Dosing system and method for deoxidant hydrazine for secondary loop system of high-temperature gas cooled reactor nuclear power plant

A high-temperature gas-cooled reactor and dosing system technology, applied in chemical instruments and methods, degassed water/sewage treatment, water/sludge/sewage treatment, etc. Large ammonia addition amount and other problems can avoid rapid decomposition and reduce flow to accelerate corrosion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation examples.

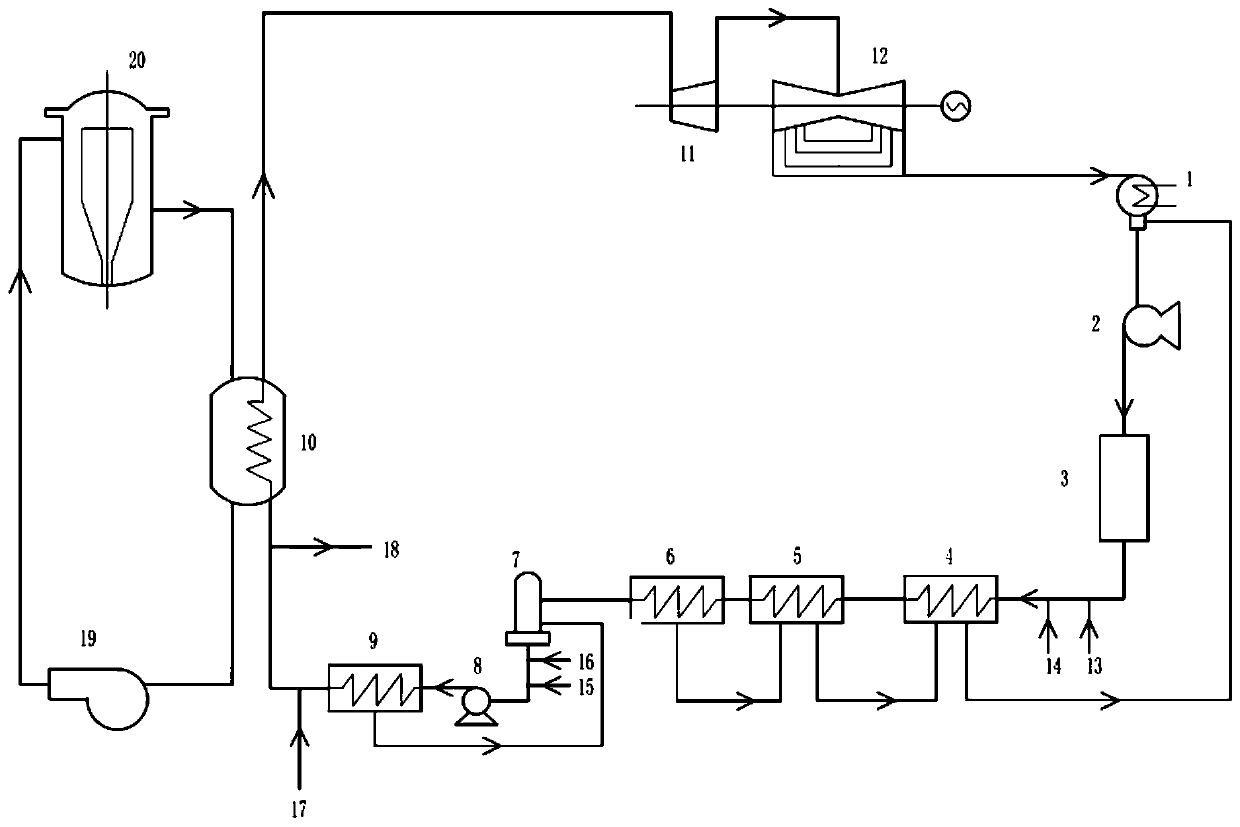

[0021] Such as figure 1 As shown, the secondary circuit system of a high temperature gas-cooled reactor nuclear power plant includes a condenser 1, a condensate pump 2, a condensate polishing device 3, a first-stage low-pressure heater 4, a second-stage low-pressure heater 5, and a third-stage low-pressure heater connected in sequence. 6, deaerator 7, feed water pump 8, high-pressure heater 9, steam generator 10, high-pressure cylinder 11 and low-pressure cylinder 12, the primary circuit is a nuclear reactor 20, helium blower 19 and steam generator 10 connected in sequence. The water vapor process of the secondary circuit system of the high-temperature gas-cooled reactor nuclear power plant is as follows: demineralized water is added to the condenser 1, and the condensed water is transported to the condensed water polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com