Electrode material with intermediate Ti4O7 coating

A titanium oxide and intermediate coating technology, applied in the field of electrode materials, can solve the problems of electrode performance decline and internal resistance increase, and achieve the effects of increasing current density, preventing corrosion and improving bonding state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

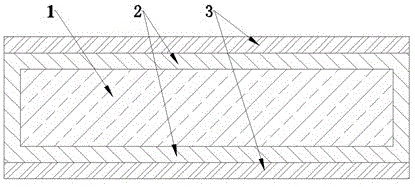

[0023] The electrode material with titanium oxide intermediate coating described in this embodiment is coated with an intermediate layer of titanium oxide (TiO) on the outer surface of the base metal plate 1 (pure titanium plate, thickness: 4 o 7 ) 2 and a surface-active coating 3 prepared (eg figure 1 shown), the thickness of the middle layer of titanium dioxide 2 is 0.5mm, and the surface active coating 3 is a highly active and cheap metal oxide coating of 0.5mm. Its main components and mass percentages are 70% lead dioxide, manganese dioxide 28.5%, and rare earth oxides are 1.5%.

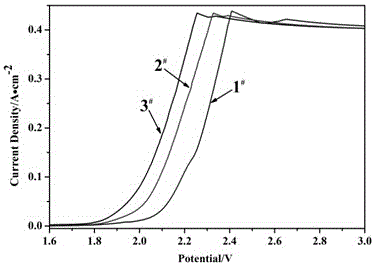

[0024] The polarization curve of the electrode material described in this example is negatively shifted compared with the traditional Ti base, the polarization potential drops by 125mV (when the current density is 0.2A), and the current density increases by 132mA (when the polarization potential is 2.2V), as figure 2 As shown in Figure 1 # - Polarization curves of cheap metal oxide coatings p...

Embodiment 2

[0026] The electrode material having a titanium oxide intermediate coating described in this embodiment is coated with an intermediate layer of titanium oxide (Ti 4 o 7 ) 2 and a surface-active coating 3 prepared (eg figure 1 shown), the thickness of the middle layer of titanium dioxide 2 is 1mm, and the surface active coating 3 is a 0.8mm high-activity cheap metal oxide coating. Its main components and mass percentages are 85% lead dioxide and 10% manganese dioxide %, rare earth oxide is 5%.

[0027] The polarization curve of the electrode material described in this example is negatively shifted compared with the traditional Ti base, the polarization potential drops by 188mV (when the current density is 0.2A), and the current density increases by 230mA (when the polarization potential is 2.2V), as figure 2 As shown in Figure 1 # - Polarization curves of cheap metal oxide coatings prepared by traditional pure titanium-based electroplating, 2 # - Polarization curves of che...

Embodiment 3

[0029]The electrode material with a titanium oxide intermediate coating described in this embodiment is coated with an intermediate layer of titanium oxide (TiO) on the outer surface of the base metal plate 1 (pure titanium plate, thickness: 4 o 7 ) 2 and a surface-active coating 3 prepared (eg figure 1 shown), the thickness of the middle layer of titanium dioxide 2 is 1.5mm, and the surface active coating 3 is a rare metal oxide coating with a thickness of 15 μm prepared by thermal decomposition method, and its main component and mass percentage are ruthenium dioxide 12 %, Tantalum Dioxide 8%, Tin Dioxide 40%, Titanium Dioxide 50%.

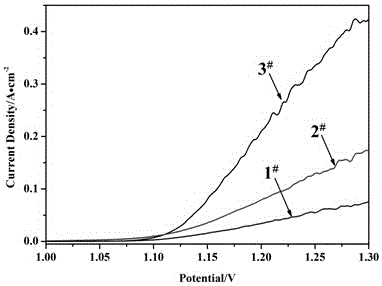

[0030] The polarization curve of the electrode material described in this example is negatively shifted compared with the traditional Ti base, the polarization potential drops by 70mV (when the current density is 0.05A), and the current density increases by 40mA (when the polarization potential is 1.2V), as image 3 As shown in Figure 1 # - Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com