Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Process window width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solder paste scaling powder

ActiveCN107931891AImprove universalityLess corrosiveWelding/cutting media/materialsSoldering mediaAcrylic resinHeat stability

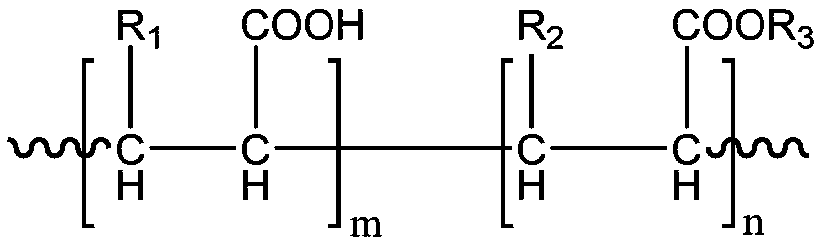

The invention discloses solder paste scaling powder. The solder paste scaling powder comprises a film forming agent. The film forming agent comprises acrylic resin. The acrylic resin comprises a repetition structure unit in a formula (I). The acrylic resin is adopted in the solder paste scaling powder for replacing rosin, corrosivity is weak, few residues exist, and tin powder is wrapped by the acrylic resin so that the tin powder can be prevented from being oxidized. Solder paste in which the solder paste scaling powder is added is provided with a wide process window, components in the solderpaste are stable in property, and the stability of the solder paste is good; and heat stability of the acrylic resin is good, and the reflow soldering temperature section is wide.

Owner:广东省先进陶瓷材料科技有限公司

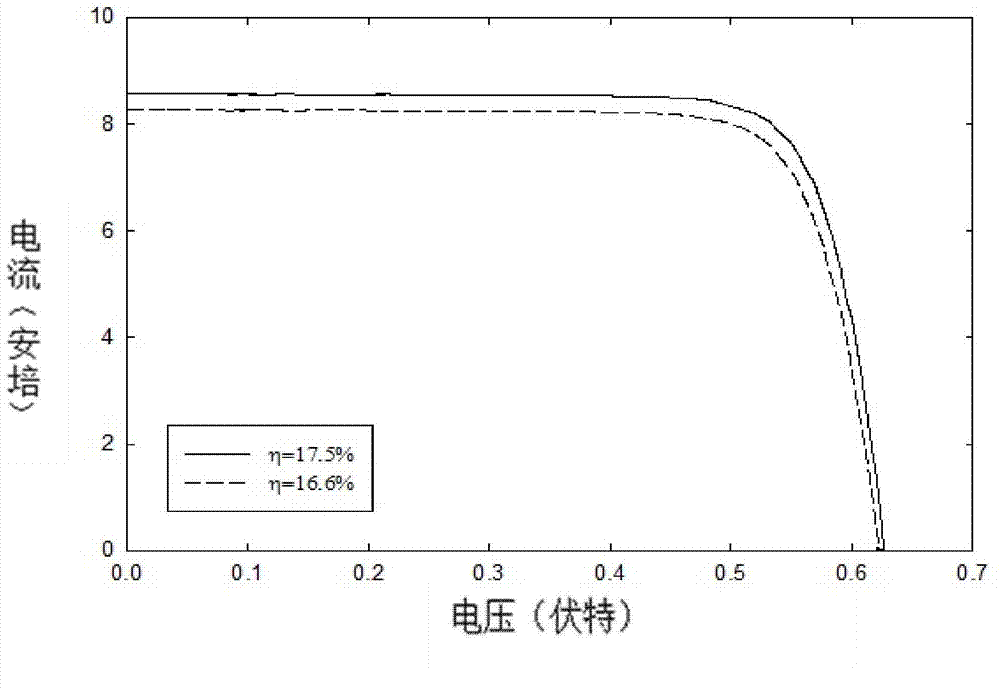

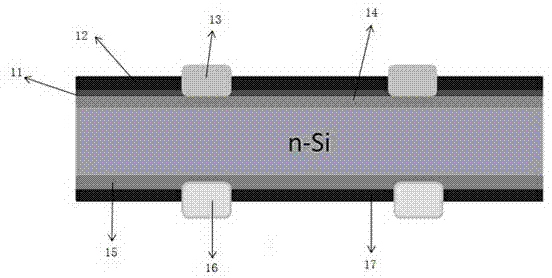

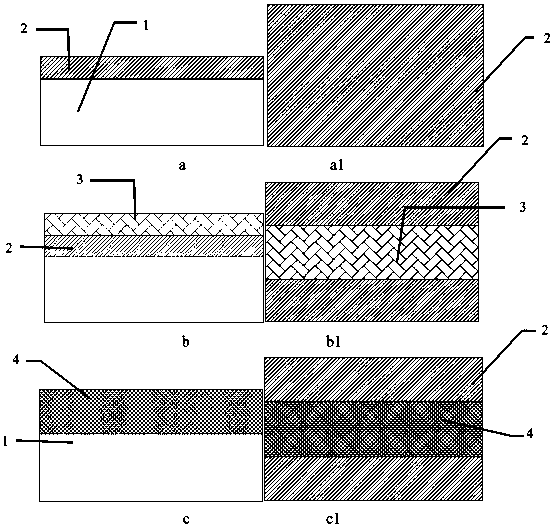

Gettering method for prolonging effective service life of crystalline silicon substrate

ActiveCN102820378AExtend effective lifeImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSolar batteryCrystalline silicon

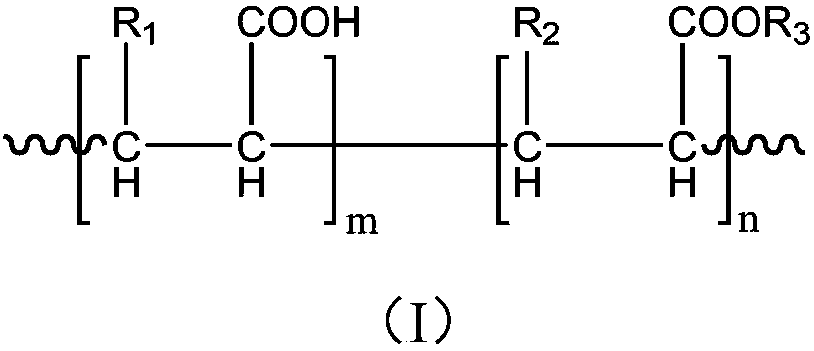

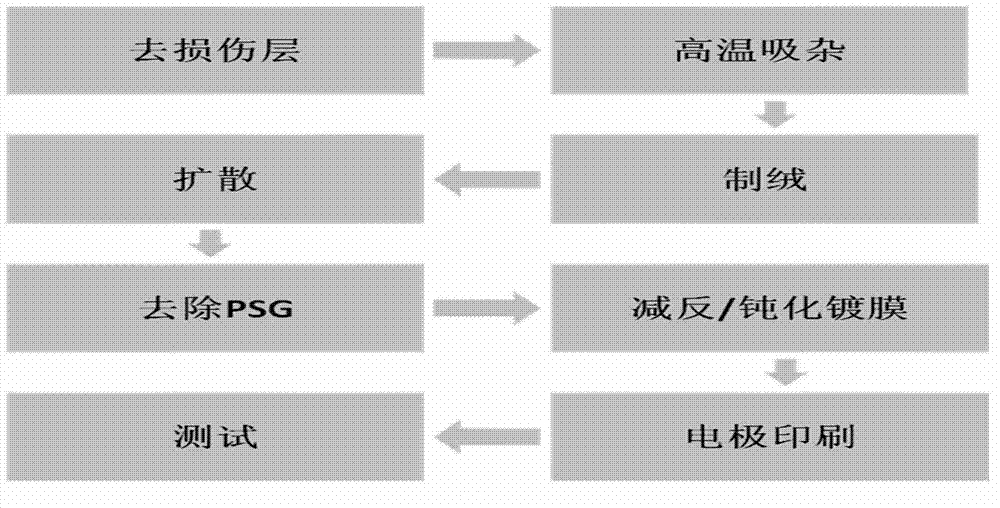

The invention provides a gettering method for prolonging the effective service life of a crystalline silicon substrate. The method comprises the following steps: carrying out a heavy phosphorous diffusion gettering on the crystalline silicon substrate without a surface damage layer by using a phosphorus source, and removing a phosphorous diffusion layer from the crystalline silicon substrate after phosphorous gettering and then carrying out the following processes. The heavy phosphorous diffusion gettering step comprises a phosphorous diffusion constant temperature process and a two-section cooling process for phosphorous gettering; the temperature of a constant temperature region in the phosphorous diffusion constant-temperature process is 800-950 DEG C, and the time of the phosphorous diffusion constant-temperature process is 30-50min; in the two-section cooling process for the phosphorous gettering, the temperature range of the first section is 980-800 DEG C and the treatment time of the temperature range of the first section is 5-30min, the temperature range of the second section is 800-700 DEG C and the treatment time of the temperature range of the second section is 30-90min, and a cooling rate is 2-10 DEG C / min. With the adoption of the method provided by the invention, the effective service life of a photo-production carrier can be prolonged; the photo-electric conversion efficiency of a solar battery is increased; the gettering method can be completely compatible with the conventional solar battery production process; and the gettering method can be directly applied to the mass production of the solar battery.

Owner:JA SOLAR TECH YANGZHOU

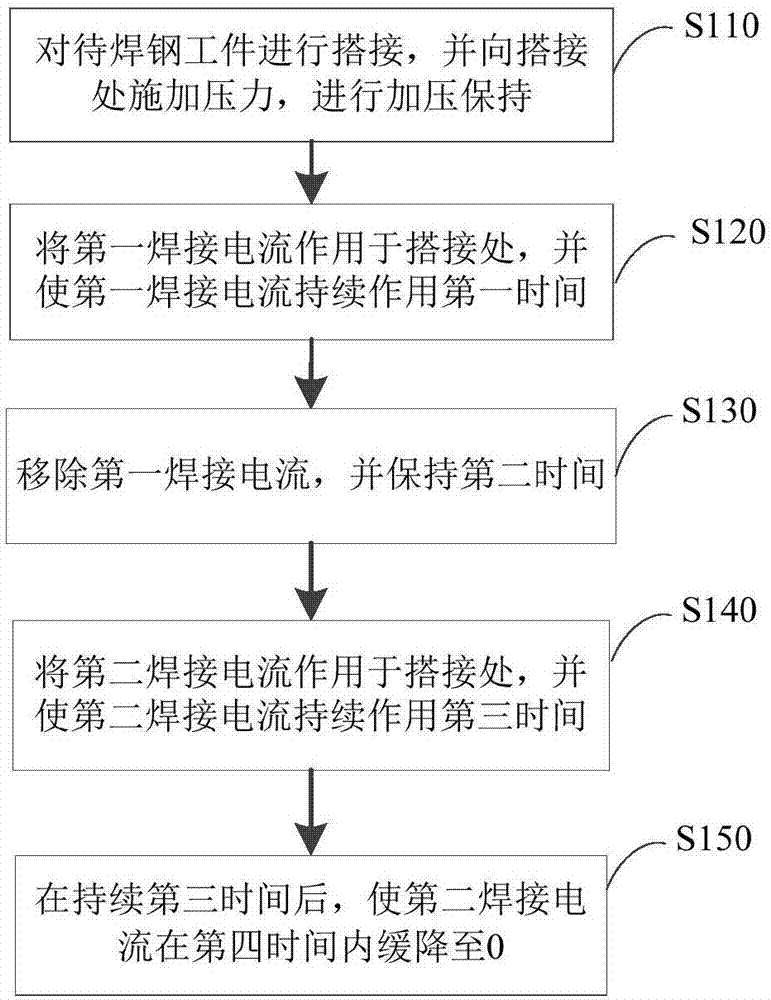

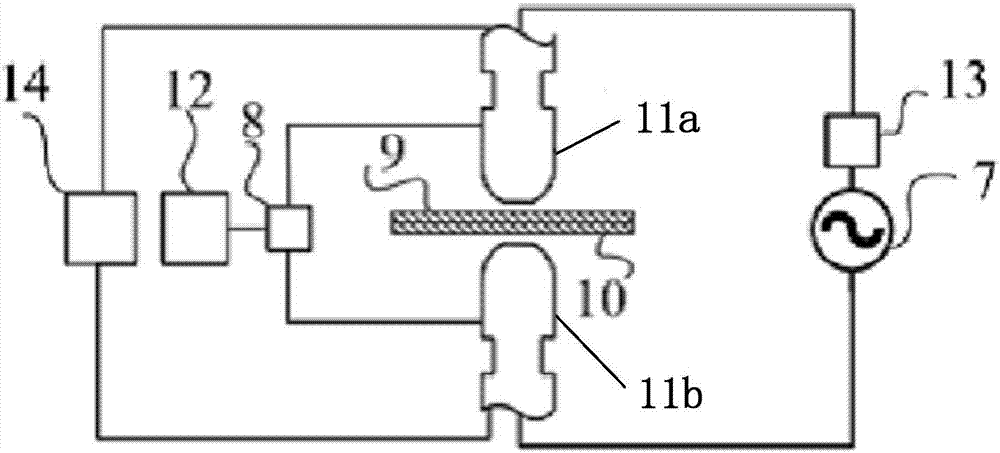

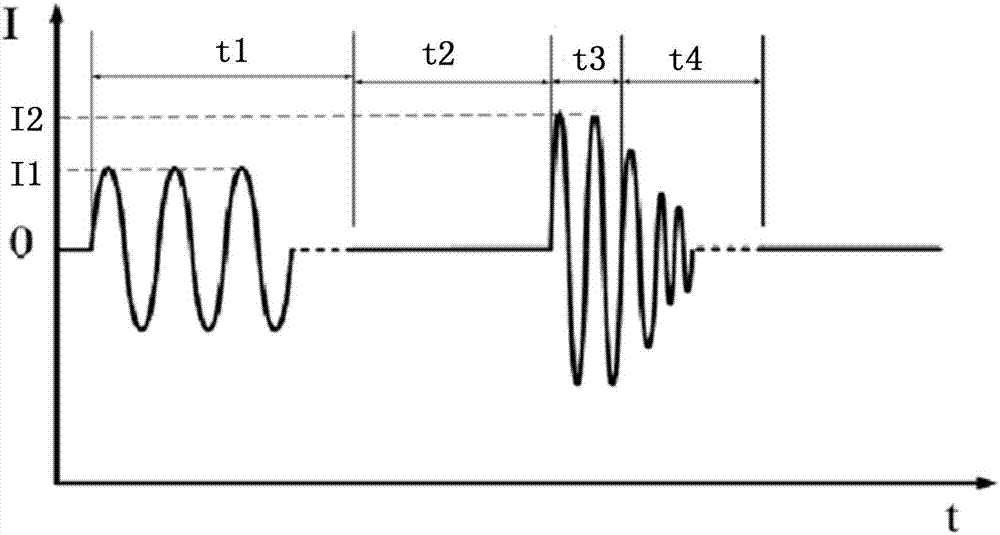

Resistance spot welding technique for steel workpiece with coating layer

ActiveCN107350613AEasy dischargeGuaranteed implementabilityWelding/soldering/cutting articlesResistance welding apparatusPower flowEngineering

The invention discloses a resistance spot welding technique for steel workpiece with a coating layer. According to the technique, the steel workpiece to be welded is connected in a lap joint mode, pressure is applied to the lap joint, and is increased and maintained; a first welding current is applied to the lap joint, and is enabled to continuously act for a first time; then the first welding current is removed and a second time is maintained; after the second time is maintained, a second welding current is applied to the lap joint, and is enabled to continuously act for a third time; after keeping for the third time, the second welding current is gradually reduced to zero within a fourth time; and wherein the second welding current is larger than the first welding current, and the sum of the first time and the second time is larger than or equal to 600 ms. The technique has the advantages that the coating layer is damaged by outputting the first welding current, the second welding current is output to complete heating welding, a longer stopping output timing sequence is arranged between the two, coating material is promoted to be discharged, splashing is inhibited, and a wide process window can be obtained.

Owner:江苏育材堂车身技术有限公司 +1

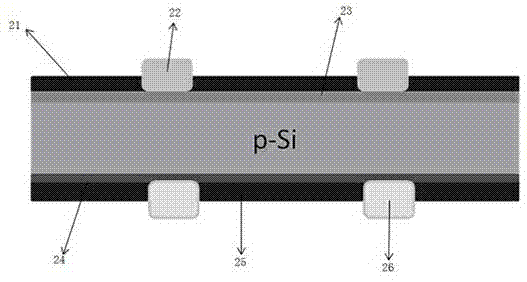

Passivation dielectric film for solar cell

InactiveCN102403369APassivation is effectiveExtend your lifeSemiconductor devicesDielectricSolar cell

The invention discloses a passivation dielectric film for a solar cell. The passivation dielectric film is of a single-layer structure formed by a first dielectric film, or the passivation dielectric film is of a laminated structure formed by the first dielectric film and a second dielectric film, wherein the first dielectric film is in direct contact with a silicon substrate material; and the second dielectric film is deposited on the first dielectric film. The passivation dielectric film has good high-temperature sintering resistance, good optical antireflection performance, wider manufacturing method process window and strong feasibility and facilitates mass production.

Owner:JA SOLAR TECH YANGZHOU +1

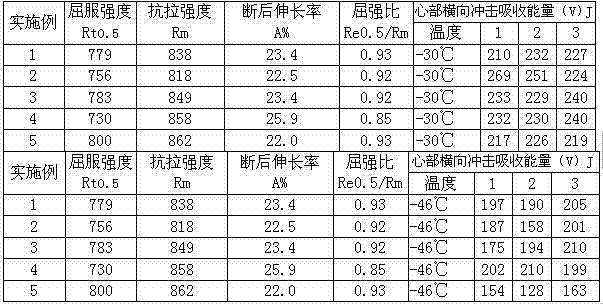

Method for producing ultrathin ultrahigh-strength steel plate

The invention provides a technical scheme of a method for producing an ultrathin ultrahigh-strength steel plate. The steel of the scheme comprises the following chemical ingredients by weight percent: 0.12-0.15% of C, 0.0-0.10% of Si, 0.9-1.3% of Mn, no more than 0.0015% of P, no more than 0.008% of S, 0.35-0.60% of Ni, 0.15-0.30% of Cr, 0.25-0.40% of Mo, 0.008-0.035% of Ti, 0.030-0.050% of Al, and the balance of iron and inevitable impurities. A production technology adopts clean steel smelting, hot continuous rolling forming, rolled plate unfolding and hot rolling base plate quenching tempering, heating temperature of casting blanks is controlled, the action of heavy pressing during rolling is exerted, the maximum potential of thermal treatment is excavated, and the structure is enabled to be ultra-thinned through a technological method, so that a finished product is the ultrathin ultrahigh-strength steel plate with the ultrathin specification of 3-10mm and tensile strength of 1000-1500Mpa. The steel plate has excellent low-temperature toughness index, and the carbon equivalent is controlled to be smaller than or equal to 0.4% according to the European committee for standardization (CEN); and the steel plate has good welding performance and is suitable for mass production.

Owner:JIGANG GRP

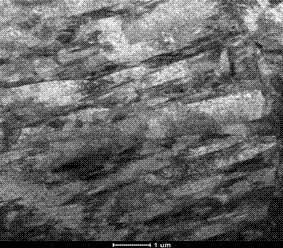

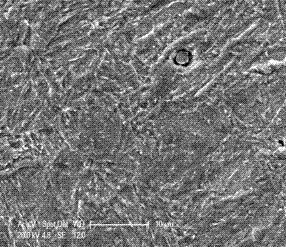

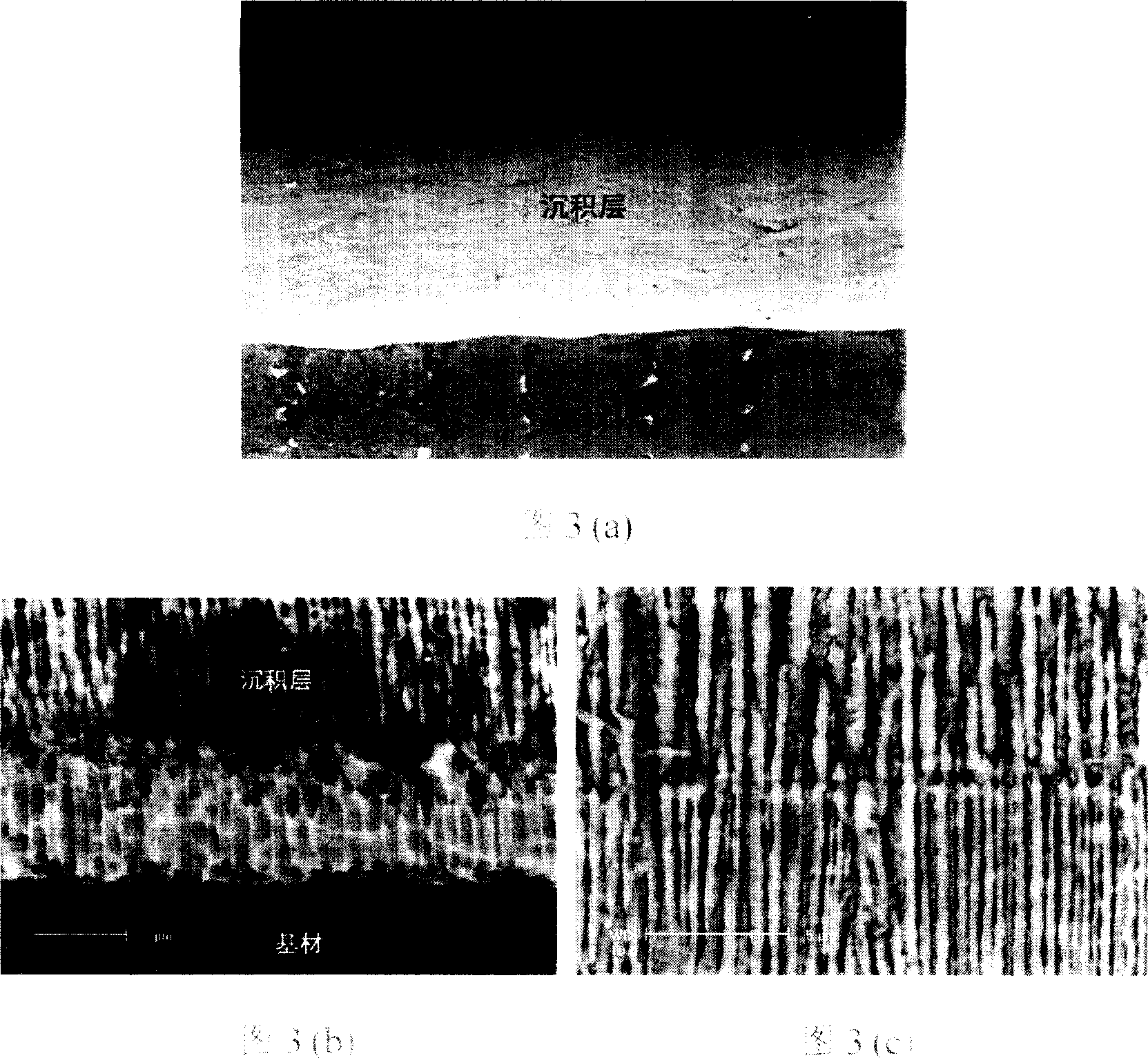

Directional freezing styloid or single-crystal nickel-base high-temperature alloy repairing or coating method

InactiveCN101126143ALittle thermal impactDoes not cause recrystallizationMolten spray coatingArc welding apparatusHeat-affected zoneSingle crystal superalloy

The invention belongs to a preparation technique of the metal surface settled layer, in particular to a method for preparing the directional solidification column crystal or single crystal settled layer which grows on the extension of the surface of the directional solidification column crystal or single crystal high temperature alloy. The proposal of the invention solves the problem of repairing and coating of the directional solidification column crystal or single crystal high temperature alloy; and to gain a compact and flawless directional solidification column crystal or single crystal settled layer which is matched with the directional solidification column crystal or single crystal. The invention discloses an extension high power differential arc spark metal deposition technique. The invention has the advantages of wide process window achieved by the extension high power differential arc spark metal deposition technique, no heat damage to the ferronickel high temperature alloy, narrow heat influence area or no heat influence area, being capable of effectively avoiding the phenomenon of heat flaw of the ferronickel high temperature, no complicated devices such as vacuum room needed and no preheating needed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

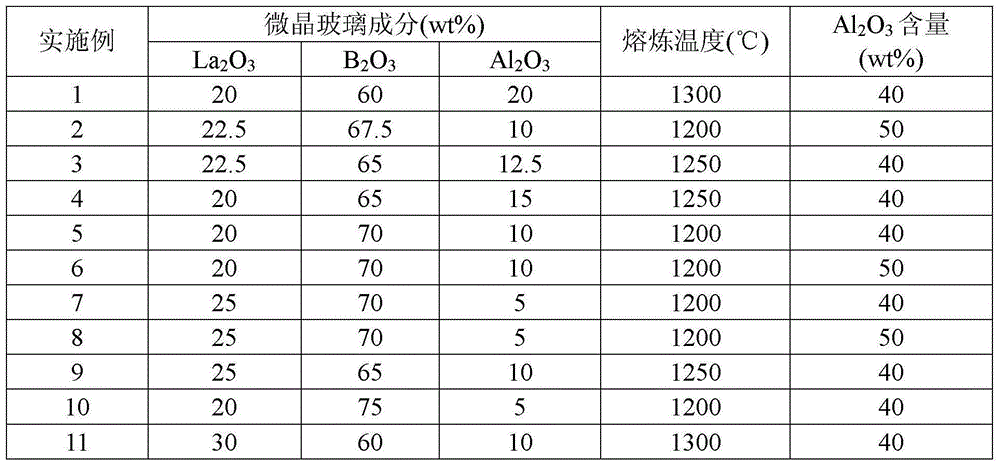

Low-temperature co-fired ceramic material and preparation method thereof

The present invention discloses a low-temperature co-fired ceramic material and a preparation method thereof, wherein the low-temperature co-fired ceramic material comprises 40-60 wt% of La2O3-B2O3-Al2O3 glass ceramic and 40-60 wt% of an Al2O3 ceramic filling phase. The preparation method comprises: La2O3-B2O3-Al2O3 glass ceramic preparation, Al2O3 ceramic powder pretreatment, composite powder preparation, composite powder molding, and low-temperature sintering. According to the present invention, the low-temperature co-fired ceramic material has advantages of wide process window, low dielectric loss and the like, and can be used in the high frequency field, and the preparation method has characteristics of simpleness, convenience, and low equipment investment.

Owner:NAT UNIV OF DEFENSE TECH

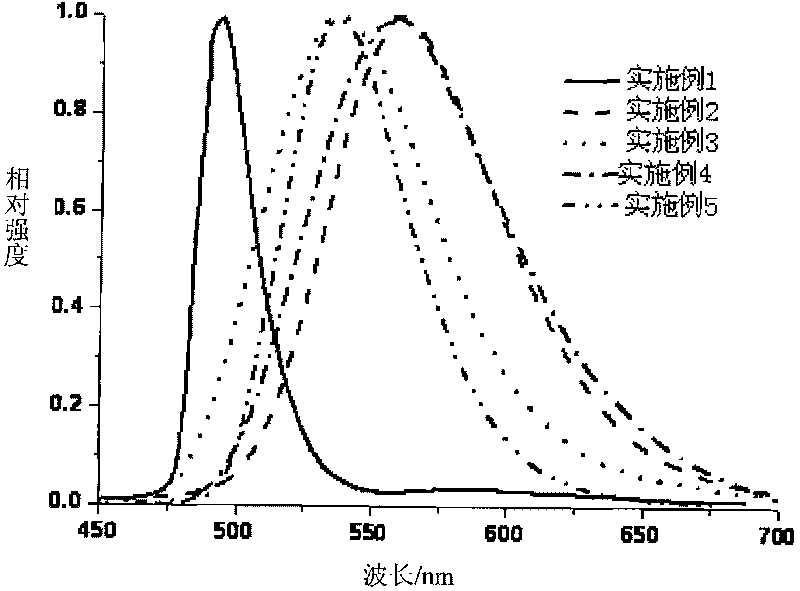

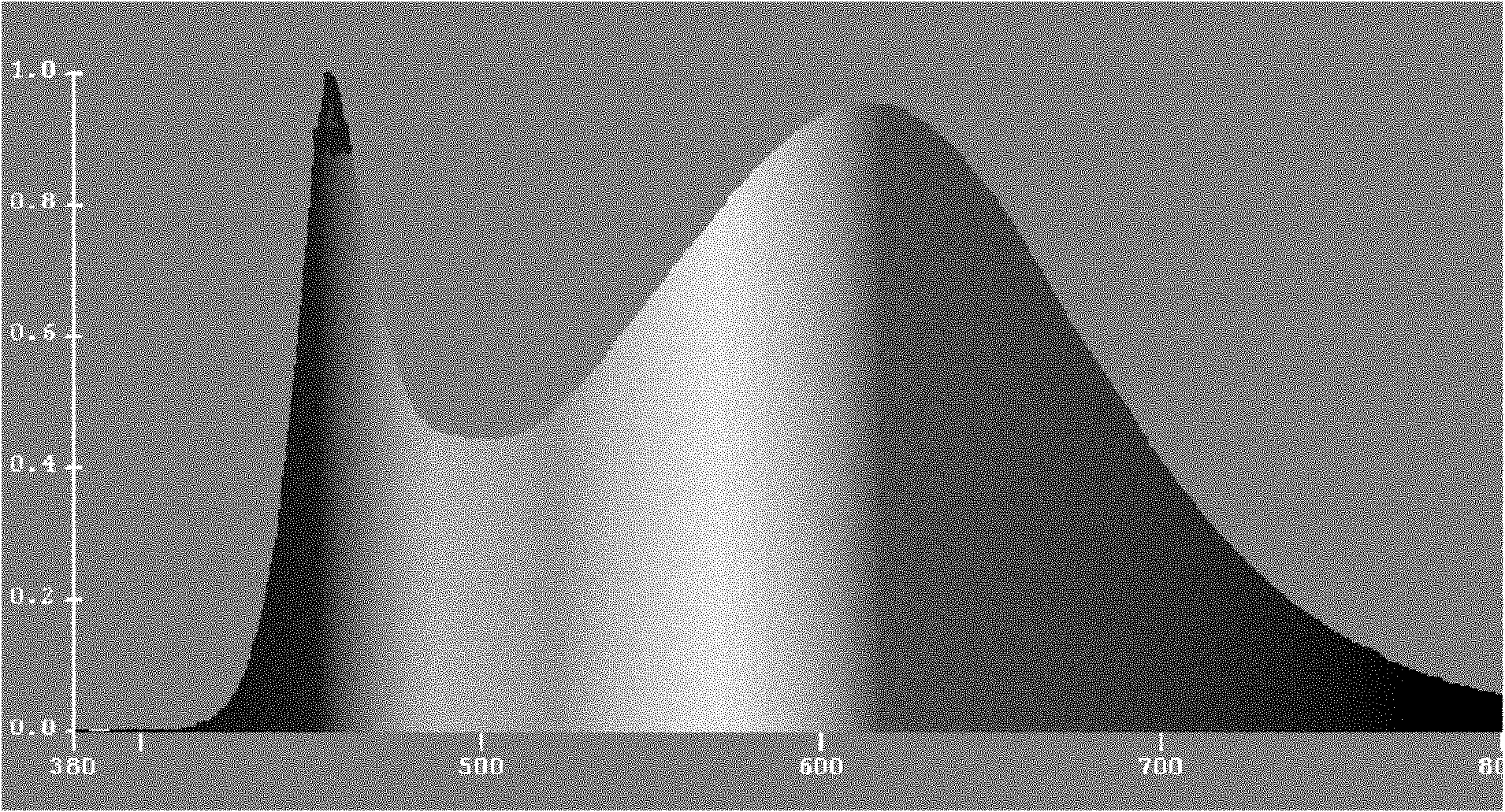

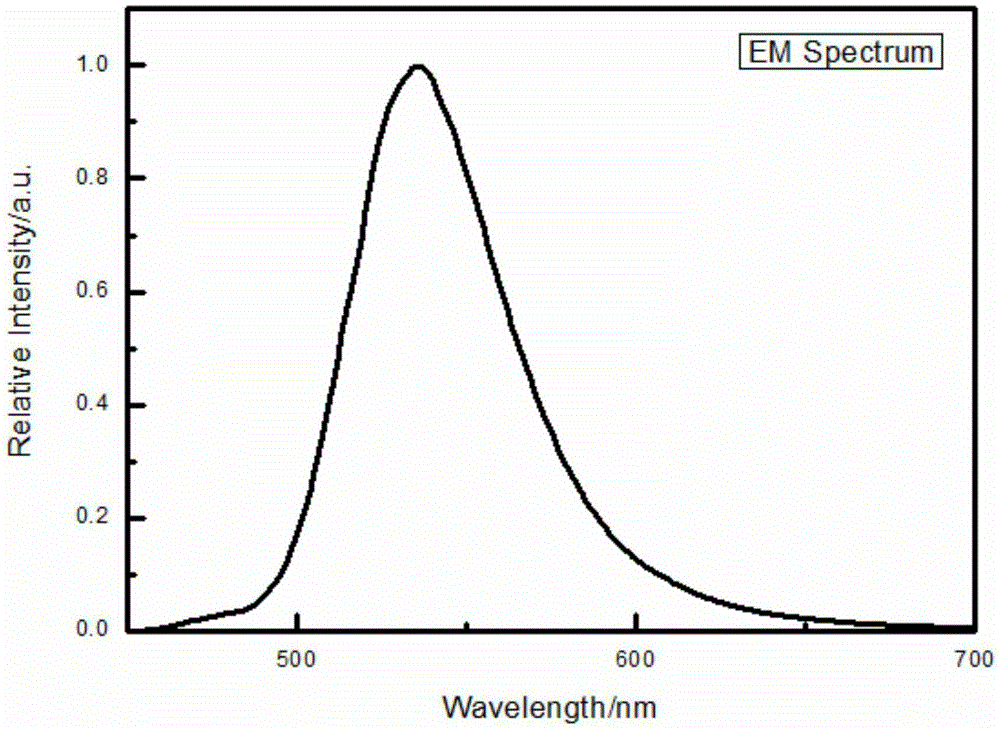

Synthetic rare earth doped nitric oxide fluorescent powder and preparation method thereof

InactiveCN101760190AEasy to operateProcess window widthLuminescent compositionsThermal decayDisplay device

The invention relates to synthetic rare earth doped nitric oxide fluorescent powder and a preparation method thereof, which is characterized in that the general chemical formula of the rare earth doped nitric oxide fluorescent powder is A1-xByOzN2 / 3+4 / 3y-2 / 3z : xRe, wherein A is one or the combination of two or more of Ca ion, Sr ion and Ba ion and comes from the oxide, carbonate or nitrate whichcontains A element; B is one or the combination of Si ion and A1 ion, at least contains Si ion and comes from the nitride which contains B element; Re is one or the combination of two or more of Eu ion, Ce ion, Dy ion and Mn ion and comes from the oxide, nitrate or acetate which contains Re element; and the relations of X is more than or equal to 0 and less than 1.0, Y is more than or equal to 1.0 and less than or equal to 2.0 and Z is more than 0 and less than or equal to 2.0 are satisfied. The luminescent material is of stable physical and chemical properties, strong thermal decay resistance and high quantum efficiency, is suitable for excitation of wavelength at 300nm-600nm and is widely applicable in LED lighting and display devices. The fluorescent powder is synthesized through two-step synthesis by taking cheap compounds as the materials and the fluorescent powder synthesized through the method under normal pressure is of pure phase.

Owner:IRICO

Preparation method for preparing surface SiC coating of silicon carbide-based composite material

The present invention relates to a preparation method for preparing the surface SiC coating of a silicon carbide-based composite material and belongs to the technical field of oxidation protection. According to the method, silicon powders are embedded in the surface of the silicon carbide-based composite material. After the high-temperature vacuum infiltration process, the composite material is embedded in a melt. After that, the composite material embedded in the melt is placed in an excess carbon source, and is subjected to the high-temperature heat treatment again. After residues on the surface of the composite material are removed, the composite material with the SiC coating can be obtained. According to the technical scheme of the invention, the coating is prepared through the reactive infiltration process. Therefore, during the preparation of the coating, the density of the base material can be further improved at the same time. the excess melt is removed by the carbon source, so that the formed SiC coating is uniform and smooth.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

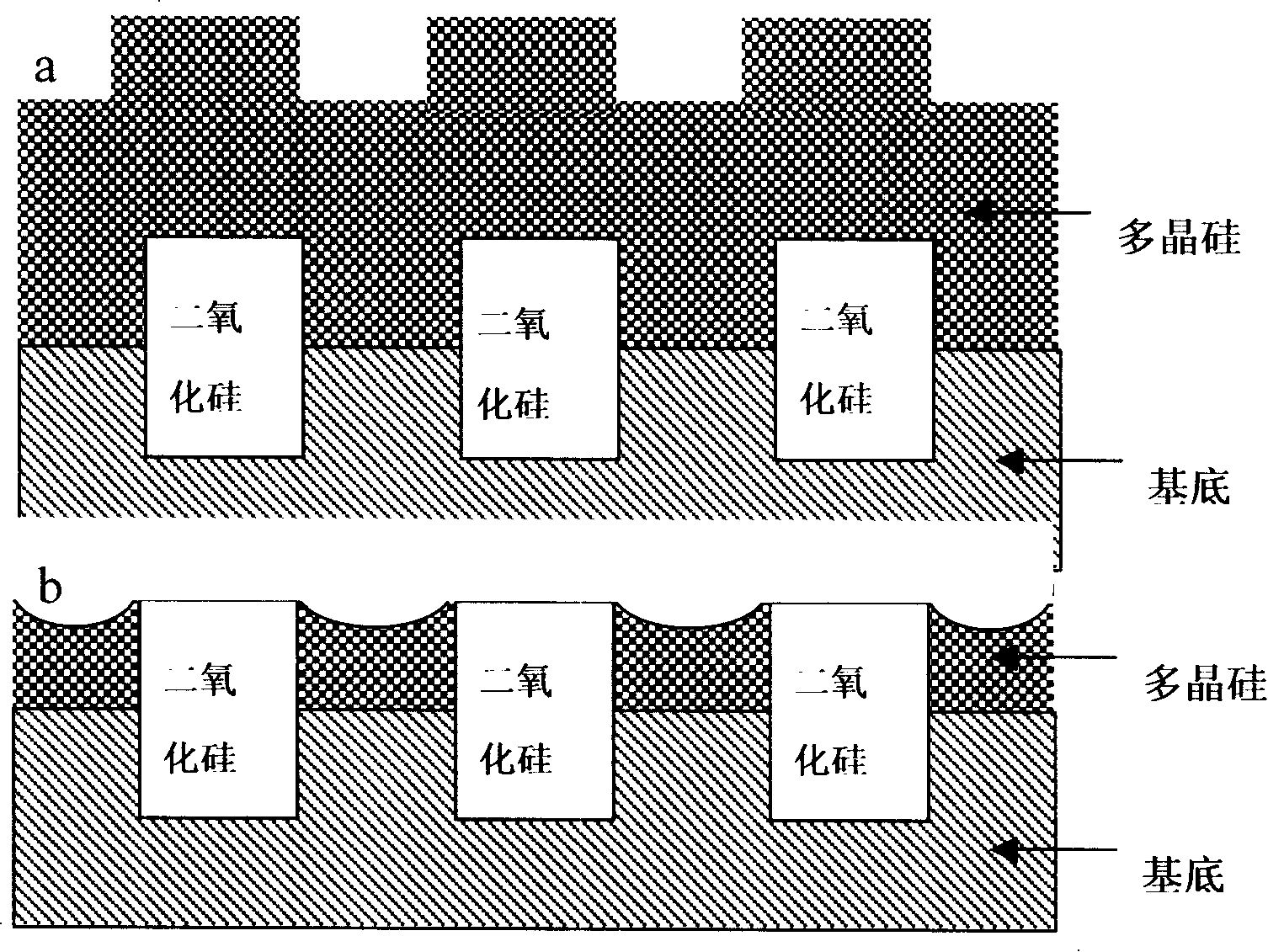

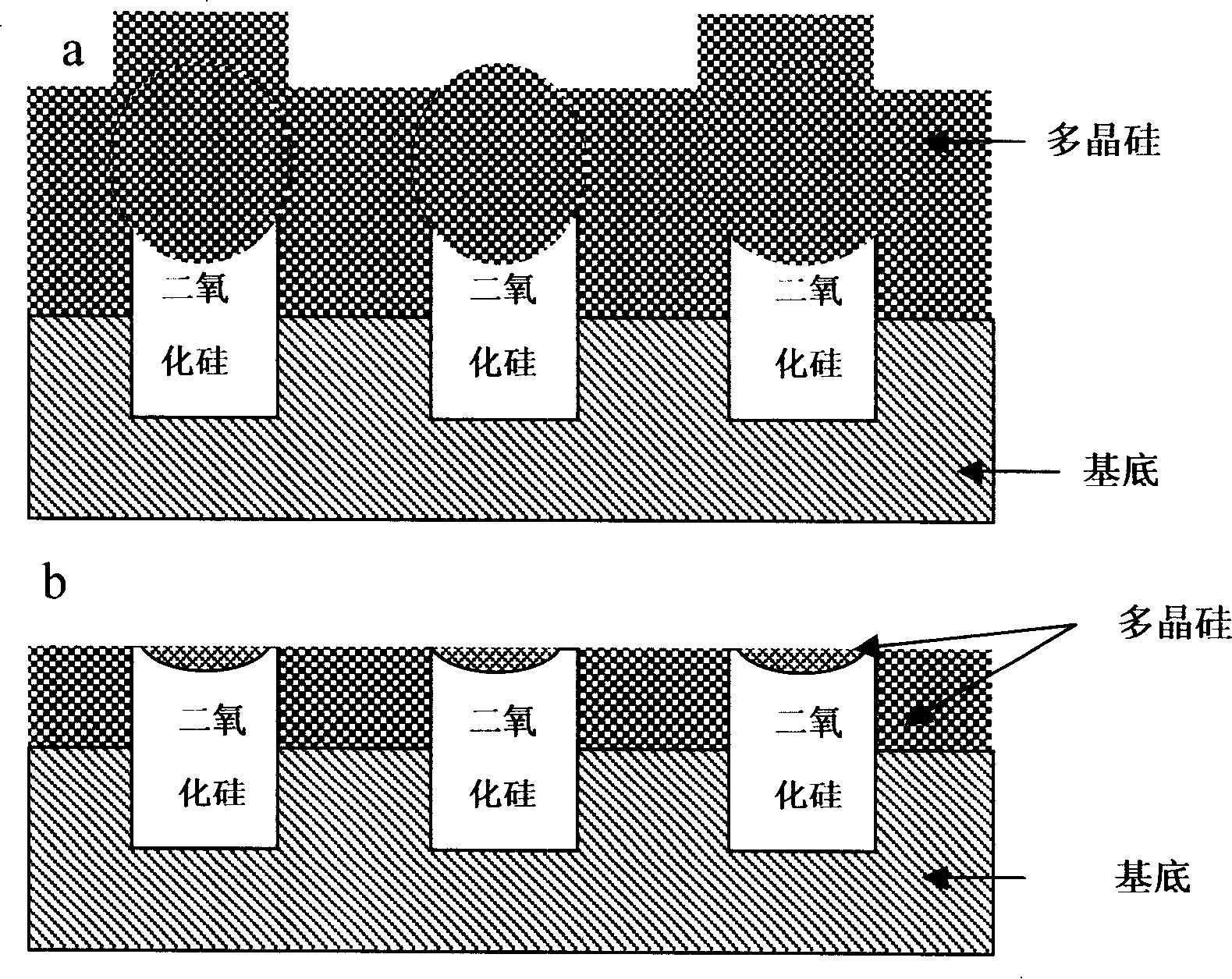

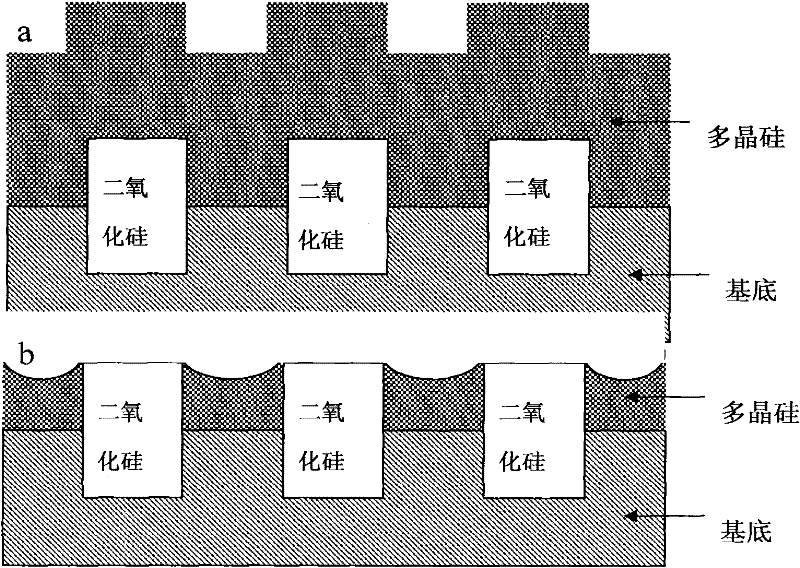

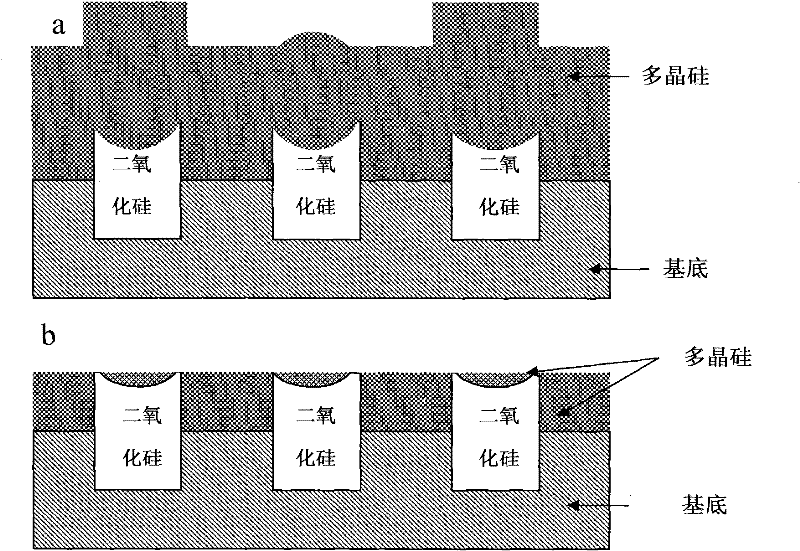

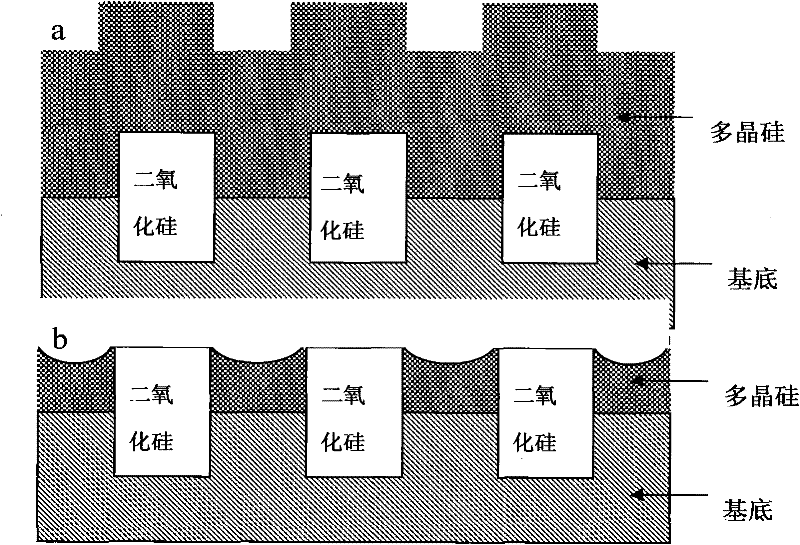

Application of non-ionic polyalcohol in producing and using self-stopping polysilicon polishing solution

InactiveCN101195729ASolve the problem of polysilicon residueHigh degree of planarizationPolishing machinesSemiconductor/solid-state device manufacturingProduction ratePolymer science

The invention discloses preparation of polymer including -(RO)- or -(RCOO)-groups in a repeating unit in polysilicon chemical mechanical polishing solution which can realize automatic stopping mechanism, and the application during the operation process of the polymer, wherein, the R is alkyl with 1 to 10 carbon atom(s). The polymer of the invention is used for the preparation of polishing solution and the use of the polishing solution, and can realize the polysilicon chemical mechanical polishing process under the fixed and conventional process parameter polishing condition, thus avoiding the generation of polysilicon dish shaped dent default in a silicon dioxide channel, removing the polysilicon residual in the polysilicon dish shaped dent default, and enhancing the smoothness of a wafer surface after being polished. The polymer has the advantage that the process window is wide, thereby the production efficiency is greatly improved, and the production cost is reduced greatly.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

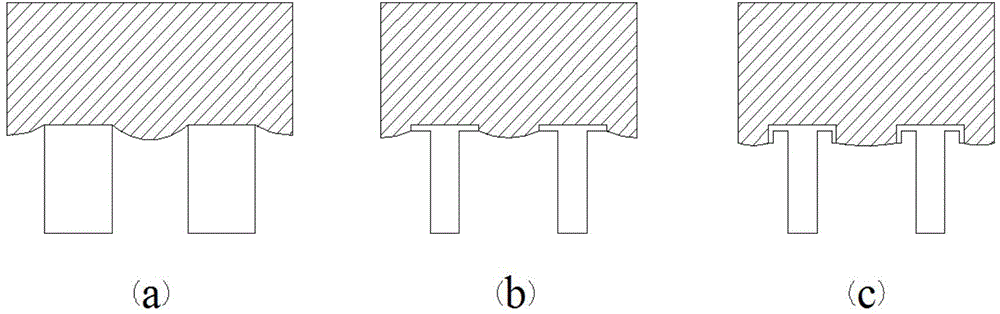

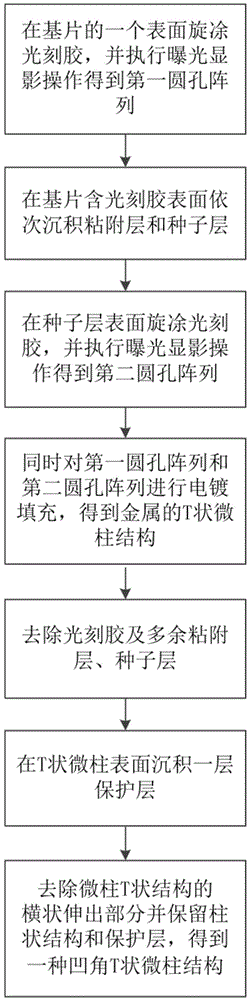

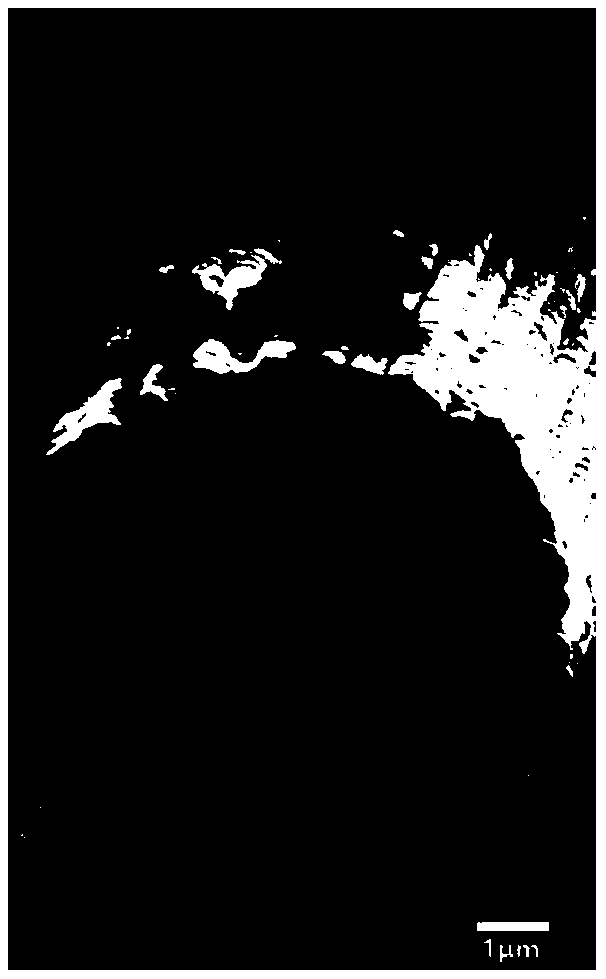

Preparing method of superhydrophobic concave angle T-shaped microcolumn structure

InactiveCN104649216AAvoid multiple sputteringAvoid filling multiple timesDecorative surface effectsCoupling light guidesProcess windowProtection layer

The invention discloses a preparing method of a superhydrophobic concave angle T-shaped microcolumn structure. The method comprises the steps of (a), rotationally coating photoresist on one surface of a chip and executing developing operation to obtain a first round hole array; (b), depositing an adhesion layer and a seed layer on the surface of the photoresist in sequence; (c) rotationally coating the photoresist on the surface of the seed layer and executing the developing operation to obtain a second round hole array; (d), performing plating and filling on the first round hole array and the second round hole array to obtain a metal T-shaped microcolumn structure; (e) removing the photoresist and surplus adhesion layer and seed layer; (f), depositing a protection layer on the surface of the T-shaped microcolumn; (g), removing a lateral extending part of the microcolumn T-shaped structure and remaining a columnar structure and the protection layer to obtain one concave angle T-shaped microcolumn structure. According to the method, a target structure of different sizes can be prepared controllably, a process window is wide, the repeatability is good, the chemical stability is high, and the superhydrophobic concave angle T-shaped microcolumn structure has excellent superhydrophobic performance and self-cleaning capacity.

Owner:HUAZHONG UNIV OF SCI & TECH

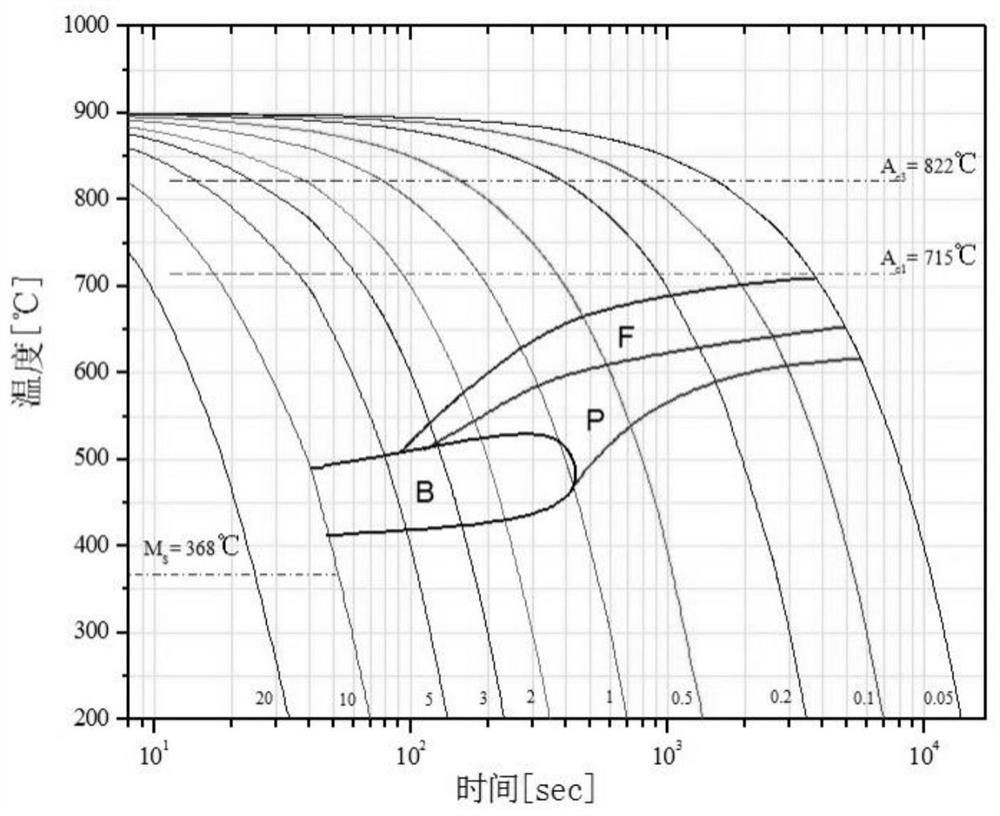

Steel plate for Ni-Mo low-temperature high-ductility X100 pipe fittings and manufacturing method thereof

The invention discloses a steel plate for Ni-Mo low-temperature high-ductility X100 pipe fittings. The steel plate is prepared from the following chemical components in percentage by weight: 0.09-0.12% of C, 1.5-1.9% of Mn, 0.1-0.3% of Si, less than or equal to 0.003% of S, less than or equal to 0.015% of P, 0.04-0.065% of Nb, 0.008-0.003% of Ti, 0.02-0.10% of V, less than or equal to 0.06% of Alt, less than or equal to 0.010% of N, less than or equal to 0.006% of O, 0.40-0.50% of Mo, less than or equal to 0.35% of Cu, 0.51-0.65% of Ni, less than or equal to 0.35% of Cr, less than or equal to 0.01% of Ca and the balance of Fe. The manufacturing process of the steel plate comprises liquid steel smelting, external refining, plate blank reheating, TMCP process and quenched-tempered heat treatment; the finished product has high strength and high low-temperature ductility, and is welded and matched with an X100 main body pipeline; the process window of the heat treatment is widened by the ratio of the components Ni and Mo, and therefore, the yield and the percent of pass of the steel products are increased.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

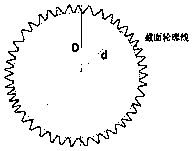

High-speed dry-spray spinning method for preparing deformed section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber

The invention discloses a high-speed dry-spray spinning method for preparing deformed section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber. An acrylonitrile polymer is dissolved byusing a solvent to obtain a uniform spinning solution, the spinning solution enters into a coagulating bath component of which the temperature is lower than the gelation temperature point of the spinning solution to form nascent fiber after passing through spinneret orifices to form a spinning trickle, and the working procedures of drafting, washing, drying and oil application aftertreatment arecarried out on the nascent fiber to obtain the carbon fiber precursor fiber. The carbon fiber precursor fiber is pre-oxidized and carbonized to obtain pre-oxidized fiber or carbon fiber. The method has the advantages of low cost and good fiber performance since fiber with similar straight toothed spur gear shape section characteristics is prepared in the condition of high-power drafting.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

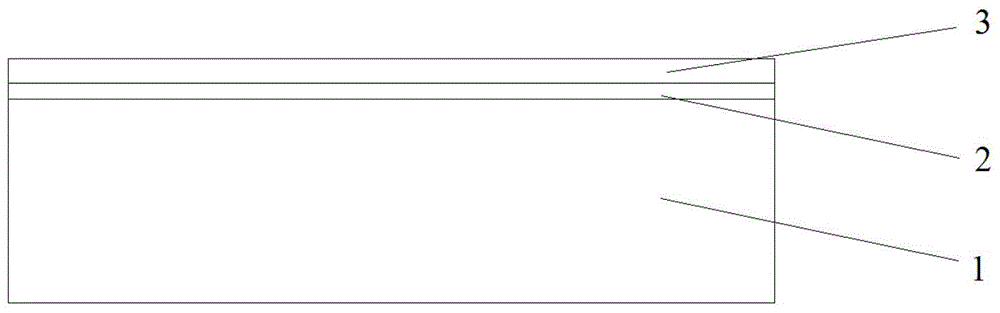

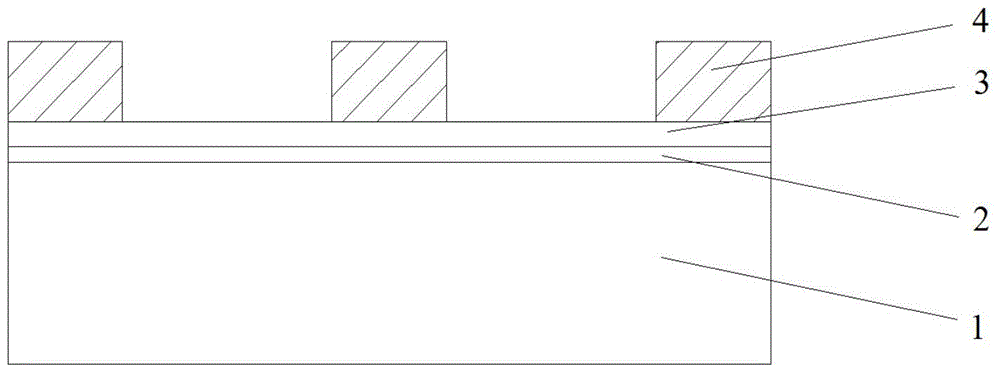

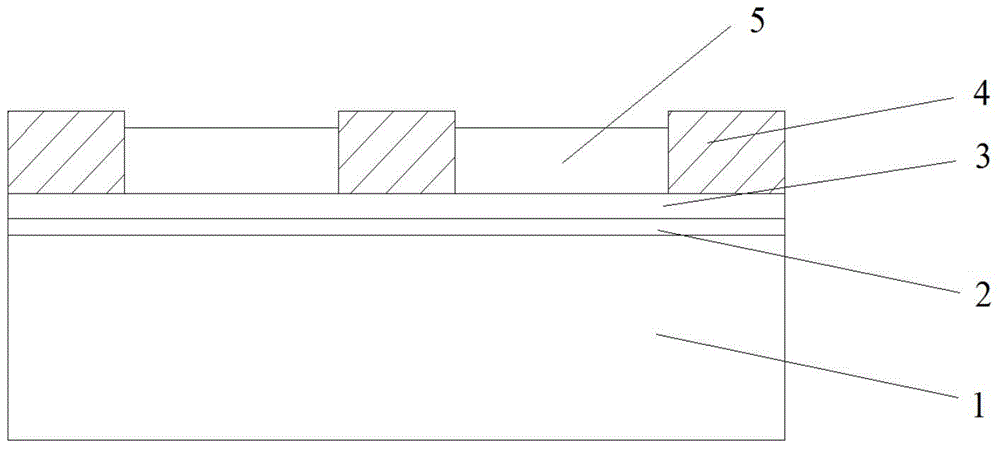

Copper nanometer wire-based copper-copper bonding process

InactiveCN104637831AHighly controllableProcess window widthSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistCopper nanowires

The invention discloses a copper nanometer wire-based copper-copper bonding process. An adhesion layer and a seed layer are sequentially precipitated on the surface of a substrate; a layer of photoresist is prepared on the seed layer, and a round hole is formed in the photoresist; copper is electroplated in the round hole to obtain a copper convex point; a Cu(OH)2 nanometer wire is grown on the surface of the copper convex point by a hydrothermal method; the residual photoresist is removed; the Cu(OH)2 nanometer wire is subjected to thermal decomposition to obtain a CuO nanometer wire; the CuO nanometer wire is reduced to obtain a copper nanometer wire; the copper nanometer wire is prepared on two substrates respectively by the steps, and the copper nanometer wires on the two substrates are bonded in a hot pressing way. The copper nanometer wires are prepared by reduction and are directly applied to subsequent bonding, an additional oxide layer removing step is avoided, a compact bonding layer can be obtained at relatively low temperature and pressure, the preparation process is simple, complex equipment is not required, the cost is low, and the bonding process has very high application value.

Owner:HUAZHONG UNIV OF SCI & TECH

Copper nanorod based copper-tin-copper bonding process and structure

ActiveCN105679683ALower requirementLower bonding temperatureMaterial nanotechnologySemiconductor/solid-state device detailsBonding processCopper

The invention discloses a copper nanorod based copper-tin-copper bonding process and structure. The process comprises the following steps of sequentially depositing an insulation layer, an adhesion layer and a seed layer on the surface of a substrate; spin-coating a layer of photoresist on the seed layer, and fabricating round holes in the photoresist; electroplating copper in the round holes to obtain copper convex points; removing the photoresist, and removing the exposed seed layer and the exposed adhesive layer; spin-coating the photoresist on the surfaces and the peripheries of the copper convex points, and exposing the upper surfaces of the copper convex points; electroplating tin convex points on the copper convex points of one of two substrate units obtained according to the above steps, and removing the photoresist; depositing copper nanorods on the copper convex points of the other substrate unit, and removing the photoresist; and bonding the two substrate units by a hot-pressing mode. The copper-tin-copper bonding structure is acquired according to the bonding process. According to the bonding process and the bonding structure, the copper nanorods are applied to copper-tin-copper bonding, the bonding temperature can be effectively reduced, and a tight bonding surface is obtained; and the preparation process is simple and controllable, is low in cost, and has great application value.

Owner:HUAZHONG UNIV OF SCI & TECH

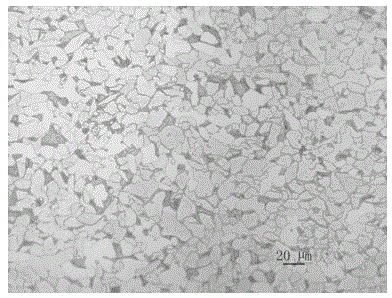

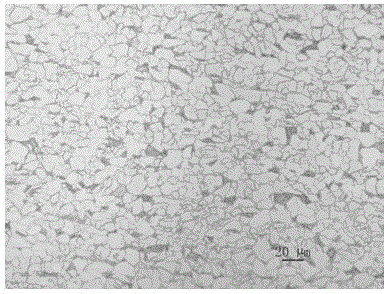

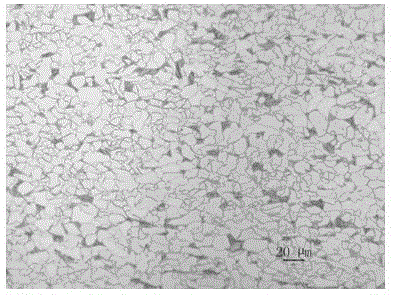

Method for manufacturing thick hot-rolled dual-phase steel based on CSP (Compact Strip Production) process

InactiveCN104593665AGood mechanical propertiesStable mechanical propertiesFurnace temperatureContinuous rolling

The invention discloses a method for manufacturing hot-rolled dual-phase steel based on a CSP (Compact Strip Production) process. The method comprises the following steps: (1) preparing a raw material comprising the following chemical compositions in percentage by weight: 0.055-0.070% of C, 0.40-0.50% of Si, 1.20-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S and the balance of Fe and unavoidable impurities; and (2) sequentially pretreating molten steel, carrying out converter top and bottom combined blowing, refining in an LF, continuously casting thin billet, soaking in a tunnel furnace, continuously rolling by virtue of an F1-F7 seven-stand hot continuous rolling mill group, cooling by virtue of a laminar cooling system, cooling by virtue of an ultra-fast cooling system and coiling. In the method, the out-of-furnace temperature of the continuous casting billet passing through the tunnel soaking furnace is equal to or greater than 1130 DEG C, the initial rolling temperature in the hot continuous rolling step is equal to or greater than 1010 DEG C, the reduction rate in an F1 stand is equal to or greater than 40%, the reduction rate in an F2 stand is equal to or greater than 33.3%, the temperature after the laminar cooling and air cooling is 600-690 DEG C, the temperature after ultra-fast cooling is 150-250 DEG C, the ultra-fast cooling speed is 70-150 DEG C / s. The microstructures of 11.0mm-thickness 590MPa-grade dual-phase steel in the thickness direction, which is produced from a simple low C-Mn-component system in an industrial mass manner, are ferrite and martensite duplex microstructures so that the dual-phase steel is excellent in comprehensive performance.

Owner:NORTHEASTERN UNIV +1

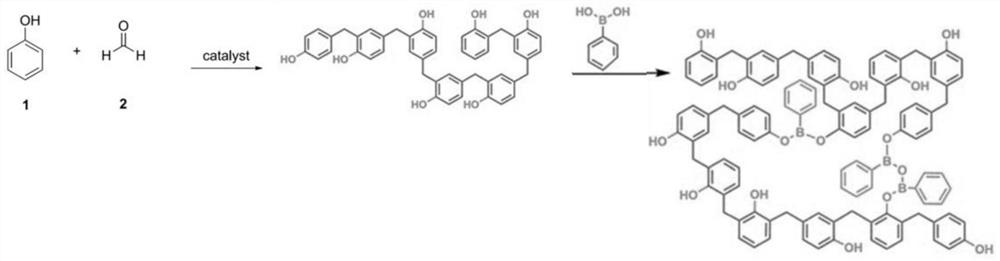

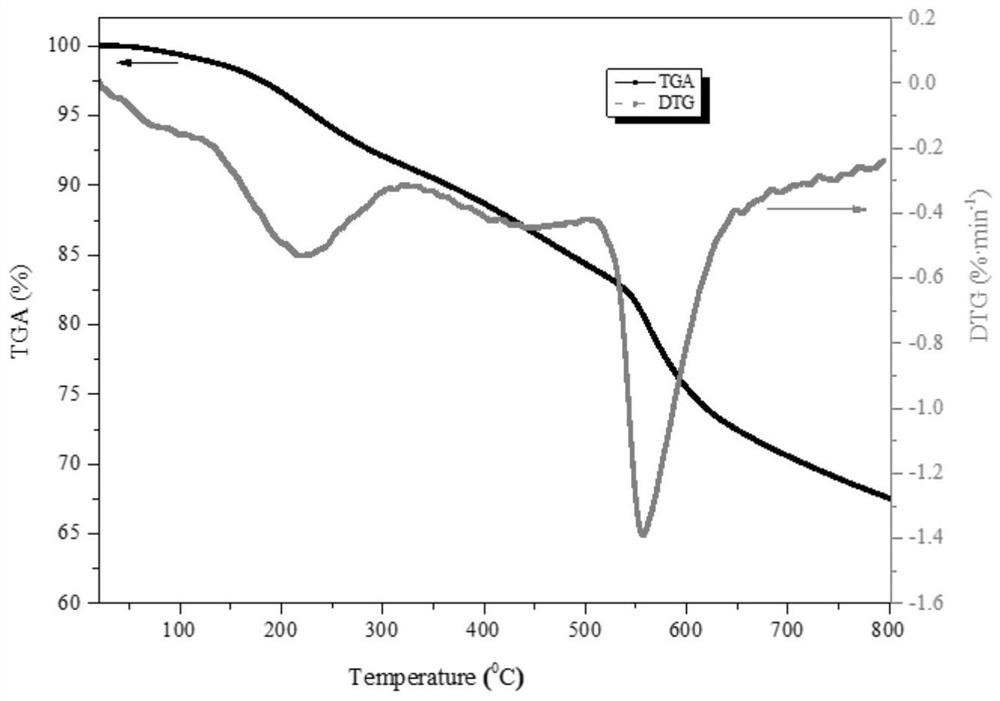

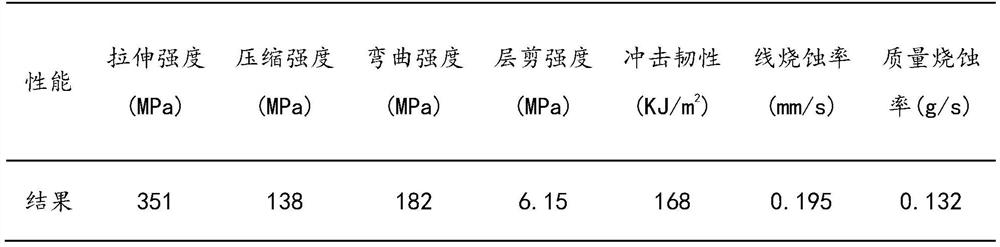

Preparation and degradation methods of hot-melt phenolic resin and composite material thereof

ActiveCN113429533AEasy to operateReduce energy consumptionPlastic recyclingPtru catalystChemical recovery

The invention provides preparation and degradation methods of hot-melt phenolic resin and a composite material thereof, and relates to the technical field of high polymer materials and chemical recovery thereof. The preparation method of the hot-melt phenolic resin comprises the following specific steps of: carrying out heating reaction on a phenolic compound and an aldehyde compound under the action of a catalyst, cooling, adding arylboronic acid and a derivative thereof, heating, boiling and refluxing again, carrying out decompression dehydration after the reaction is finished, adding a modifier and a flexibilizer, and vacuumizing to obtain the hot-melt phenolic resin. The preparation method of the hot-melt phenolic resin-based composite material comprises the following steps of: preparing a resin adhesive film from the hot-melt phenolic resin by adopting a hot-melt preimpregnation method, compounding the resin adhesive film with a fiber reinforcement body, and carrying out hot-pressing treatment to obtain the hot-melt phenolic resin-based composite material. The hot-melt phenolic resin and the hot-melt phenolic resin-based composite material are heated and decomposed in an ethanol or acetone solvent, and can be degraded and recycled. The preparation process is simple to operate and low in energy consumption, the production process is easy to control, and large-batch continuous production can be realized. The degradation process is safe, environment-friendly, green and pollution-free.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

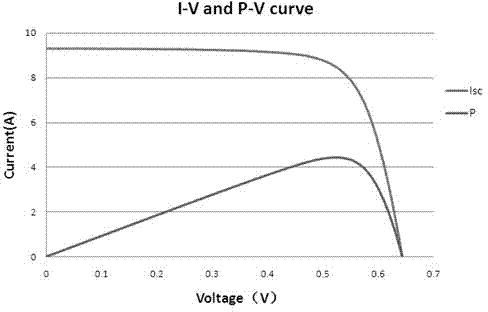

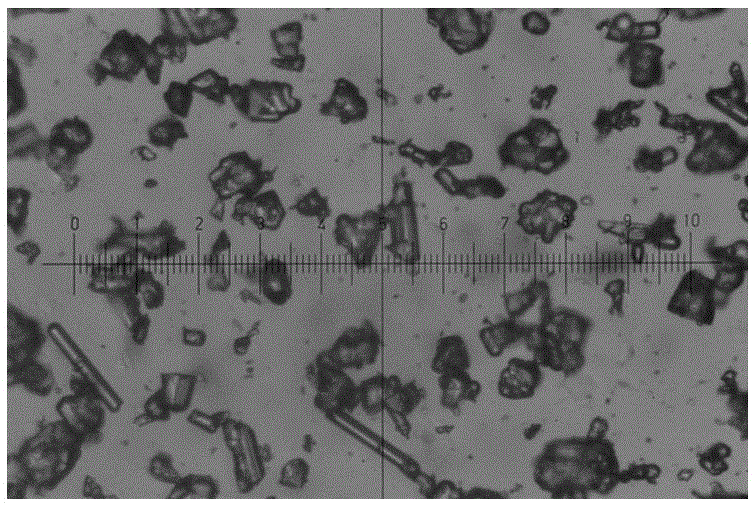

Efficient crystalline silicon solar battery front side silver paste and preparation method thereof

InactiveCN102831948AProcess window widthIncrease short circuit currentNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteOhmic contact

The invention provides an efficient crystalline silicon solar battery front side silver paste which is prepared by adding glass powder into the silver paste, wherein the glass powder is prepared from the following ingredients in weight percentage: 0-90% of Bi203, 0-30% of B203, 0-50% of SiO2, 0-20% of Al203 and 0-20% of ZnO. The efficient crystalline silicon solar battery front side silver paste provided by the invention has a wider process window, has excellent ohmic contact and at the same time has a high short-circuit current, so that the conversion efficiency is high, the stability is good and the cost performance is high.

Owner:浙江金诺新能源科技有限公司

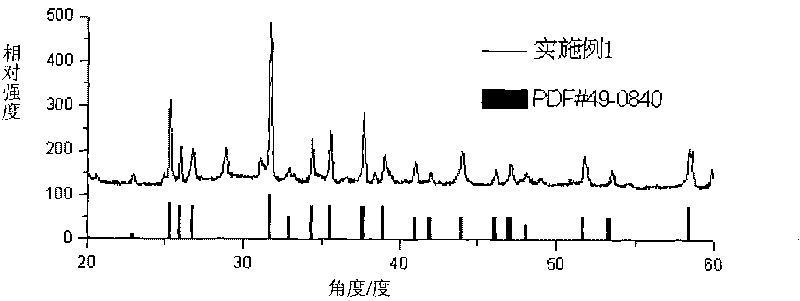

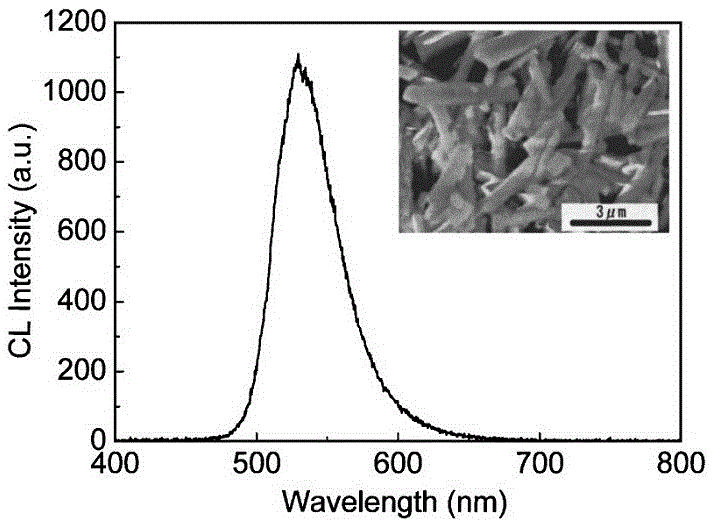

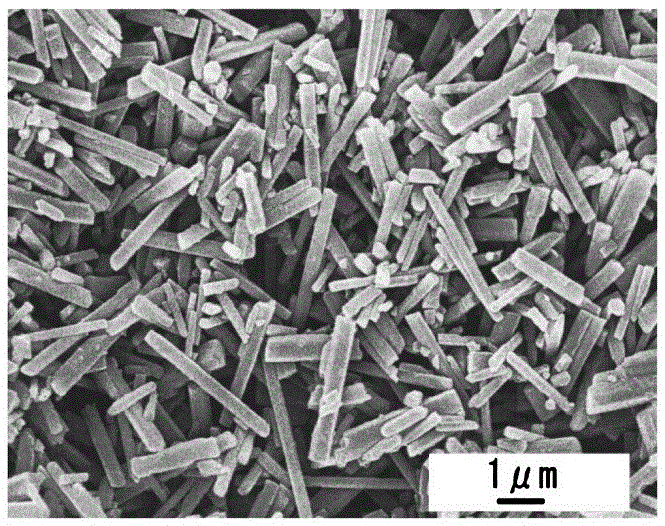

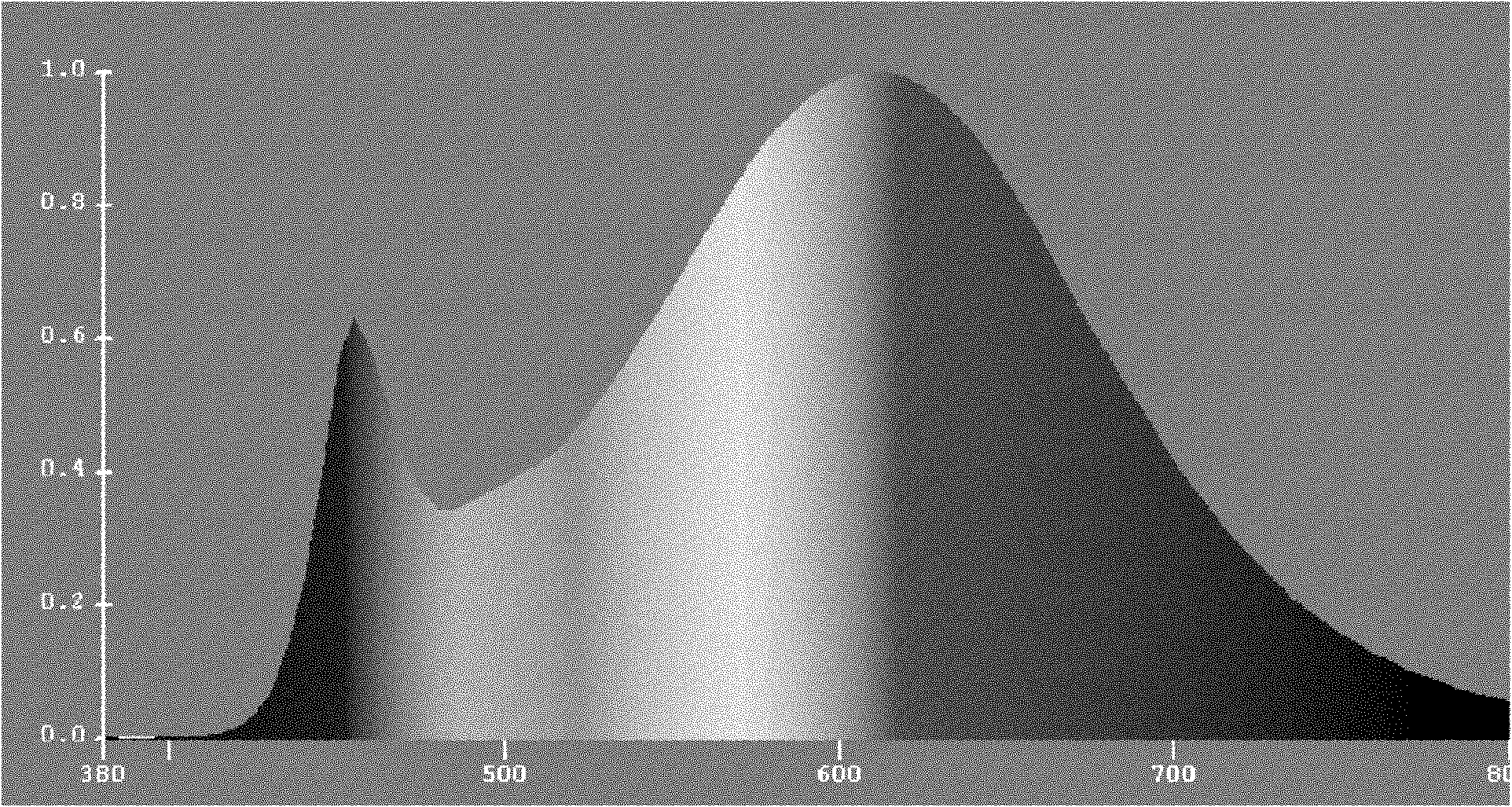

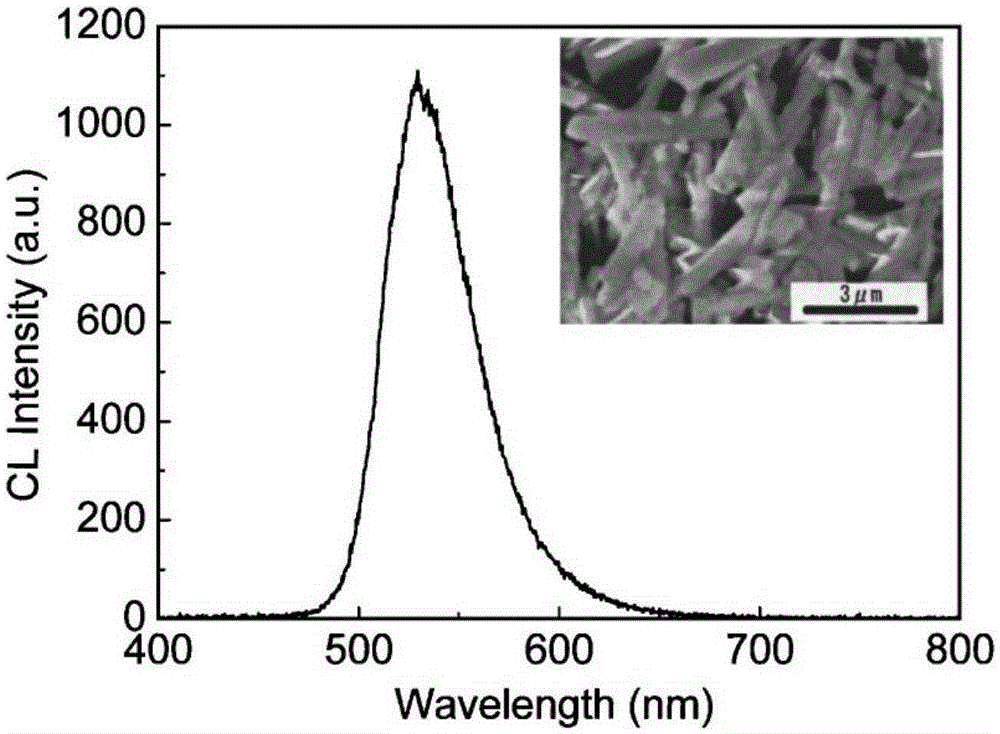

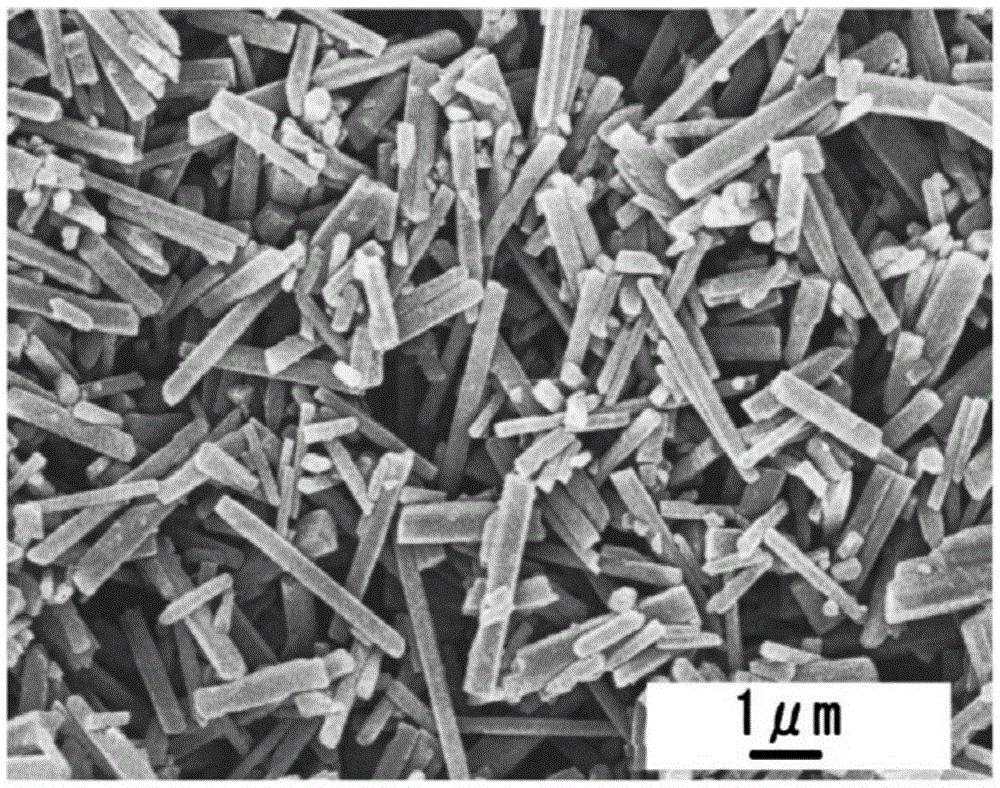

High-brightness large-particle-size beta-SiAlON:Eu<2+> green emitting phosphor and preparation method thereof

ActiveCN106281317AUniform particlesLarge particle sizeLuminescent compositionsLiquid-crystal displayPhosphor

The invention relates to a high-brightness large-particle-size beta-SiAlON:Eu<2+> green emitting phosphor and a preparation method thereof. The chemical general formula of the phosphor is Sia(AlxGa1-x)bOcNd:Eue<2+>, wherein 0.4<=a<=0.5, 0.01<=b<=0.02, 0.006<=c<=0.02, 0.47<d<=0.664, 0<e<=0.010, and 0<x<1; and the phosphor is prepared through double sintering, and the second sintering is performed by mixing a first sintering material obtained by first sintering and raw materials and then sintering. The beta-SiAlON:Eu<2+> green emitting phosphor prepared by the invention has the advantages of uniform particles, large average particle size and high luminescent intensity, has a wide prospect in preparation of white light LEDs (light-emitting diode), and is further mainly used as a backlight liquid crystal display (LCD) in a semiconductor light-emitting device. The process method provided by the invention is suitable for large-scale industrial production, and can realize preparation of the beta-SiAlON:Eu<2+> green emitting phosphor with expected particle size and uniformity, high brightness and narrow peak by controlling raw material proportioning and temperature regulation.

Owner:HEBEI LIFU CHEM TECH

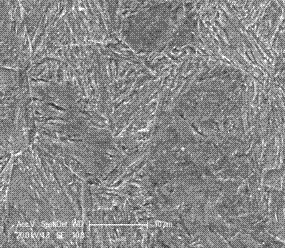

Diffusion technology for preparing Se battery by using etching process

InactiveCN102969403AIncrease concentrationIncreasing the thicknessFinal product manufactureSemiconductor devicesEngineeringNitrogen gas

The invention discloses a diffusion technology for preparing a Se battery by using an etching process. According to the diffusion technology, the gradient diffusion temperature, the source flow and the oxygen flow are adopted; and the diffusion technology specifically comprises the following steps of: a, putting a silicon sheet into a diffusion furnace; b, rising the temperature to 840-850 DEG C, introducing nitrogen and oxygen from a carrying source, keeping the temperature, gradually reducing the flow of a diffusion source, adding the flow of the oxygen and lasting the whole process for 10-30min; c, increasing the temperature to 860-870 DEG C, and keeping for 5-15min; and d, reducing the temperature and finishing the diffusion. By utilizing the diffusion technology for preparing the Se battery by using the etching process, high enough surface concentration and phosphorosilicate glass thickness are ensured with very good phosphorus concentration distribution curves, and a very low emitter saturation current and a very wide process window are ensured for a later etching method in etching a high sheet resistor.

Owner:泰州德通电气有限公司

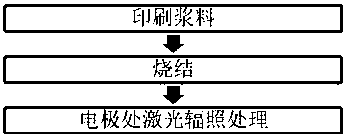

Preparation method of solar battery electrode

InactiveCN107946381AImprove conversion efficiencyReduce contact resistanceFinal product manufacturePhotovoltaic energy generationElectrical batterySlurry

The invention provides a preparation method of a solar battery electrode. The preparation method comprises the following steps: carrying out imaging to form an electrode slurry layer containing a conductive component; integrally carrying out a first heat treatment process on a semiconductor base including the electrode slurry layer containing the conductive component; and carrying out a second heat treatment process on the area of the electrode slurry layer. According to the preparation method of the solar battery electrode, the sintering temperature can be reduced, the contact resistance andseries resistance of the battery electrode can be reduced, and the sintering process window of a battery can be broadened, so that preferable battery conversion efficiency is achieved.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Mixed fluorescent powder matched with blue-light chip and preparation method thereof

InactiveCN101948692AEvenly dispersedStable physical and chemical propertiesLuminescent compositionsAlcoholPolyvinyl alcohol

The invention discloses mixed fluorescent powder matched with a blue-light chip and a preparation method thereof. The method comprises the following steps of: mixing red fluorescent powder A1-xByOzN2 / 3+4 / 3y-2 / 3z:xRe and yellow fluorescent powder Y3-a-bAl5Baa012:Ceb3+ according to a mass ratio of 50-35:100 in ethanol in the mass which is 2 to 10 times that of the yellow fluorescent powder, adding polyvinyl alcohol in the mass which is 5 to 10 times that of the yellow fluorescent powder and polyacrylamide in the mass which is 5 to 10 times that of the yellow fluorescent powder, and fully mixing to form a gelatinous mixture. In the method, two conventional fluorescent powders are mixed in absolute ethyl alcohol, and the polyvinyl alcohol and the polyacrylamide are added to be prepared into a supermolecular template for auxiliary mixing, so that the two fluorescent powders are uniformly dispersed to form a low-color temperature mixed fluorescent powder gel with stable homogeneous phase.

Owner:IRICO

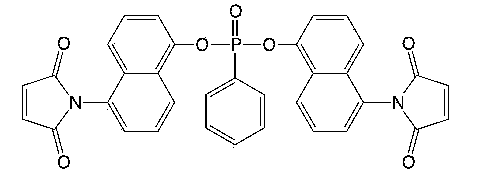

Flame-retardant heat-resistant bismaleimide resin and preparation method thereof

InactiveCN104193994AImprove flame retardant performanceLocal alignmentHeat resistanceLimiting oxygen index

The invention discloses flame-retardant heat-resistant bismaleimide resin and a preparation method thereof, belonging to the technical field of high performance thermosetting resin. According to the technical scheme, the flame-retardant heat-resistant bismaleimide resin is prepared from the following raw materials in parts by weight: 5-20 parts of phenylphosphonic dichloride, 21-52 parts of 1-amino-5-naphthol and 10-40 parts of maleic anhydride. The bismaleimide resin has a good molding technology and a cured product has high heat resistance and excellent flame retardance; the glass-transition temperature of the cured product reaches 370 DEG C, and the limit oxygen index reaches 48; benzyl di(5-amino) naphthoxy phosphonic acid is prepared by reaction between phenylphosphonic dichloride and excessive 1-amino-5-naphthol, and prepared benzyl di(5-amino) naphthoxy phosphonic acid is reacted with maleic anhydride to obtain the flame-retardant heat-resistant bismaleimide resin. The flame-retardant heat-resistant bismaleimide resin and the preparation method disclosed by the invention have the beneficial effects that the reaction is stable, the process condition is easy to control, unreacted raw materials can be recycled, and no three wastes are generated, so that the flame-retardant heat-resistant bismaleimide resin and the preparation method are suitable for industrialized production.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

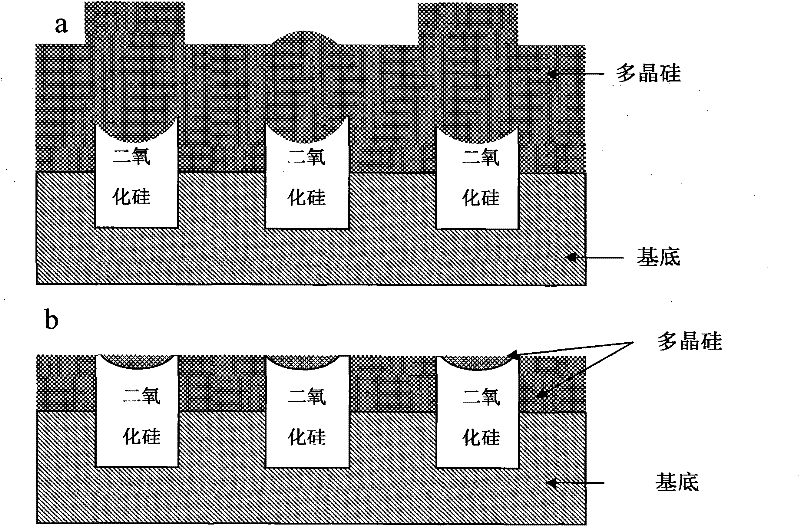

Chemically mechanical polishing solution

InactiveCN102533125AIncreased process windowProcess window widthPolishing compositions with abrasivesSilicon dioxideMineralogy

The invention discloses a novel chemically mechanical polishing solution for polycrystal silicon. The novel chemically mechanical polishing solution comprises grinding particles, at least one azoles compound and at least one polyalcohol nonionic surfactant. The novel chemically mechanical polishing solution can be used for adjusting the selection rate between the polycrystal silicon and silicon dioxide and remarkably improving the polarization efficiency of the polycrystal silicon.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

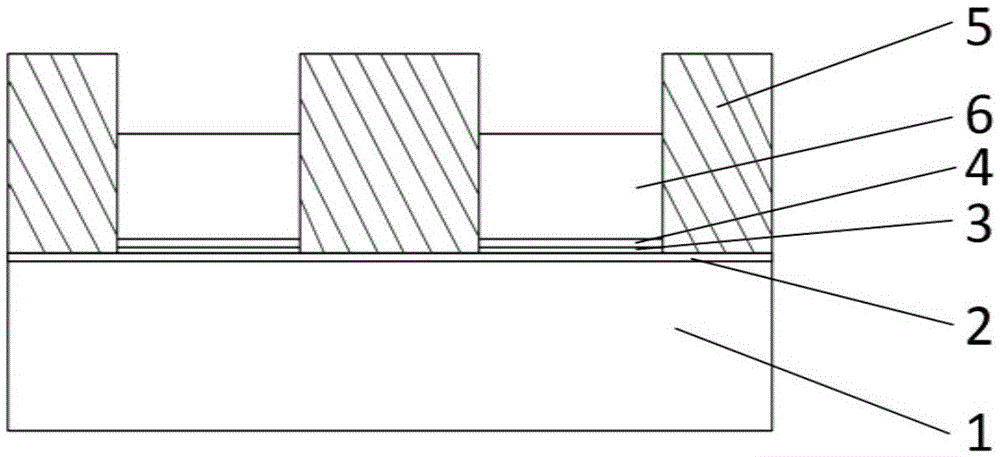

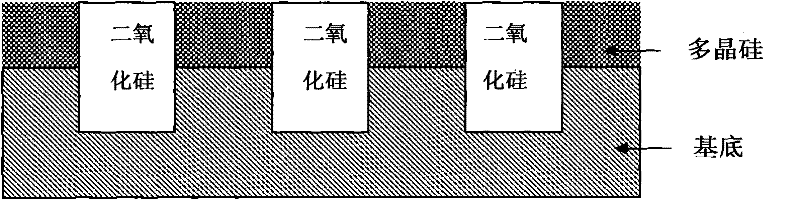

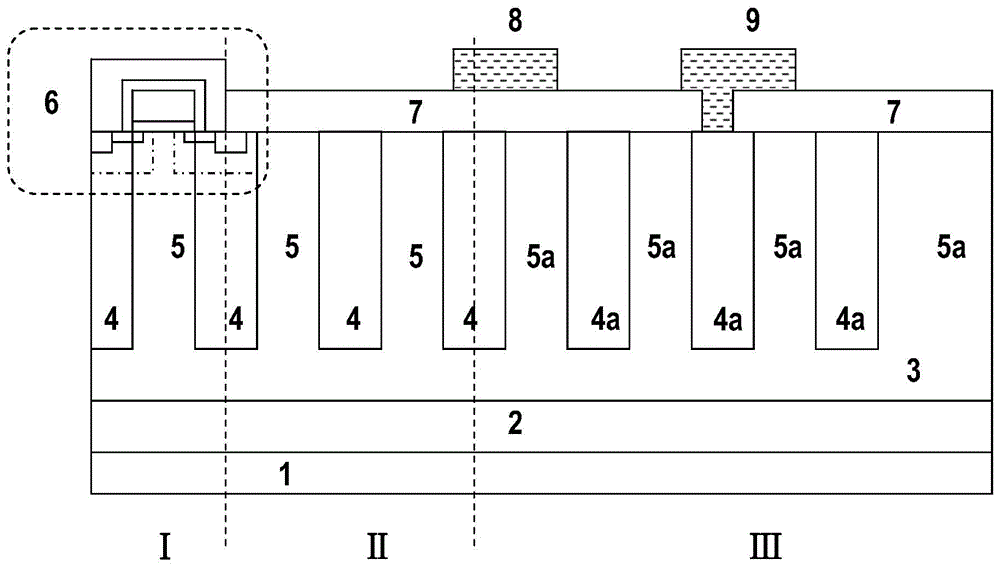

Terminal structure of super-junction semiconductor device and manufacturing method thereof

InactiveCN104952910ARandom combinationTerminal structure is highly reliableSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialProcess window

The invention discloses a terminal structure of a super-junction semiconductor device and a manufacturing method thereof. The terminal structure comprises a plurality of super-junction P-pillars; each super-junction P-pillar comprises a top P-pillar and a bottom P-pillar; the top P-pillar of each super-junction P-pillar is narrower than the bottom P-pillar thereof. The thermal structure and the manufacturing method thereof have the advantages that the terminal structure can be high in reliability and small in size, the cost is low, the process is simple and easy to implement and a process window is wide.

Owner:ADVANCED SEMICON MFG CO LTD

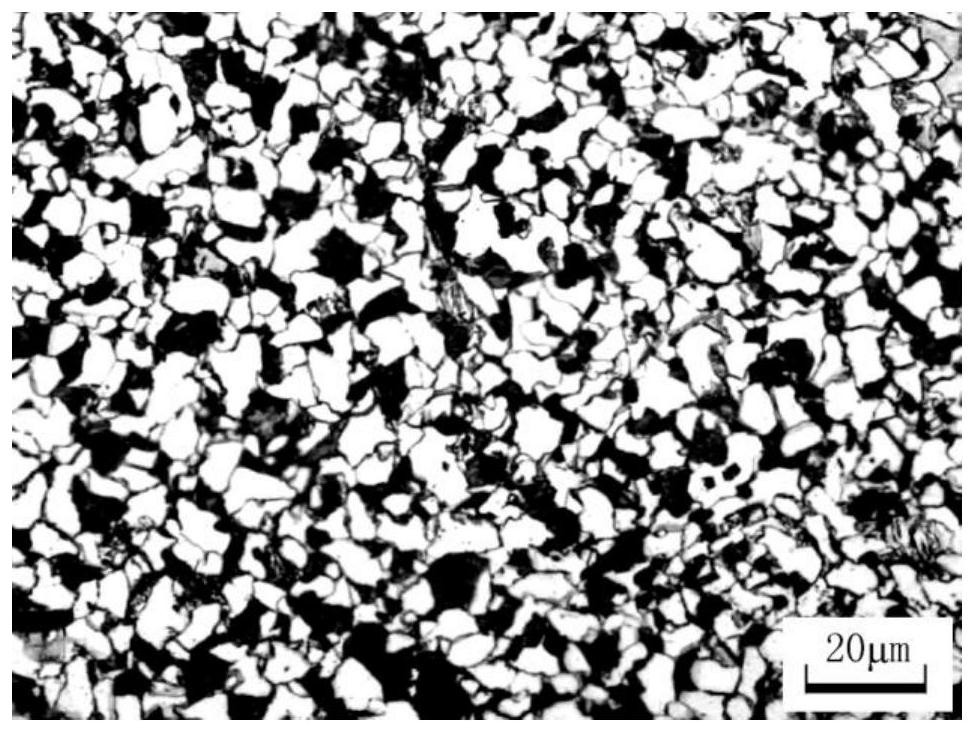

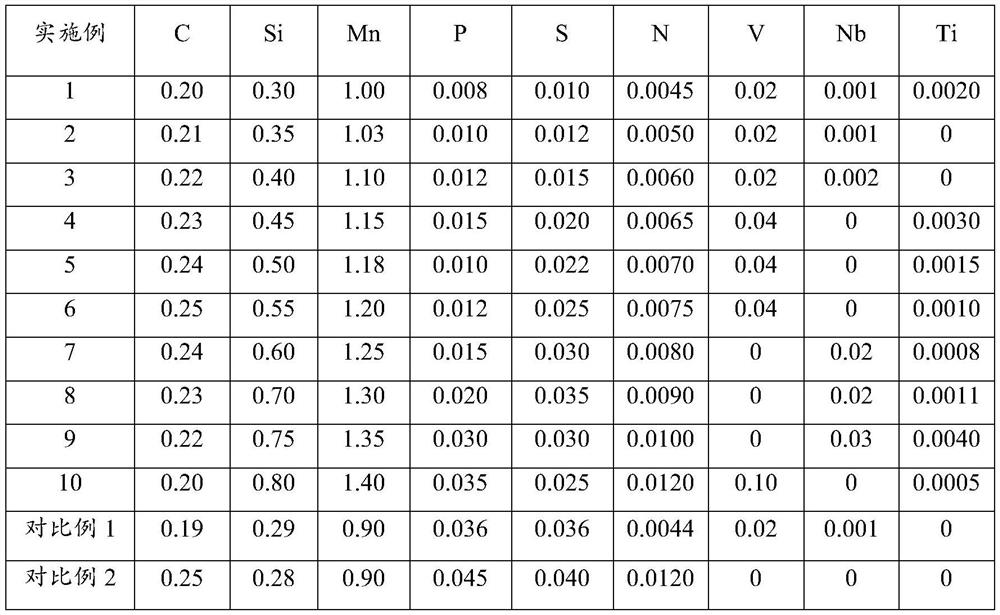

500MPa-grade hot-rolled coiled reinforced bar and production method thereof

The invention discloses a 500MPa-grade hot-rolled coiled reinforced bar and a production method thereof. According to the 500MPa-grade hot-rolled coiled reinforced bar, the hot-rolled yield strength Rel of the prepared 500MPa-grade hot-rolled coiled reinforced bar is greater than or equal to 500MPa, Rm is greater than or equal to 630MPa, the elongation A is greater than or equal to 15%, Agt is greater than or equal to 9%, the yield strength ratio is greater than or equal to 1.25, the yield standard ratio is less than or equal to 1.30, a metallographic structure mainly comprises ferrite and pearlite and contains no tempered martensite, the content of bainite is less than or equal to 9%, and the content of ferrite and pearlite is greater than or equal to 91%. According to the production method for the 500MPa-grade hot-rolled coiled ribbed steel bar with the obvious tensile test yield point, the alloy can be selected in a targeted mode for microalloying according to the V, Nb and Ti alloyresource market and price conditions, the enterprise production cost is greatly lowered, in addition, the process is not complex, and the product performance is stable.

Owner:武汉钢铁有限公司

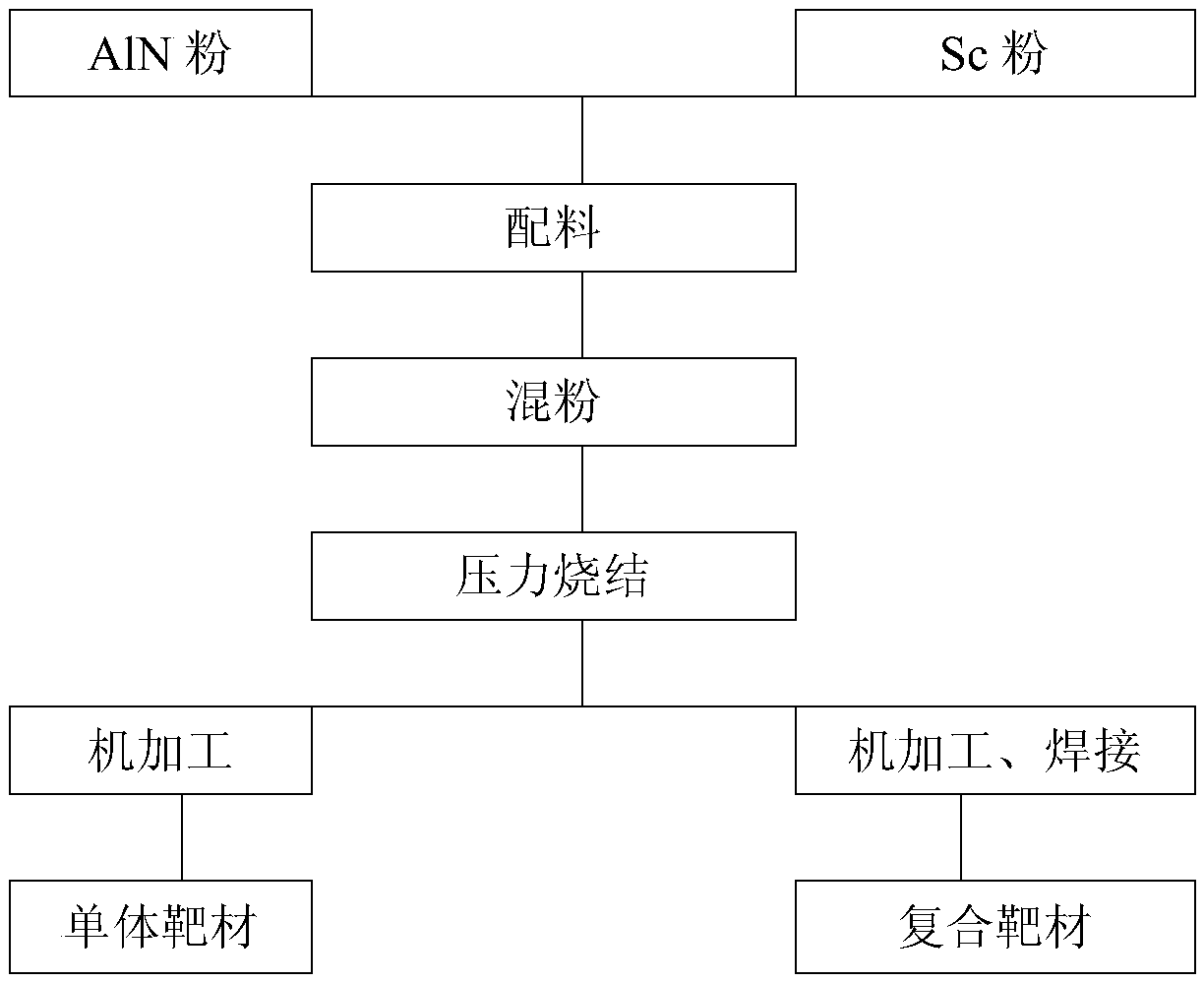

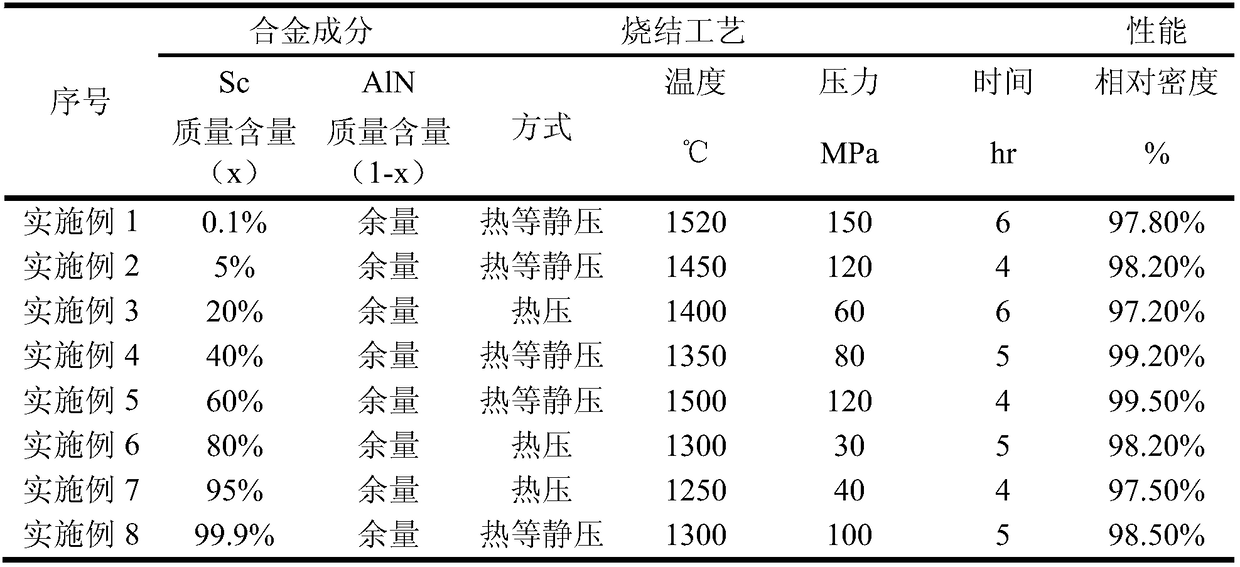

Preparation method and application of aluminum nitrogen scandium alloy target material

ActiveCN109267020AHigh densityAvoid crackingVacuum evaporation coatingSputtering coatingNitrogenAlloy

The invention discloses a preparation method and application of an aluminum nitrogen scandium alloy target material, and belongs to the technical field of magnetic control sputtering target preparation. By using the method, the aluminum nitrogen scandium alloy target material is obtained by using AlN powder and Sc powder as raw materials through mixing, pressure sintering shaping and mechanical processing. The relative density of the obtained aluminum nitrogen scandium alloy target material is greater than 97 percent; the target material can be applied to sputtering deposition of a nitride film; in a sputtering film plating process, the stable film forming can be realized without introducing reaction gas of nitrogen gas.

Owner:有研新材料股份有限公司

Beta-SiAlON:Eu<2+> green fluorescent powder and preparation method thereof

The invention relates to beta-SiAlON:Eu<2+> green fluorescent powder. The chemical general formula of the beta-SiAlON:Eu<2+> green fluorescent powder is EuaSibAlcOdNe, wherein a is more than 0 and less than or equal to 0.010, b is more than or equal to 0.4 and less than or equal to 0.5, c is more than or equal to 0.01 and less than or equal to 0.02, d is more than or equal to 0.006 and less than or equal to 0.02, and e is more than 0.47 and less than or equal to 0.664. The invention further discloses a preparation process of the fluorescent powder. The preparation process mainly comprises the following steps: firstly sintering at 1900-2200 DEG C for 8-12 hours; then carrying out negative pressure sintering at a negative pressure of 1000Pa-2000Pa for 8-10 hours by virtue of the control of a pressure control pump. The prepared beta-SiAlON:Eu<2+> green fluorescent powder has uniform particles, large average grain diameter and high illumination intensity and has wide prospect in the preparation of a white light LED. The process method is applicable to the large-scale industrial production and has the beneficial effects that the operation is simple and feasible, the raw material cost is low, and a process window is wide; by controlling the process conditions of the pressure control pump, the fluorescent powder with expected particle size and uniformity can be prepared.

Owner:HEBEI LIFU CHEM TECH

High-color-saturation silicon-based OLED micro display device and preparation method thereof

PendingCN112201678AReduce manufacturing costMake up for the gap in the marketSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverDisplay device

The invention relates to the technical field of organic light-emitting diode manufacturing, particularly to a silicon-based OLED micro display device and a preparation method thereof. The display device is composed of a silicon-based CMOS drive circuit substrate, a top light-emitting multilayer composite anode, a blue light organic light-emitting layer, an antireflection layer, a quantum dot colorfilter layer, an inorganic or polymer composite film sealing layer and a glass cover plate. In the preparation of the display device, a dry etching process is used for preparing composite anode pixelpoints, and a doping mode is used for realizing the preparation of a blue light organic light-emitting layer. The display device has the characteristic of low optical loss.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

Chemi-mechanical polishing fluid

InactiveCN102533120AReduced removal rateLower selection ratioSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxideSilicon

The invention relates to a polishing fluid for chemi-mechanically polishing silicon. The polishing fluid contains water, grinding particles, at least one silicon accelerator and at least one silicon inhibitor. The amounts of the silicon accelerator and the silicon inhibitor can be adjusted to adjust the selection ratio of silicon to silicon dioxide, thereby enhancing the flattening efficiency.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com