Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Flow-accelerated corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow-accelerated corrosion (FAC), also known as flow-assisted corrosion, is a corrosion mechanism in which a normally protective oxide layer on a metal surface dissolves in a fast flowing water. The underlying metal corrodes to re-create the oxide, and thus the metal loss continues.

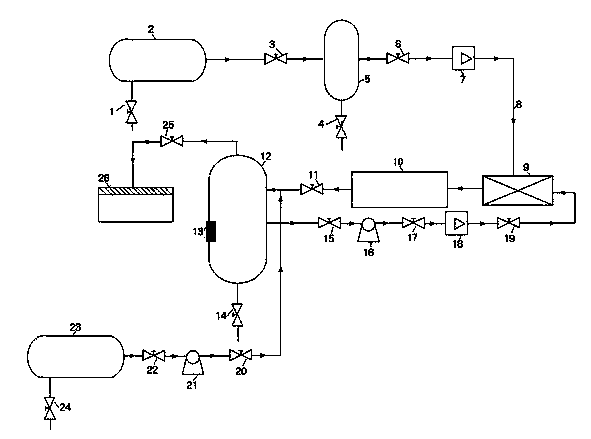

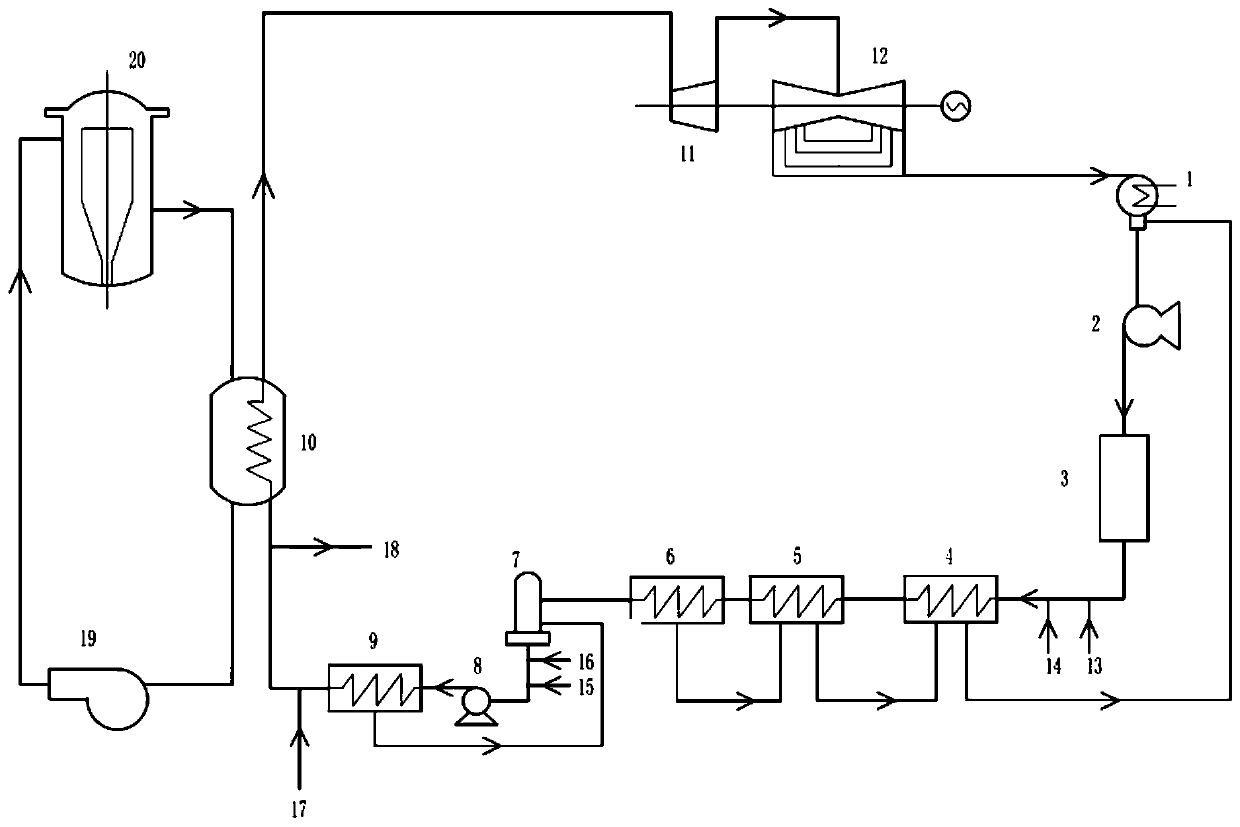

Gas and liquid two-phase flow loop corrosion experiment device

The invention relates to the field of oil and gas field corrosion research, in particular to a gas and liquid two-phase flow loop corrosion experiment device, which is applicable to coupon corrosion experiment and in-situ corrosion electrochemical test of gas and liquid two-phase flow of an oil and gas field production system on an oil pipe under the simulated working condition. An experiment testing module is arranged in a horizontal pipeline, and oil and gas field high-temperature and high-pressure fluid simulated by an experiment device is subjected to loop corrosion experiment by using an electrochemical workstation and a three-electrode electrochemical corrosion measuring device, so that flow accelerated corrosion weight loss and appearance features are obtained; an 'in-situ' electrochemical signal of a working electrode in simulated high-temperature and high-pressure fluid is monitored, so that the corrosion behavior and mechanism of the gas and liquid two-phase flow loop are mastered.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

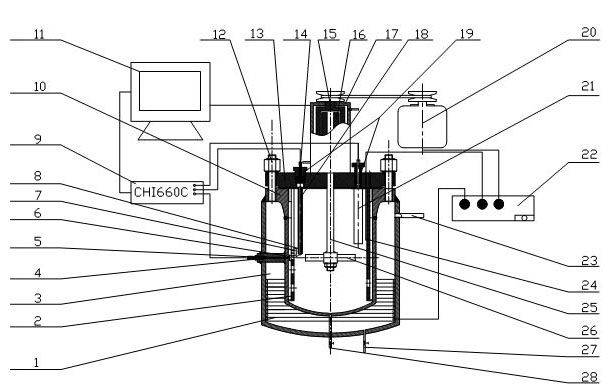

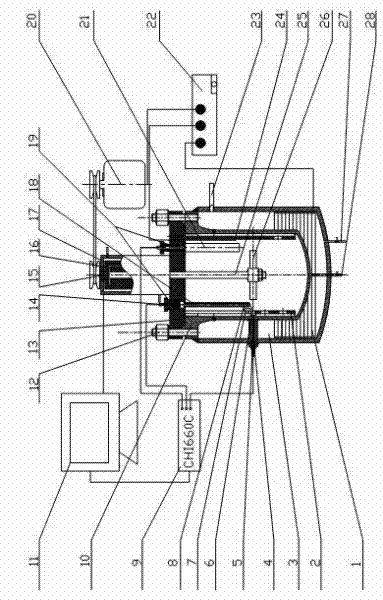

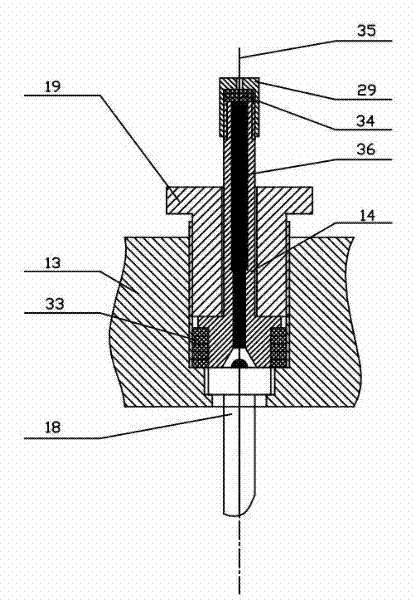

Vapour-liquid two-phase flow accelerated corrosion test device

InactiveCN101900664ASimple structureEasy to operateWeather/light/corrosion resistanceCorrosion reactionGas phase

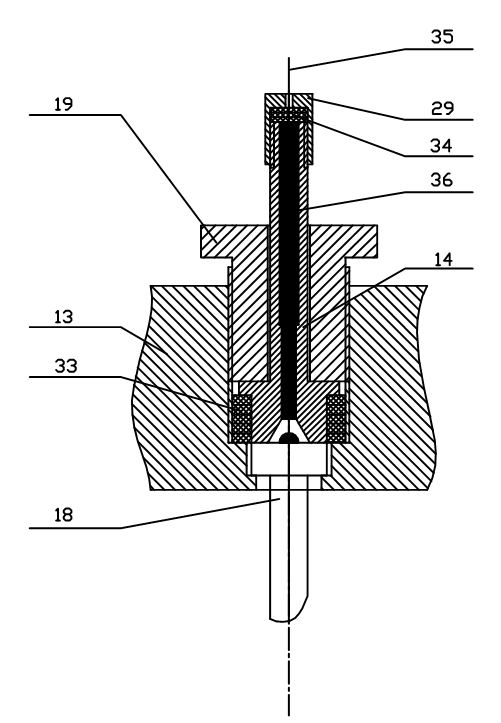

The invention relates to a vapour-liquid two-phase flow accelerated corrosion test device which is characterized by comprising a testing autoclave body, an oil bath heating jacket, an autoclave body cover, a magnetic rotating device, a high-temperature reference electrode, a graphite auxiliary electrode, a working electrode, a variable frequency motor, a potentiostat, a corrosion measurement computer, an equipment control cabinet, an inner lining, a gas-phase generator, an electric heater and a thermocouple sensor. In the invention, an electrochemical measurement method is adopted to carry out experimental study on the relevant properties of vapour-liquid two-phase flow accelerated corrosion, including the measurement of relevant coefficients of the transient corrosion property, the corrosion impedance and the corrosion reaction, the relation between mass transfer and corrosion reaction, the relation between the vapour-liquid two-phase flow pattern and the corrosion rate and production and breakage mechanism of a corrosion product membrane and the critical characteristic of the breakage. The high-speed rotation is realized and meanwhile, and the good sealing property is ensured by adopting the magnetic rotating device.

Owner:NANJING UNIV OF TECH

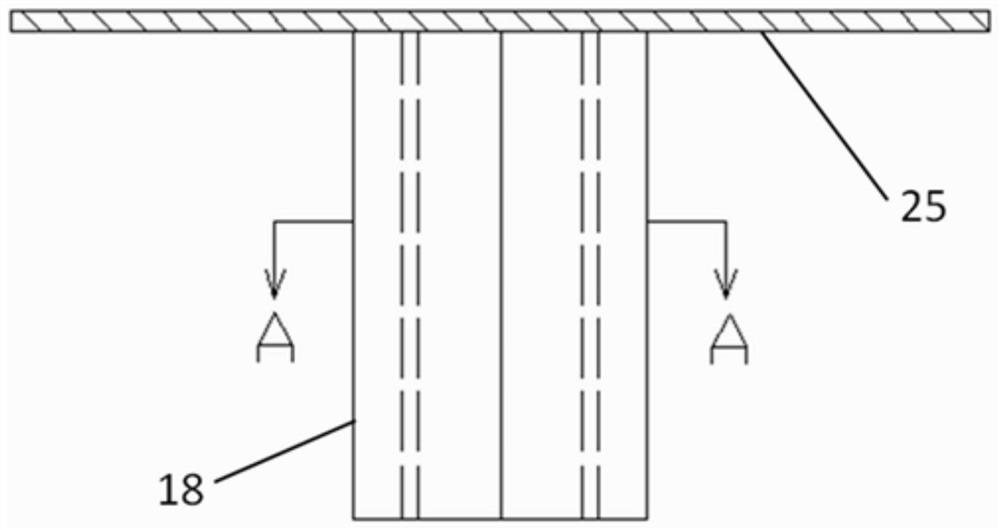

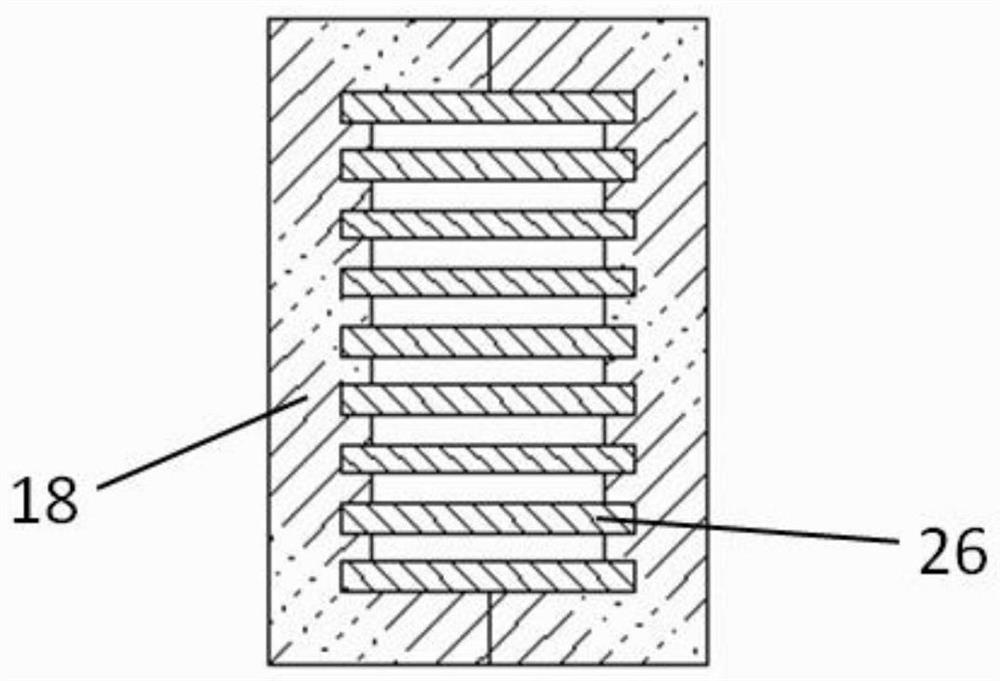

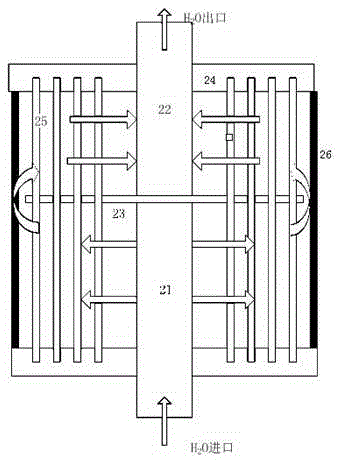

High-temperature and high-pressure water vapor environment structural material testing device

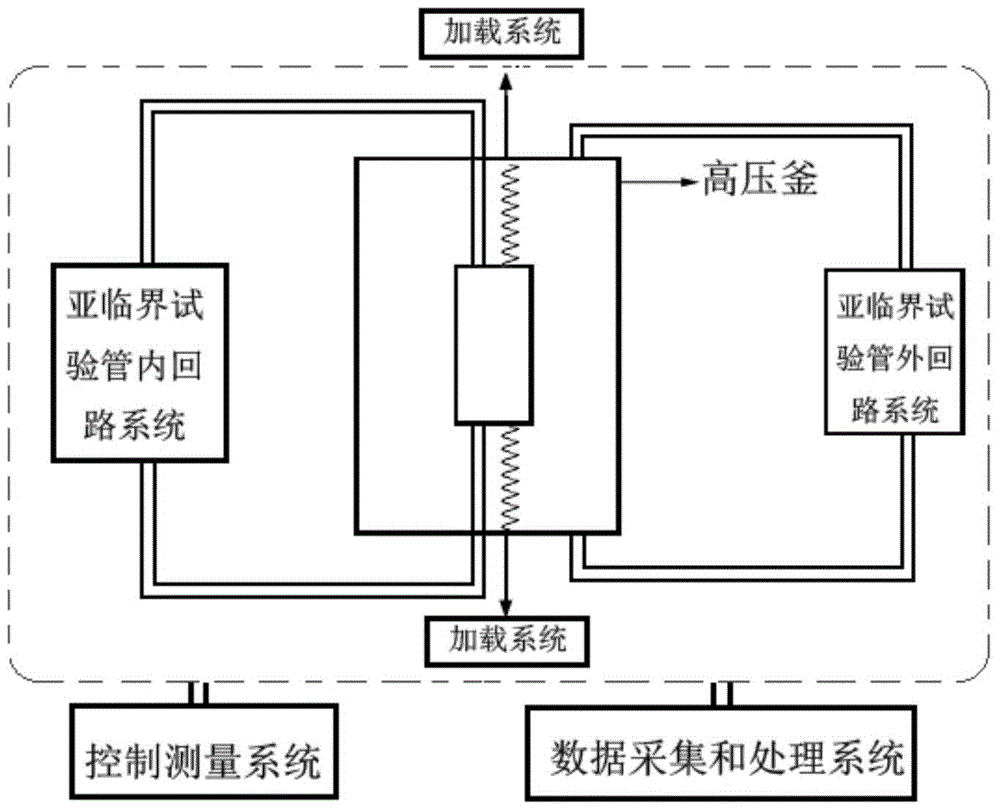

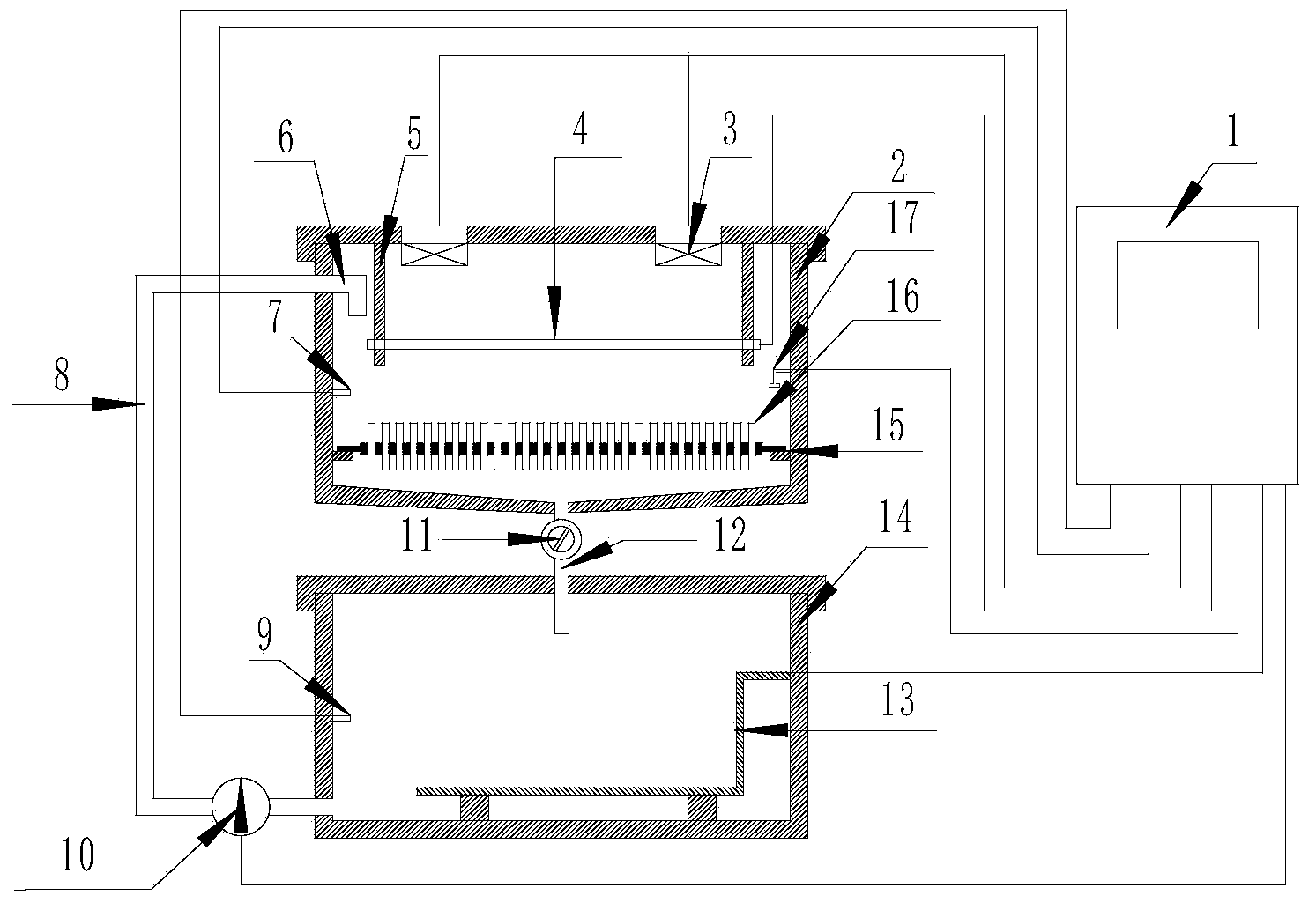

ActiveCN104458400AWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePressurized water reactorData acquisition

The invention discloses a high-temperature and high-pressure water vapor environment structural material testing device. The testing device is provided with a pipe, wherein high-temperature water flows inside and outside the pipe. The testing device comprises an autoclave, a test tube loading system, a loop system inside a test tube, a loop system outside the test tube, a controlling and measuring system and a data acquisition and processing system. The testing device which can be used for simulating the temperature, pressure, flow velocity, water chemical conditions, load and the like of a high-temperature and high-pressure water vapor environment structural material is applicable to tests in the aspects of corrosion, stress corrosion, corrosion fatigue, flow accelerated corrosion and the like of tubular specimens through complex flow and complex load coupling effect. Especially, the working conditions of different flow, different inner-side and outer-side temperatures, different pressures and different water chemistry in a heat exchange tube of a steam generator in a nuclear reaction pressurized-water reactor can be simulated to carry out related testing and research on the heat exchange tube.

Owner:UNIV OF SCI & TECH BEIJING

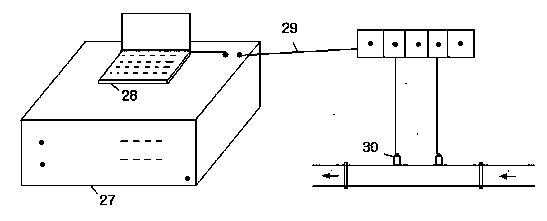

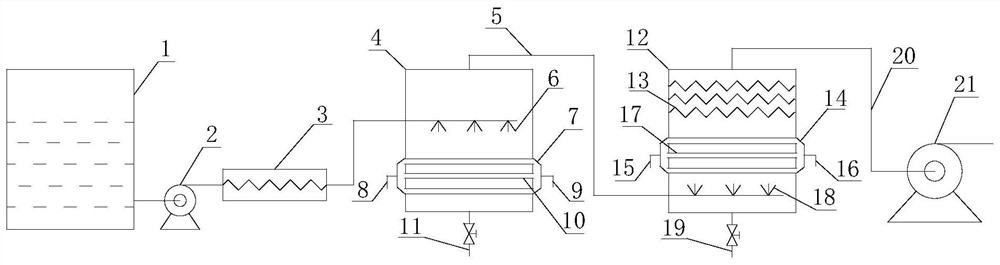

Periodic soaking accelerated corrosion test system for metal material and metal protective coating and application thereof

InactiveCN104020099ASimple structureEasy to disassembleWeather/light/corrosion resistanceTest efficiencyElectrical control

Belonging to the field of metal corrosion and protection, the invention relates to a periodic soaking accelerated corrosion test system for metal materials and metal protective coatings and application thereof. The system is mainly for the accelerated corrosion test of metals and metal protective coatings, significantly improves test efficiency, shortens evaluation cycle of metals and the protective coatings. The system includes a working groove and a liquid storage tank. An axial flow fan, an infrared heating lamp, an infrared heating lamp hanger, a temperature sensor I, a sample, a sample holder and a double float ball liquid level sensor are arranged in the working groove; and a temperature sensor II and a heater are arranged in the liquid storage tank. An electrical control system, a chemical pump, a liquid inlet pipeline, a leakage pipe and a ball valve are arranged outside the working groove and the liquid storage tank. The invention has the advantages of simple structure, low cost, reliable performance and long service life, and can evaluate the corrosion resistance of the metals and the protective coatings in a relatively short period of time, and significantly improve the test efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

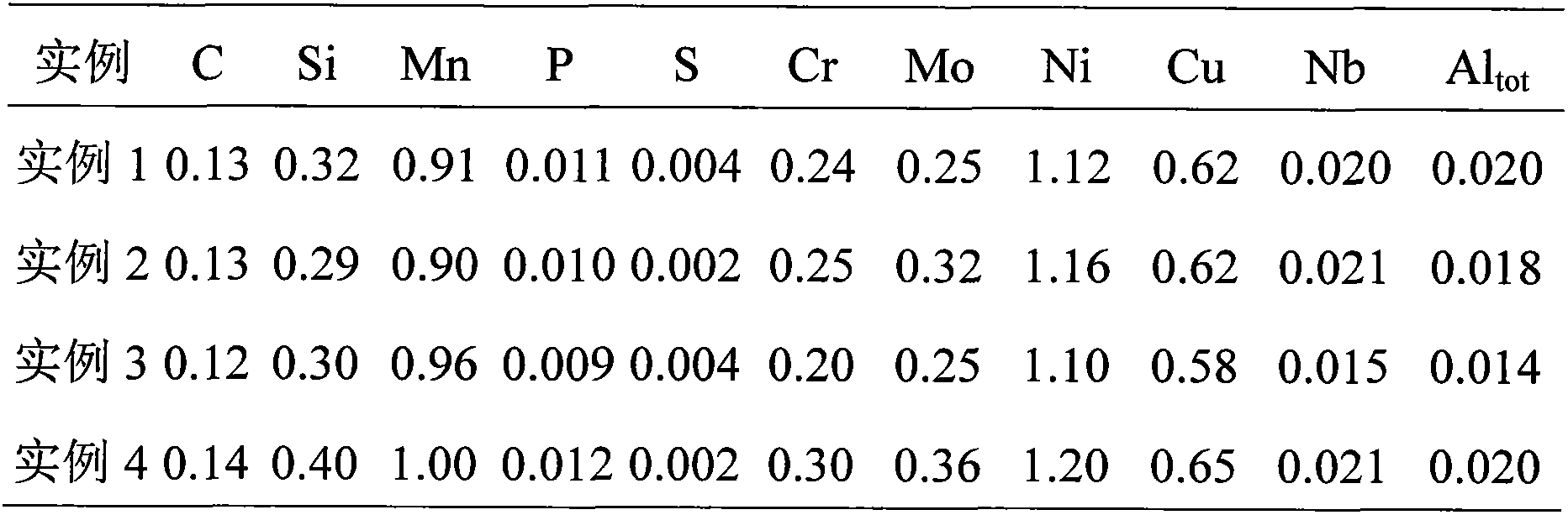

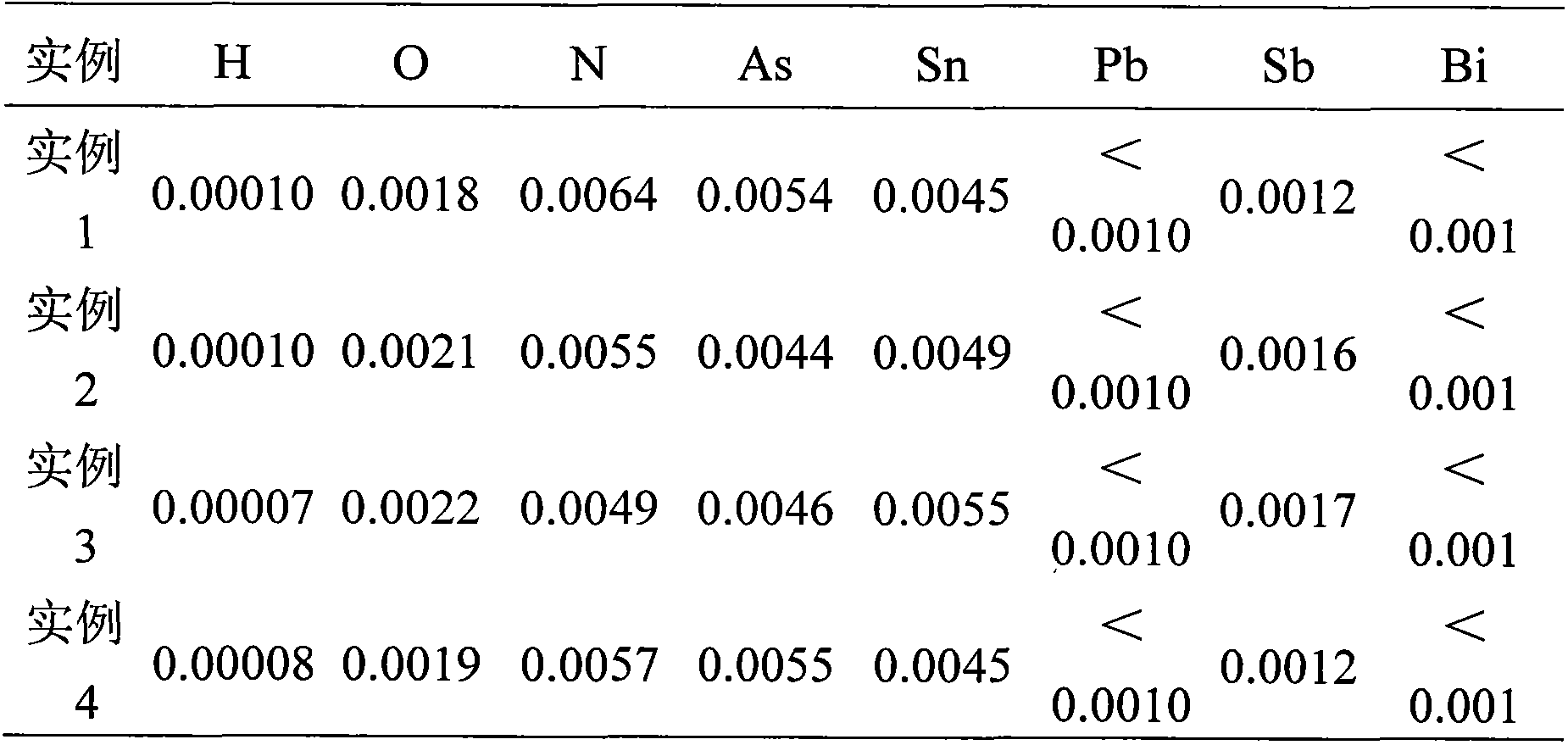

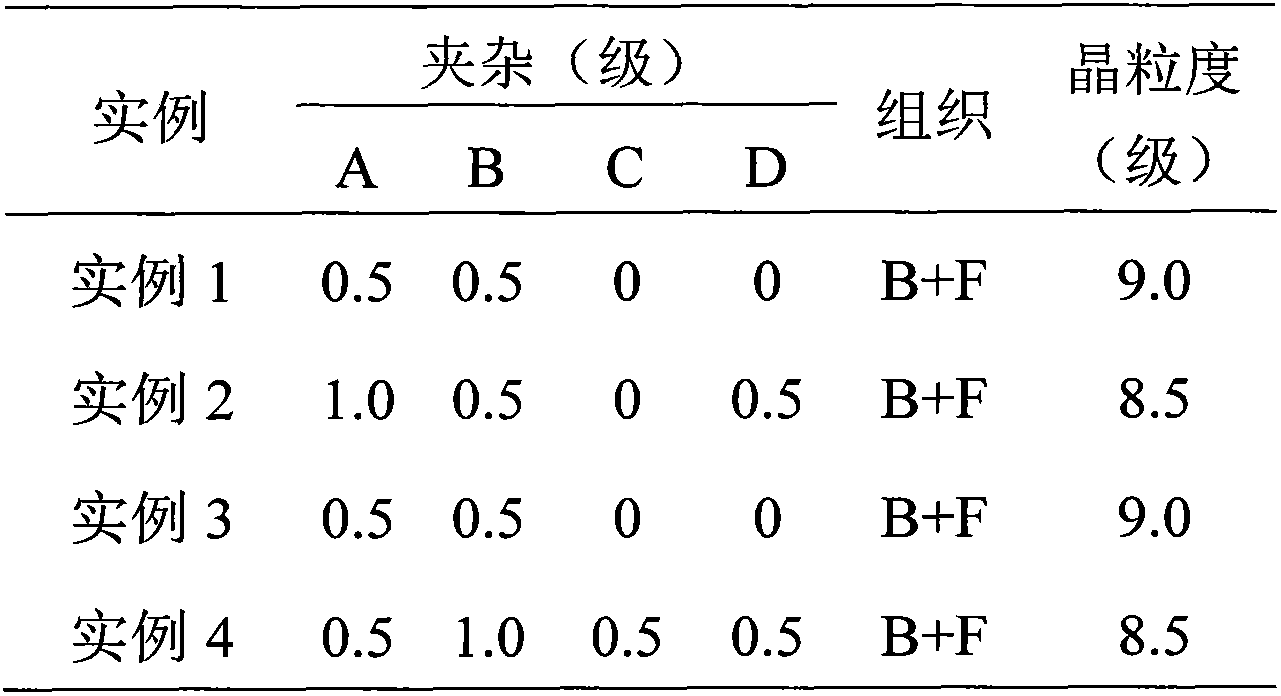

Cu-contained and Cr-controlled seamless steel tube for nuclear power station and production method for Cu-contained and Cr-controlled seamless steel tube

The invention relates to a Cu-contained and Cr-controlled seamless steel tube for a nuclear power station and a production method for the seamless steel tube. The seamless steel tube comprises the following chemical components in weight percentage: 0.10-0.15 percent of C, 0.90-1.20 percent of Mn, 0.20-0.45 percent of Si, not greater than 0.015 percent of P, not greater than 0.005 percent of S, 0.20-0.30 percent of Cr, 0.25-0.40 percent of Mo, 1.10-1.25 percent of Ni, 0.55-0.65 percent of Cu, 0.015-0.025 percent of Nb, not greater than 0.02 percent of Altot, not greater than 0.008 percent of N, not greater than 0.0002 percent of H, not greater than 0.003 percent of O, not greater than 0.012 percent of As and Sn, not greater than 0.020 percent of As, Sn, Pb, Sb and Bi and the balance Fe and inevitable impurities. According to the production method for the seamless steel tube, steel for a round tube blank is treated by adopting an oxygen converter through external refining and vacuum refining, and the round tube blank is produced by adopting a continuous casting method. The invention has the advantages that through adding alloying elements, such as Cu and Cr, the round tube blank with high purity, low gas content and low impurity content is obtained through strictly controlling harmful elements, and moreover, a reasonable reheating schedule, a rolling technology and a heat treating regime are formulated, so that the steel grade has much higher strength than carbon steel and is good in flow accelerated corrosion (FAC) resistance, is capable of saving wall thickness, is safe and reliable and is suitable for the demanding seamless steel tube for the nuclear power station.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Anti-corrosion device and method for heater drain system of heat-engine plant

ActiveCN103833122AAvoid corrosionReal-time monitoring of pHWater/sewage treatment by neutralisationWater/sewage treatment by substance additionEngineeringOxygen

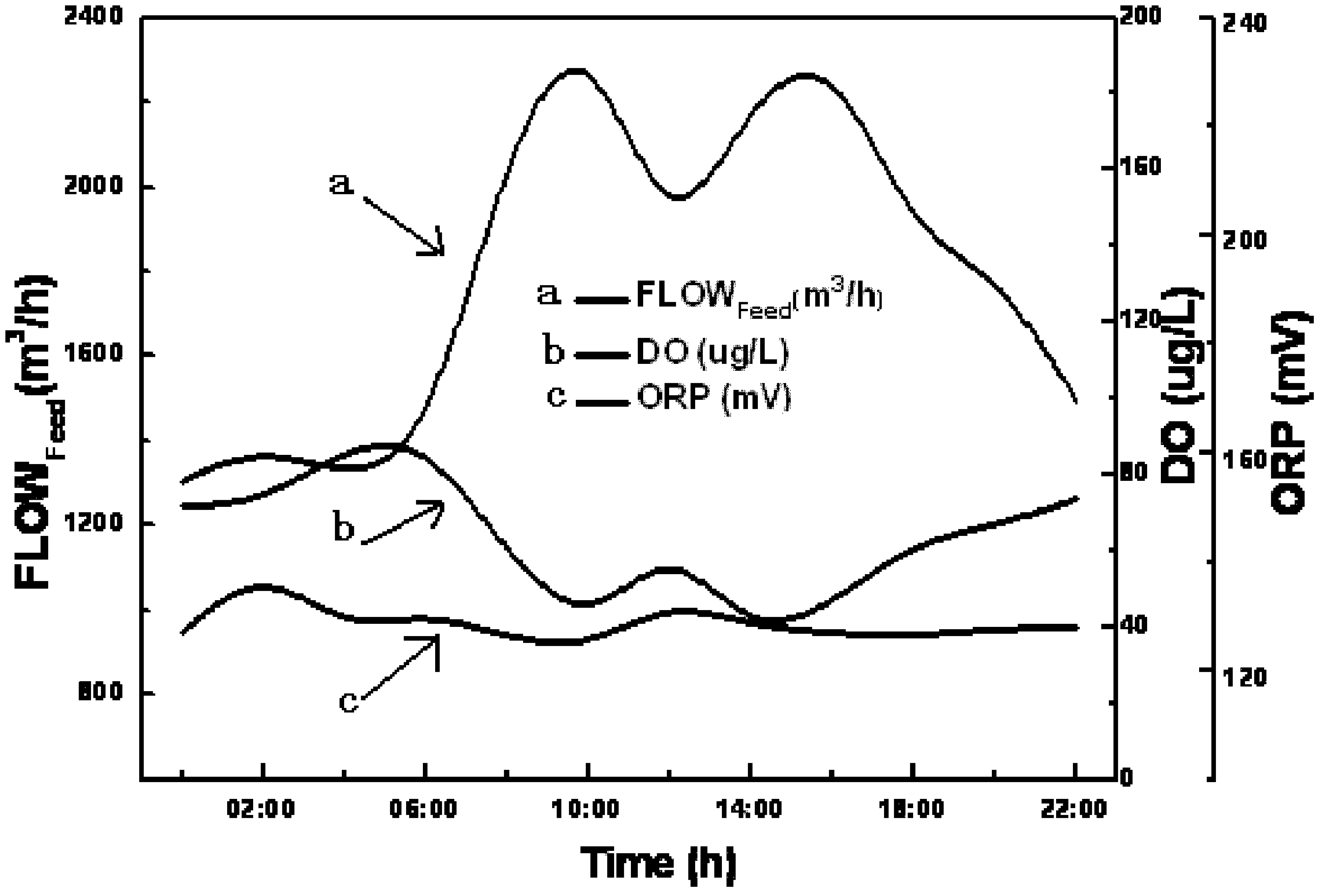

The invention relates to an anti-corrosion device and a method for a heater drain system of a heat-engine plant. The device comprises a heater and an ammonification pump, an oxygenation pump, a pH sensor and an online oxygen dissolving instrument which are communicated with the heater through a valve on a pipeline, wherein the ammonification pump and an ammonification system are connected, the oxygenation pump and an oxygenation system are connected, and the ammonification pump, the oxygenation pump, the pH sensor and the online oxygen dissolving instrument are all connected on a variable frequency speed regulation control cabinet. The innovation point of the device is as follows: a sensor for monitoring pH and the online oxygen dissolving instrument are installed behind the valve of the heater drain system, thus detecting the hydrophobic pH and oxygen concentration of the heater drain system in real time, and transmitting the hydrophobic pH and oxygen concentration to the variable frequency speed regulation control cabinet at real time so as to control the ammonification pump to add ammonia and oxygen into the hydrophobic system to regulate the pH to be about 9.0 and the oxygen concentration to be about 100mu g / L, being beneficial to maintaining a passive film in the drain system pipeline, and effectively inhibiting flow accelerated corrosion.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

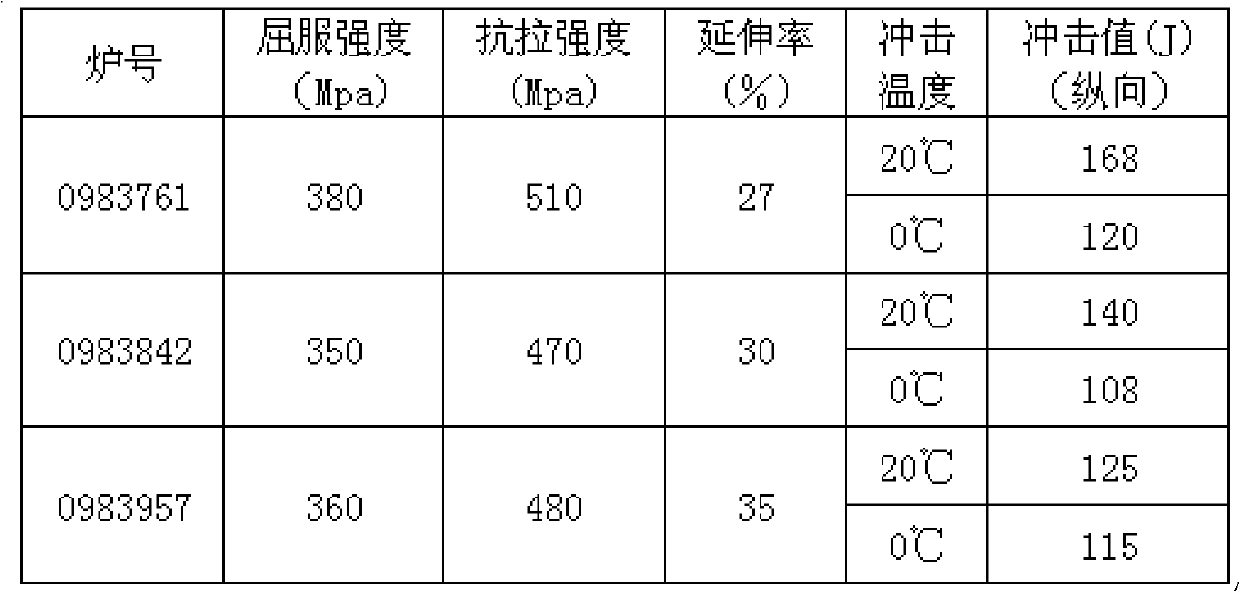

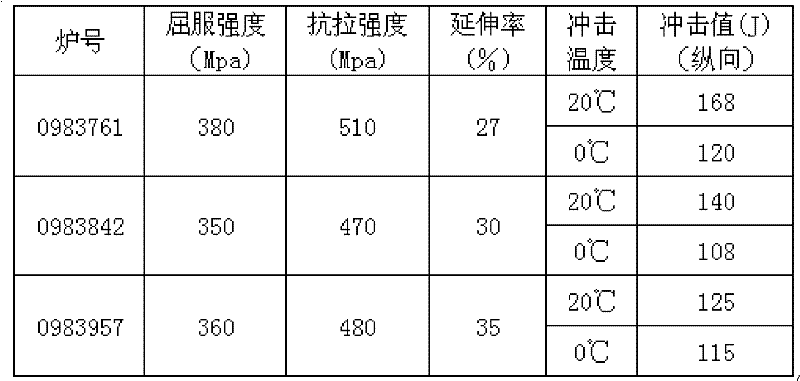

Seamless steel tube for nuclear power and production method thereof

InactiveCN101769403ACorrosion preventionPipe protection against corrosion/incrustationChemical compositionNuclear power

The invention relates to a seamless steel tube for nuclear power and a production method thereof, belonging to the field of seamless steel tubes. The invention solves the technical problem of providing the seamless steel tube for nuclear power, and the seamless steel tube can reduce 'flow-accelerated corrosion (FAC)'. The seamless steel tube for the nuclear power comprises the following chemical compositions in percentage by weight: 0.17-0.24% of C, 0.17-0.37% of Si, 0.35-0.65% of Mn, 0.18-0.35% of Cr and the balance of Fe and unavoidable impurities. The mechanical property and impact property (20 DEG C, 0 DEG C) and high-temperature instaneous tension of the seamless steel tube for nuclear power can fully satisfy the technical requirements of the seamless steel tube for a conventional island of a nuclear power plant, and the function of 'FAC (flow-accelerated corrosion)' resistance is achieved. The invention provides a novel choice for the seamless steel tube for the conventional island of the nuclear power plant, and has wide application prospect.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Common pipe ditch cast-in-place extrusion flow state concrete lining material

ActiveCN102515658AImprove early strengthFacilitate reasonable and effective circulationFineness modulusPortland cement

The invention relates to a common pipe ditch cast-in-place extrusion flow state concrete lining material, which is used in an extrusion flow state concrete material. strength grade of configured concrete is C30, 42.5 grades ordinary Portland cement is adopted, content of C3A is required to be less than 8%, fineness modulus of fine aggregate are 2.6-3.0, grain size scope of coarse aggregate is 5-31.5mm, sand ratio is 36-40%, coal ash occupies 20% of total weight of gelled materials, and water to binder ratio scope is controlled in a range of 0.40-0.44. Mix proportion with the unit of Kg / m3 of the concrete material is the cement of 320-355, the river sand of 630-690, the gravel of 1080-1160, the coal ash of 80-90, water of 175-185, and dosage of flow accelerated corrosion (FAC) high efficiency slushing agent is 1.5-1.8% of the weight of the gelled material. The common pipe ditch cast-in-place extrusion flow state concrete lining material conducts a 1:1 testing model test, workability index, strength index and cement dosage all meet requirements, and anti-permeability of the concrete is larger than P20. Various indexes of the concrete all meet design requirements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

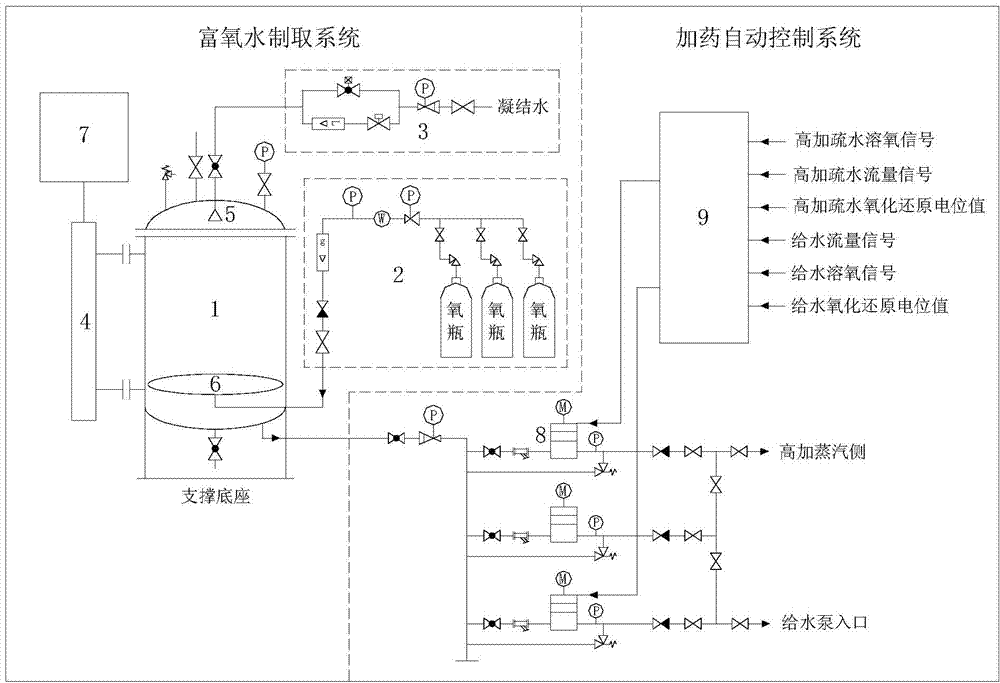

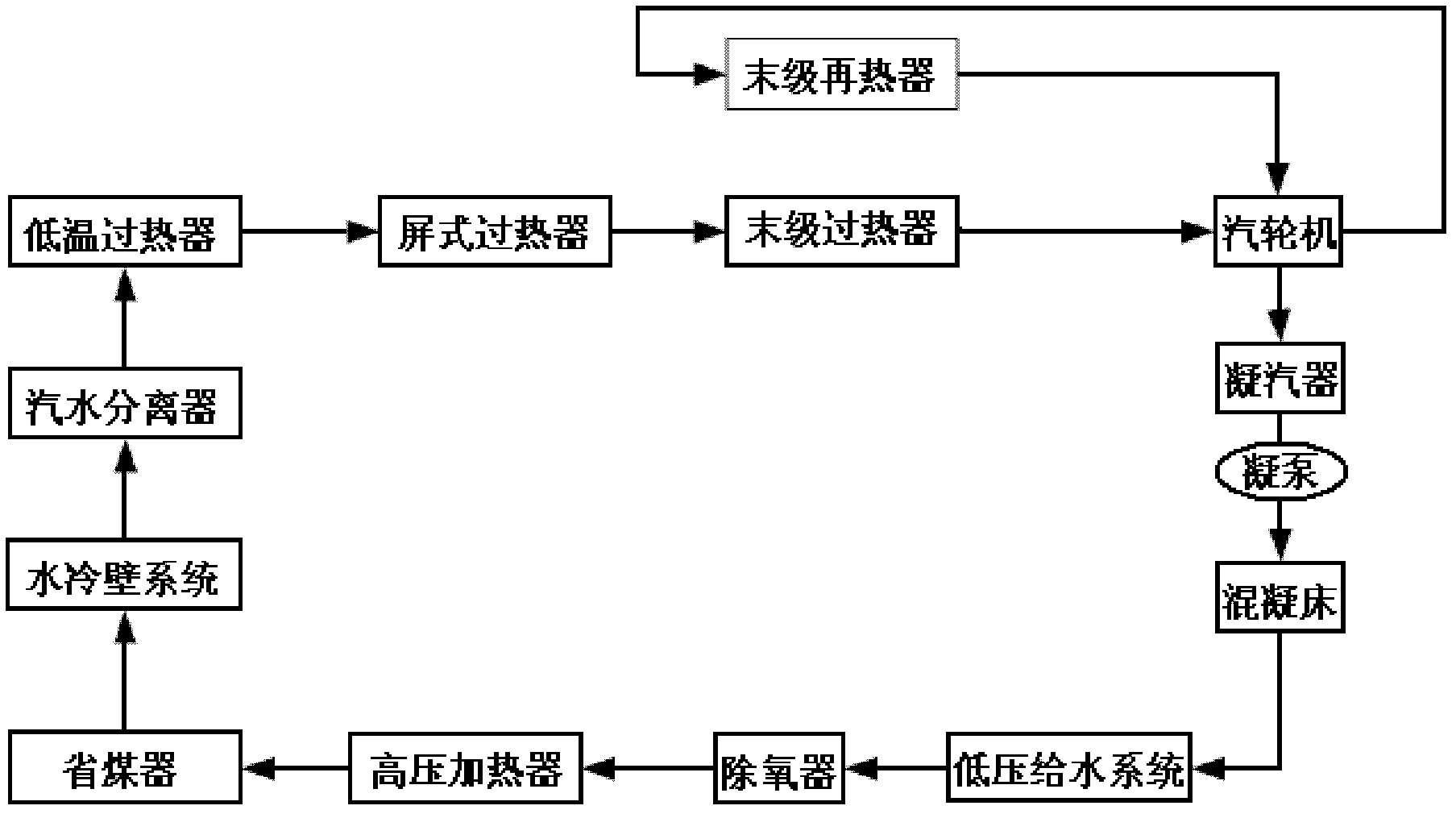

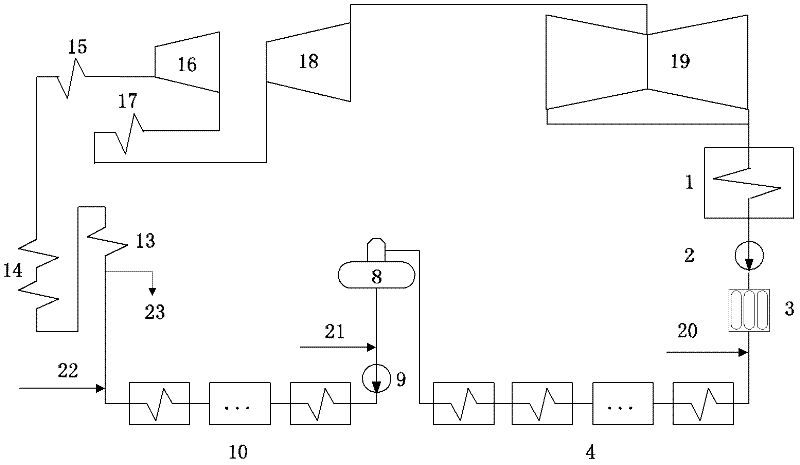

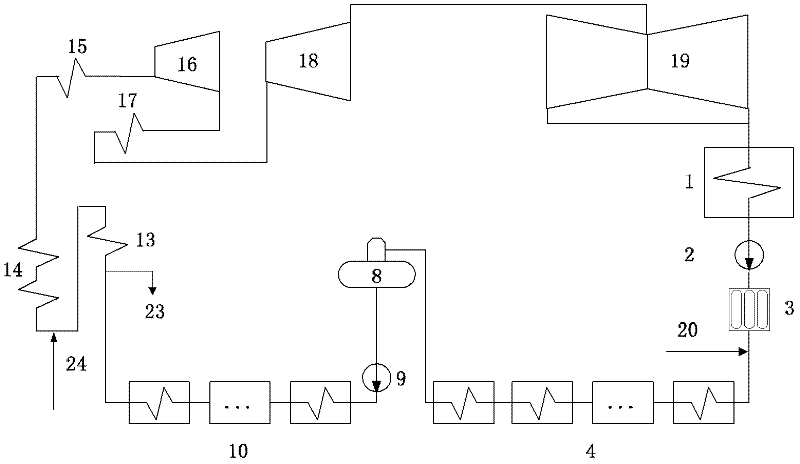

Segmental oxidation treatment system and treatment method of thermodynamic system of novel coal-fired power plant

InactiveCN103880230AImprove securityImprove economyMultistage water/sewage treatmentWater/sewage treatment by oxidationEngineeringSuperheater

The invention discloses a segmental oxidation treatment system and a segmental oxidation treatment method of a thermodynamic system of a novel coal-fired power plant. The system comprises an oxygen-enriched water preparing system and an automatic reagent-adding control system. The treatment method comprises the following steps: preparing oxygen-enriched water by using the oxygen-enriched water preparing system; and carrying out segmental oxidation treatment on the thermodynamic system in an oriented reagent-adding manner by taking the oxygen-enriched water as an oxidizing agent, thereby promoting a water supply system and a high-pressure heater drainage system to be in an aerobic working condition and a steam system to be in an anaerobic working condition. According to the system and the method which are disclosed by the invention, the problem of flow accelerated corrosion of the water supply system and the high-pressure heater drainage system which are arranged at the front of a furnace is solved; and meanwhile, the surplus oxygen is prevented from entering the steam system to possibly perform adverse effects on a superheater and a reheater.

Owner:XIAN THERMAL POWER RES INST CO LTD

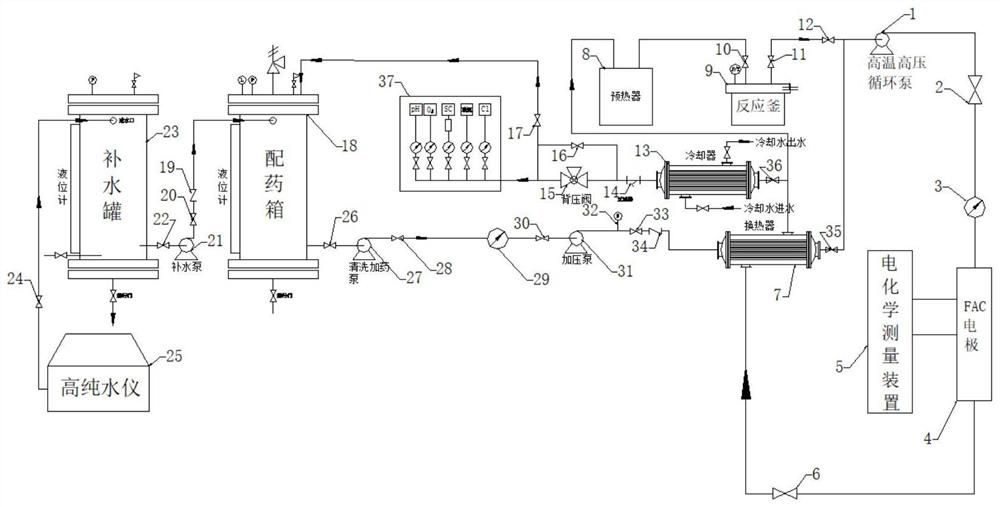

Power station flow accelerated corrosion simulation experiment pipeline apparatus with electrochemistry measurement mode

InactiveCN105223128AShorten experiment timeTrue Flow Accelerated CorrosionWeather/light/corrosion resistanceTemperature controlPower station

The invention discloses a power station flow accelerated corrosion simulation experiment pipeline apparatus with electrochemistry measurement mode. The pipeline apparatus comprises a water tank and an experiment pipeline which is connected to the water tank, and the water tank is provided with a temperature control module, a pressure control module, a flow control module, a medium oxygen content control module and an pH control module, a wall surface of an experiment segment of the pipeline is embedded with working electrodes, and the electrochemistry measurement method is used for monitoring corrosion of the inner wall of the pipeline segment. According to the method, the flow condition and the flow corrosion of industrial fields can be really reflected, and the corrosion rate of the experiment electrodes can be instantly measured.

Owner:SOUTHEAST UNIV

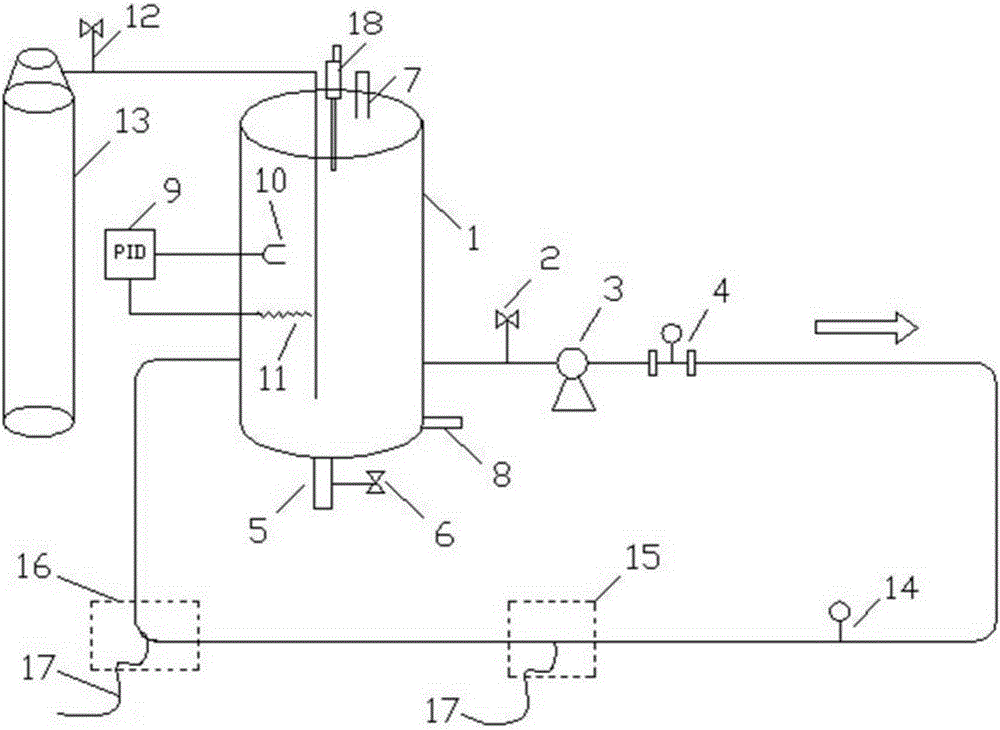

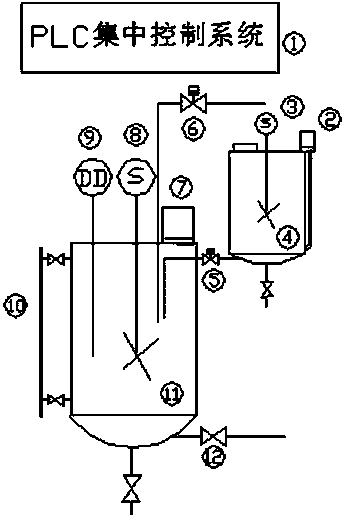

Full-automatic boiler feedwater oxygenating device and full-automatic boiler feedwater oxygenating method

ActiveCN102633371ASensitive adjustmentEasy to controlScale removal and water softeningTotal factory controlEngineeringOxygen

The invention discloses a full-automatic boiler feedwater oxygenating device, which comprises a PLC (programmable logic controller), a low detection device, a dissolved oxygen detection device, an oxidation-reduction potential detection device, a hydrogen conductive detection device and a flow controller. The invention further discloses a method of using the full-automatic boiler feedwater oxygenating device to oxygenate feedwater. By means of feedwater composite oxygenating treatment, feedwater is subjected to trace oxygenating with feewater flow serving as feed forward to assist in proportion-integration-differentiation control through the full-intelligent oxygenating control technique, so that the structure and form of a water-gas contact interface oxide film can be changed, the oxide film can be more compact and firm, and FAC (flow accelerated corrosion) of a water feeding system can be relieved or eliminated. Accordingly, the problem of flow accelerated corrosion of the water feeding system can be solved, the service life of equipment is prolonged, energy is saved while consumption is reduced, and economic and social benefits can be improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Main steam and main water supply pipeline in a conventional island of nuclear power plants and preparation method thereof

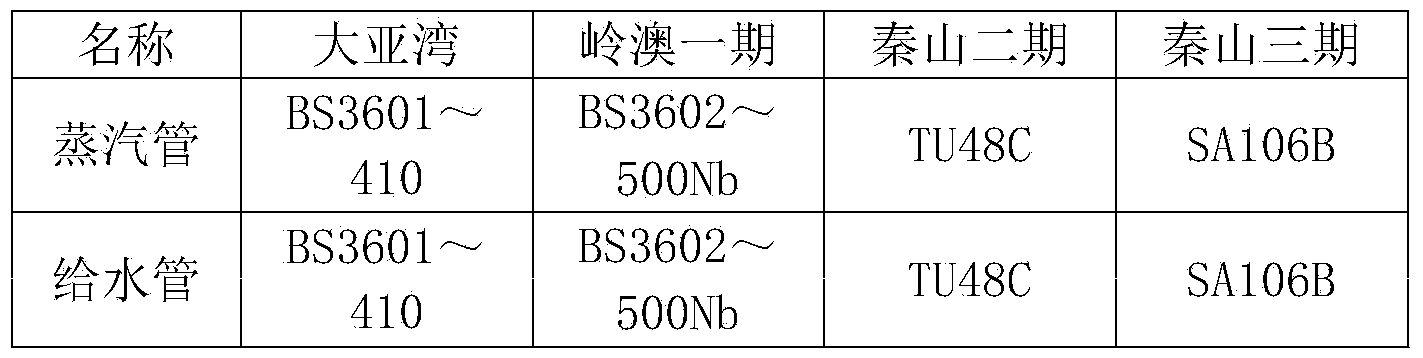

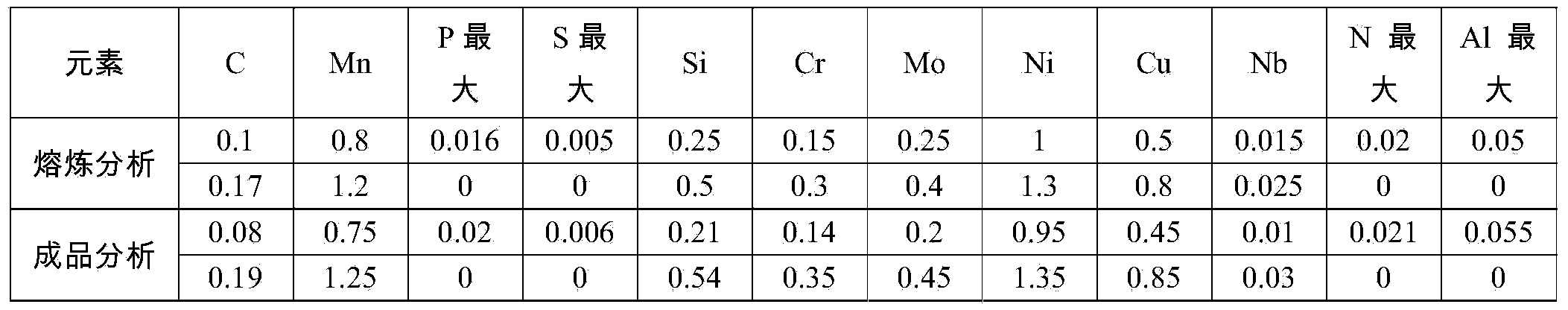

The present invention discloses a main steam and main water supply pipeline in a conventional island of nuclear power plants and a preparation method thereof. The main water supply pipeline comprises the following components in percentage by weight: 0.06-0.20% of C, 0.70-1.30% of Mn, 0-0.020% of P, 0-0.006% of S, 0.20-0.60% of Si, 0.15-0.35% of Cr, 0.15-0.50% of Mo, 0.90-1.40% of Ni, 0.40-0.90% of Cu, 0.008-0.035% of Nb, 0-0.021% of N, 0-0.055% of Al and the balance of Fe and unavoidable impurities. The preparation method comprises the following two methods, namely, directly rolling pipes on a periodic mill and carrying out pipe cross-rolling piercing on a forging blank. The main steam and main water supply pipeline disclosed by the invention has the advantages of good FAC (Flow Accelerated Corrosion) resistance, good mechanical properties at room temperature and tensile properties at high temperature and impact toughness at low temperature.

Owner:中广核工程有限公司 +1

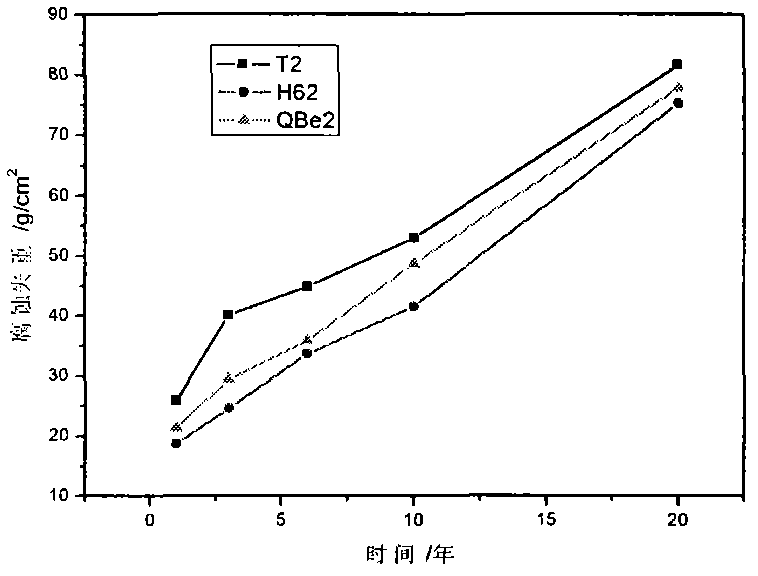

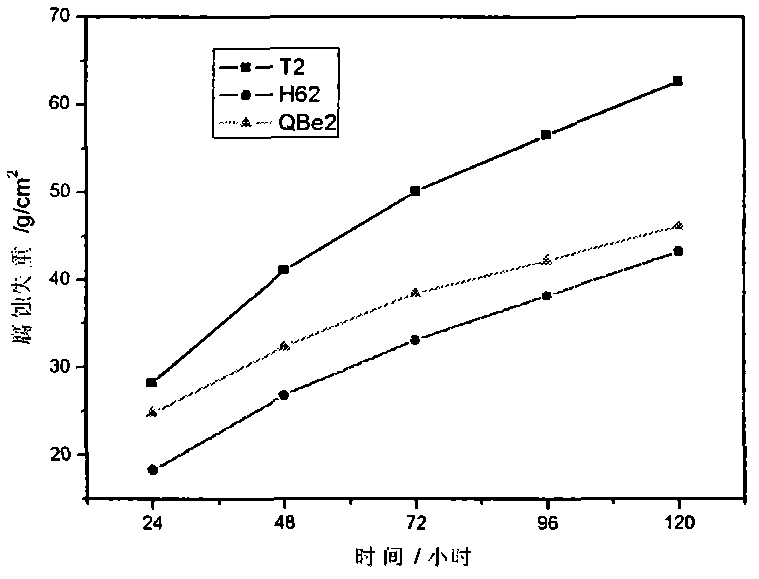

Method of accelerated corrosion test used for simulating corrosion process of copper and alloy thereof in atmosphere

InactiveCN102466613ARapid evaluation of atmospheric corrosion resistanceHighly corrosiveWeather/light/corrosion resistanceTest sampleTested time

The invention relates to a method of an accelerated corrosion test used for simulating a corrosion process of copper and alloy thereof in the atmosphere. The method comprises steps that: (1) copper or copper alloy is prepared into a test sample; (2) an aqueous solution of CuCl2, (NH4)2SO4 and NaHSO3 is adopted as an impregnation solution; (3) the sample is subject to a circulated test according to a sequence of impregnating, moisturizing, and drying; and single-time and total test times are determined according to specific requirements; (4) the sample obtained from the step (3) is treated, and researches such as corrosion weight loss, corrosion products and morphological analysis are carried out. The method provided by the invention is used for simulating the corrosion process of copper and alloy thereof in different environments such as a damp and hot environment and a marine environment. The test method has a simulating capacity, an accelerating capacity, and repeatability. The method can be used in the researches of atmosphere corrosion behaviors and rules of copper and alloy thereof in different environments, and can be used in rapid evaluations of corrosion resistances of various copper and alloy thereof.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

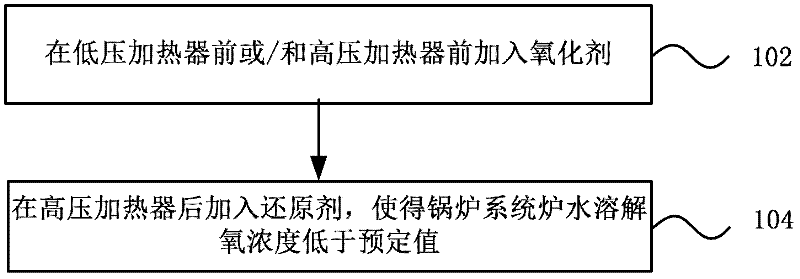

Feed water treatment method of thermal generator set

InactiveCN102408148AInhibit flow accelerates corrosionAvoid corrosionWater/sewage treatment by reductionWater/sewage treatment by oxidationEngineeringPower engineering

Belonging to the technical field of electric power and power engineering, the invention discloses a feed water treatment method of a thermal generator set. The method comprises: adding an oxidant before a low-pressure heater or / and a high-pressure heater so as to inhibit flow accelerated corrosion in a feed water system; adding a reducing agent after the high-pressure heater for reacting with theoxidant so as to make the concentration of dissolved oxygen in water within a boiler system lower than a predetermined value, thus eliminating the reinforcing effect of oxygen on boiler pipe metal oxidation rate during oxygenation treatment. The method of the invention can inhibit flow accelerated corrosion in a feed water system and reduce oxygen corrosion on the inner wall of a boiler pipe simultaneously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

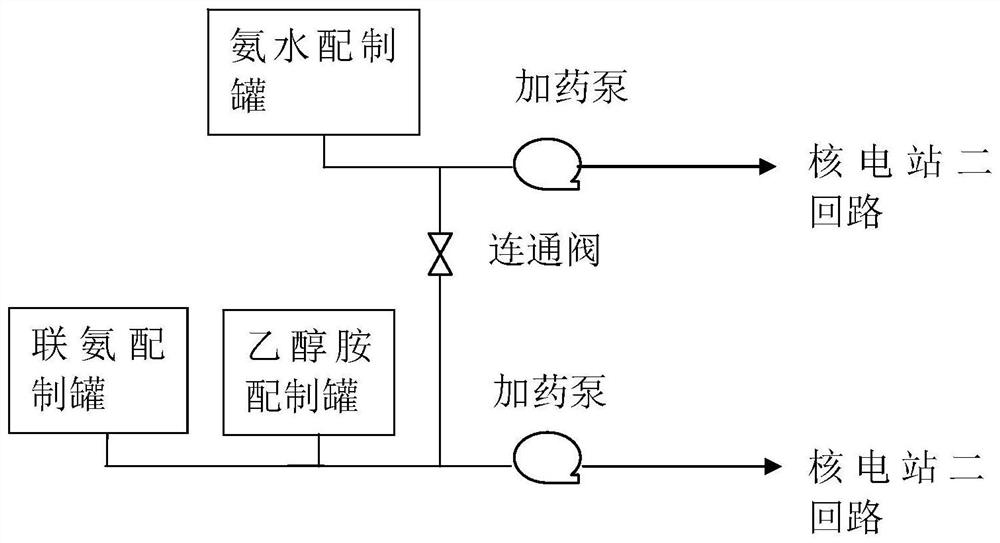

Dosing system and method for deoxidant hydrazine for secondary loop system of high-temperature gas cooled reactor nuclear power plant

PendingCN110713220AIncreased redox potentialReduce flow accelerated corrosion rateWater contaminantsWater/sewage treatment by degassingNuclear plantNuclear power

The invention discloses a dosing system and method for a deoxidant that is hydrazine for a secondary loop system of a high-temperature gas cooled reactor nuclear power plant. The dosing system comprises a water feeding and hydrazine adding device which is arranged on an outlet pipeline of a high-pressure heater and used for adding the hydrazine, and a sampling monitoring device which is arranged at an inlet pipe of a steam generator and used for monitoring dissolved oxygen and hydrazine contents and controlling the hydrazine adding amount. According to the dosing system and the method, the flow accelerated corrosion rate of the secondary loop water supply system can be reduced to the maximum extent under the condition that a chemical water treatment agent is not changed in the secondary loop of the nuclear power unit and only the hydrazine dosing position is changed. The sampling position of the secondary loop system is changed, so that the sampled sample is more reasonable and representative.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

Seamless steel tube for nuclear power and production method thereof

InactiveCN101769403BCorrosion preventionPipe protection against corrosion/incrustationChemical compositionNuclear power

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

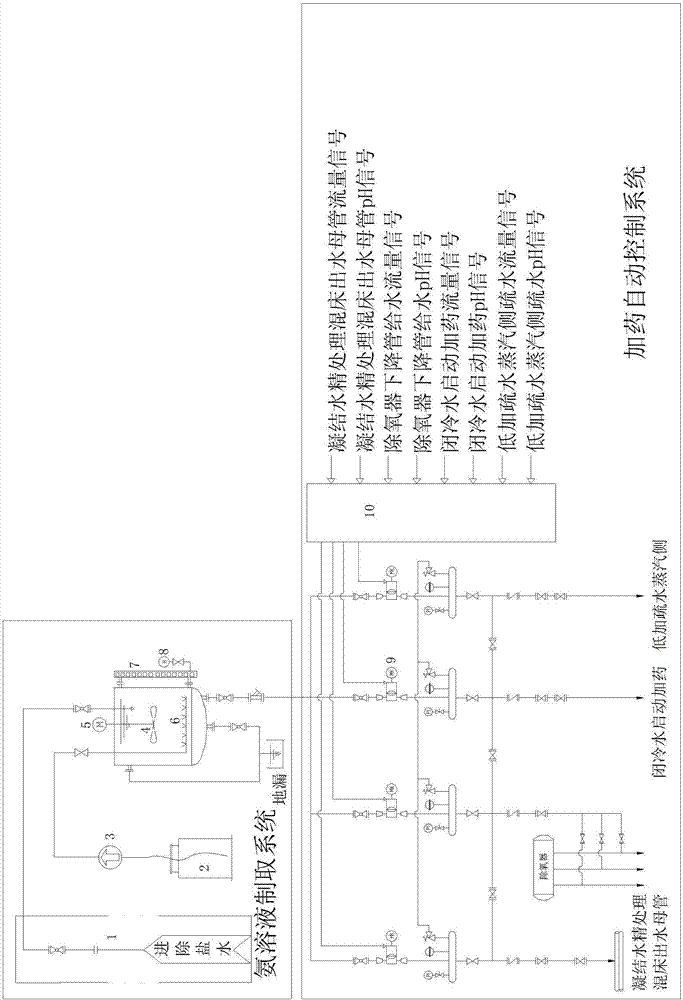

System and method for sectional pH (potential of hydrogen) value adjusting of thermal system of thermal power plant

InactiveCN107381763AImprove securityImprove economyWater treatment parameter controlWater/sewage treatment by neutralisationAutomatic controlHydrogen

The invention relates to a system and a method for sectional pH (potential of hydrogen) value adjusting of a thermal system of a thermal power plant, which are used for controlling the sectional pH value adjusting of the thermal system and enabling a water supply system and a water drain system of a low pressure heater to avoid corrosion accelerating caused by flowing. The system comprises an ammonia solution preparation system and a dosage automatic control system. The adjusting method comprises the following steps of enabling the ammonia solution preparation system to prepare a low-concentration ammonia water solution, using the low-concentration ammonia water solution as a pH value adjuster, enabling a directional dosage pipeline to adjust the pH value of the thermal system by sections, and enabling the water supply system and the water drain system of the low pressure heater to avoid corrosion accelerating caused by flowing. The system and the method have the advantages that the problem of easiness in corrosion accelerating caused by flowing in the water supply system and the water drain system of the low pressure heater in front of the furnace are solved; the content of iron in the drained water is greatly reduced, and the influence to the thermal system is avoided.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

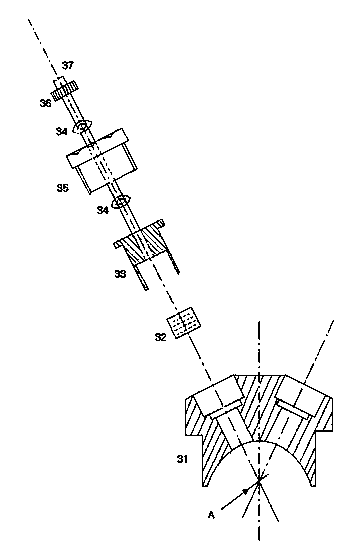

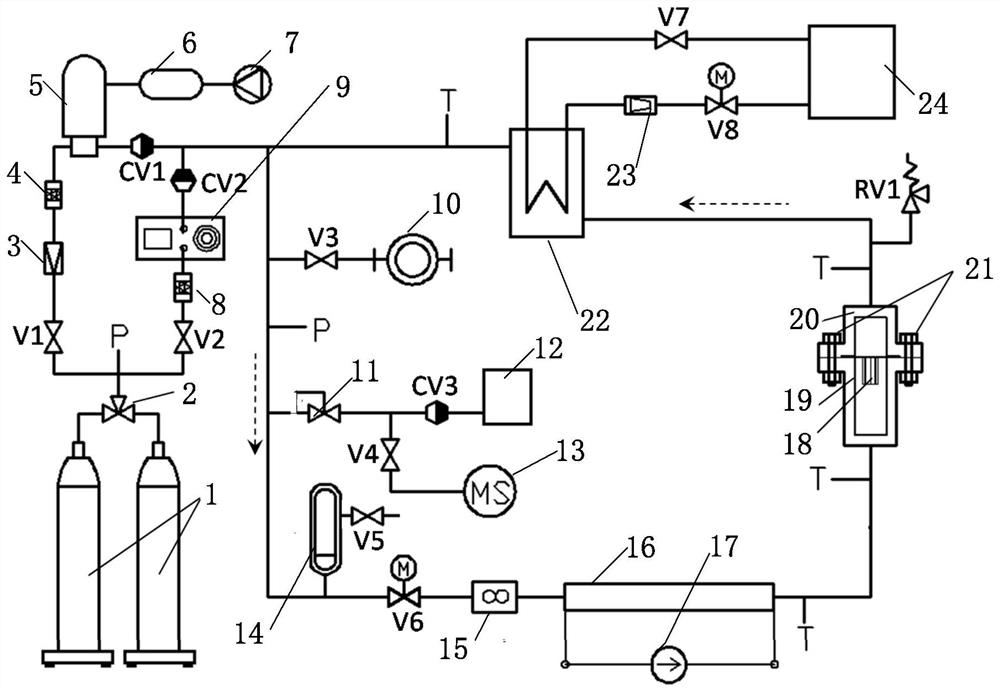

High-temperature high-pressure supercritical carbon dioxide flow accelerated corrosion test system and method

ActiveCN112285011AHigh heating power adjustment accuracySensitive temperature controlWeather/light/corrosion resistanceEngineeringMass analyzer

The invention discloses a high-temperature high-pressure supercritical carbon dioxide flow accelerated corrosion test system and method. The test system comprises a closed circulation loop and a gas supply system; the closed circulation loop comprises a pulse damper, a carbon dioxide mass flow meter, an electric control valve V6, a heating device, a high-temperature and high-pressure reaction kettle and a cooler which are connected through a pipeline, and the cooler is arranged at the rear end of the high-temperature and high-pressure reaction kettle; the pulse damper, the carbon dioxide massflow meter, the electric control valve V6 and the heating device are arranged at the front end of the high-temperature and high-pressure reaction kettle, and a mass spectrometer and a back pressure valve are arranged on the closed circulation loop; the gas supply system comprises a carbon dioxide storage tank and a high-pressure liquid chromatography pump and is used for providing carbon dioxide gas flow for the closed circulation loop. The problems that in the prior art, the working condition of high-flow-speed supercritical carbon dioxide is difficult to achieve, and a supercritical carbon dioxide flow accelerated corrosion test cannot be carried out are solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for adjusting dissolved gases in boiler feed water

InactiveCN105417609AAvoid easy cloggingReduce pollutionLiquid degasificationWater/sewage treatment bu osmosis/dialysisFiberSolubility

The invention discloses a method for adjusting dissolved gases in boiler feed water. The steam of a boiler forms condensed water after the work of a steam turbine; the condensed water flows out of a condenser and enters a polishing apparatus through a condensed water pump; the condensed water is subjected to degassing or oxygenation treatment by a membrane degasser or membrane oxygenator, wherein the membrane degasser is connected with a vacuum pump, and the membrane oxygenator is connected with an oxygen bottle; the treated water enters the boiler through a low-pressure heater, a water feed pump and a high-pressure heater; and the membrane degasser and the membrane oxygenator are fiber membrane contactors. According to the adjusting method, a fiber membrane is adopted as a gas-liquid exchange interface; according to different water qualities, membrane degassing treatment is carried out in AVT (all-volatile treatment) working condition, and membrane oxygenation treatment is carried out in OT (oxygenated treatment) working condition; and the gas content of the boiler feed water can be quickly and accurately adjusted, the flow accelerated corrosion (FAC) is avoided, and the operation safety of the unit is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Vapour-liquid two-phase flow accelerated corrosion test device

InactiveCN101900664BImprove sealing propertiesSimple structureWeather/light/corrosion resistanceCorrosion reactionEngineering

The invention relates to a vapour-liquid two-phase flow accelerated corrosion test device which is characterized by comprising a testing autoclave body, an oil bath heating jacket, an autoclave body cover, a magnetic rotating device, a high-temperature reference electrode, a graphite auxiliary electrode, a working electrode, a variable frequency motor, a potentiostat, a corrosion measurement computer, an equipment control cabinet, an inner lining, a gas-phase generator, an electric heater and a thermocouple sensor. In the invention, an electrochemical measurement method is adopted to carry out experimental study on the relevant properties of vapour-liquid two-phase flow accelerated corrosion, including the measurement of relevant coefficients of the transient corrosion property, the corrosion impedance and the corrosion reaction, the relation between mass transfer and corrosion reaction, the relation between the vapour-liquid two-phase flow pattern and the corrosion rate and production and breakage mechanism of a corrosion product membrane and the critical characteristic of the breakage. The high-speed rotation is realized and meanwhile, and the good sealing property is ensured byadopting the magnetic rotating device.

Owner:NANJING TECH UNIV

Corrosion-resistant pressure-bearing seamless steel tube and production method thereof

InactiveCN108277435AHigh strengthImprove plasticityFurnace typesHeat treatment furnacesPipeline transportCorrosion resistant

The invention discloses a corrosion-resistant pressure-bearing seamless steel tube. The steel tube comprises the following components of, by weight, 0.11-0.15% of C, 0.30-0.45% of Si, 0.90-1.10% of Mn, 0.15-0.25% of Cr, 1.10-1.30% of Ni, 0.55-0.65% of Cu, 0.015-0.025% of Nb, 0.015-0.045% of Al, 0.01-0.02% of Ti, less than or equal to 0.020% of P, less than or equal to 0.010% of S and less than orequal to 0.008% of N. The invention further discloses a production method of the seamless steel tube. The corrosion-resistant pressure-bearing seamless steel tube produced by the production method iscorrosion-resistant and pressure-bearing and high in flowing resistance and accelerated-corrosion resistance, so that the service life is prolonged, pipeline transportation safety is improved, and meeting of requirements of social development are facilitated.

Owner:BAOTOU IRON & STEEL GRP

High-precision full-automatic preparation process technology of industrial microgram-grade strong base

PendingCN109513356AAchieve precisionFully automatedTransportation and packagingMixer accessoriesNuclear powerHyperplasia

The invention provides a high-precision full-automatic preparation process technology of industrial microgram-grade strong base, and is applicable to the industrial field, such as steam power stations(thermal power, nuclear power, turbine engine and the like) drum boilers, water supply of direct current furnace, furnace water dosing high precision and full automatic preparation. The process comprises a concentrate liquid feed system, diluted demineralized water feed system, a precise preparation system and a detection and calculation control system. Compared with the prior art, the technologyhas the advantages that (1) industrial strong base administration is introduced from manual extensive mode into intelligent high-precise full-automatic mode; and (2) the feed water with strong base treatment process technology is gradually accepted in the field, has a conclusive effect in effectively preventing pipe burst caused by oxidative hyperplasia and falling of overheating and re-heating steam pipe. The technology realizes high precision and full automation of feedwater with strong base, and further control of feedwater pipeline flow accelerated corrosion (FAC) and pipe burst caused byoxidative hyperplasia and falling of a steam pipe.

Owner:云南聚杰环保科技有限公司

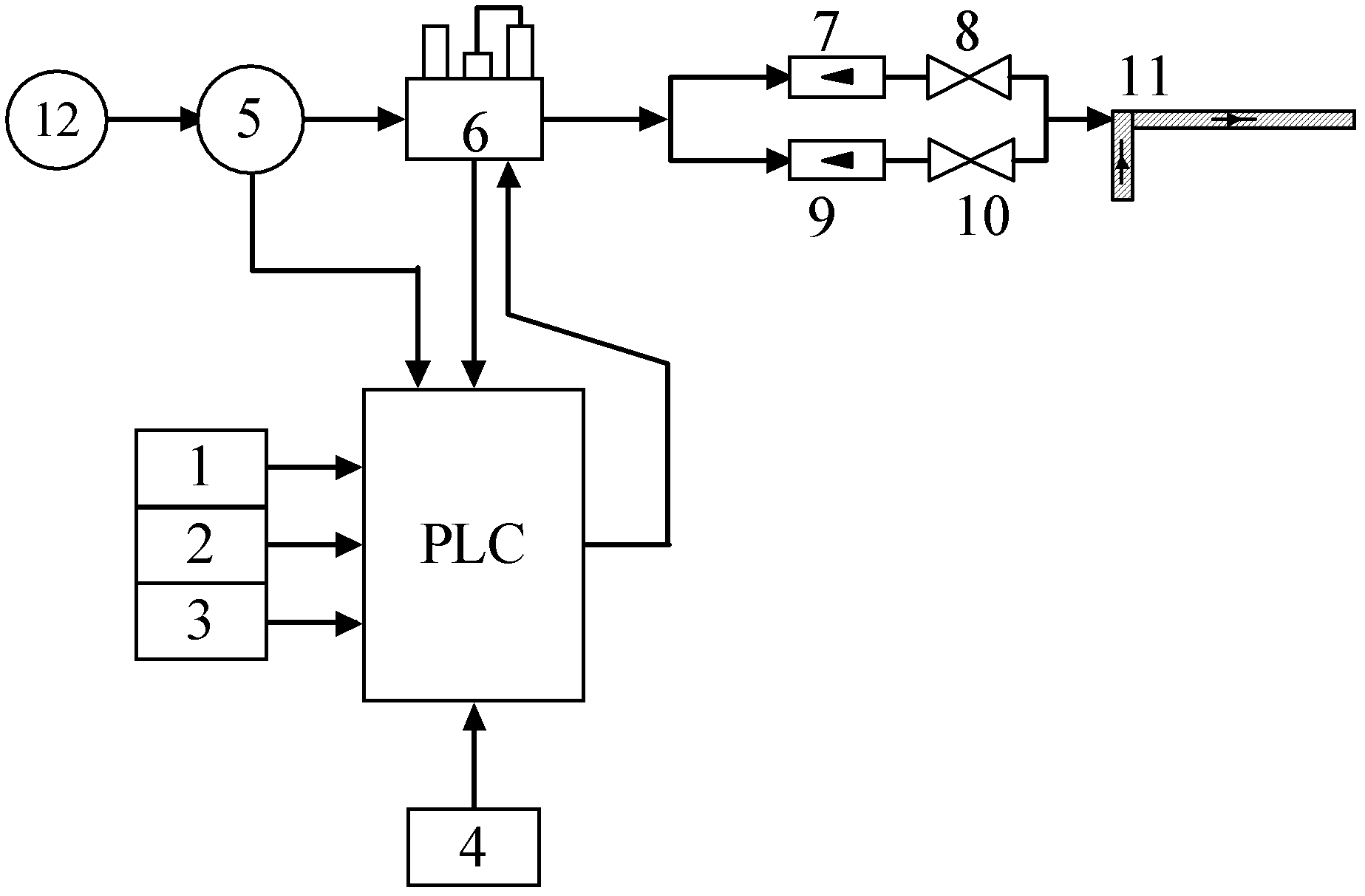

Alkalizer compounding device and method for inhibiting air cooling island vapor-liquid two-phase flow FAC

PendingCN111921213AEasy to operateAvoid corrosionEvaporator accessoriesEvaporator regulation/controlFluid phaseEngineering

The invention discloses an alkalizer compounding device and method for inhibiting air cooling island vapor-liquid two-phase flow FAC. The device comprises a medicine dissolving box, a medicine feedingpump, a heating device, a vapor-liquid separation device, a vapor exhaust pipe, a vapor phase collection device, an insoluble gas exhaust pipe and a vacuum pump which are sequentially communicated. The vapor-liquid separation device is composed of an alkalizer compound liquid spraying device, a liquid phase cooler and a liquid phase sampling device; the liquid phase cooler is provided with a cooling water inlet pipe, a cooling pipe and a cooling water outlet pipe; the vapor phase collecting device is composed of an alkalizer compound liquid vapor phase hole homogenizing device, a vapor phasecondenser, a demister and a vapor phase condensate sampling device; the vapor phase condenser is provided with a cooling water inlet pipe, a condensation pipe and a cooling water outlet pipe; the invention further discloses an alkalizer compounding method of the device. The types and dosages of the compound basifying agent can be adjusted at will according to actual needs so that vapor and liquidphases of the basifying agent are uniformly distributed, and flow accelerated corrosion caused by non-uniform distribution of the basifying agent in the vapor and liquid phases is prevented.

Owner:XIAN THERMAL POWER RES INST CO LTD

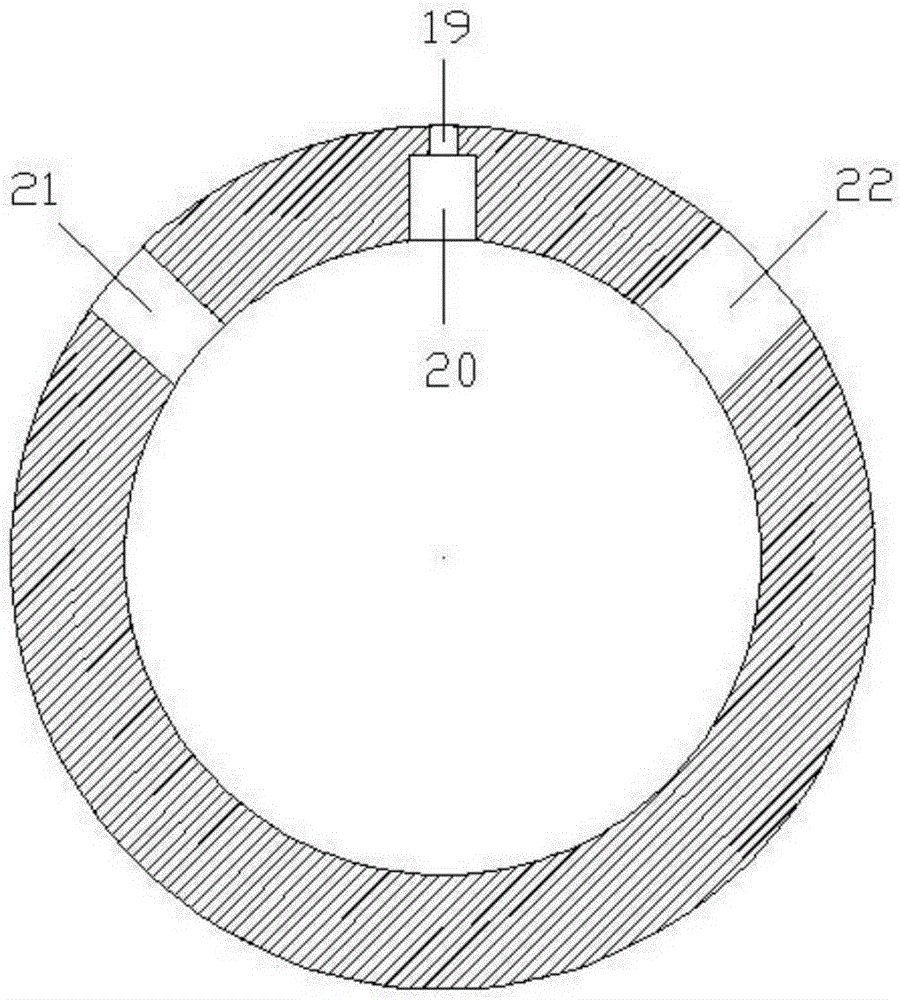

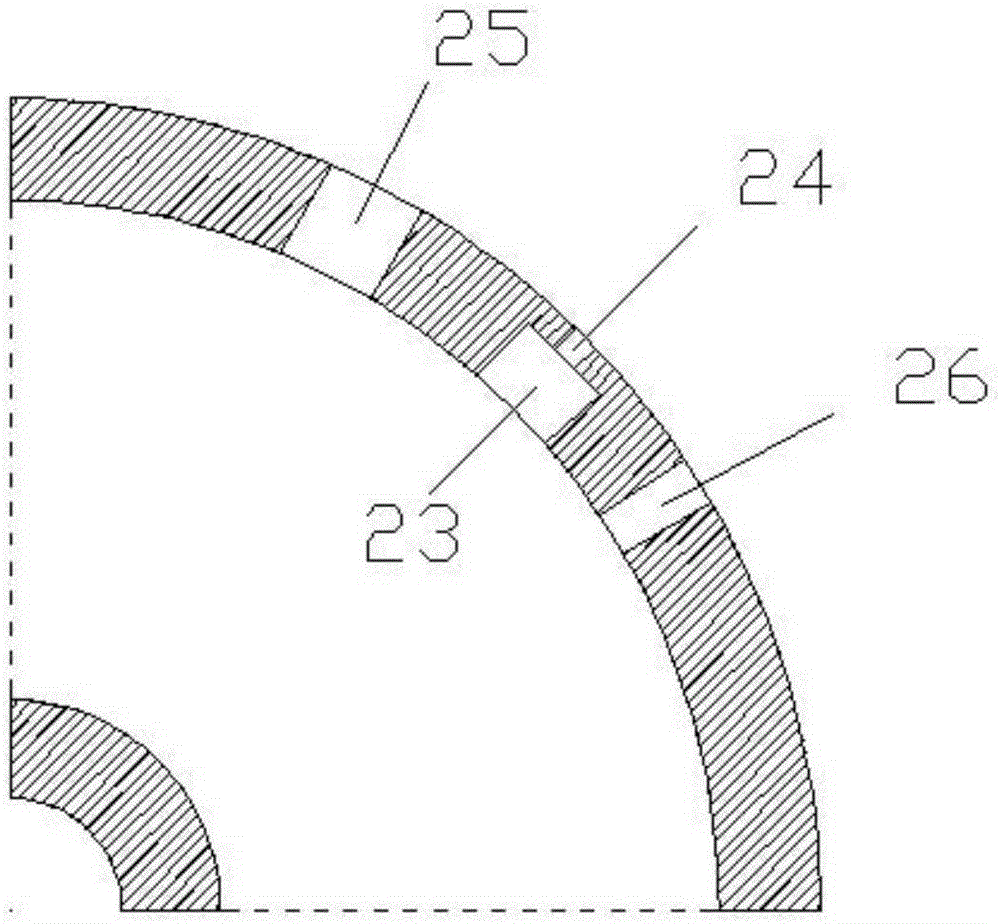

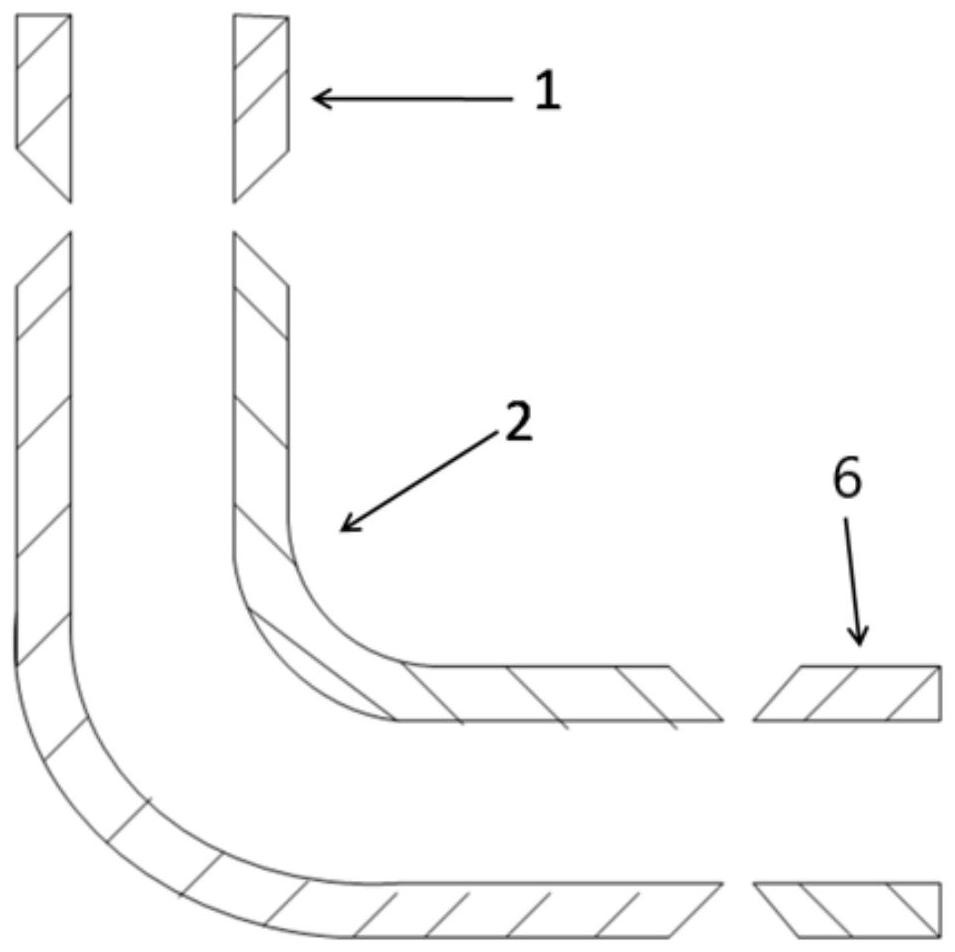

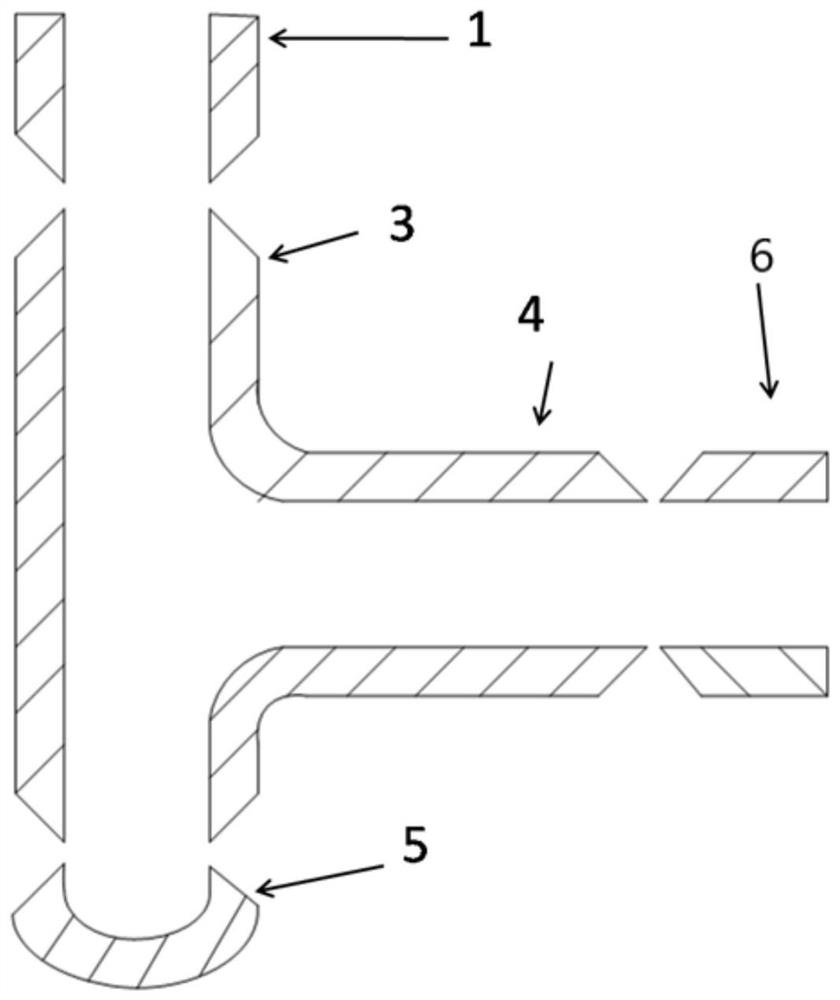

Pipeline structure capable of preventing scouring and flow accelerated corrosion and changing flow direction of fluid

PendingCN113431974AExtended service lifeImprove securityPipe elementsBranching pipesMining engineeringStraight tube

The invention provides a pipeline structure capable of preventing scouring and flow accelerated corrosion and changing the flow direction of fluid. The pipeline structure comprises a first straight pipe section and a second straight pipe section, wherein the first straight pipe section and the second straight pipe section are connected through a connecting component used for buffering the flow speed of the fluid. The novel structure for changing the flow direction of the fluid provided by the invention has great significance in prolonging the service life of a pipeline system, reducing the maintenance difficulty of the pipeline system and improving the safety and the reliability of pipeline operation, and also has very wide application prospects.

Owner:XIAN THERMAL POWER RES INST CO LTD

Gas-liquid two-phase flow loop corrosion experimental device

The invention relates to the field of oil and gas field corrosion research, in particular to a gas and liquid two-phase flow loop corrosion experiment device, which is applicable to coupon corrosion experiment and in-situ corrosion electrochemical test of gas and liquid two-phase flow of an oil and gas field production system on an oil pipe under the simulated working condition. An experiment testing module is arranged in a horizontal pipeline, and oil and gas field high-temperature and high-pressure fluid simulated by an experiment device is subjected to loop corrosion experiment by using an electrochemical workstation and a three-electrode electrochemical corrosion measuring device, so that flow accelerated corrosion weight loss and appearance features are obtained; an 'in-situ' electrochemical signal of a working electrode in simulated high-temperature and high-pressure fluid is monitored, so that the corrosion behavior and mechanism of the gas and liquid two-phase flow loop are mastered.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Membrane method to analyze the accelerated corrosion degree of water vapor system flow in supercritical unit

ActiveCN104359824BStrong targetingEnrichment effectWeather/light/corrosion resistanceAnalysis dataWater vapor

The invention relates to a method for analyzing the flow accelerated corrosion degree of a water vapor system of a supercritical unit. The method comprises the following steps: (1) making a standard color chart, and representing the colloidal iron content by taking the color of residues on each filter membrane as the color of the standard color chart; (2) directly connecting a sampling head with a water sample; (3) mounting the filter membrane, connecting the sampling head with a test point sampling pipe, filtering the water sample, enriching colloidal iron in the water sample, and drying; (4) collecting and testing the color chart of the water sample of the unit on site, emphatically the water sample with a relatively large amount of residues in the color chart, pointedly acquiring scale quantity analysis data of unit maintenance, and building a flow accelerated corrosion degree evaluation set; (5) comparing the color of the residues on the filter membrane with the color chart, quantifying the content of colloidal iron in different water samples, and quantitatively determining the flow accelerated corrosion degree according to the flow accelerated corrosion degree evaluation sample set. Compared with the prior art, the method is relatively high in accuracy, simple, feasible, low in analysis cost and relatively institutive in analysis result.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

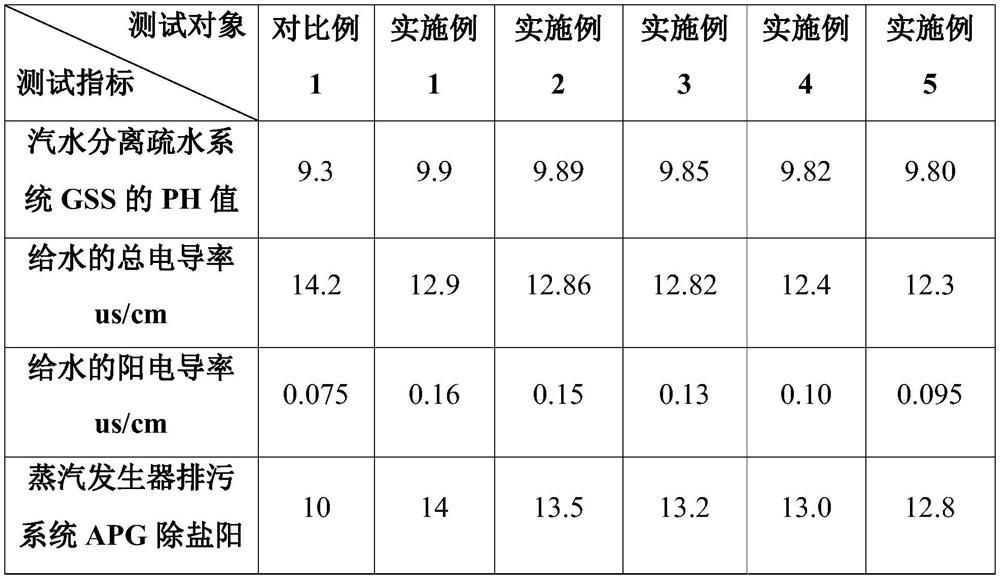

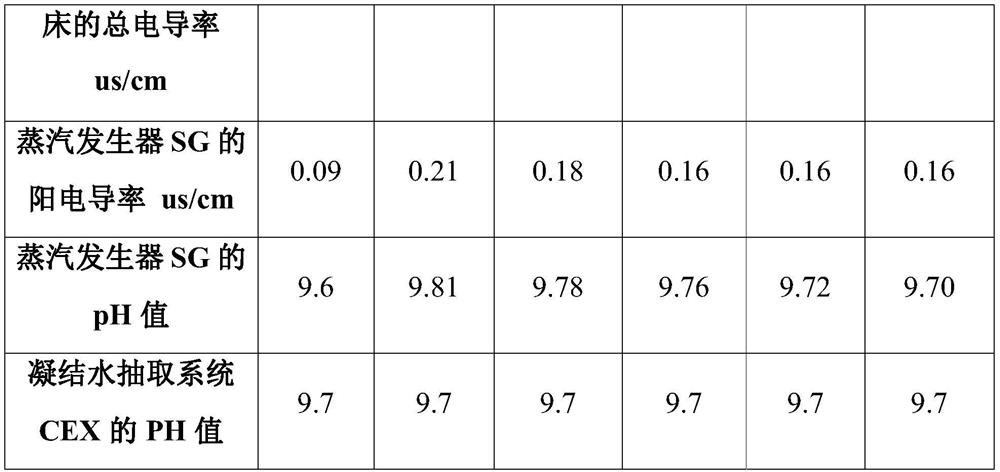

Nuclear power station secondary circuit pH adjusting method and system

PendingCN114477407AReduce corrosionImprove stabilityWater treatment parameter controlWater/sewage treatment by neutralisationThermodynamicsNuclear power

The invention belongs to the technical field of nuclear power station corrosion prevention, and particularly relates to a nuclear power station secondary circuit pH adjusting method and system. According to the method for adjusting the pH value of the secondary loop of the nuclear power plant, ethanolamine, ammonia water and hydrazine are adopted as pH adjusting agents of secondary loop feed water, so that the pH value of the feed water in the secondary loop of the nuclear power plant is 9.7-10 at the temperature of 25 DEG C. According to the method for adjusting the pH value of the secondary circuit of the nuclear power station, the pH value of the secondary circuit is more uniformly distributed through common adjustment of the ethanolamine, the ammonia water and the hydrazine, the pH value of feed water in the secondary circuit of the nuclear power station is 9.7-10 at 25 DEG C, particularly, the MSR hydrophobic pH value can be increased to 9.7, and corrosion of a structural material of the secondary circuit of the nuclear power station can be effectively reduced in the alkaline environment. Particularly, flow accelerated corrosion of a secondary loop and migration of corrosion products are reduced, and the service life of system components is prolonged.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +5

Chemical cleaning system and method for high-temperature and high-pressure experimental facility

ActiveCN113843206AReduce heat transfer powerEasy to cleanNuclear energy generationCleaning using liquidsOil and greaseProcess engineering

The invention relates to a chemical cleaning system and method for a high-temperature and high-pressure experimental facility. The cleaning system comprises a high-purity water instrument and a dosing box, the dosing box is connected to a heat exchanger through a cleaning dosing pump and a dosing pipeline, then cleaning fluid enters the high-temperature and high-pressure experimental facility, and cleaning power is provided by a high-temperature and high-pressure circulating pump; After passing through an outlet door of the circulating pump, the cleaning fluid enters a flow accelerated corrosion measuring electrode and then enters the heat exchanger to exchange heat, and after heat exchange, one path passes through a preheater and a reaction kettle to continue circular cleaning in an experimental loop; and the other path is cooled by a cooler, the pressure of the experimental circulation loop is maintained by a back pressure valve, and then the cleaning fluid returns to the dosing box for continuous circulation. By means of the system and method, systematic and efficient cleaning of the high-temperature and high-pressure experimental facility can be achieved, various kinds of grease such as various corrosion products, anti-rust oil, cutting lubricating oil and sealing oil can be completely removed, it is guaranteed that the interior of the high-temperature and high-pressure experimental facility is clean, and the accuracy of experimental results is guaranteed.

Owner:XIAN THERMAL POWER RES INST CO LTD

Common pipe ditch cast-in-place extrusion flow state concrete lining material

The invention relates to a common pipe ditch cast-in-place extrusion flow state concrete lining material, which is used in an extrusion flow state concrete material. strength grade of configured concrete is C30, 42.5 grades ordinary Portland cement is adopted, content of C3A is required to be less than 8%, fineness modulus of fine aggregate are 2.6-3.0, grain size scope of coarse aggregate is 5-31.5mm, sand ratio is 36-40%, coal ash occupies 20% of total weight of gelled materials, and water to binder ratio scope is controlled in a range of 0.40-0.44. Mix proportion with the unit of Kg / m3 of the concrete material is the cement of 320-355, the river sand of 630-690, the gravel of 1080-1160, the coal ash of 80-90, water of 175-185, and dosage of flow accelerated corrosion (FAC) high efficiency slushing agent is 1.5-1.8% of the weight of the gelled material. The common pipe ditch cast-in-place extrusion flow state concrete lining material conducts a 1:1 testing model test, workability index, strength index and cement dosage all meet requirements, and anti-permeability of the concrete is larger than P20. Various indexes of the concrete all meet design requirements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

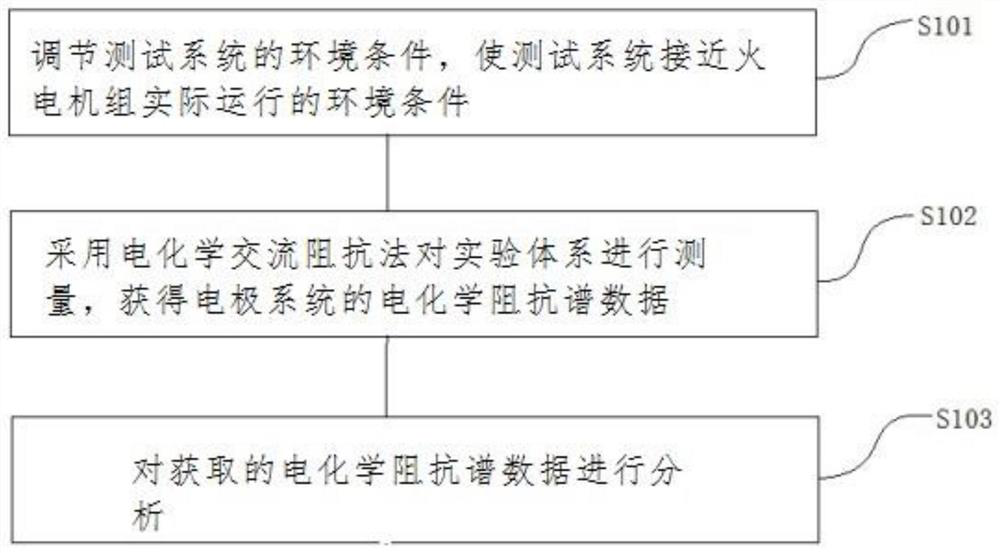

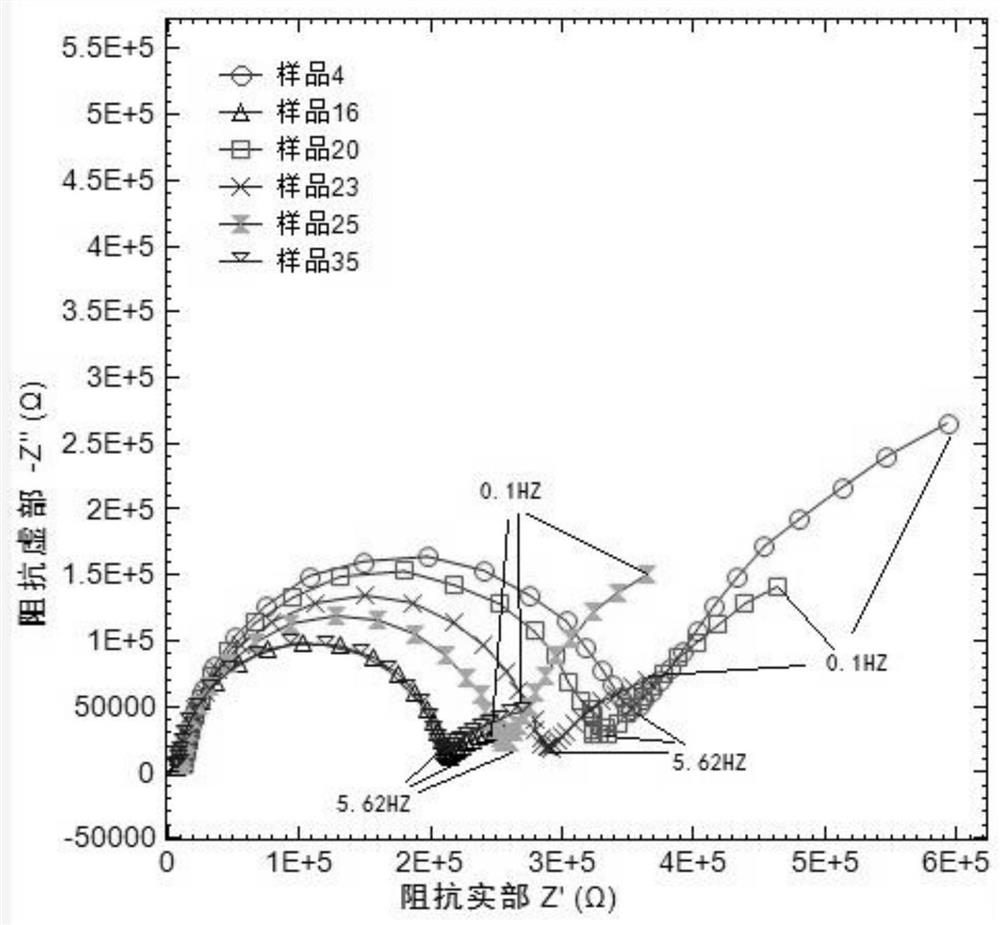

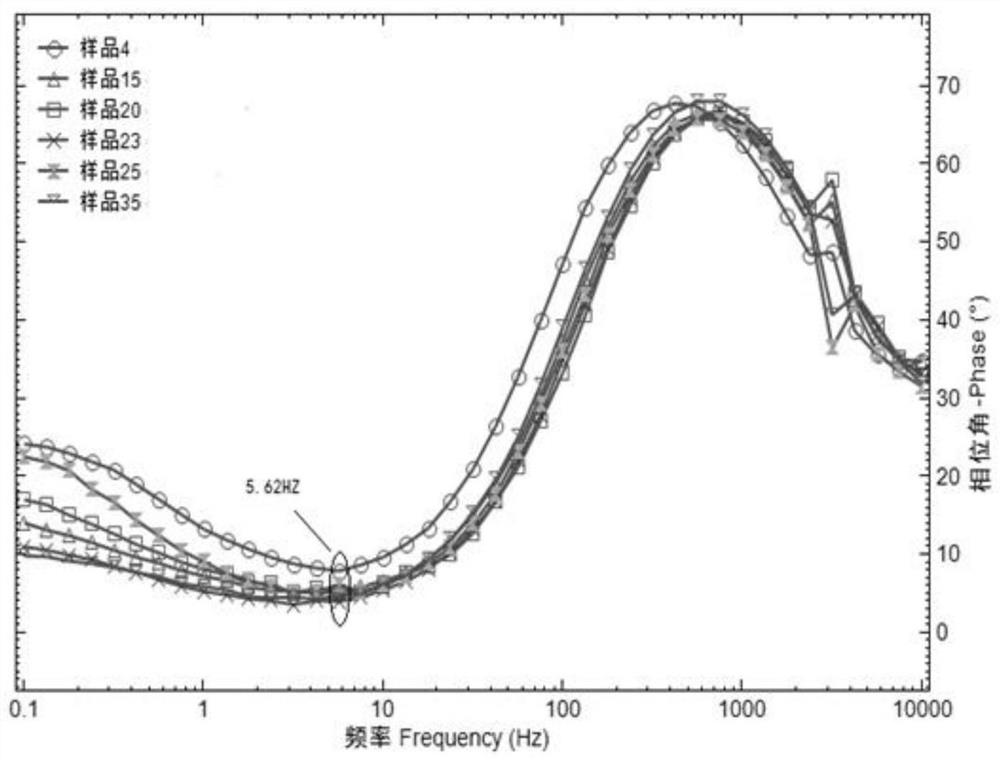

Flow accelerated corrosion experiment test analysis method and system

InactiveCN114199973AEliminate FAC phenomenonMaterial analysis by electric/magnetic meansExperimental testingTest analysis

The invention discloses a flow accelerated corrosion experiment test analysis method and system, and the analysis method comprises the steps: adjusting the environment condition of a test system, and enabling the test system to meet the actual operation environment condition of a thermal power generating unit; measuring the experimental system by adopting an electrochemical alternating-current impedance method to obtain electrochemical impedance spectroscopy data of the electrode system; and analyzing the acquired electrochemical impedance spectroscopy data. According to the method, the actual operation environment condition of the thermal power generating unit can be approached, in addition, the accurate FAC experiment data is greatly helpful for the mechanism analysis of the FAC, the accurate FAC experiment data can be obtained under the environment condition of an electrochemical measurement method and a control experiment system, and the FAC phenomenon in a water supply and drainage system can be eliminated.

Owner:中国电建集团江西省电力设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com