Oily diamond grinding liquid and preparation method thereof

A technology of abrasive liquid and diamond, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of low polishing efficiency, large waste, easy to stutter and precipitate, etc., and achieve the effect of good polishing quality, high polishing efficiency and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

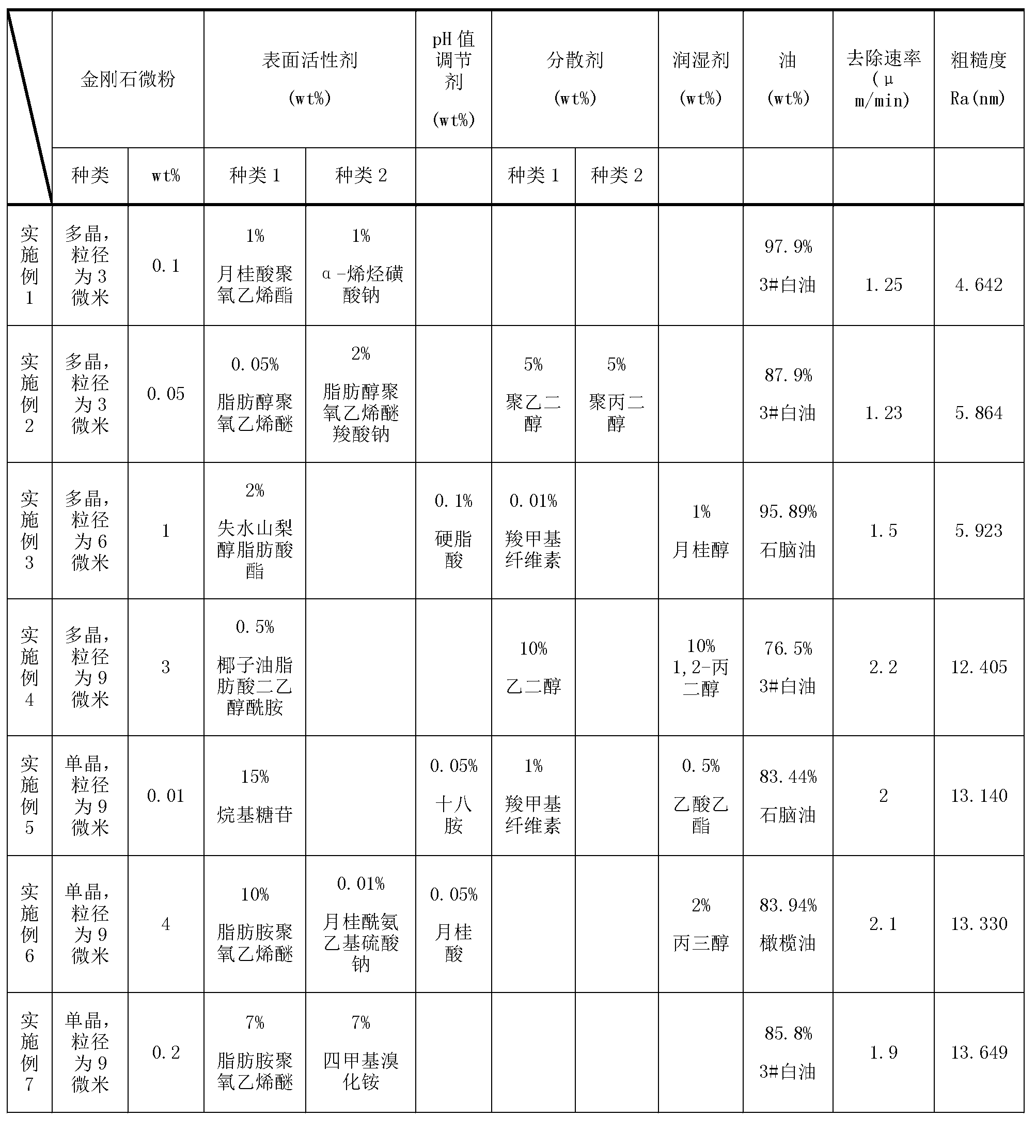

Examples

specific Embodiment 1

[0031] Take specific embodiment 1 as an example:

Embodiment 1

[0032] Embodiment 1: (preparation of 1000 grams of oily diamond grinding fluid)

[0033] Each component of grinding liquid and its weight percent are as follows in the present embodiment:

[0034] 3 micron diamond polycrystalline powder 0.1%

[0035] Surfactant polyoxyethylene laurate 1%

[0036] Surfactant sodium alpha-olefin sulfonate 1%

[0037] The rest is 3# industrial grade white oil, origin: Maoming Petrochemical.

[0038] Get 10 grams of surfactant polyoxyethylene laurate and 10 grams of surfactant sodium α-olefin sulfonate and add them to 979 grams of white oil, and stir thoroughly for 5 minutes.

[0039] Take 1 gram of polycrystalline diamond powder with a particle size of 3 microns and mix it with the above-mentioned oily liquid, stir and sonicate for 15 minutes, fully wet the surface of the diamond powder, and prepare an oily grinding liquid.

[0040] The preparation method of the oily diamond grinding liquid of embodiment 2-6, concrete steps are:

[0041] 1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com