Seamless steel tube for nuclear power and production method thereof

A seamless steel pipe, nuclear power technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of large flow rate, high medium flow rate, low steam working parameters, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

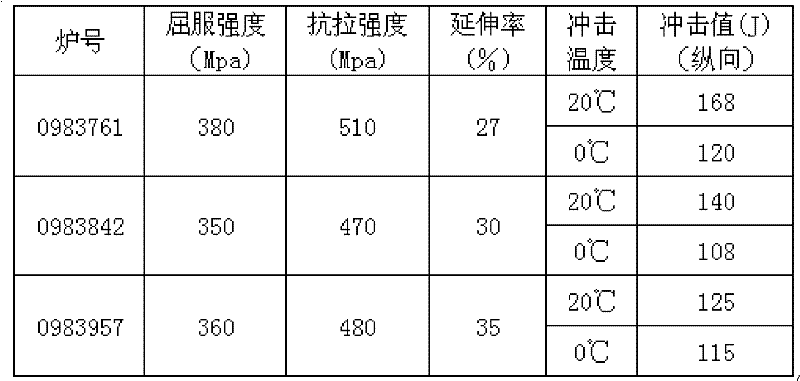

[0016] Embodiment Production of seamless steel pipe for nuclear power of the present invention

[0017] 1. Smelting tube billet

[0018] See Table 1 for the chemical composition of the smelted tube billet by weight percentage.

[0019] Table 1 Chemical composition of tube billets (%)

[0020] furnace number

C

Si

mn

Cr

P

S

0983761

0.19

0.26

0.50

0.32

0.010

0.006

0983842

0.20

0.24

0.48

0.20

0.012

0.008

0983957

0.22

0.27

0.52

0.26

0.013

0.007

[0021] In the process of smelting, refining outside the furnace, and casting, the operation is strictly in accordance with the specifications, so that the chemical composition of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com