High yield ratio and high-strength hot-dip galvanized steel sheet excellent in workability and production method thereof

A hot-dip galvanizing and high-strength technology, which is applied in the manufacture of tools, hot-dip galvanizing process, metal material coating process, etc., can solve problems such as low yield strength, uneven structure, and difficult particle precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

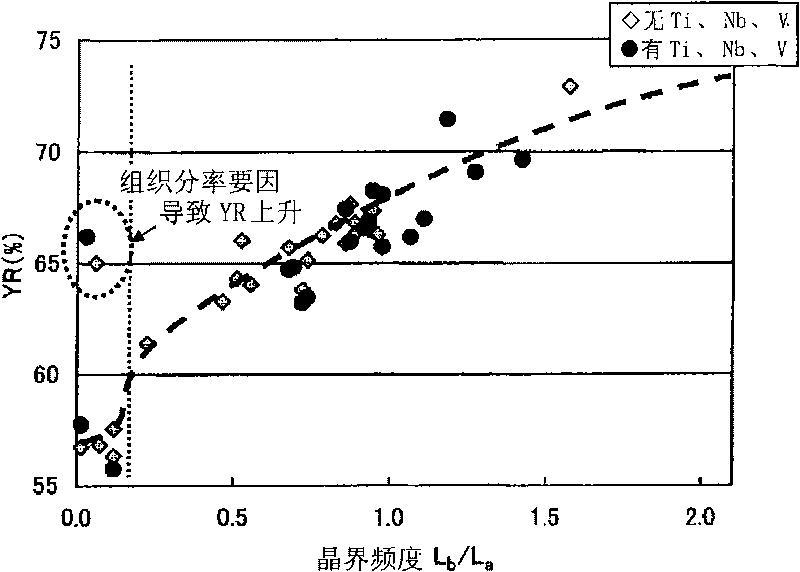

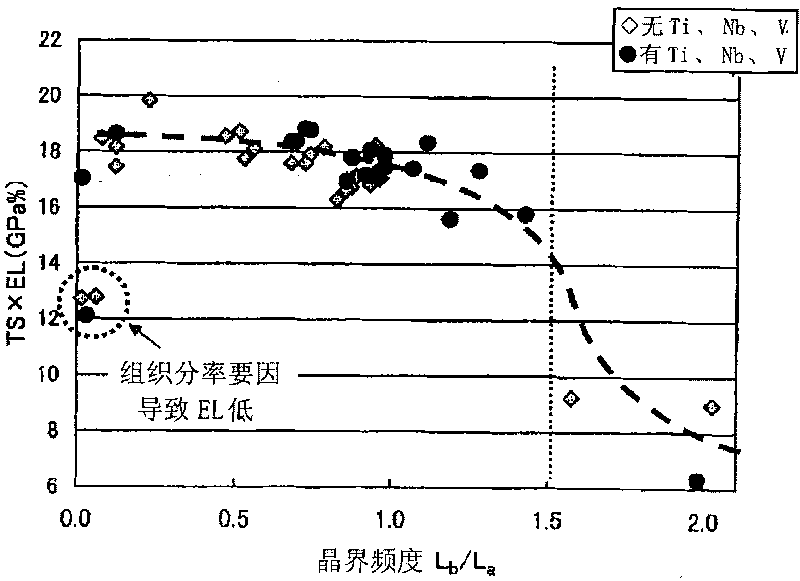

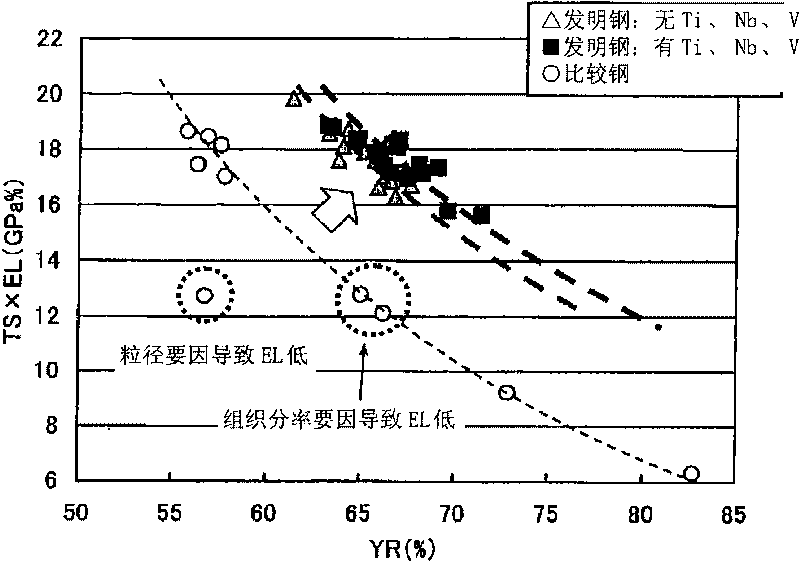

[0024] The inventors of the present invention have intensively studied in order to realize a high-strength hot-dip galvanized steel sheet of 980 MPa or more having a high yield ratio and excellent elongation in a steel sheet with a composite structure including ferrite and martensite in the metal structure. As a result, it was found that by controlling the composition of the steel and setting (i) the length L per unit area of the grain boundary with a crystal orientation difference of 10° or more a , and the length per unit area of a grain boundary with a crystallographic orientation difference below 10° is L b Ratio (L b / L a ) (hereinafter referred to as "grain boundary frequency") is controlled within a specified range, the yield ratio can be increased, and (ii) ferrite grains surrounded by grain boundaries with a crystal orientation difference of 10° or more When the equivalent circle diameter of the grains is D, reduce the average value of D to be less than 25 μm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com