Segmental oxidation treatment system and treatment method of thermodynamic system of novel coal-fired power plant

A technology of oxidation treatment and thermal system, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. problems such as bed operation cycle, to achieve the effect of improving safety and economy, easy and accurate measurement and control, and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

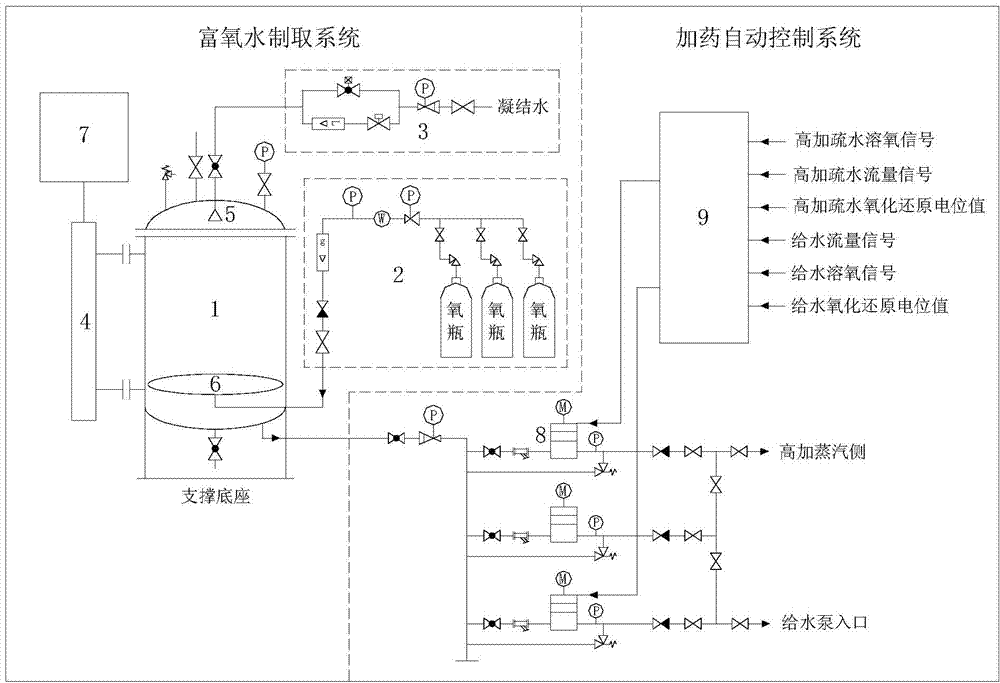

[0014] The structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] As shown in the attached figure, the oxygen used in the oxygen manifold 2 is industrial oxygen with a purity greater than 99.2%. The tank 1 and the aeration disc 6 distribute the oxygen from the oxygen manifold 2 into the closed pressure tank 1, and form a headspace pressure above the pressure tank 1, and the pressure can be adjusted in the range of 0.5-1.0 MPa. Then, the condensed water enters the pressure tank 1 from the top through the condensed water supply line 3 and is decompressed by the pressure reducing valve, and forms mist-like fine droplets through the high-pressure water mist nozzle 5, which fully contacts and mixes with the oxygen in the pressure space at the top. At this point, the metering pump 8 can be turned on to add medicine to the system. At the same time, the liquid level and pressure control system 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com