Full-automatic boiler feedwater oxygenating device and full-automatic boiler feedwater oxygenating method

A boiler feed water, fully automatic technology, applied in chemical instruments and methods, comprehensive factory control, comprehensive factory control, etc., can solve the problems of accelerated corrosion of water flow in the water supply system, advanced scaling parts, and large deposition of iron oxide scale. Improve economic and social benefits, the boiler pressure difference rises significantly, and the boiler pressure difference decreases significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Taking the existing boiler feed water circulation system as an example below, the fully automatic boiler feed water oxygenation device and method of the present invention are further described:

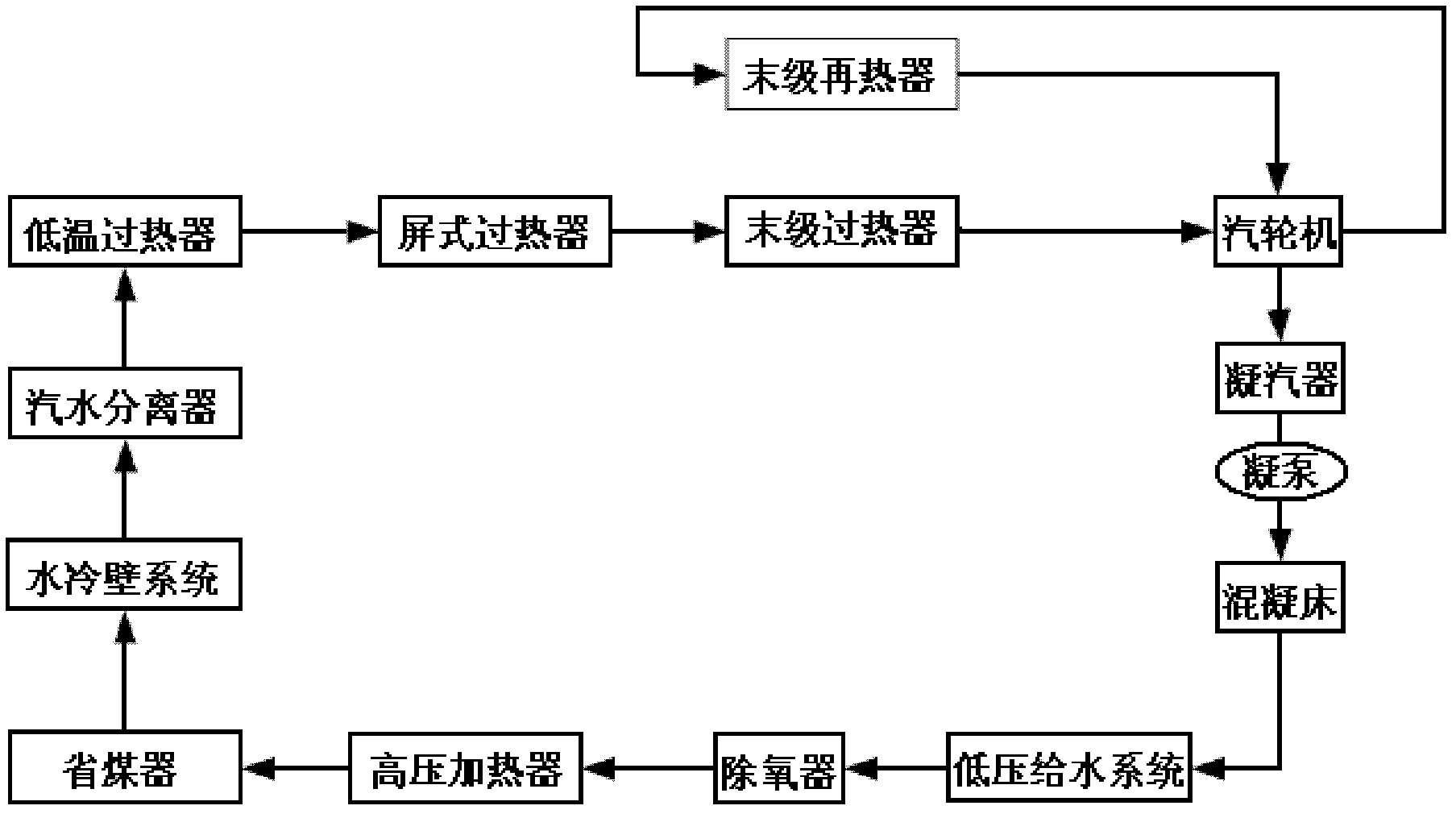

[0049] Such as figure 1 as shown, figure 1 Boiler feed water circulation system to be tested: including steam turbines, condensers, condensate pumps, coagulation beds, low-pressure water supply systems, deaerators, high-pressure heaters, economizers, water wall systems, steam-water separators for low-temperature superheating in series In addition, it also includes the final reheater for heat recovery and utilization of part of the steam in the steam turbine. The operation process of the above circulation system is: part of the steam from the steam turbine is diverted to the final reheater for reuse after heating, and the rest of the gas-liquid mixture from the steam turbine is condensed by the condenser, and then condensed water, water drainage and external supply The water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com