Integrated electroplating treatment method for waste water

A technology for electroplating wastewater and wastewater treatment is applied in the field of recycling precious metal resources, which can solve the problems of secondary pollution of sludge, inability to recycle precious metals, and inability to reuse effluent, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

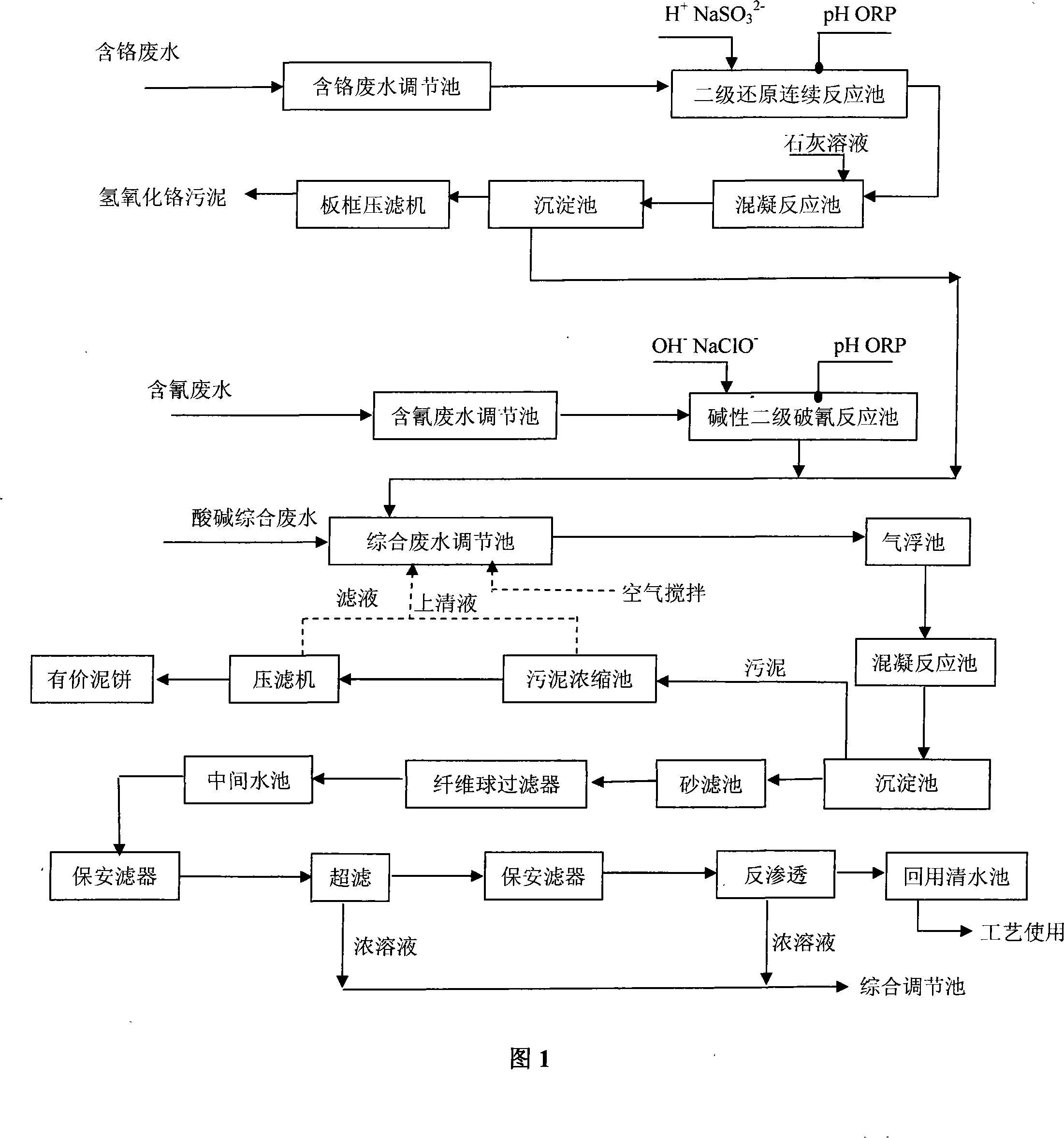

Image

Examples

Embodiment 1

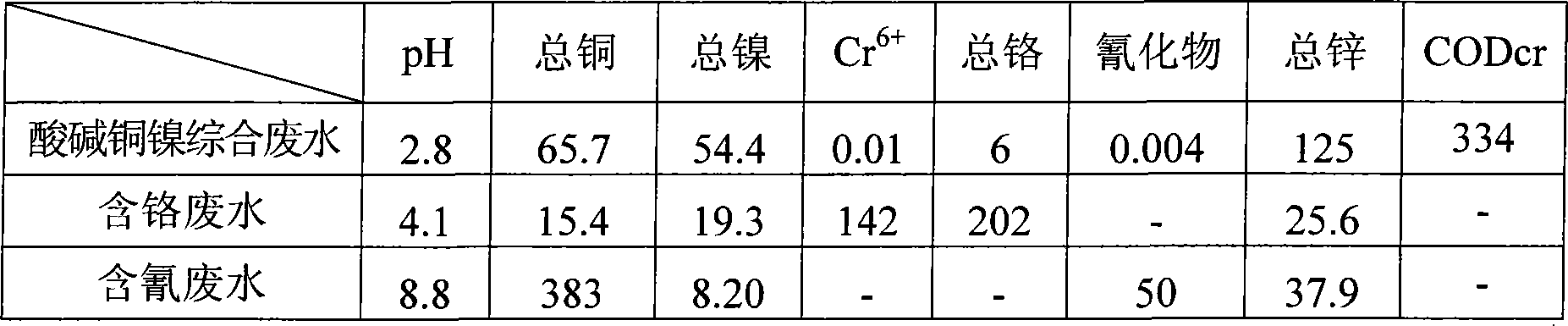

[0024] Example 1: An industrial park in Shenzhen discharges 3,000 tons of comprehensive electroplating wastewater every day. Influent water quality index:

[0025] Table 1 Sewage water quality of three kinds of sewage Unit: mg / L

[0026]

[0027] Use the method shown in Figure 1:

[0028] 1. Pretreatment of chromium-containing wastewater

[0029] The chromium-containing wastewater enters the pH value adjustment tank, and then enters the chromium reduction tank through the lifting pump. A set of pH automatic control system and ORP automatic control system are installed in the reduction tank. The pH control system automatically controls the amount of acid added to adjust the wastewater. The pH is 2.5, and at the same time, the addition of reducing agent is controlled by the ORP automatic control system, so that the ORP value of the wastewater is 250mV. Add NaOH to the reduced chromium-containing wastewater to control the pH value to 7.5, so that the trivalent chromium will...

Embodiment 2

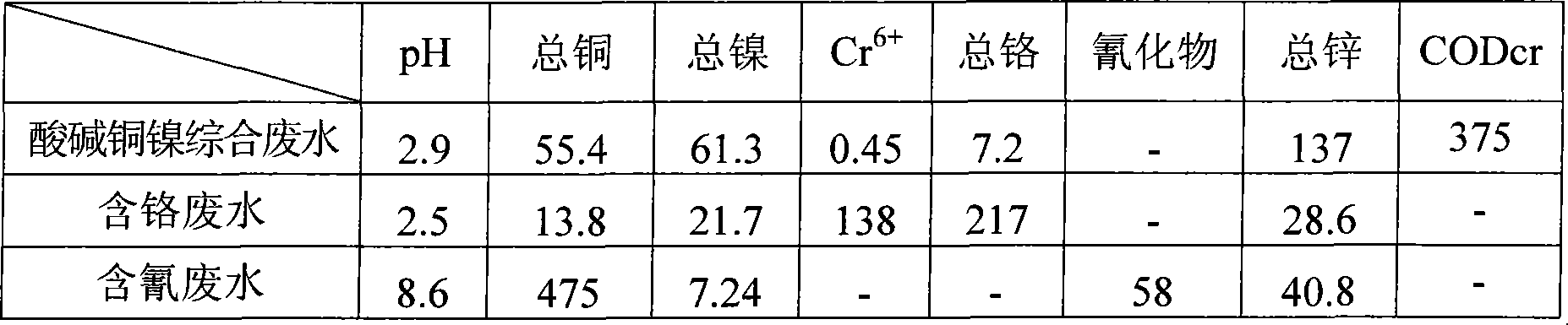

[0044] Example 2: Treatment and reuse of comprehensive electroplating wastewater in an "Electroplating City" (daily treatment capacity: 2,000 tons)

[0045] Table 1 Sewage Water Quality of Three Kinds of Sewage Unit: mg / L

[0046]

[0047] 1. Pretreatment of chromium-containing wastewater

[0048] The pH of the wastewater was adjusted to 2.7, and the ORP value of the wastewater reached 270mV by adding a reducing agent. NaOH was added to the reduced chromium-containing wastewater to control the pH to 7.8. The rest of the process steps were the same as in Example 1.

[0049] 2. Pretreatment of cyanide-containing wastewater

[0050] The pH of the wastewater is adjusted to 11, the ORP value is 330mV; the pH of the wastewater is adjusted to 7.7 in the secondary oxidation tank, the ORP value is 640mV, and the hydraulic retention time is 1 hour. All the other processing steps and reaction conditions are with embodiment 1.

[0051] 3. Comprehensive waste water

[0052] (1) Coag...

Embodiment 3

[0062] Example 3: Treatment and reuse of electroplating comprehensive wastewater in an electroplating enterprise (daily processing capacity: 2500 tons)

[0063] Table 1 Sewage Water Quality of Three Kinds of Sewage Unit: mg / L

[0064]

[0065] 1. Pretreatment of chromium-containing wastewater

[0066] Adjust the pH of the wastewater to 3.0, and make the ORP value of the wastewater reach 300mV by adding a reducing agent. Add NaOH to the reduced chromium-containing wastewater to control the pH value to 8.0, and the rest of the process steps are the same as in Example 1.

[0067] 2. Pretreatment of cyanide-containing wastewater

[0068] Adjust the pH of the wastewater to 11.8, the ORP value is 320mV; adjust the pH of the wastewater to 8.0 in the secondary oxidation tank, the ORP value is 650mV, and the hydraulic retention time is 1 hour. All the other processing steps and reaction conditions are with embodiment 1.

[0069] 3. Comprehensive waste water

[0070] (1) Coagula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com