Preparation method and application of aluminum nitrogen scandium alloy target material

An alloy target, aluminum-nitrogen technology, applied in metal material coating process, ion implantation coating, coating and other directions, can solve the problems of abnormal discharge in sputtering etching area, mismatch of thin film alloy composition ratio, affecting coating performance, etc. , to improve the problem of nitrogen atom deficiency in the film layer, ensure the composition ratio of the film alloy, and the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

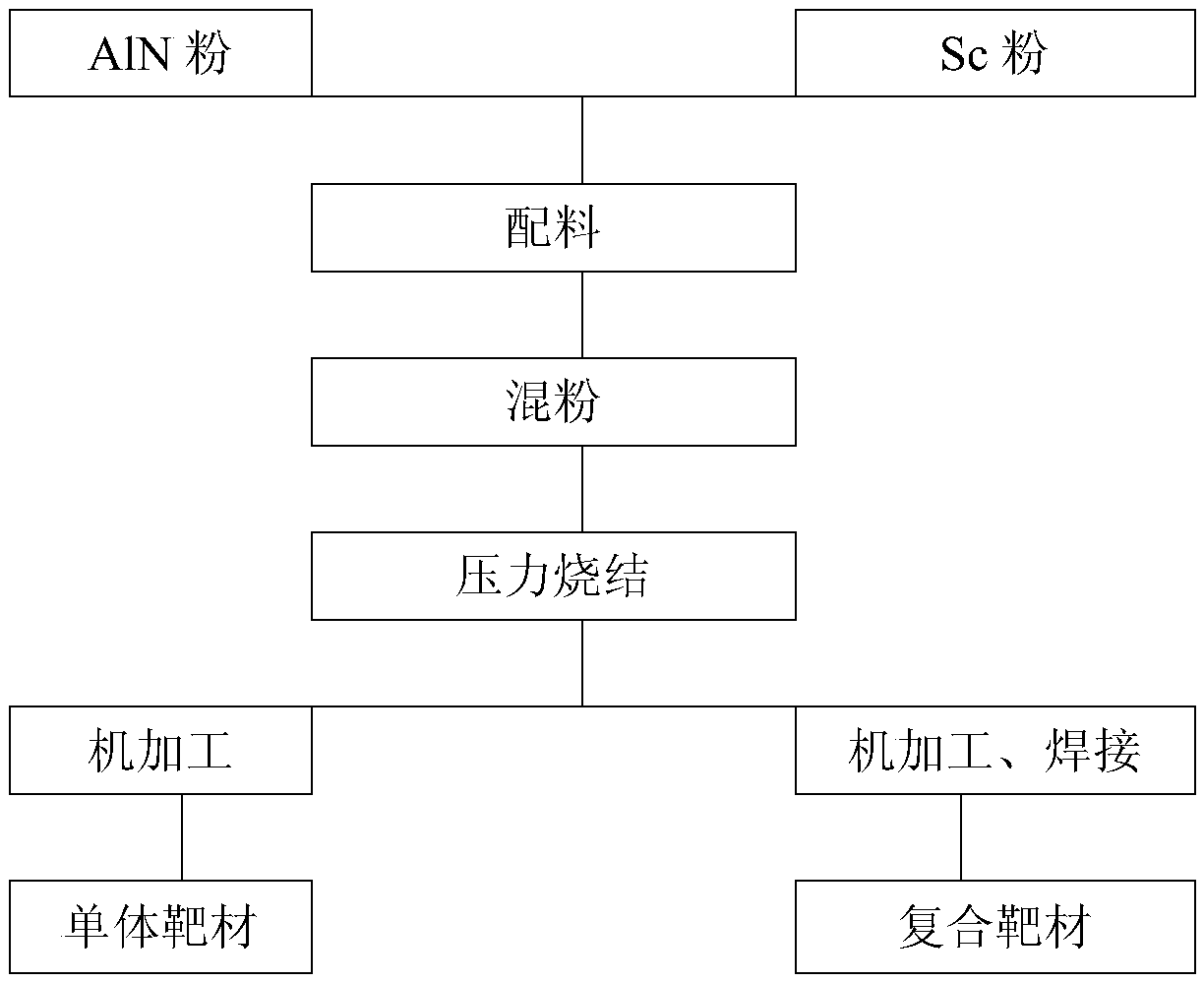

[0017] According to attached figure 1 The method shown in the preparation of aluminum nitride scandium alloy target:

[0018] (1) Ingredients

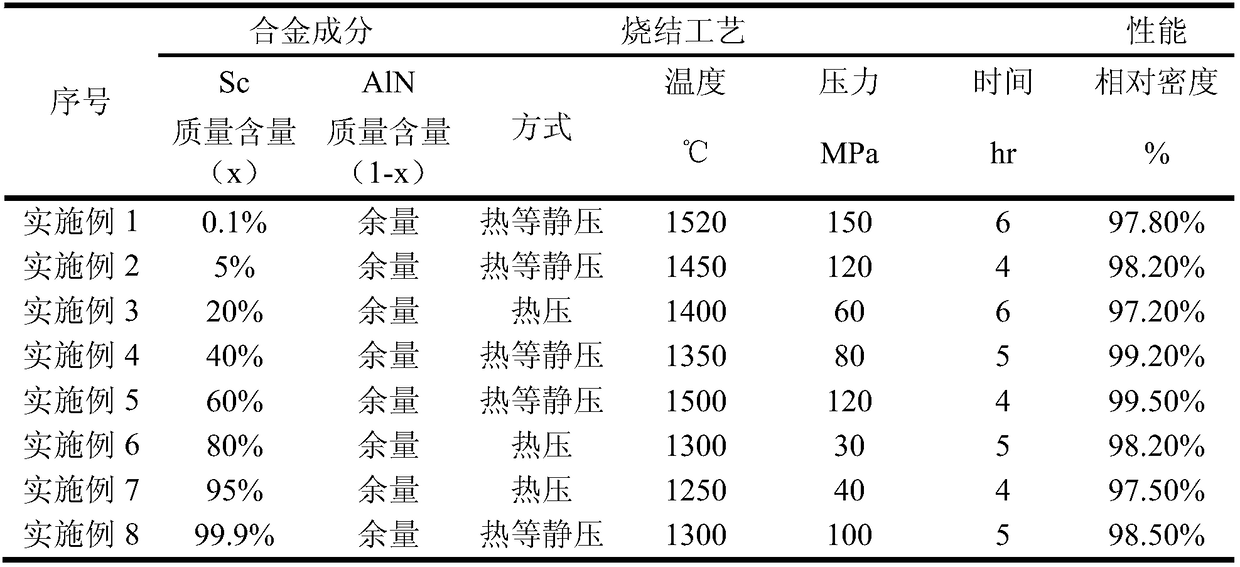

[0019] According to the composition of the aluminum nitrogen scandium alloy target in Table 1, the raw material ingredients are carried out: the chemical composition of the target is (AlN) 1-x sc x , wherein, the mass content x of Sc is 1-99%, and the balance is AlN; wherein the particle size of AlN powder is 0.1-50 μm, and the particle size of Sc powder is 1-150 μm.

[0020] (2) mixed powder

[0021] Put the two raw materials in the ratio into a mixer or ball mill and mix them evenly; during the mixing process, in order to prevent powder oxidation, the mixer or ball mill is in a vacuum state or protected by an inert gas Ar.

[0022] (3) Pressure sintering

[0023] The mixed powder is sintered into a target blank by hot pressing or hot isostatic pressing, wherein the sintering temperature is 1250-1520°C, the pressure is 30-150MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com