Mixed rare earth compound-doped and modified lithium iron phosphate cathode material and preparation method thereof

A cathode material, lithium iron phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of environmental pollution, complex separation process of rare earth elements, high cost, and achieve good compatibility, excellent cycle performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

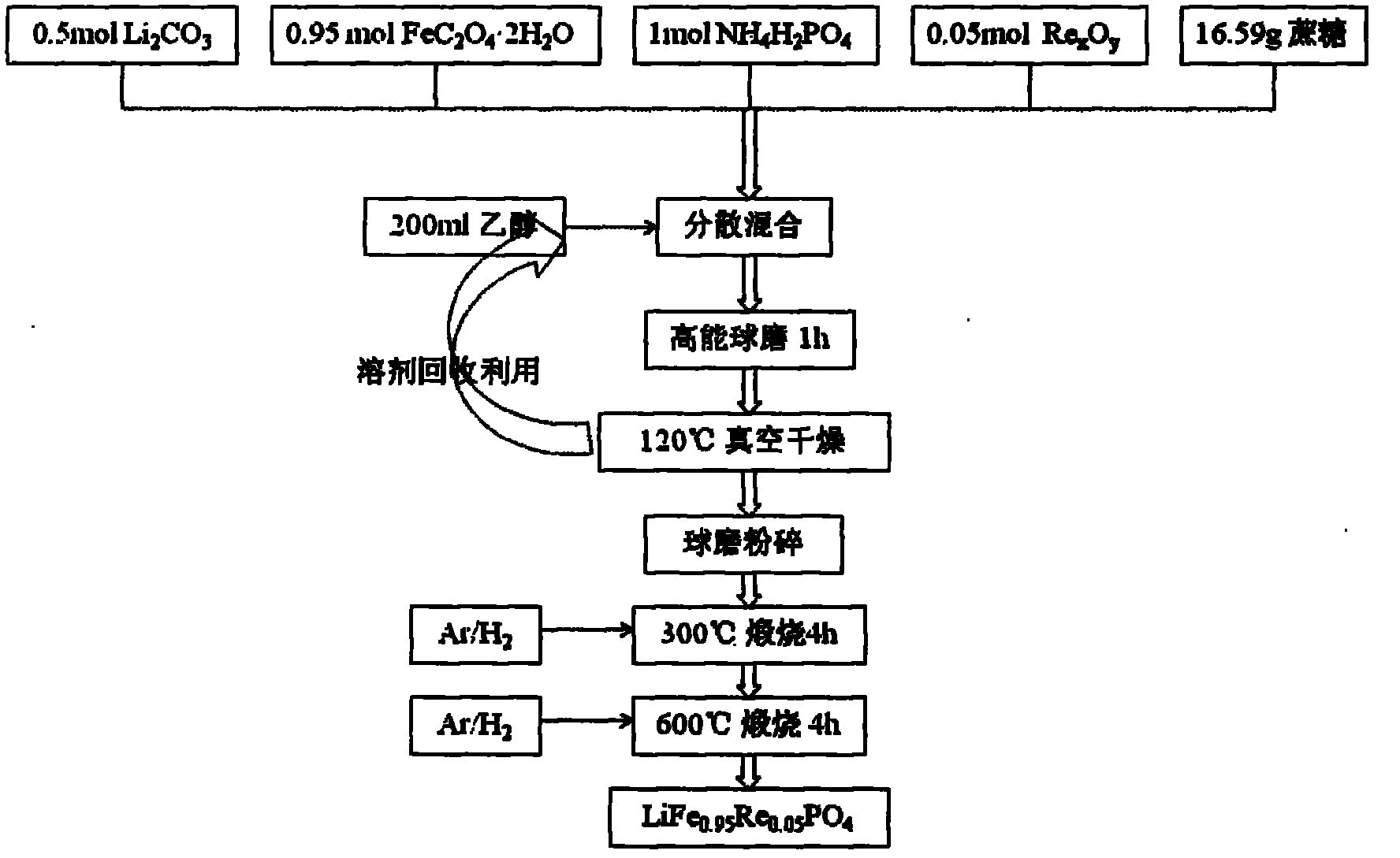

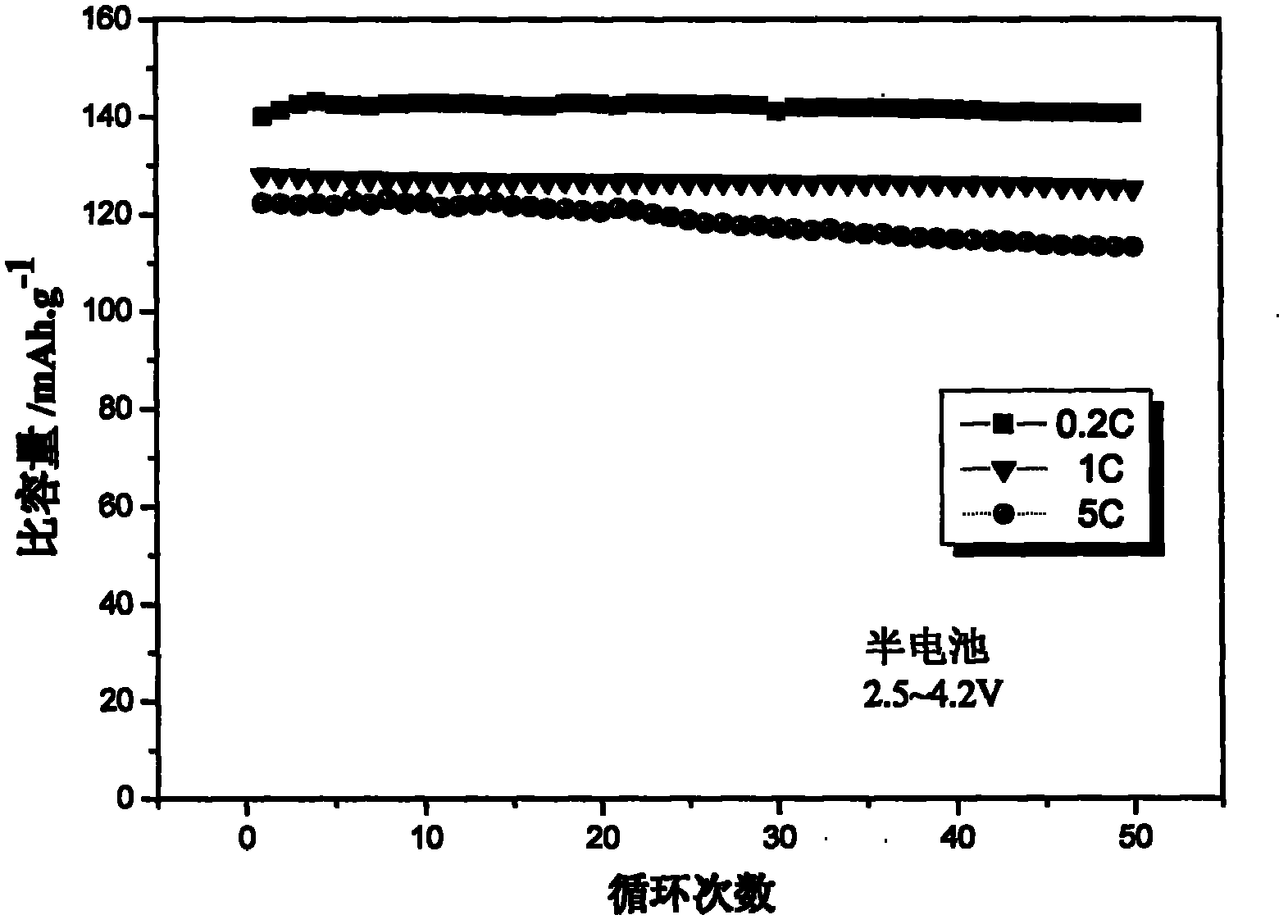

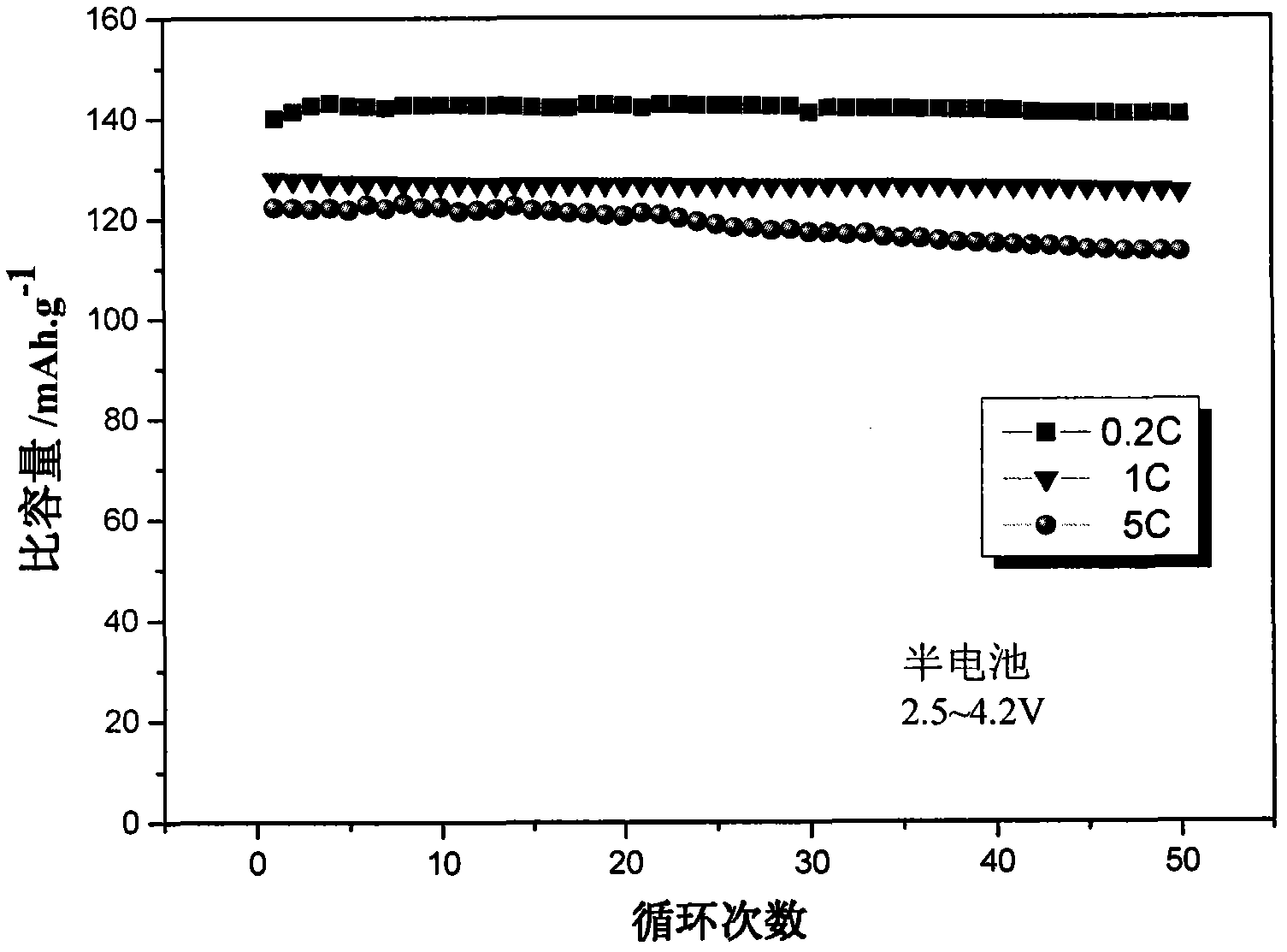

[0034] Mix 0.5mol of lithium carbonate, 0.95mol of ferrous oxalate, mixed rare earth oxides containing 0.05mol of rare earth elements and 1mol of ammonium dihydrogen phosphate, add 16.59g of sucrose, add 200ml of absolute ethanol to mix and disperse, and use a horizontal Type grinding equipment for grinding for 1 hour, using a solvent recovery drying oven to dry at 120°C, and recycling the dispersant at the same time; after crushing the dried material, use a planetary ball mill for dry ball milling for 2 hours to obtain the precursor of lithium iron phosphate cathode material . The precursor was placed in a tube resistance furnace under Ar / H 2 Under the atmosphere, after pre-calcining at 300°C for 4 hours, cool to room temperature, grind and compact, then carry out secondary calcination under the protection of the inert atmosphere in the above-mentioned furnace body, the calcination temperature is 600°C, the calcination time is 2h, cool to room temperature, and use The planet...

Embodiment 2

[0037] Mix 1 mol of lithium hydroxide, 0.49 mol of ferric oxide, mixed rare earth oxides containing 0.02 mol of rare earth elements and 1 mol of ammonium dihydrogen phosphate, add 30.1 g of sucrose, add 300 ml of absolute ethanol to mix and disperse, and use Grind for 4 hours with a horizontal grinding device, dry at 180° C. with a centrifugal spray dryer, and dry ball mill for 2 hours with a planetary ball mill to obtain a lithium iron phosphate cathode material precursor. Place the precursor body in a pusher furnace at N 2 / H 2 Under a reducing atmosphere, pre-calcine at 400°C for 2 hours, cool to room temperature, grind and compact, then carry out secondary calcination under the protection of the inert atmosphere in the furnace body, the calcination temperature is 700°C, the calcination time is 5h, and cool to room temperature. Use a planetary ball mill to crush the calcined material to the required particle size to obtain LiFe 0.98 Re 0.02 PO 4 / C cathode material.

...

Embodiment 3

[0040] Mix 1mol of lithium dihydrogen phosphate, 0.85mol of ferrous acetate, and mixed rare earth oxides containing 0.15mol of rare earth elements, add 18.34g of sucrose, and add 250ml of acetone dispersant to mix and disperse, then use a planetary ball mill for wet grinding, grinding The time is 8 hours. After drying at 200° C. in a constant temperature vacuum drying oven, dry ball milling is carried out for 2 hours using a planetary ball mill to obtain a lithium iron phosphate cathode material precursor. Place the precursor in a pusher furnace under Ar / H 2 Under the atmosphere, after pre-calcining at 500°C for 6h, cool to room temperature, grind and compact, then carry out secondary calcination under the protection of the inert atmosphere in the above-mentioned furnace body, the calcination temperature is 800°C, the calcination time is 12h, cool to room temperature, use The planetary ball mill crushes the calcined material to the required particle size to obtain LiFe 0.85 R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com