Electromagnetic induction heating substrate and system thereof

An electromagnetic induction heating and induction heating technology, which is applied in the application and manufacture of cigars, tobacco, etc., can solve problems such as unfavorable miniaturization and stable operation of appliances, inaccurate measurement and control of temperature, uneven heating of cigarettes, etc., to avoid problems such as Effect of permeability, simple fixing structure, effect of reducing process complexity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The detailed features and advantages of the present invention are described below in the specific embodiments, and the content is sufficient to enable those skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the description, claims and drawings, those skilled in the art can Objects and advantages associated with the present invention are readily understood.

[0116] For ease of understanding, azimuth terms such as "upper", "lower", "top" and "bottom" used in this specification are based on the upright state of the electromagnetic induction heating substrate.

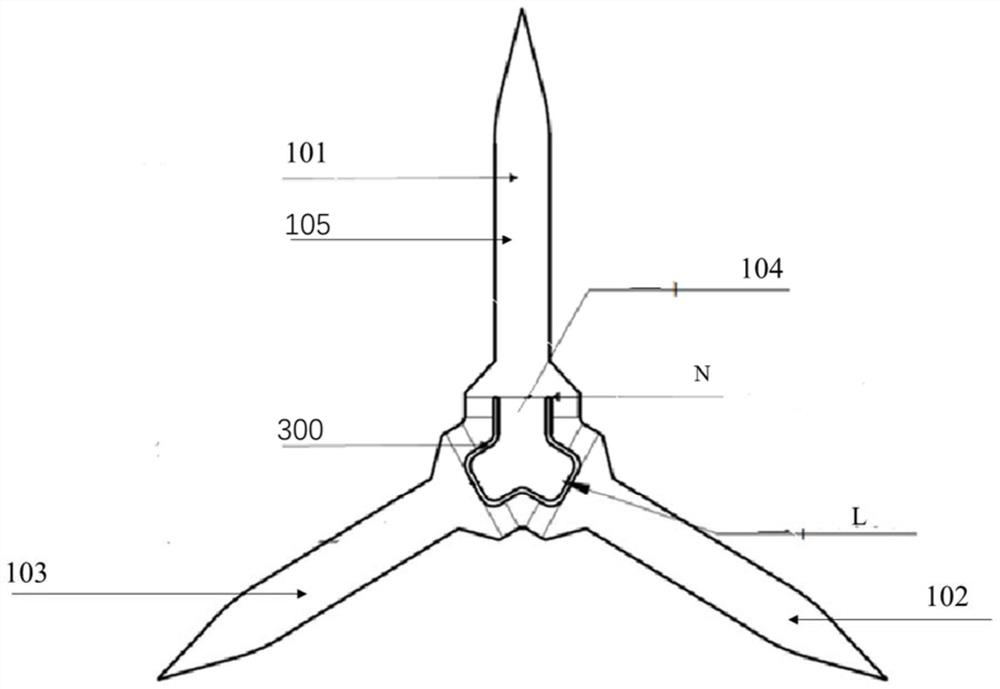

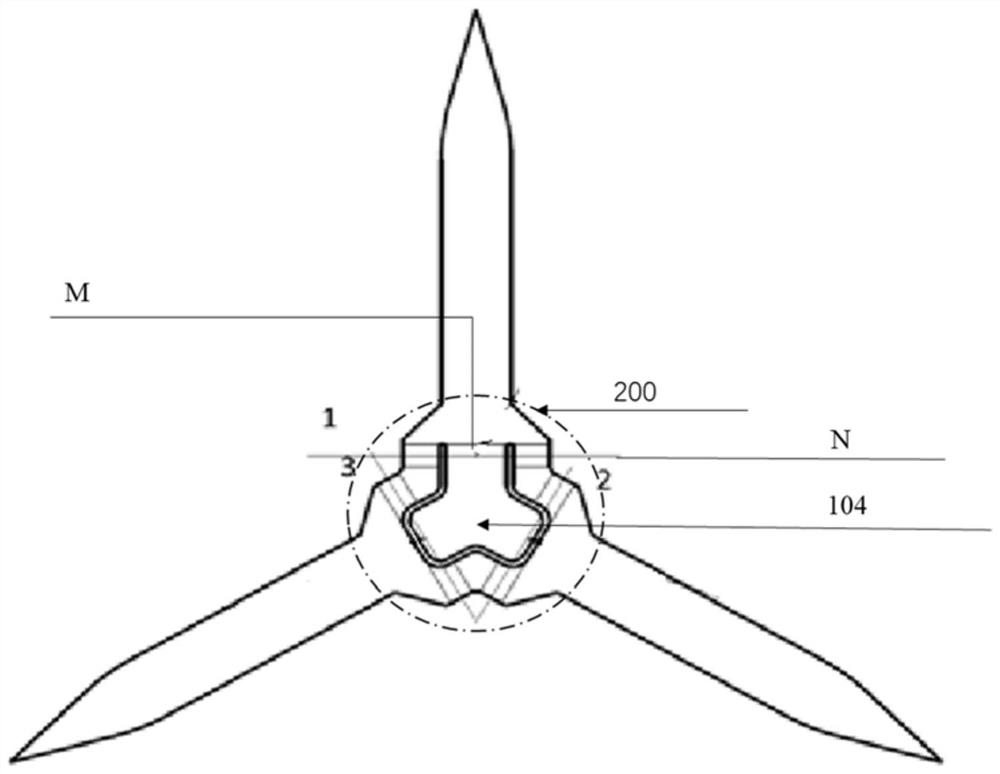

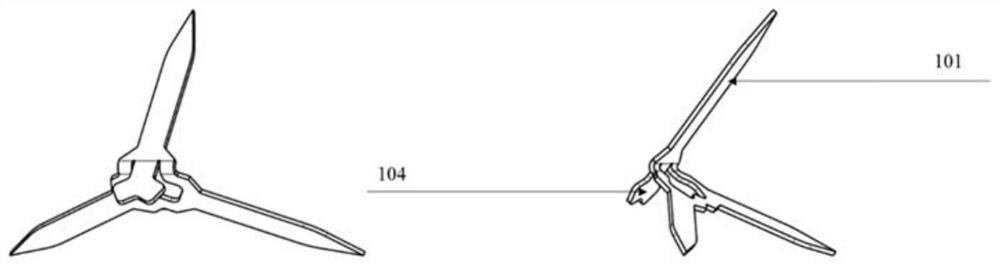

[0117] figure 1 An embodiment of an electromagnetic induction heating substrate is shown. In this embodiment, the electromagnetic induction heating base includes a first induction heating body 101 and a second induction heating body 102 and 103, and the induction heating bodies are distributed in the circumferential direction. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com