Flame-retardant heat-resistant bismaleimide resin and preparation method thereof

A bismaleimide resin and bismaleimide technology are applied in the field of bismaleimide and its synthesis and preparation to achieve the effects of inhibiting chain segment movement, improving flame retardancy and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

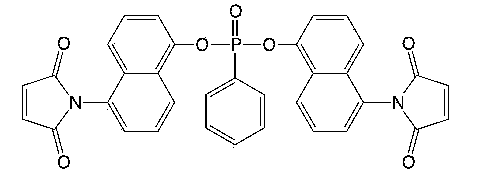

Image

Examples

Embodiment 1

[0027] Add 32 g 1-amino-5-naphthol and 90 g acetone to a 250 mL four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and nitrogen introduction device, slowly increase the temperature of the oil bath to 80°C, wait for 1- After the amino-5-naphthol was completely dissolved, 15 g of phenylphosphorus oxychloride was added dropwise to the reaction system, the 0.5h feeding was completed, the reaction temperature was controlled at 110°C, and the reaction was continued for 4h. After the reaction is completed, the unreacted 1-amino-5-naphthol is removed by concentration and filtration, washed with deionized water at 80°C for 5 times, and the solvent and excess water are removed by distillation under reduced pressure to obtain a brown viscous liquid. The resulting brown viscous liquid product 25g, 20g maleic anhydride, epichlorohydrin, and 15g acetone were mixed and dissolved in a 125 ml four-necked flask with stirring, reflux condenser and thermometer. The o...

Embodiment 2

[0030] Add 32 g 1-amino-5-naphthol and 90 g acetone into a 250 mL four-neck flask equipped with mechanical stirring, thermometer, reflux condenser and nitrogen introduction device, slowly increase the temperature of the oil bath to 80℃, After the amino-5-naphthol was completely dissolved, 15 g of phenylphosphorus oxychloride was added dropwise to the reaction system, the 0.5h feeding was completed, the reaction temperature was controlled at 110°C, and the reaction was continued for 4h. After the reaction is completed, the unreacted 1-amino-5-naphthol is removed by concentration and filtration, washed with deionized water at 80°C for 5 times, and the solvent and excess water are removed by distillation under reduced pressure to obtain a brown viscous liquid. The resulting brown viscous liquid product 25g, 20g maleic anhydride, epichlorohydrin, and 15g acetone were mixed and dissolved in a 125 ml four-necked flask with stirring, reflux condenser and thermometer. The oil bath tempe...

Embodiment 3

[0033] Add 600 g 1-amino-5-naphthol and 350 g acetone into a 2500 mL four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and nitrogen introduction device, slowly increase the temperature of the oil bath to 80℃, and wait for 1 After the amino-5-naphthol was completely dissolved, 500 g of phenylphosphorus oxychloride was added dropwise to the reaction system, the 0.5h addition was completed, the reaction temperature was controlled at 115°C, and the reaction was continued for 4h. After the completion of the reaction, it was concentrated and filtered to remove unreacted 1-amino-5-naphthol, washed with deionized water at 80°C for 3 times, and distilled under reduced pressure to remove the solvent and excess water to obtain a brown viscous liquid. The resulting tan viscous liquid product 500g, 400g maleic anhydride, epichlorohydrin, and 300g acetone were mixed and dissolved in a 1500ml four-necked flask equipped with stirring, reflux condenser and thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com