All-organic waterless engine coolant

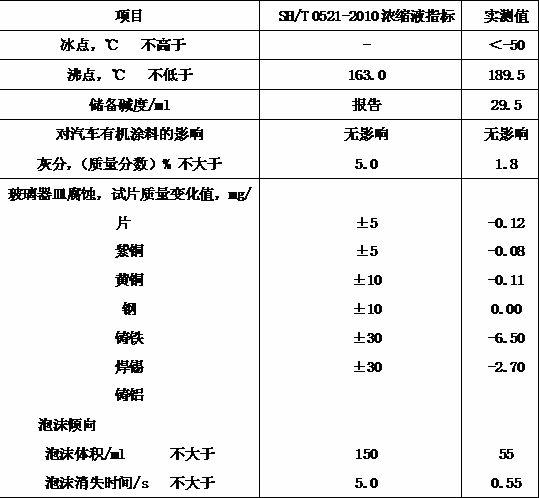

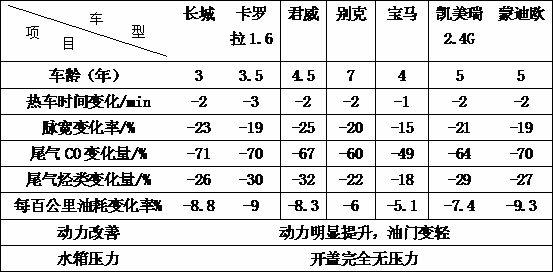

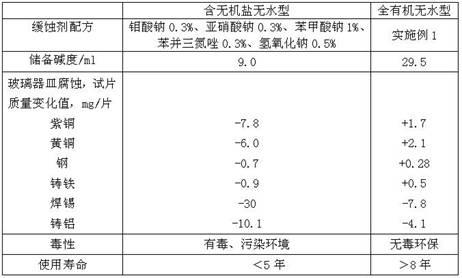

An engine coolant, water-free technology, applied in the field of coolant, can solve the problems of reduced heat transfer capacity, short service life, low reserve alkalinity, etc., to achieve improved engine power, superior anti-corrosion performance, and good market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The all-organic anhydrous engine coolant of the present embodiment comprises following components and percentage by weight:

[0022] Coolant base fluid------propylene glycol: 82.847%;

[0023] All organic corrosion inhibitor --- sebacic acid: 2%, isooctanoic acid: 1.5%, sodium benzoate: 1%;

[0024] Azole corrosion inhibitor------benzotriazole: 0.3%;

[0025] Viscosity specific heat regulator --- diethylene glycol monoethyl ether: 10%;

[0026] Ph value regulator------2-amino-2-methyl-1-propanol: 2.3%;

[0027] Defoamer------polyol block polyether: 0.05%;

[0028] Dyeing agent --- metal complex dye: 0.003%.

[0029] Preparation process: Dissolve sebacic acid, isooctanoic acid, sodium benzoate, benzotriazole, diethylene glycol monoethyl ether, polyol block polyether, metal complex dyes, etc. in propylene glycol at normal temperature and pressure, and stir Evenly, adjust the Ph value to 7.5-9.0 with 2-amino-2-methyl-1-propanol.

[0030] The comparison data between E...

Embodiment 2

[0034] The all-organic anhydrous engine coolant of the present embodiment comprises following components and percentage by weight:

[0035] Coolant base fluid------propylene glycol: 39.6235%, ethylene glycol: 39.6235%;

[0036] All organic corrosion inhibitor --- sebacic acid: 1%, caprylic acid: 1%, benzoic acid: 1%;

[0037] Azole corrosion inhibitor --- methyl benzotriazole: 0.2%;

[0038] Viscosity specific heat regulator --- diethylene glycol monoethyl ether: 15%;

[0039] Ph value regulator------2-amino-2-methyl-1-propanol: 1.8%, triethyl phosphate: 0.7%;

[0040] Defoamer------polyol block polyether: 0.05%;

[0041] Dyeing agent --- metal complex dye: 0.003%.

[0042] Preparation process: Mix ethylene glycol and propylene glycol at normal temperature and pressure, stir evenly, then mix sebacic acid, octanoic acid, benzoic acid, methyl benzotriazole, diethylene glycol monoethyl ether, polyol block polymer Dissolve ethers, metal complex dyes, etc. in the mixture of et...

Embodiment 3

[0045] The all-organic anhydrous engine coolant of the present embodiment comprises following components and percentage by weight:

[0046] Coolant base fluid------propylene glycol: 22.5741%, ethylene glycol: 49.6729%;

[0047] All-organic corrosion inhibitor --- sebacic acid: 1%, adipic acid: 1.5%, terpolymeric acid: 0.5%, sodium benzoate: 1%;

[0048] Azole corrosion inhibitor --- mercaptobenzothiazole: 0.4%;

[0049] Viscosity specific heat regulator --- diethylene glycol monoethyl ether: 20%;

[0050] Ph value regulator------2-amino-2-methyl-1-propanol: 1.5%, diethyl phosphate: 1.8%;

[0051] Defoamer------polyol block polyether: 0.05%;

[0052] Dyeing agent --- metal complex dye: 0.003%.

[0053] Preparation process: Mix ethylene glycol and propylene glycol at normal temperature and pressure, stir evenly, and then mix sebacic acid, adipic acid, ternary polycarboxylic acid, sodium benzoate, mercaptobenzothiazole, diethylene glycol monoethyl ether, Polyol block polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com