Power station flow accelerated corrosion simulation experiment pipeline apparatus with electrochemistry measurement mode

A flow-accelerated corrosion and measurement method technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., to achieve the effect of shortening the experiment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

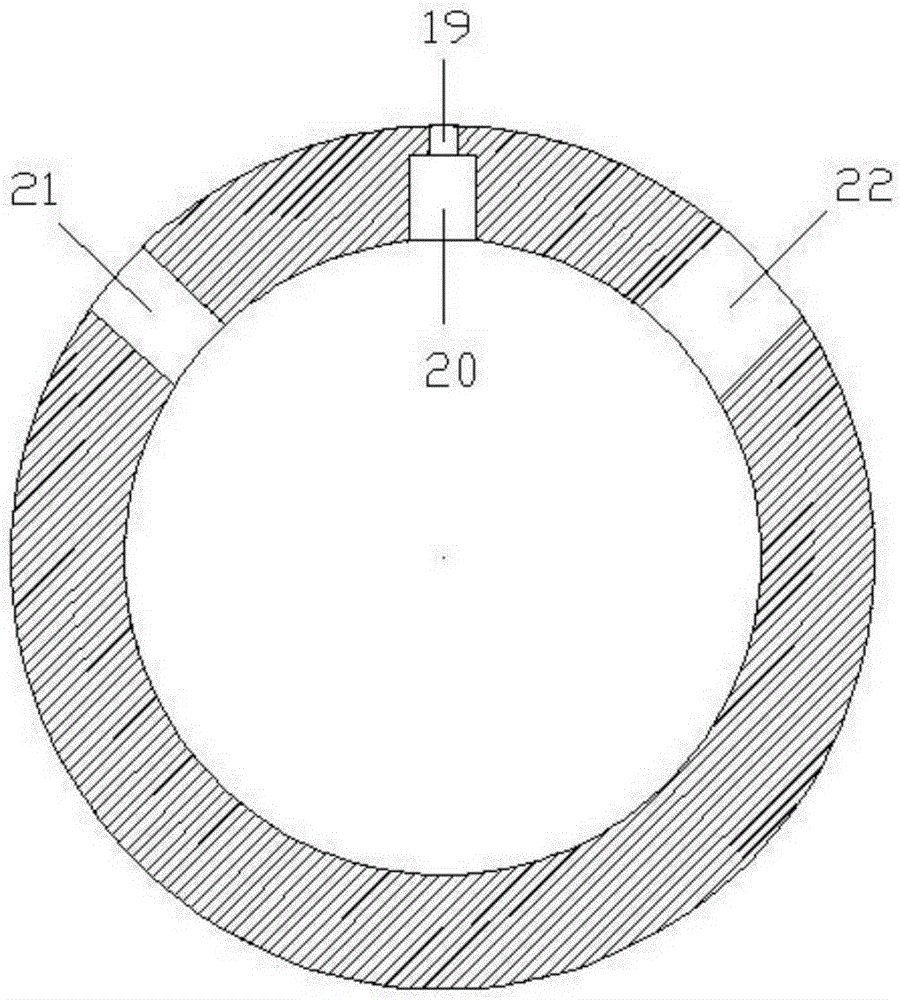

[0030] Such as figure 1 As shown, the wires and working electrodes of the horizontal pipeline in the corrosion test section are respectively embedded in the first wire hole 19 and the first working electrode hole 20, and the Ag / Agcl electrode is installed in the first reference electrode hole 21 as a reference electrode. An electrode as an auxiliary electrode is installed into the first auxiliary electrode hole 22 .

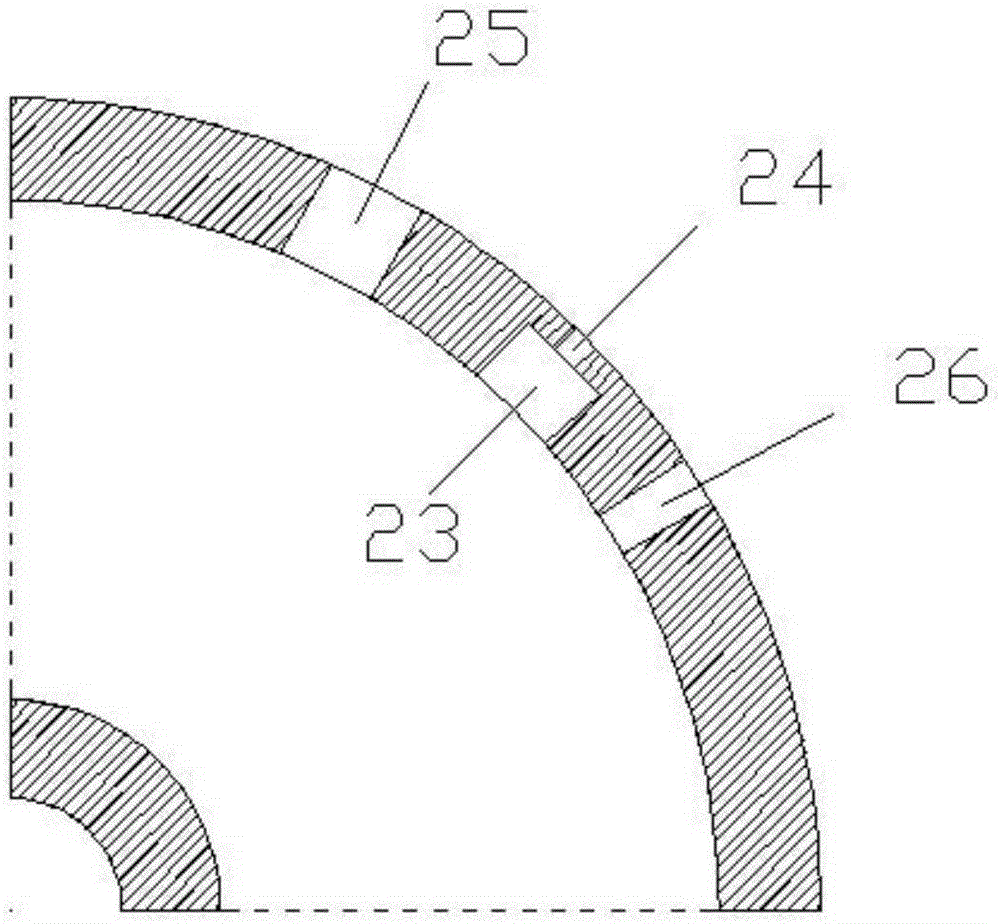

[0031] Such as figure 2As shown, the wire 17 and the working electrode of the complex flow pipeline in the corrosion test section are respectively embedded in the second wire hole 24 and the second working electrode hole 23, and the platinum disk electrode is installed in the second auxiliary electrode hole 25 as the auxiliary electrode, and the Ag / The Agcl electrode is installed into the second reference electrode hole 26 as a reference electrode.

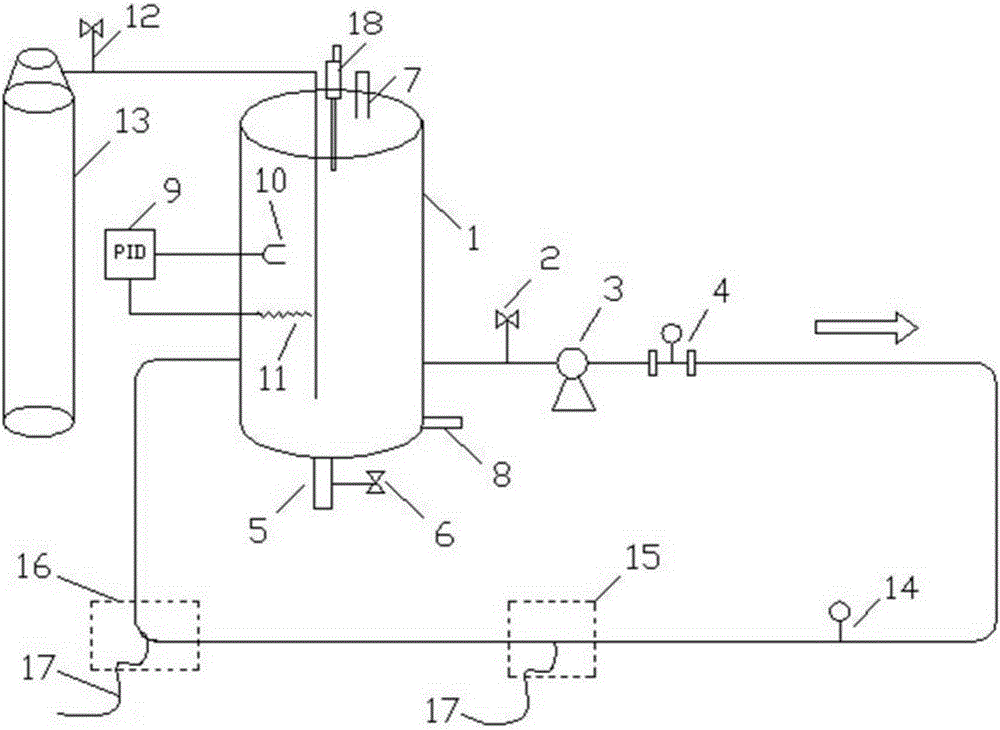

[0032] like image 3 As shown, when the pipeline device of the electrochemical measurement mode of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com