High-temperature high-pressure supercritical carbon dioxide flow accelerated corrosion test system and method

A flow-accelerated corrosion, high-temperature and high-pressure technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. The effect of sensitive control, stable operation and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

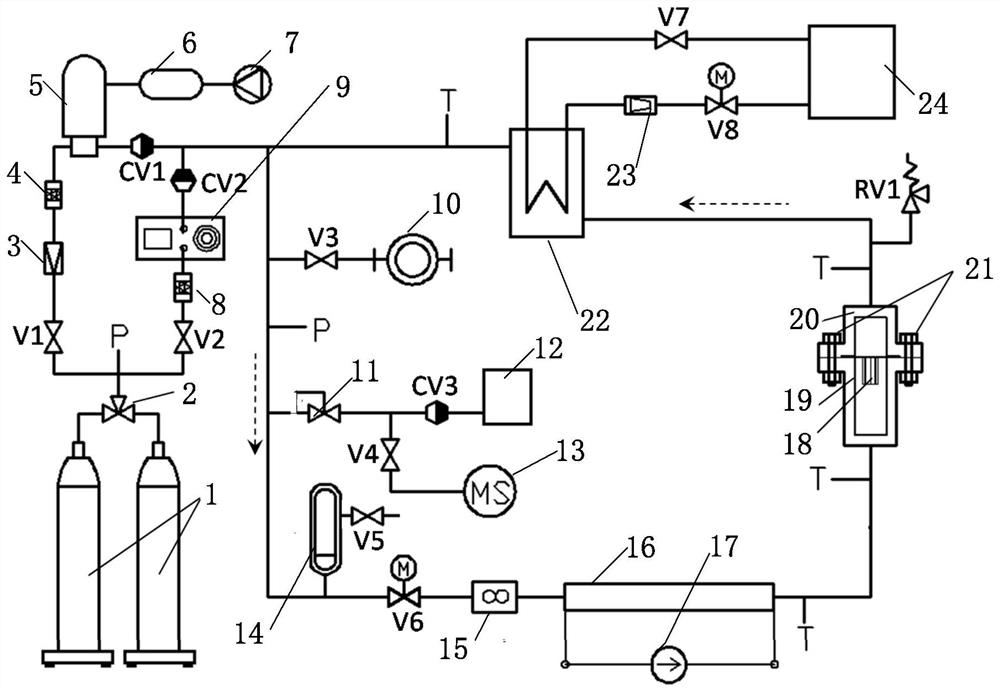

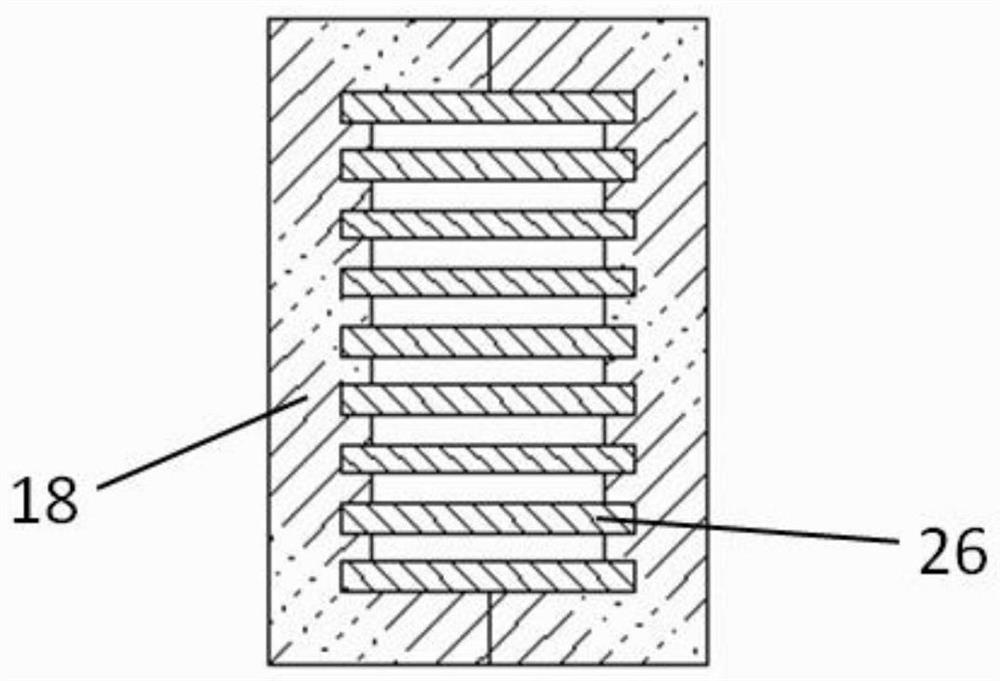

[0040] Such as Figure 1-Figure 3As shown, the high temperature and high pressure supercritical carbon dioxide flow accelerated corrosion test system includes a closed loop circuit and a gas supply system; the closed loop loop includes a pulse damper 14 connected by pipelines, a carbon dioxide mass flowmeter 15, an electric control valve V6, a heating Device 16, high-temperature and high-pressure reactor and cooler 22, the cooler 22 is arranged at the rear end of the high-temperature and high-pressure reactor, and the pulse damper 14, carbon dioxide mass flow meter 15, electric control valve V6, and heating device 16 are arranged at a high temperature At the front end of the high-pressure reactor, the outlet of the pulse damper 14 is provided with a shut-off valve V, and the closed loop is provided with 2 branches, one of which is provided with a shut-off valve V3 and a vacuum pump 10, and the vacuum pump 10 is used for The air in the equipment and pipeline is exhausted in the...

Embodiment 2

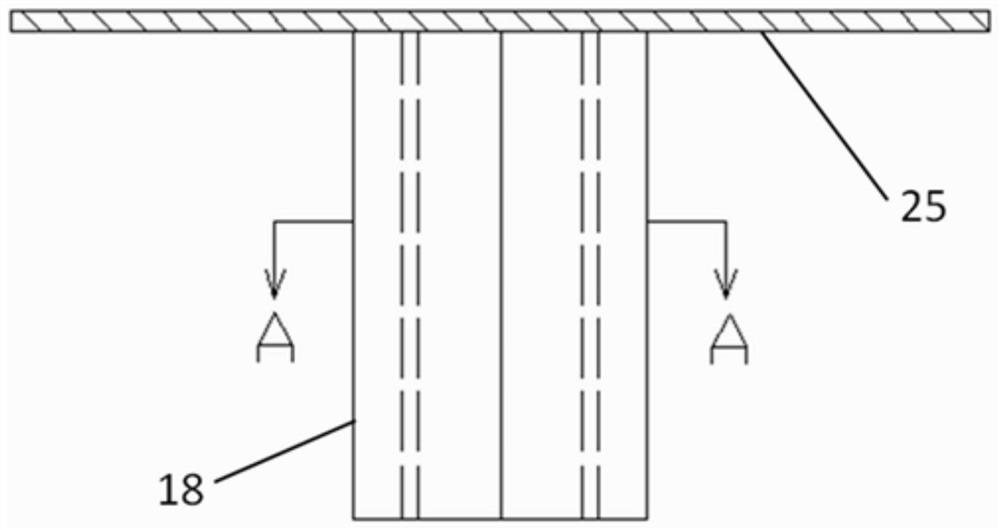

[0046] Such as Figure 1-Figure 3 As shown, this embodiment is based on Embodiment 1, and a baffle plate 25 is provided between the high-temperature and high-pressure reactor body 19 and the high-temperature and high-pressure reactor cover 20 .

Embodiment 3

[0048] Such as Figure 1-Figure 3 As shown, this embodiment is based on Embodiment 1, and also includes an alarm system, the alarm system includes a controller, and also includes an overpressure / low pressure alarm, an abnormal flow alarm, an over-temperature alarm, and a carbon dioxide alarm electrically connected to the controller. The abnormal gas composition alarm also includes a pressure sensor and a temperature sensor arranged on the closed loop, the pressure sensor and the temperature sensor are electrically connected to the controller, and the carbon dioxide mass flow meter 15 and the mass spectrometer 13 are electrically connected to the controller.

[0049] This embodiment is equipped with an overpressure / low pressure alarm, an abnormal flow rate alarm, an overtemperature alarm, and an abnormal carbon dioxide gas component alarm, and a series of actions occur through the existing computer control system to ensure the safety and reliability of the system. . When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com