High barrier packaging laminate, method for manufacturing of the packaging laminate and packaging container

A technology for packaging laminated materials and barrier layers, applied in packaging, household packaging, packaging food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

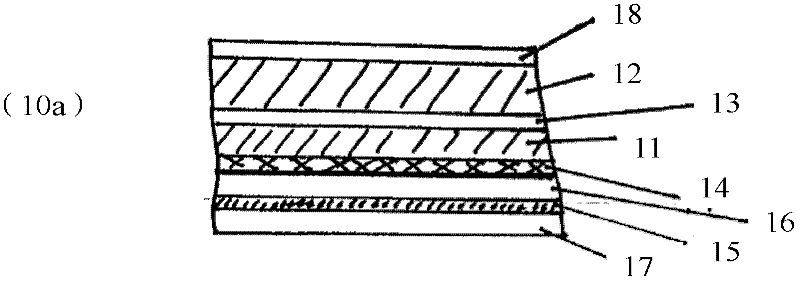

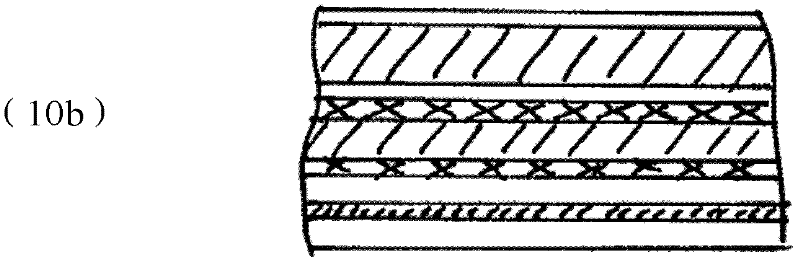

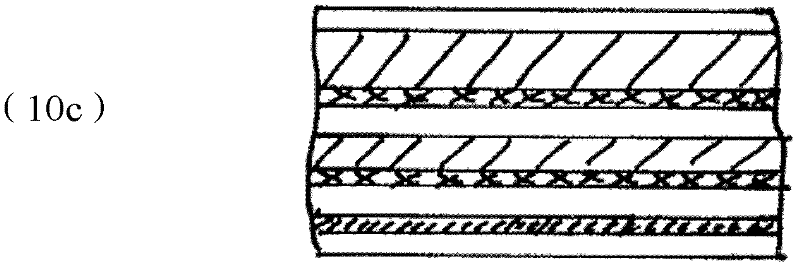

Image

Examples

Embodiment 1

[0140] 2 x 1 g / m 2 An aqueous solution of dissolved and dispersed PVOH and 30 wt% bentonite clay (calculated on dry matter) as a gas barrier component liquid film is applied to a liquid film with approximately 50 g / m 2 The surface area weight of tissue paper is used to produce packaging laminates.

[0141] Aqueous solution gas barrier composition preparation: about 1-5 wt% of an aqueous dispersion of exfoliated layered montmorillonite particles (Kunipia F from Kunimine Kogyo) having an aspect ratio of about 50-5000 was mixed with about 10 wt% of PVOH (Mowiol 15-99, with a degree of saponification above 99%), an aqueous solution was mixed at 60-90° C. for 1-8 hours. Dispersions of exfoliated layered mineral particles can be stabilized by stabilizer additives. Alternatively, the layered mineral particles may be exfoliated directly in a PVOH solution at 60-90°C during 1-8 hours.

[0142] The inside half of the first paper layer material with liquid film coating gas barrier is ...

Embodiment 2

[0147] In tests where similar liquid gas barrier compositions were coated onto different paperboard grades, it was further seen that widely varying oxygen transmission results were obtained. It is not entirely understood why different paperboards lead to different oxygen barrier results. Different paperboards as above were with 2 x 1 g / m of montmorillonite 2 PVOH coating and then further laminated with PE inner side or with metallized PE film, respectively, as described above. The oxygen transmission on the flat packaging laminate was measured at 23°C and 50% relative humidity. The following boards were coated (numbered from 1 to 8):

[0148] 1. 260mN

[0149] 2. 320mN

[0150] 3. 260mN

[0151] 4. 150mN

[0152] 5. 80mN

[0153] 6. Stora Enso 260mN

[0154] 7. International Paper 260mN

[0155] 8. Klabin 260mN

[0156] From Figure 7 As can be seen in the graph of the oxygen transmission value (cc / m 2 / day / atmospheric pressure (100% oxygen, 23°C, 50% rel...

Embodiment 3

[0166] By way of this example, a gas barrier layer comprising inorganic particles is combined with an inner side polyolefin-based layer having inorganic filler particles as a separation layer in a packaging laminate when coated onto a single paperboard in a laminate. The synergistic water vapor barrier effect resulting from the combination of water vapor barrier layers is shown.

[0167] According to the invention, a gas barrier composition is coated onto the first paper layer. A laminated pre-made inside with a moisture vapor barrier layer and an inside layer is laminated to a second paperboard layer in the final step. The barrier effect of the laminates of the present invention will be at least as good, or possibly even better, than according to the examples below.

[0168] The 2 x 1 g / m 2 An aqueous solution of dissolved and dispersed PVOH and 30 wt% bentonite clay (calculated on dry matter) as a gas barrier component liquid film was applied to the The company's 320mN C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com