatic polyurethane acrylate, a leveling agent, a dispersant, a defoaming agent and a photo-curing agent, and mixing well; third, adding light guide powder, and mixing well; fourth, adding a rheological agent, and mixing well to obtain a finished product; the prepared UV-curing light guide adhesive has excellent advantages of excellent yellowing resistance, peel strength, impact resistance, high luminance, uniformity and the like; the UV-curing light guide adhesive is applied to the surface of reflecting film by means of printing, roll coating, brush coating, and curtaining and is cured by UV irradiation, the technique omits the procedure of manufacturing a light guide plate, production efficiency is improved, and production cost is lowered.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

Masonry mortar used in underwater alkaline environment

The invention discloses masonry mortar used in an underwater alkaline environment. The masonry mortar comprises the following components, according to a weight ratio, 180-220 parts by weight of Portland cement, 30-50 parts by weight of special cement, 705-715 parts by weight of natural medium sand, 13-18 parts by weight of resin glue powder, and 30-40 parts by weight of a special additive. The special additive is mixed from 2-5 parts by weight of a thickening agent, 0.5-1 part by weight of a super-plasticizer, 5-8 parts by weight of a thixotropic agent, 12-15 parts by weight of an adjusting admixture, and 5-8 parts by weight of an early strength agent. The masonry mortar is adjusted by high-performance additives special for underwater masonry mortar, and resin materials good in alkaline resistance are added, so that the masonry mortar is prevented from undergoing a reaction in the alkaline condition, and hardening and mortar performance aren't affected. At last, the masonry mortar is not prone to disperse, good in construction, resistant to alkaline, normal in underwater hardening, and high in strength in a working condition with water.

Owner:北京建工新型建材有限责任公司

Concrete protecting sol

ActiveCN104556944AImprove the lack of low void compactnessSimple structureWater reducerAlkoxyl radicals

The invention relates to the technical field of concrete protective materials and in particular relates to concrete protecting sol. The concrete protecting sol comprises the following components in parts by mass: 50-60 parts of a cementitious material, 5-10 parts of mineral powder, 2-6 parts of a nano cement additive, 10-20 parts of alkoxyl alkylsilane and a modified compound thereof, 1-8 parts of an air-leading and water-reducing agent, 0.3-1.2 parts of a water-retaining and thickening agent, 0.4-0.8 part of an expansion component, 0.3-1.2 parts of a macromolecular polymer, 0.2-0.8 part of a defoaming agent, 0.2-0.8 part of a wetting-dispersing agent, 0.5-0.8 part of a stabilizing agent, 2-10 parts of a modifying agent and 100-150 parts of deionized water. The concrete protecting sol has the beneficial effects that due to mixed use of the nano cement additive, alkoxyl alkylsilane and the modified compound thereof and the air-leading and water-reducing agent, the defect that gap compacting degree of concrete is low is overcome, and the penetrating agent alkoxyl alkysilane and the modified compound thereof can permeate into the concrete, a concrete structure is improved, and the defects that the concrete is cracked, strength is low and service life is short are fundamentally overcome.

Owner:徐州加贝力建材科技有限公司

Multi-mechanism cured anti-condensation polyurethane sealing part and preparation method thereof

The invention discloses a multi-mechanism cured anti-condensation polyurethane sealing part and a preparation method thereof. The multi-mechanism cured anti-condensation polyurethane sealing part is prepared from isocyanate, polyhydric alcohol, vinyl monomer, radical initiators and foaming agents. The preparation method of the multi-mechanism cured anti-condensation polyurethane sealing part includes the steps: mixing the polyhydric alcohol, the vinyl monomer, the radical initiators and the foaming agents into a component A; taking the isocyanate as a component B; slowly adding the component Binto the component A and uniformly mixing the component B and the component A to form polyurethane sealing part prepolymer; casting the prepolymer into a finished product and curing the finished product at room temperature to obtain the sealing part. The sealing part has excellent heat insulation, anti-condensation property, water resistance, aging resistance, dimensional stability, plugging property and the like.

Owner:安徽火峰电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com