Solid electrolyte for dye-sensitized solar cell and preparation method thereof

A technology of solar cells and solid electrolytes, applied in the field of dye-sensitized solar cells, can solve the problems of volatile electrolyte solvents, limited wide use, low electrolyte conductivity, etc., achieve excellent conductivity and ion mobility, improve stability and Effects that do not require high photoelectric conversion efficiency, equipment and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

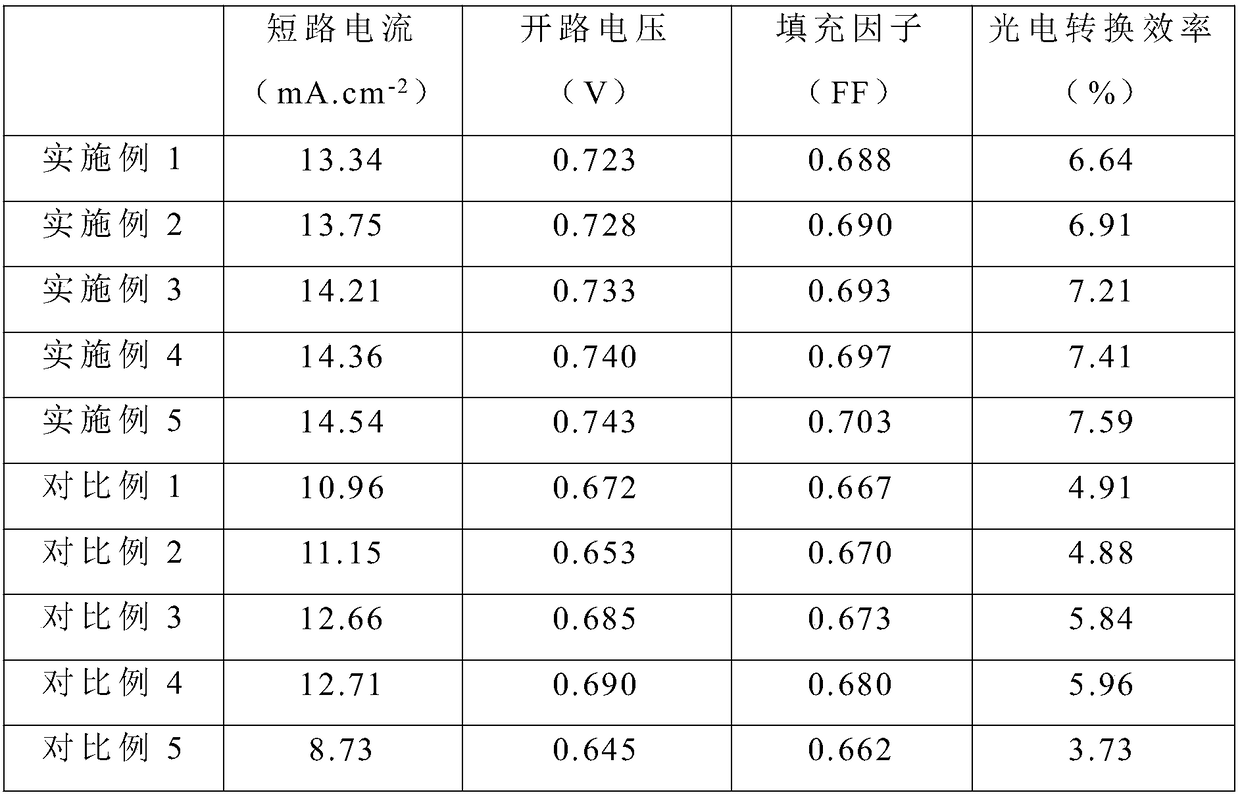

Examples

Embodiment 1

[0026] A dye-sensitized solar cell solid electrolyte, comprising the following components by weight: 30 parts of benzonitrile-type alkynyl quaternary ammonium salt ionic crystals, 3-cyanobenzyl-type tripropargyl quaternary ammonium salt organic ions 20 parts, 2 parts of ferroceneacetylene, 1 part of propylonitrile, 4 parts of simple iodine, 4 parts of lithium iodide, and 5 parts of methylbenzimidazole (MBI).

[0027] The preparation method of the benzonitrile-type alkynyl quaternary ammonium salt ion crystal comprises the following steps: dissolving 10 g of di-but-2-ynyl-amine and 41.5 g of 4,4'-chloromethylene diphenyl in In 100g of acetonitrile, and stirred at 40°C for 6 hours, then the solvent was removed by rotary evaporation, and the crude product was washed 5 times with ether, and finally the ether was removed by rotary evaporation, and it was baked in a vacuum oven at 50°C for 8 hours to obtain benzyl Nitrile type alkynyl quaternary ammonium salt ion crystal.

[0028] ...

Embodiment 2

[0034] A solid electrolyte for a dye-sensitized solar cell, comprising the following components by weight: 33 parts of benzonitrile-type alkynyl quaternary ammonium salt ionic crystals, 3-cyanobenzyl-type tripropargyl quaternary ammonium salt organic ions 23 parts, 3 parts of ferroceneacetylene, 2 parts of propylonitrile, 5 parts of simple iodine, 5 parts of potassium iodide, and 7 parts of butylbenzimidazole (NBB).

[0035] The preparation method of the benzonitrile-type alkynyl quaternary ammonium salt ion crystal comprises the following steps: dissolving 10 g of di-but-2-ynyl-amine and 41.8 g of 4,4'-chloromethylene diphenyl in In 110g of acetone, stirred and reacted at 43°C for 6.5 hours, then the solvent was removed by rotary evaporation, and the crude product was washed 6 times with ether, and finally the ether was removed by rotary evaporation, and baked in a vacuum oven at 52°C for 9 hours to obtain benzyl Nitrile type alkynyl quaternary ammonium salt ion crystal.

[...

Embodiment 3

[0042] A dye-sensitized solar cell solid electrolyte, comprising the following components by weight: 35 parts of benzonitrile-type alkynyl quaternary ammonium salt ionic crystals, 3-cyanobenzyl-type tripropargyl quaternary ammonium salt organic ions 26 parts, 3 parts of ferroceneacetylene, 2 parts of propylonitrile, 6 parts of simple iodine, 6 parts of 1-methyl-3-propylmethylimidazolium iodide, 7 parts of tert-butylpyridine (TBP).

[0043] The preparation method of the benzonitrile-type alkynyl quaternary ammonium salt ion crystal comprises the following steps: dissolving 10 g of di-but-2-ynyl-amine and 42 g of 4,4'-chloromethylene diphenyl in diphenyl In 130g of methyl chloride, stirred and reacted at 46°C for 7 hours, and then the solvent was removed by rotary evaporation, and the crude product was washed 7 times with ether, and finally the ether was removed by rotary evaporation, and placed in a vacuum oven at 56°C for 10 hours to obtain benzene A cyanonitrile-type alkynyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com